-

Figure 1.

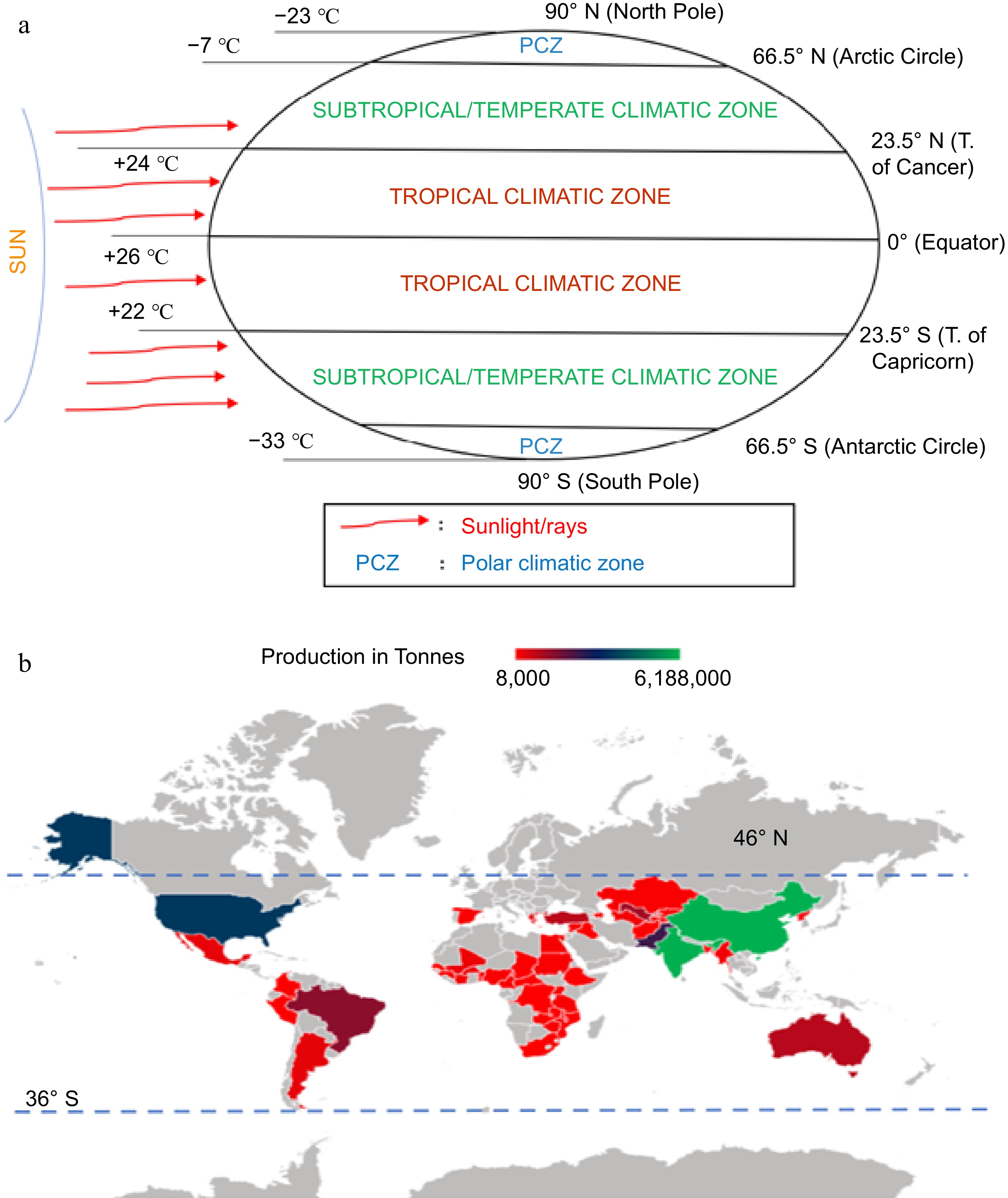

Global maps showing (a) regions of the world and the relationship between latitude, irradiation, and average regional temperature and (b) the top 50 cotton-producing countries and their 2017 production. All are geographically located in the warm tropical or subtropical regions between 36° S and 46° N.

