-

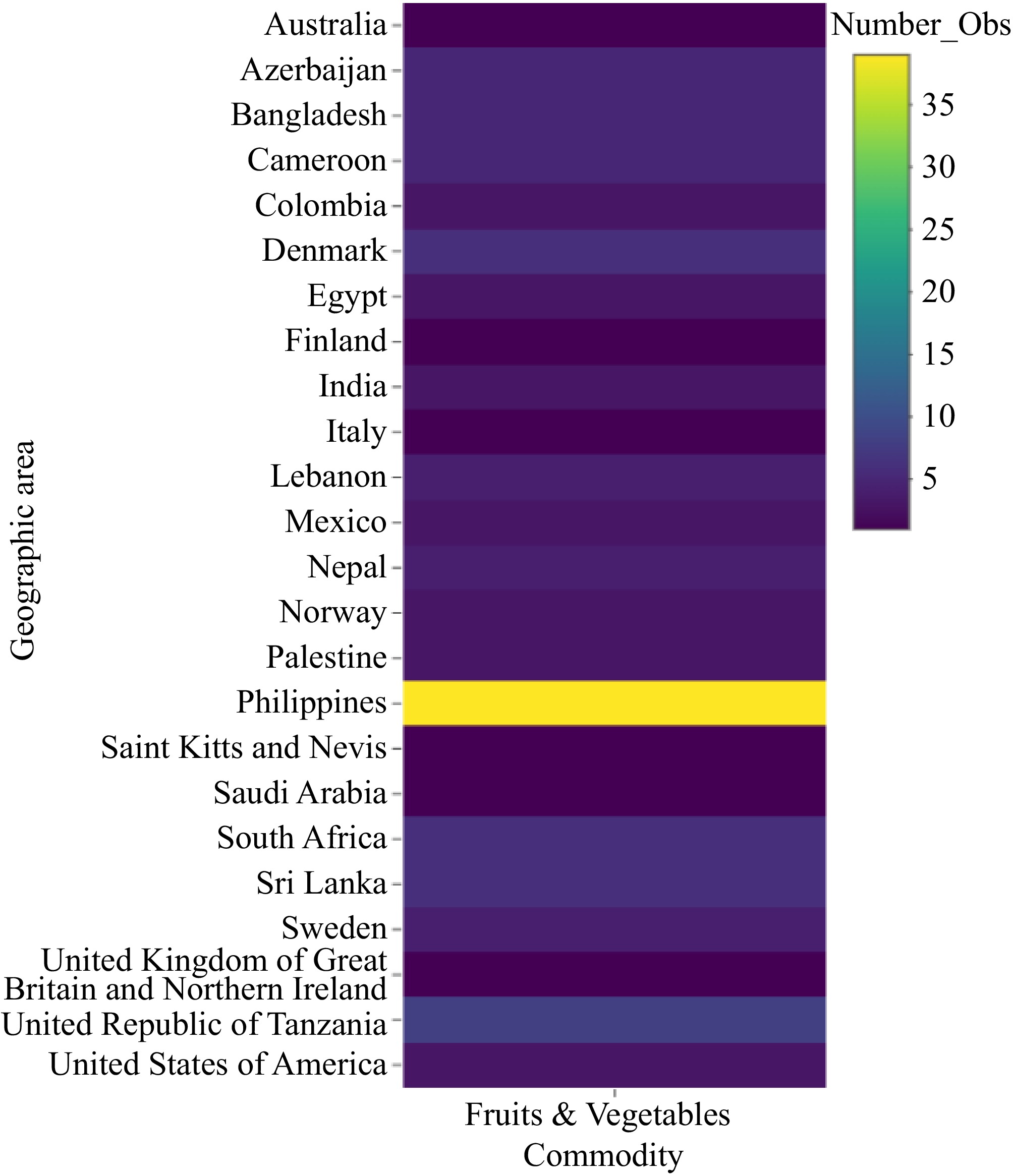

Figure 1.

Food loss and waste (2016−2022) across different countries.