-

-

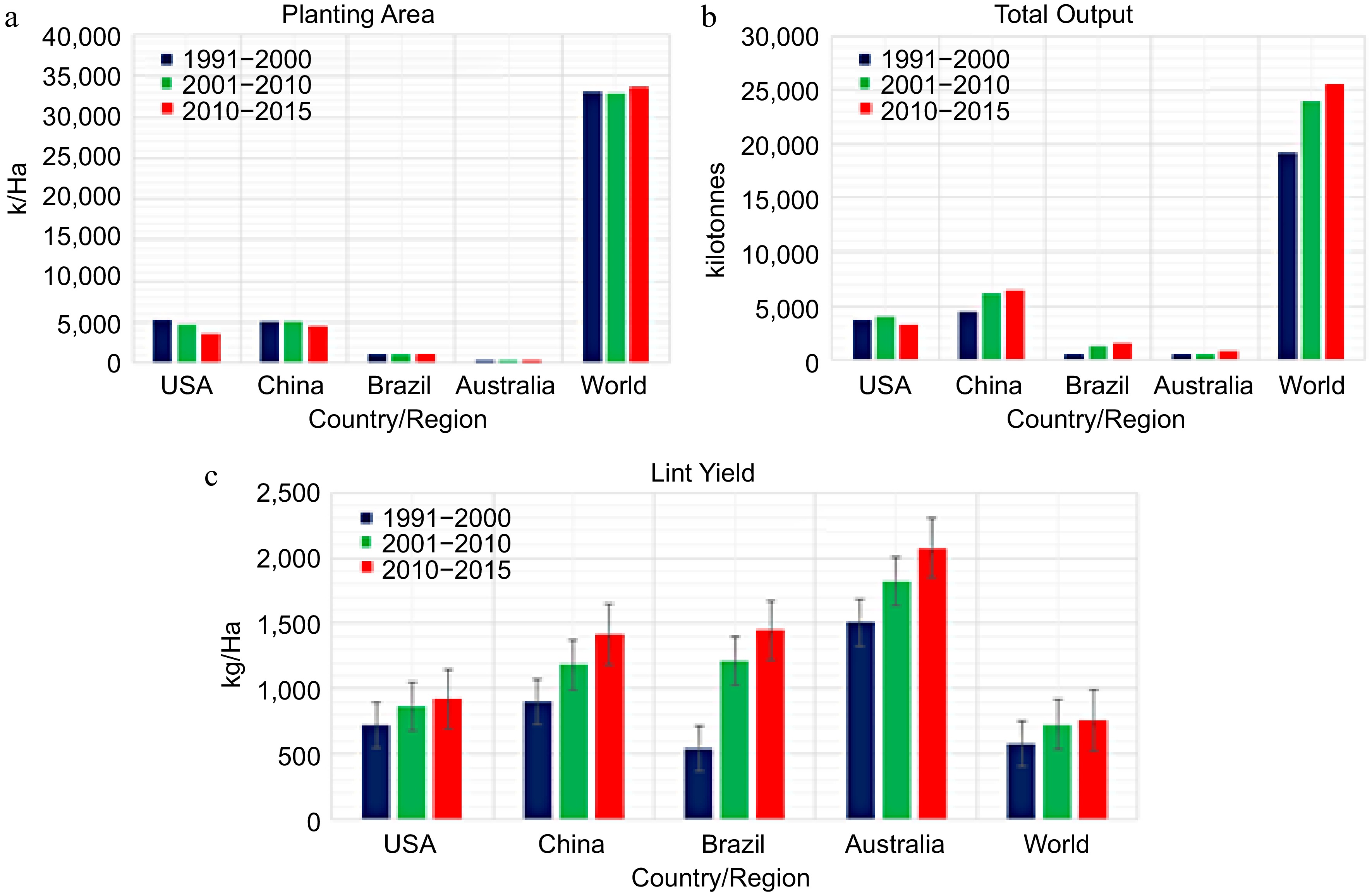

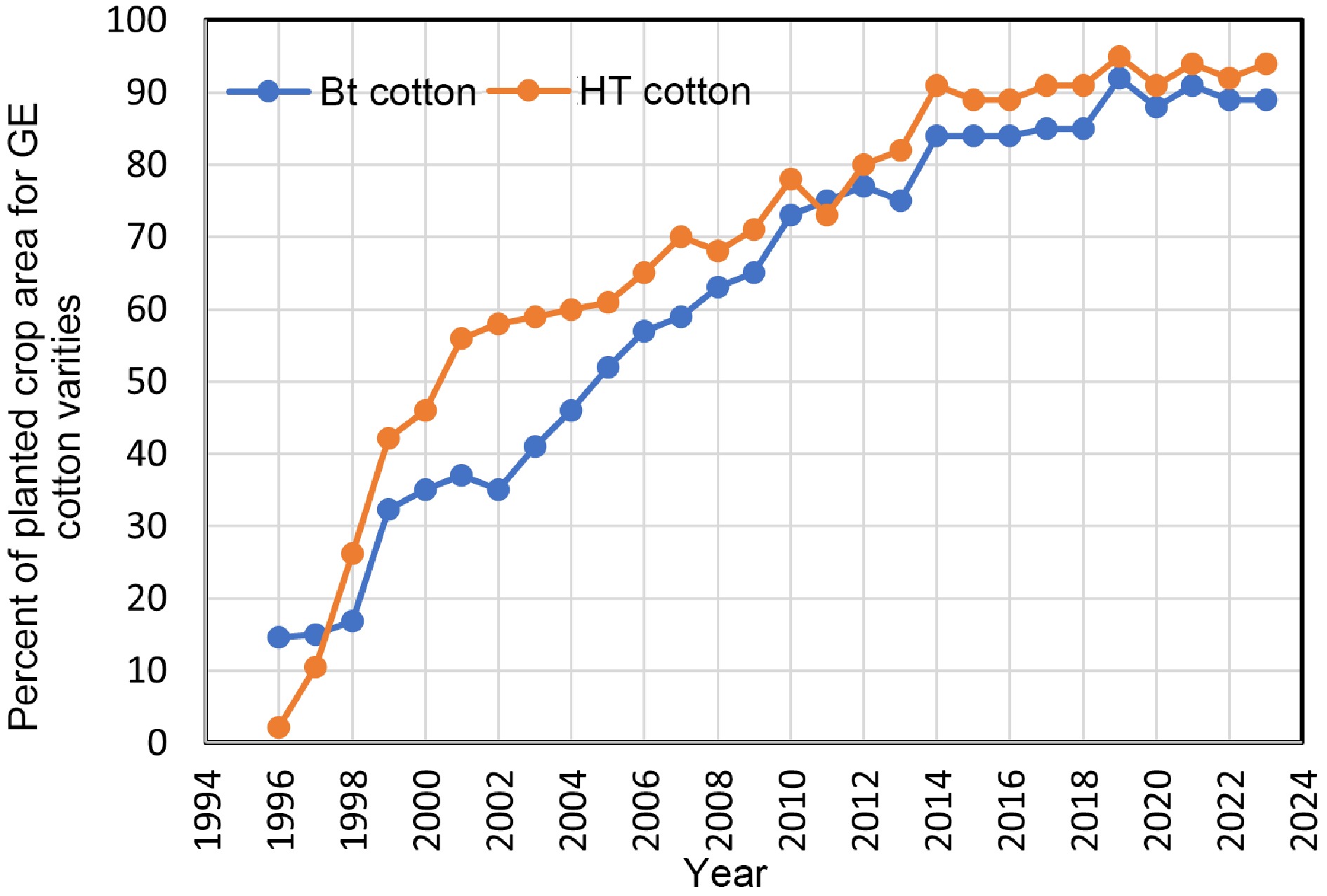

Figure 3.

Recent trends in genetically enhanced (GE)/GM cotton adoption rates in the US for Bt cotton and herbicide-tolerant (HT) cotton. The adoption rate has increased exponentially since the introduction of the varieties, surpassing the 90% level in the past few years. (Data extracted from the USDA[33]).

-

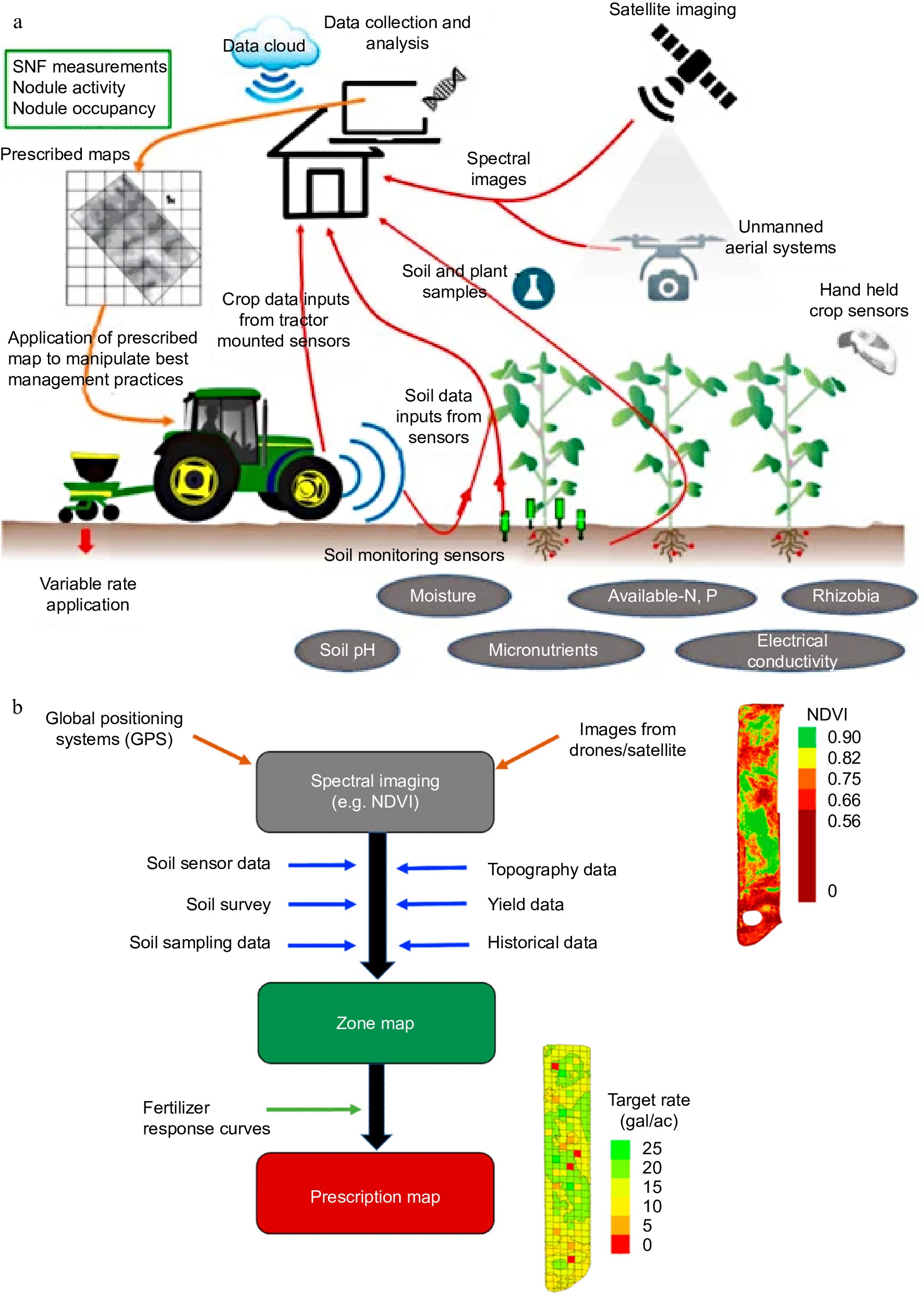

Figure 4.