-

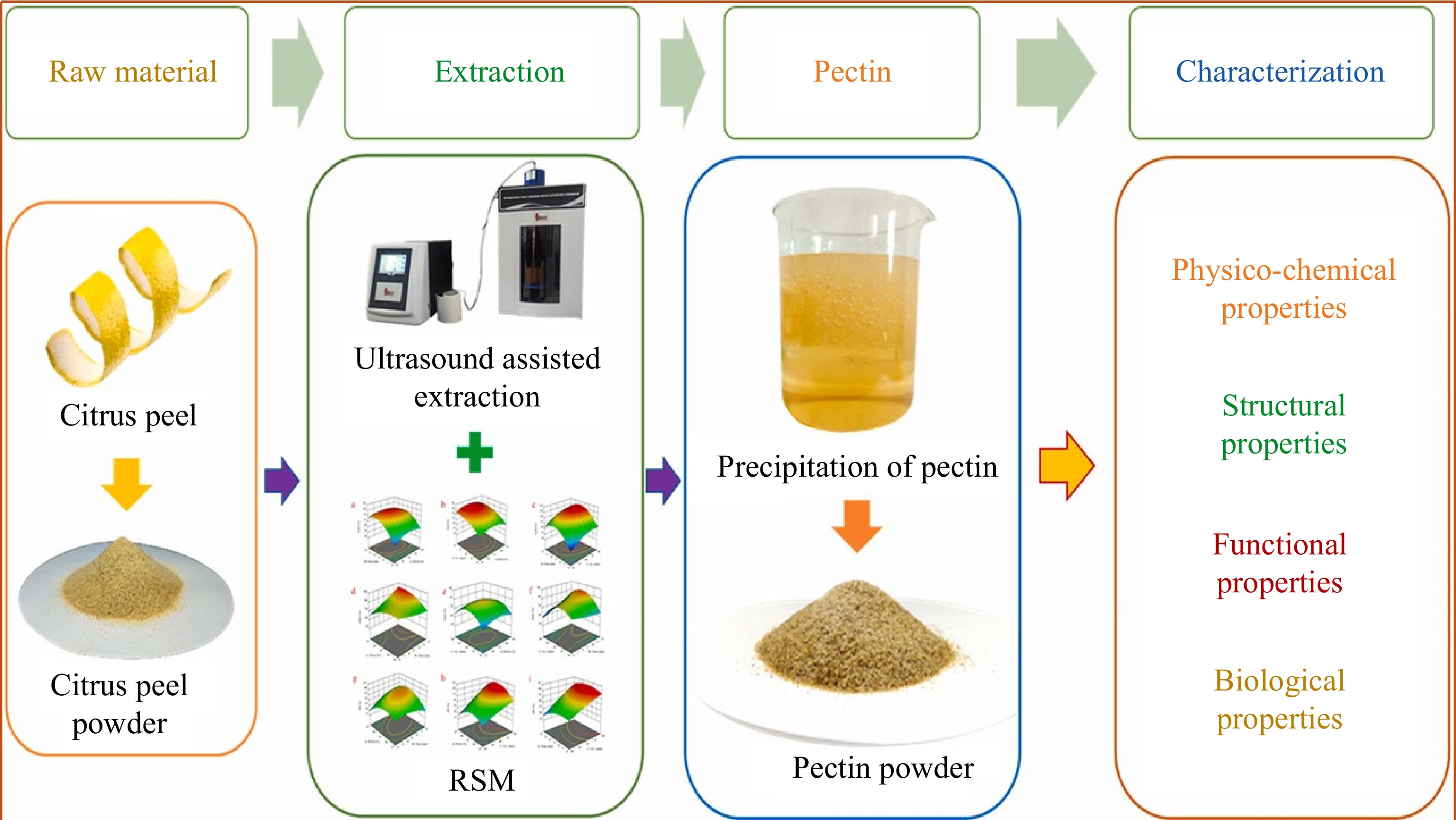

Figure 2.

Ultrasound-assisted extraction for pectin from citrus peel[55].

-

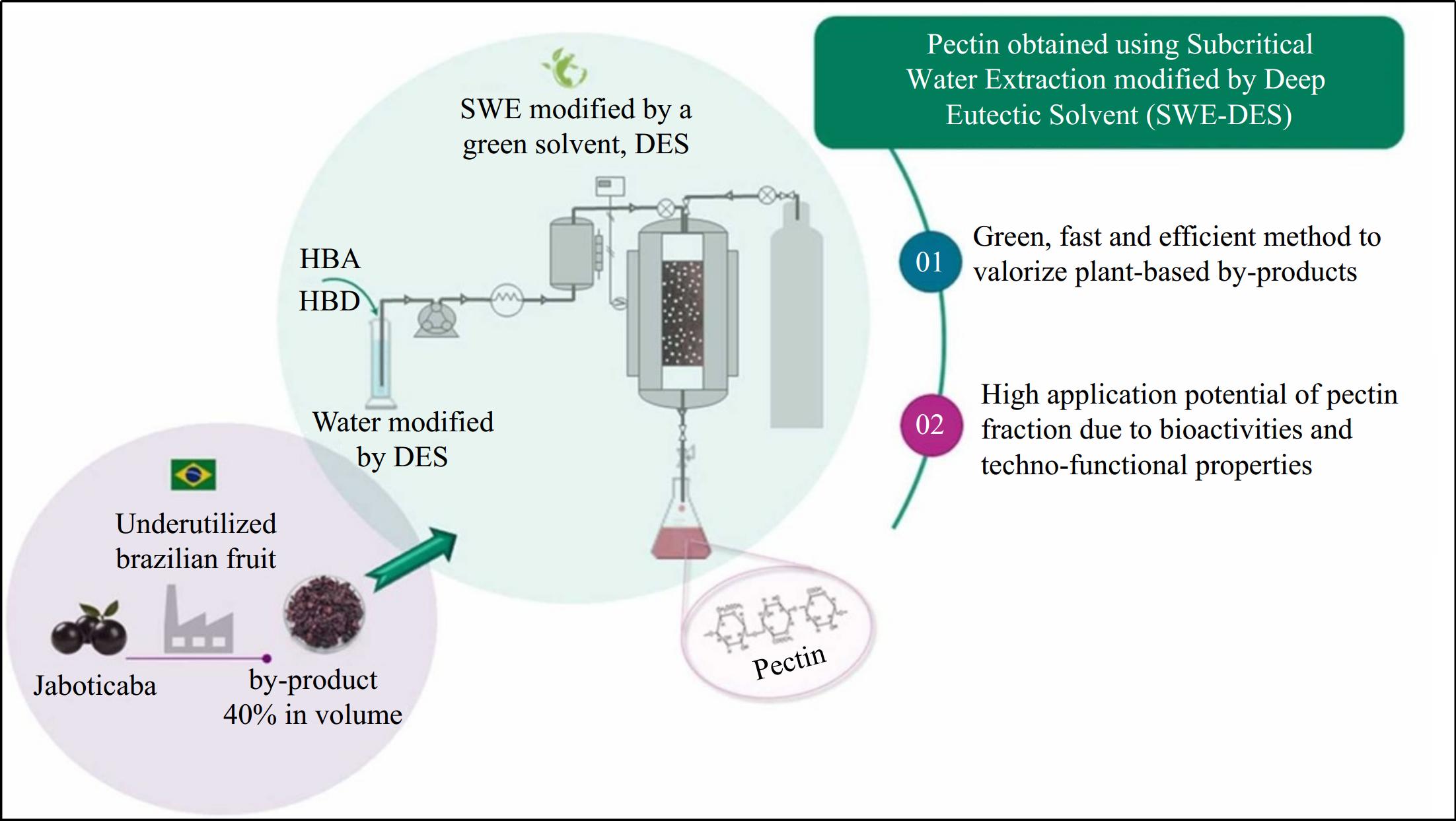

Figure 3.

High-potential of extrtacting pectin from plant-based by-products[72].