PA: (a) conceptual overview of the processes involved in a PA framework where a large field is divided into smaller units and different sensors collect data (moisture, nutrients, foliage health, yield, etc.) that can be used for managing crop field on a site-specific or zone map need basis as in (b). (Adapted from Thilakaranthna & Raizada[37]).

-

Figure 5.

An example of modern irrigation system—center pivot (or linear move machine). It is more suitable for variable rate irrigation water application on a larger scale compared to drip irrigation method which is more suitable for smaller farms. (Source: Valley Irrigation).

-

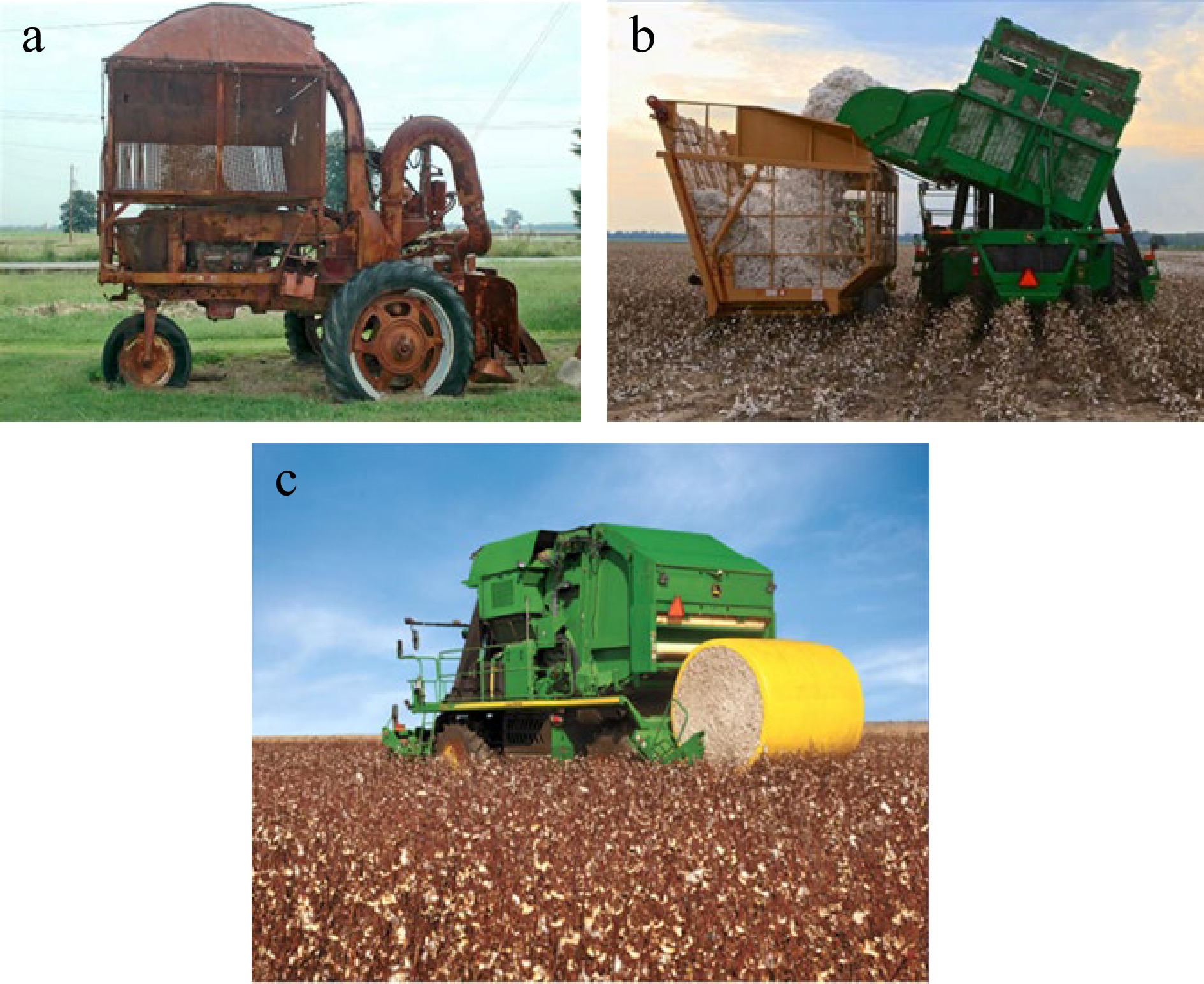

Figure 6.

Evolution of mechanized cotton harvesting. (a) A second generation commercially successful cotton picker M produced in the 1940s. (b) A boll buggy receiving seed cotton from a cotton picker, an approach that required multiple equipment types and is labor intensive. (c) A 7760 JD cotton harvester with onboard module building feature, requiring no extra human labor and expensive equipment and tractors to build cotton modules. (Sources: (a) Mississippi State University Extension, (b)West Tennessee Historical Society, and (c) John Deere, Inc.).