-

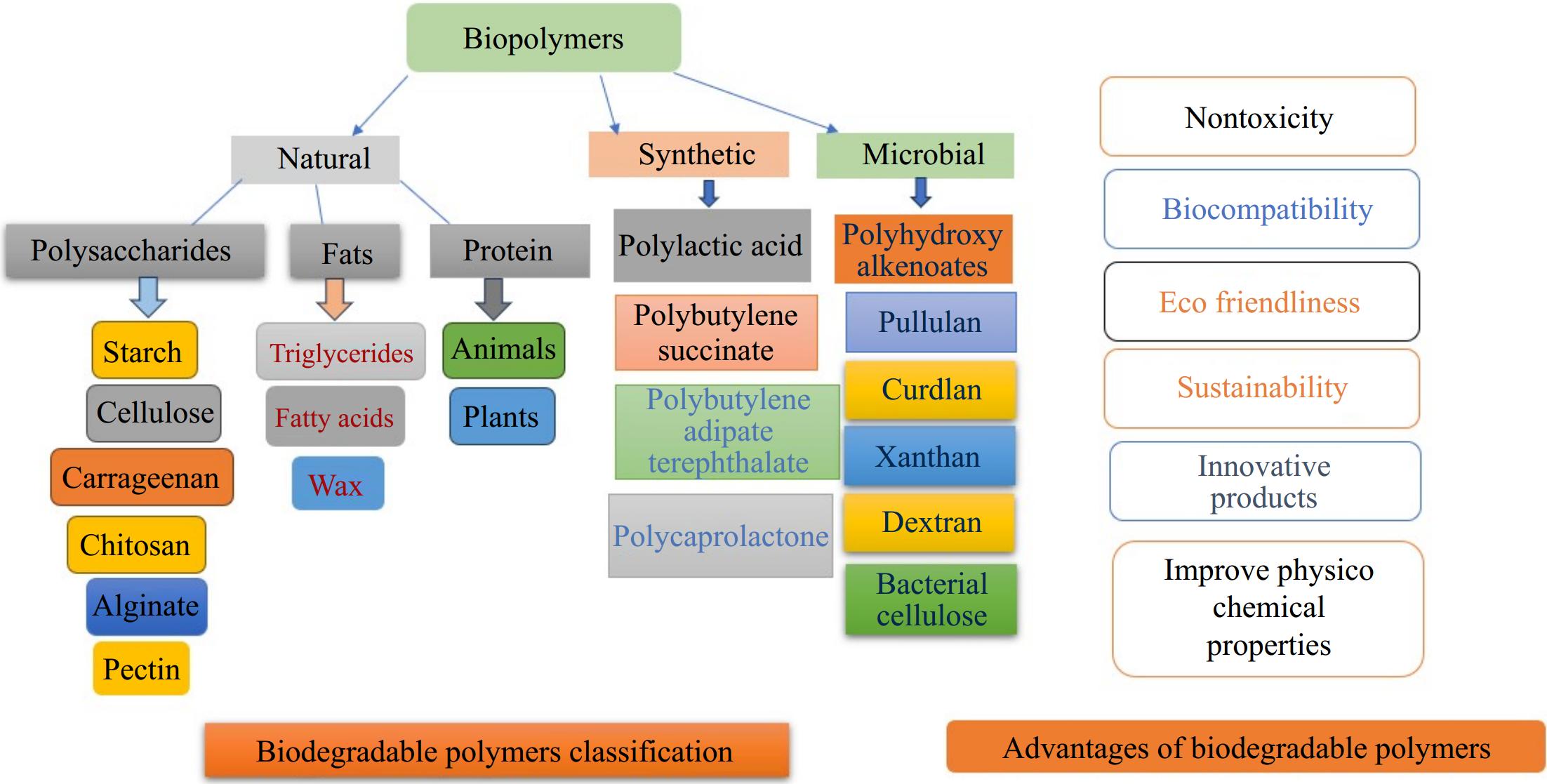

Figure 4.

Advantages and classification of biodegradable polymers.