-

Figure 7.

A 3D model of the CHAP equipped with a suction system, a bin and a harvesting nozzle for picking seed cotton from open bolls. (Adopted from: Maja et al.[24]).

-

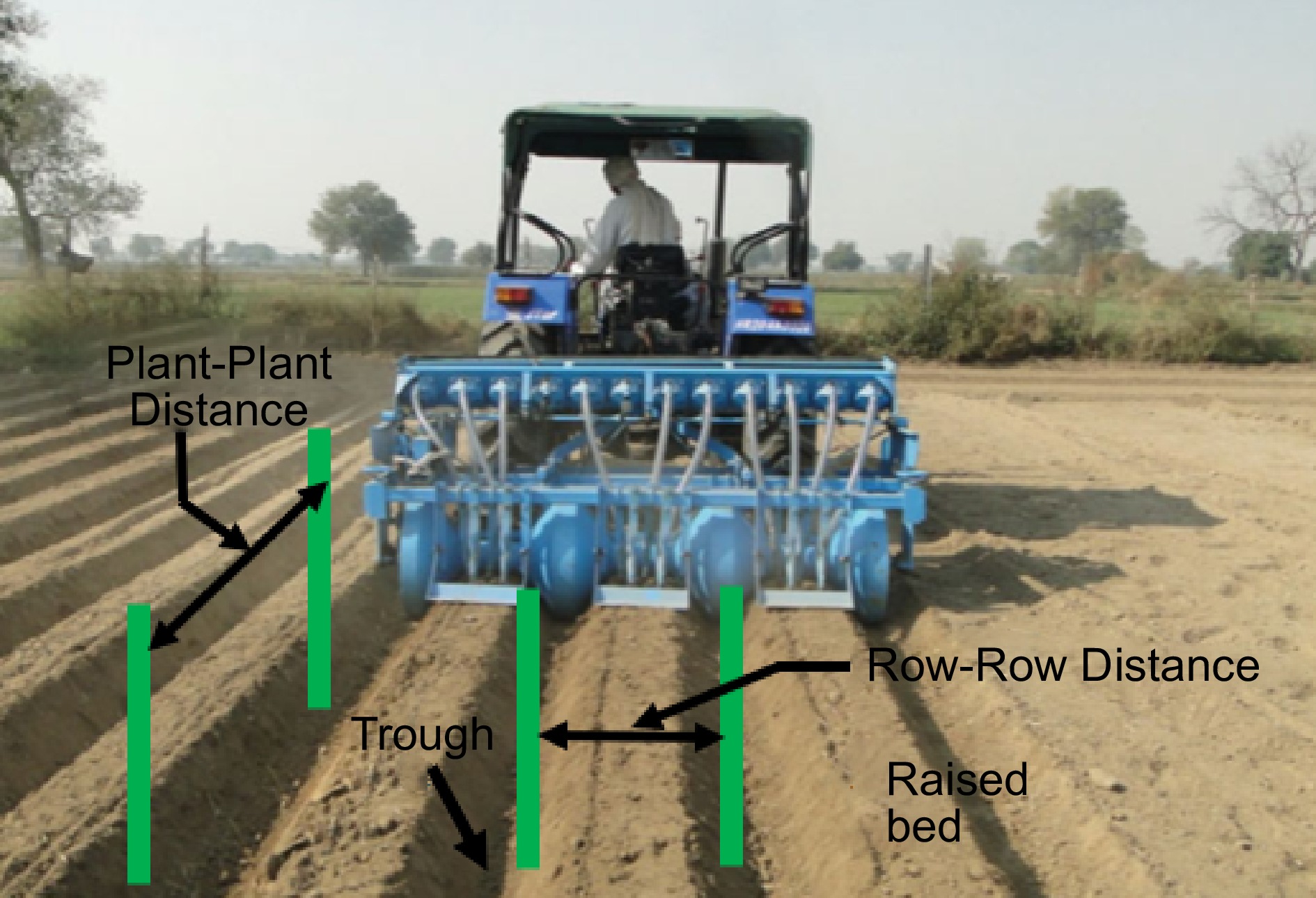

Figure 8.

An image showing a multi-crop raised seedbed planter operating on a field with illustrated bed configuration parameters. The machine first creates the raised trapezoidal seedbeds and plants the seeds in its trail. (Image adapted from Kumar et al.[73]).

-

Figure 9.

An image of a farm in the US showing a typical flat-row cotton field with irrigated borders. Most farmlands for the flat planting technique are laser leveled, and the borders are untouched between reaping to maintain the leveling. (Adapted from Cotton Farming, 2015[68]).