-

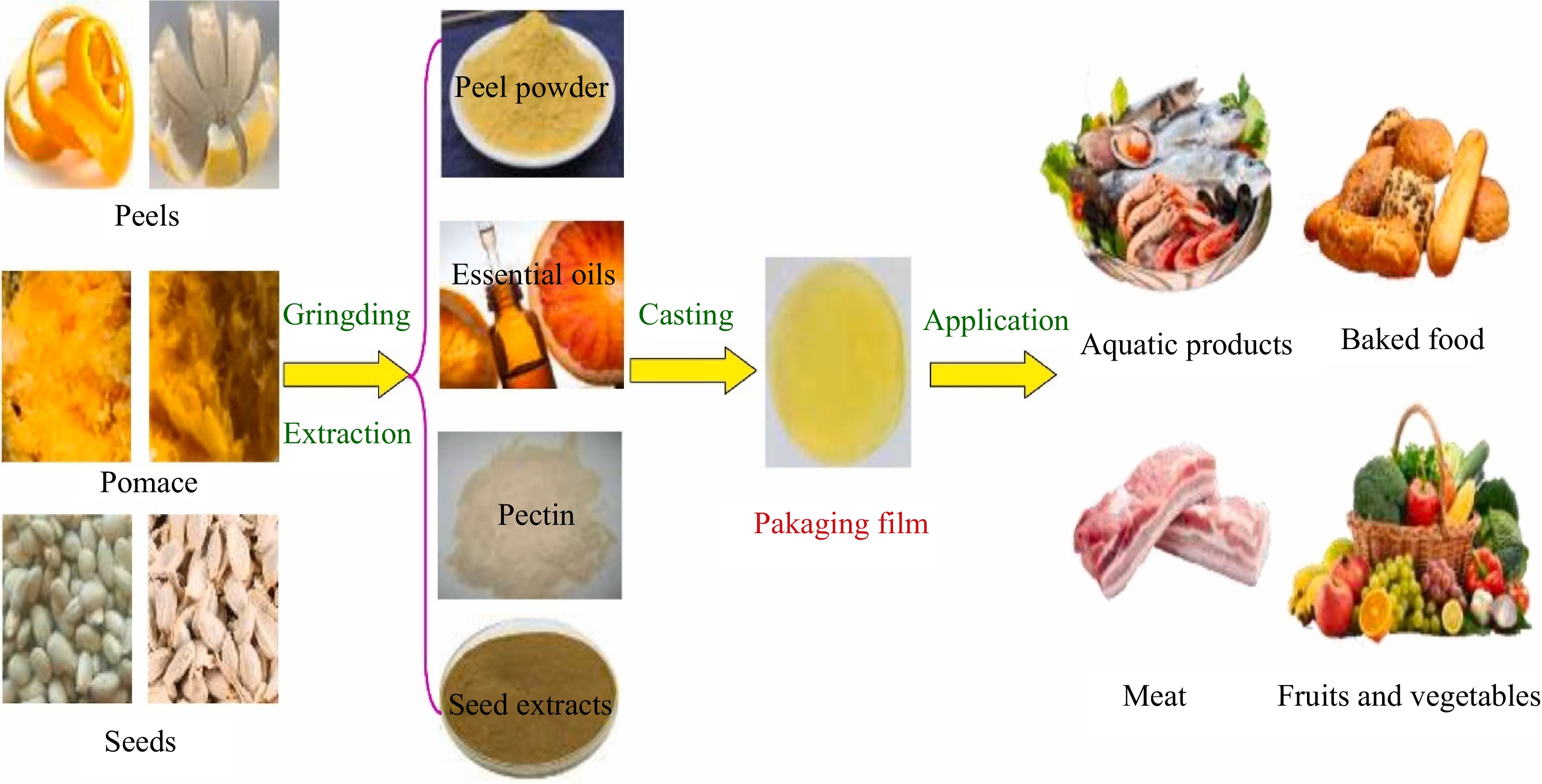

Figure 5.

Citrus peels/pomace rich in pectin and used as food packaging films[90].

-

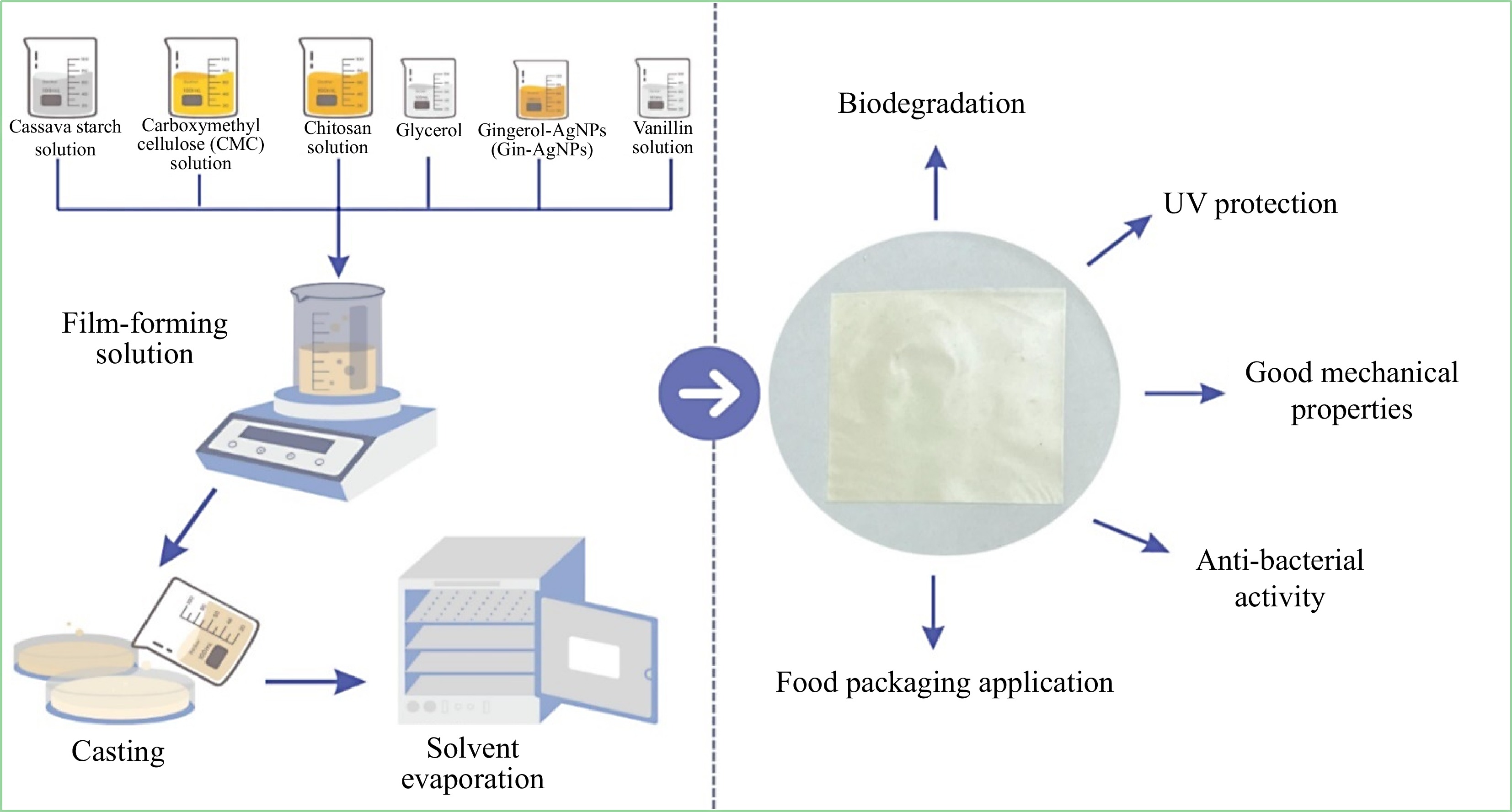

Figure 6.

Cassava starch and other biopolymer films used for food packaging[126].