-

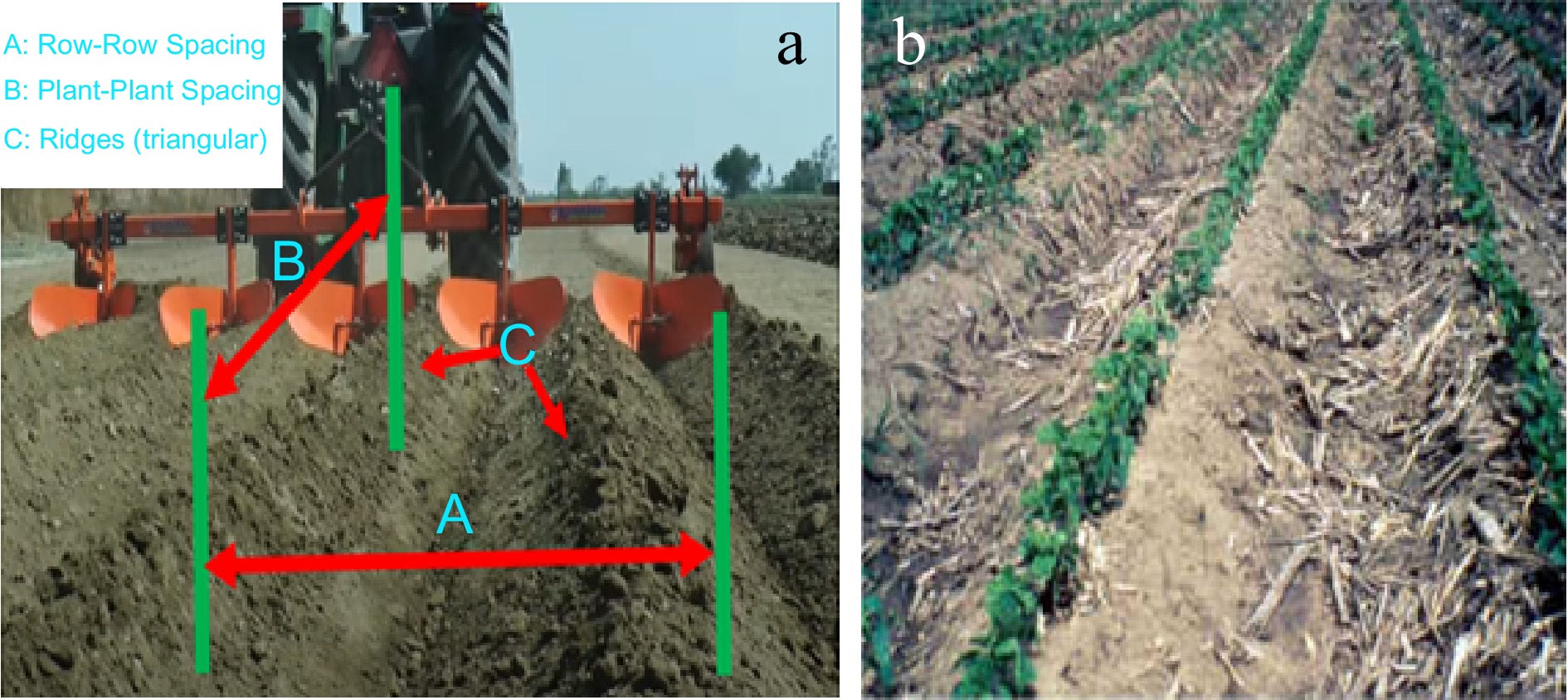

Figure 10.

Ridge-planting technique for cotton: (a) A five-row ridger making fresh ridges in a cotton field, with illustrated general planting geometry. (b)Ridged field cultivated with new crops while the previous year growth/crop residue remains in the furrow, helping with erosion control, typically, 30%–50% nonuniformly distributed residue may be found in row-crop rotated ridge-sowing fields[77].

-

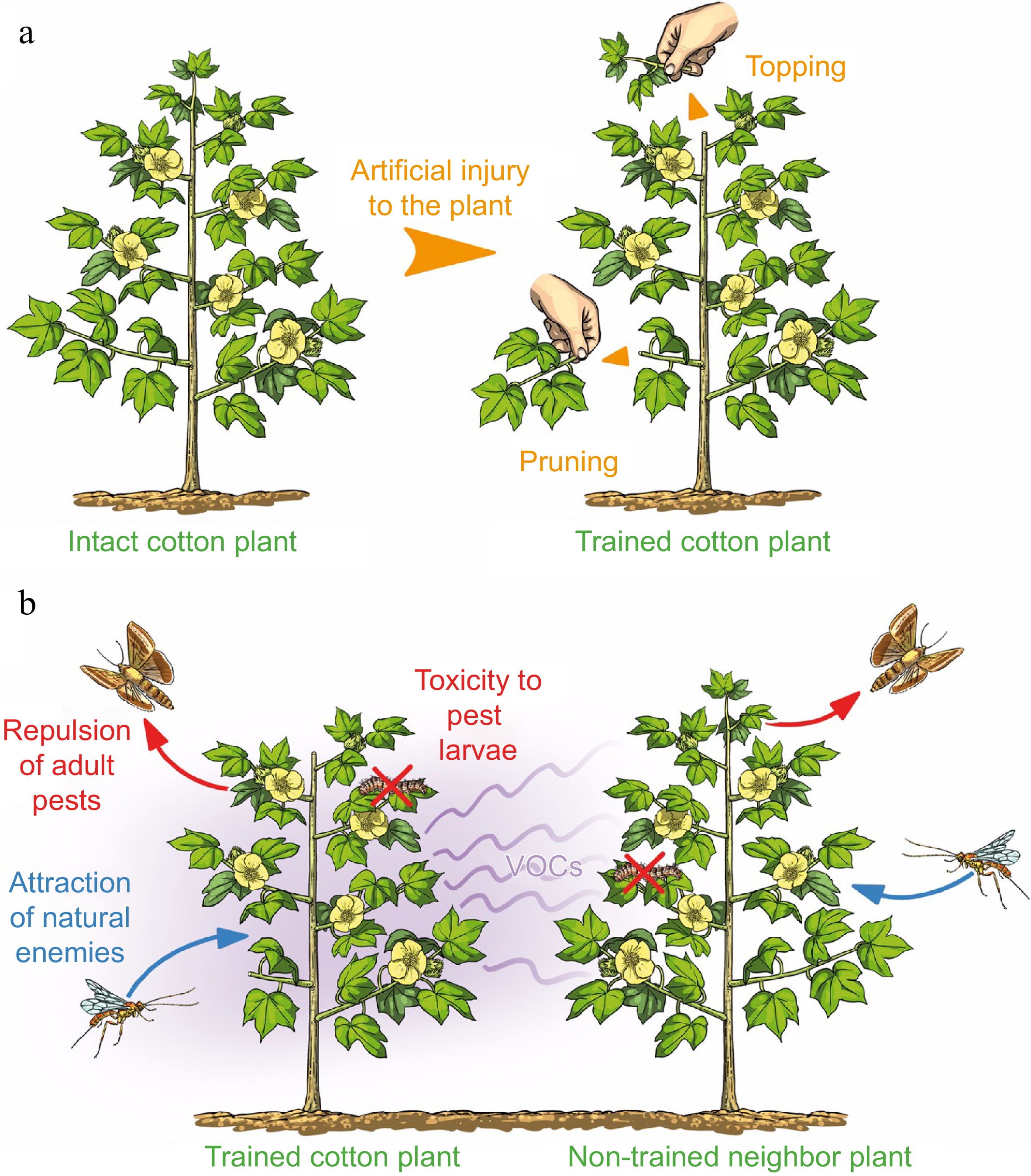

Figure 11.

(a) Representation of cotton plant topping (apical bud removal from the main stem) and pruning (vegetative and fruiting branches apical points removal). (b) Depiction of some benefits of these cotton agronomy practices. (Adopted from Llandres et al.[91]).

-

Change Key benefits Challenges Prospects Region of adoption/use Plastic mulching • Improved soil temperature and moisture level regulation[3].

• Offers opportunity for early planting, germination, and maturing cotton production[48].

• Minimizes water use and contributes to preserving freshwater sources.

• Good for weed control/management[31].• Increasing in-field residual plastic; plastic contaminant source in value chain[2].

• Potential soil pollution which may affect soil microbes’ natural habitat.• Full development and use of biodegradable plastic instead of polyethylene mulch[2]. China, US[31,49] Fertigation technique • Improved fertilizer- and water-use efficiency[52].

• Reduced groundwater contamination from either solid or liquid fertilizers and human labor needs.• Some expensive equipment, which generally require expensive, skilled maintenance schedules, are needed for these advanced irrigation systems. • Cost optimization to minimize the associated high capital outlay. US, China, Australia[51,52] GM crop/New hybrids • Resistance to pest and diseases.

• Higher yield/acre globally[29,30].

• Ease of selecting desired fiber and seed quality and trait from a growing pool of cultivars.

• Improved plant physiology with more tunable features for automation management.• Large-scale crop growth simulation models now need fine-tuning not only for local environmental conditions, but for genetic variations of which the pool of available cultivars keeps growing exponentially with the continuous introduction of several new cultivars by researchers and seed companies[61].

• High cost of cultivation (especially for seed acquisition).

• Seed production is difficult and not reuseable, makes breeding for improved fiber yield and quality challenging.• Continuous development of new hybrid varieties with stacked traits to meet multiple needs simultaneously.

• Higher adoption rate in countries not yet accepting GM crops.US, India,

China, Australia,

some African Countries[29−30,

33−36]Heavy-duty mechanical harvesters • High harvesting efficiency.

• Generally reduces labor costs/input.

• Minimizes investments in multiple equipment (tractor, boll buggys, module builders, etc.) for harvesting.• High capital outlay

• In regions of cheaper labor, machine-harvested cotton is more expensive and contains higher trash content than manually harvested seed cotton[100].• Seed cotton module Plastic cover will likely be replaced by another sustainable material[2].

• Will most likely be replaced by smaller, modular and cheaper multipurpose robotic platforms[24].US, Australia, Israel, Brazil[2,24,59] Multipurpose robotic platforms • High modularity and multifunctional systems.

• Cheaper compared to large heavy-duty machinery.

• Low soil compaction and better steerability[24].

• Enables cost-effective multi-pass, gradual cotton harvesting.

• Supports the goals of PA/SSCM.• Technology has not reached maturity, research ongoing to

perfect operational modalities for

various agronomy practices.

• Usually limited onboard seed

cotton storing capacity.

• Currently, reported operational efficiencies for many agronomy operations have significant rooms

for improvement.• After full development, will mostly replace heavy duty machinery and equipment for

in-field agronomy management.

• Prospect for cheaper and more precise agronomic practices.US, Australia, Israel, partly China[24,59] Drip/center-pivot irrigation technology • High water-use efficiency with minimal labor cost[50,51].