-

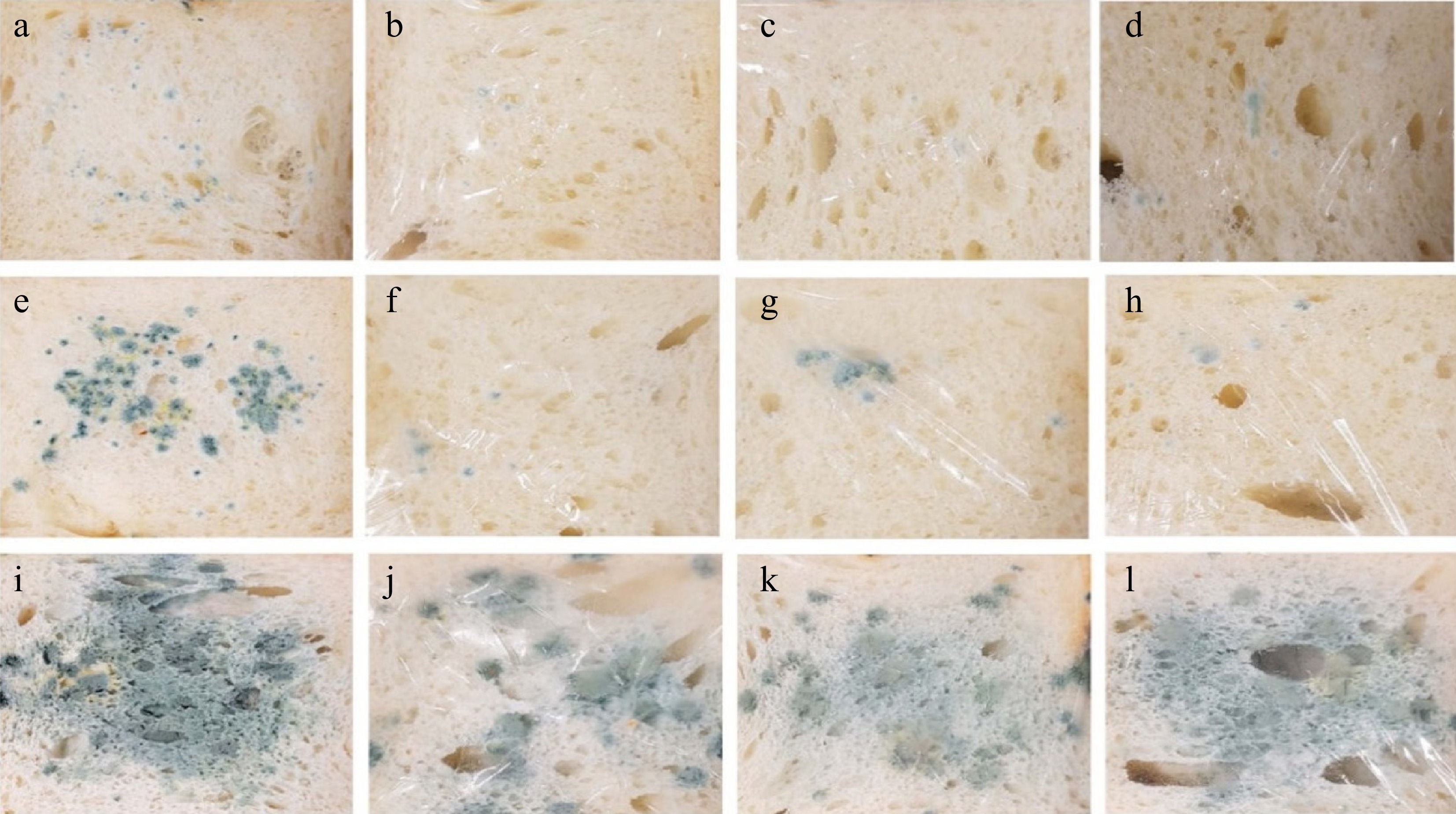

Figure 7.

Growth of fungi in wheat bread: (a), (e), (i) control (unpacked); (b), (f), (j) with 2% film; (c), (g), (k) covered with DES-10% film; (d), (h), (l) with MO-10% film. (a)–(d) 6 d, (e)–(h) 7 d, (i)–(l) 11 d[36].