• Enable simultaneous application of water and chemicals thereby enhancing chemical use[50,51].

• Suitable for medium and broad-acre farms.• High capital outlay and sometimes running costs.

• A significant source of groundwater depletion which may lead to future water crisis[51].• When combined with other sustainability-oriented agronomy practices like biodegradable PM, will enhance the continued cotton profitability and appeal of cotton to users.

• Creation of official standard for preventing the depletion of groundwater sources when using these technologies[51].US, China, Australia, Israel[39−41,51,52] Organic cotton cultivation technique • Highly environment friendly and sustainability compliant[3].

• Minimal input and no use of inorganic/synthetic inputs/

chemicals in many cases.

• Preserves the natural balance of soil microbes, ensuring sustainability for future generations[3].• Uneconomical production in many regions, like Australia, US and other advanced economies with high land and labor costs[62].

• Highly susceptible to pest damage compared to GM/transgenic cotton[62].• Will be more widely acceptable as more people choose sustainable products. Tanzania, India, China, Turkey, US[62] High-density planting technique • High input efficiency.

• Fast maturity and improved yield[31,63].

• Early crop establishment (high leaf area index) and suitability for rain-fed cultivation[31,63].• The optimum planting density must be matched to prevent excessive competition among plants, which results in lower lint yield[63].

• Small boll size and squares/bolls shedding because of crowding[31].• Universal standardization of the protocol for HDPT of cotton cultivation[31]. China, US, Brazil Mexico Australia, India[31,63] Plastic film mulching combined with drip irrigation and fertigation • Combines the benefits of PM and the most water-efficient irrigation technology to enhance early cotton planting and plant establishment possibilities[3,50,51].

• Minimizes water-use costs and helps with weed control, ensuring optimal soil nutrient utilization and crop growth.• Plastic is potentially the most harmful contaminant in the cotton value chain. It should be cautiously used, or its use should be minimized[2].

• Although drip irrigation is water-efficient, it requires a high capital outlay and strict maintenance.• Development of fully biodegradable plastic material that can practically reduce contamination of the cotton value chain.

• Opportunity to apply high-tech UAV, remote sensing, computer vision, and machine learning for an effective integrated water use system on a large scale.US, China[31,48,49] Flat-sowing technique • Offers cost- and water-saving benefits on farmlands where drip irrigation systems are not feasible (e.g., leased farmlands)[68].

• Supports convenient mechanical harvesting not needing row-end plow down as in raised-bed planted cotton harvesting[64, 68].

• When used it helps compensate for yield losses in HDPT paradigm[64].• On large-scale farms, it requires laser leveling of the ground to achieve the best outcome[68]. This may be expensive and inaccessible to small scale-farmers and developing economies.

• Less efficient than raised-bed sowing method.• Adoption for higher density planting with narrow-row spacing configuration to gain improved lint output benefits[76] US, Pakistan, India, and rest of the world (ROW)[64,68] Ridge-planting technique • High seed-cotton yield than flat-planting technique[64].

• Offers good erosion-and weed-control benefits[77].

• It complements furrow irrigation and is suitable for use on poorly drained level–gently sloping farmlands[77].• The suitability and success of this sowing technique are also significantly influenced by crop rotation practices. It requires perennial maintenance of ridges[77].

• Produces lower seed cotton yield than raised-bed sowing[80].• Improving the yield to be on par with the raised-bed planting method. Pakistan, USA India, ROW[64,77−79] Chemical topping • Offers benefits of low-labor need, enhanced harvest efficiency easily mechanized operation[92−94].

• Increased Seed cotton yield without quality defect[99].• Environmental pollution and risk of increased pest and disease resistance[91,96−98].

• Despite being less labor-intensive, it is more expensive than other methods.• Optimizing the rates and time of PGR applications for different regions and growing conditions. USA, Australia, China, Pakistan[88,95,96]. Mono-seeding/

Single-seed

planting• Improves stand establishment with comparable yield to HDPT[85].

• Offers the potential to reduce seed and thinning labor inputs without sacrificing yield of cotton[85].• There is bigger pressure on individual seedlings from top-soil during emergence compared to cluster seeding[85].

• Only works well with good-quality seeds and conducive soil microenvironment[85].• Experimentation to adapt the technique to regions with similar growing conditions as Yellow River valley of China. China[85] Early planting assisted by transplanting • Excellent for enhancing production in regions with temperature extremities (e.g., arid and semi-arid regions) during the prime sowing periods[31,81,82].

• Provides optimal establishment and growing conditions for young cotton seedlings, minimizing exposures to adverse weather that affect root development[82].

• Minimizing the effect of weed competition with seedlings[83].• Requires investments in additional resources like greenhouses and irrigation facilities[81].

• Coordinating the transplanting process with optimal planting dates can be challenging.

• Transplanted cotton plants may experience transplant shock, causing slowed growth and development.• Research to refine and optimize the implementation of early planting strategies, considering regional variations and specific crop management practices is essential as global warming spreads desertification[81].

• Establishing standard procedures for low-cost seedling production.Pakistan, China, India, Iran[82−84] Table 1.

Summary of some technological and methodological shifts in conventional cotton agronomy, their benefits and associated challenges, and applicable regions.

Figures

(11)

Tables

(1)