-

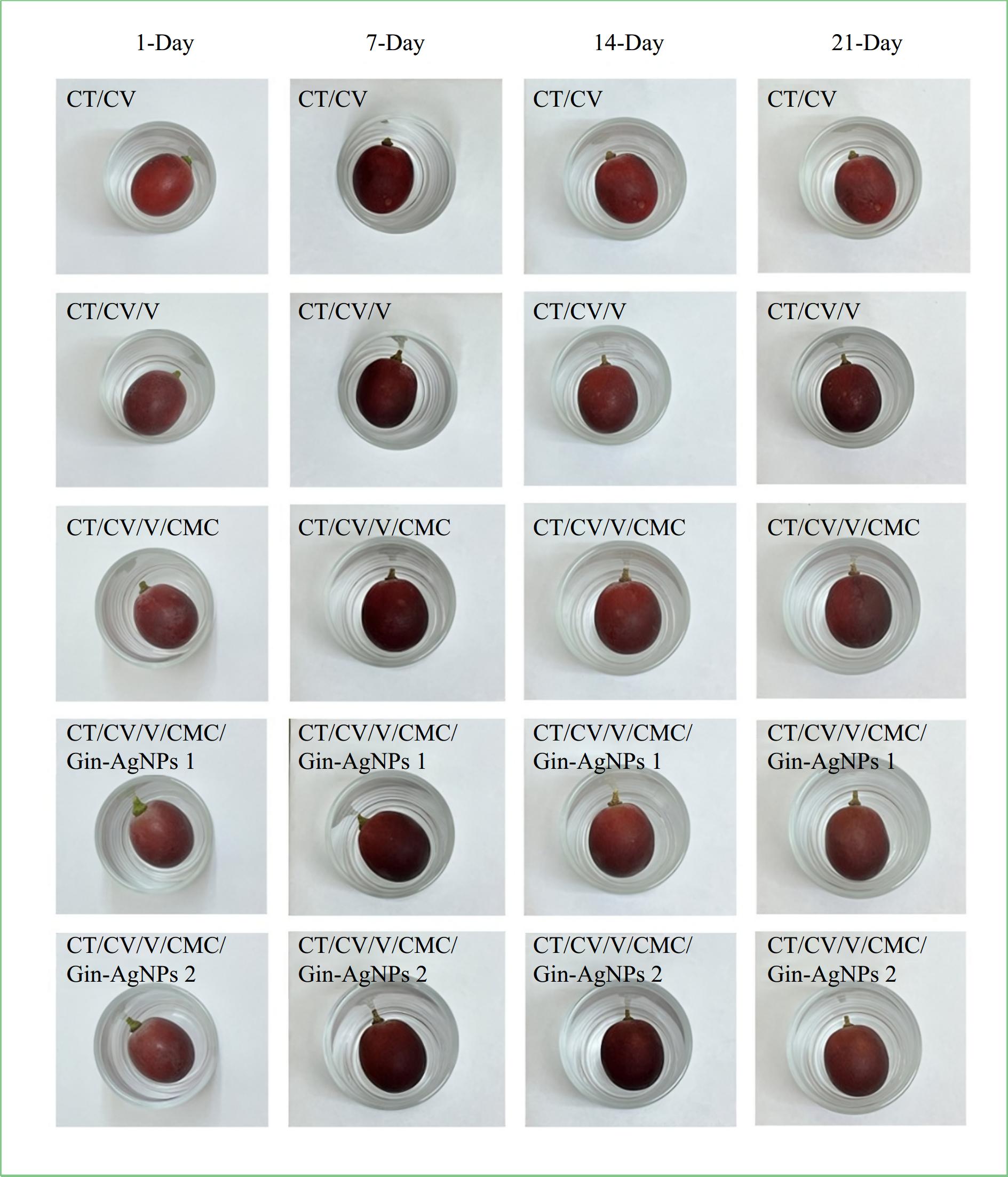

Figure 8.

Preserved grapes with CT/CV, CT/CV/V, CT/CV/V/CMC, CT/C V/V/CMC/Gin-AgNPs 1, and CT/CV/V/CMC/Gin-AgNPs 2 films for 1, 7, 14, and 21 d[126].

-

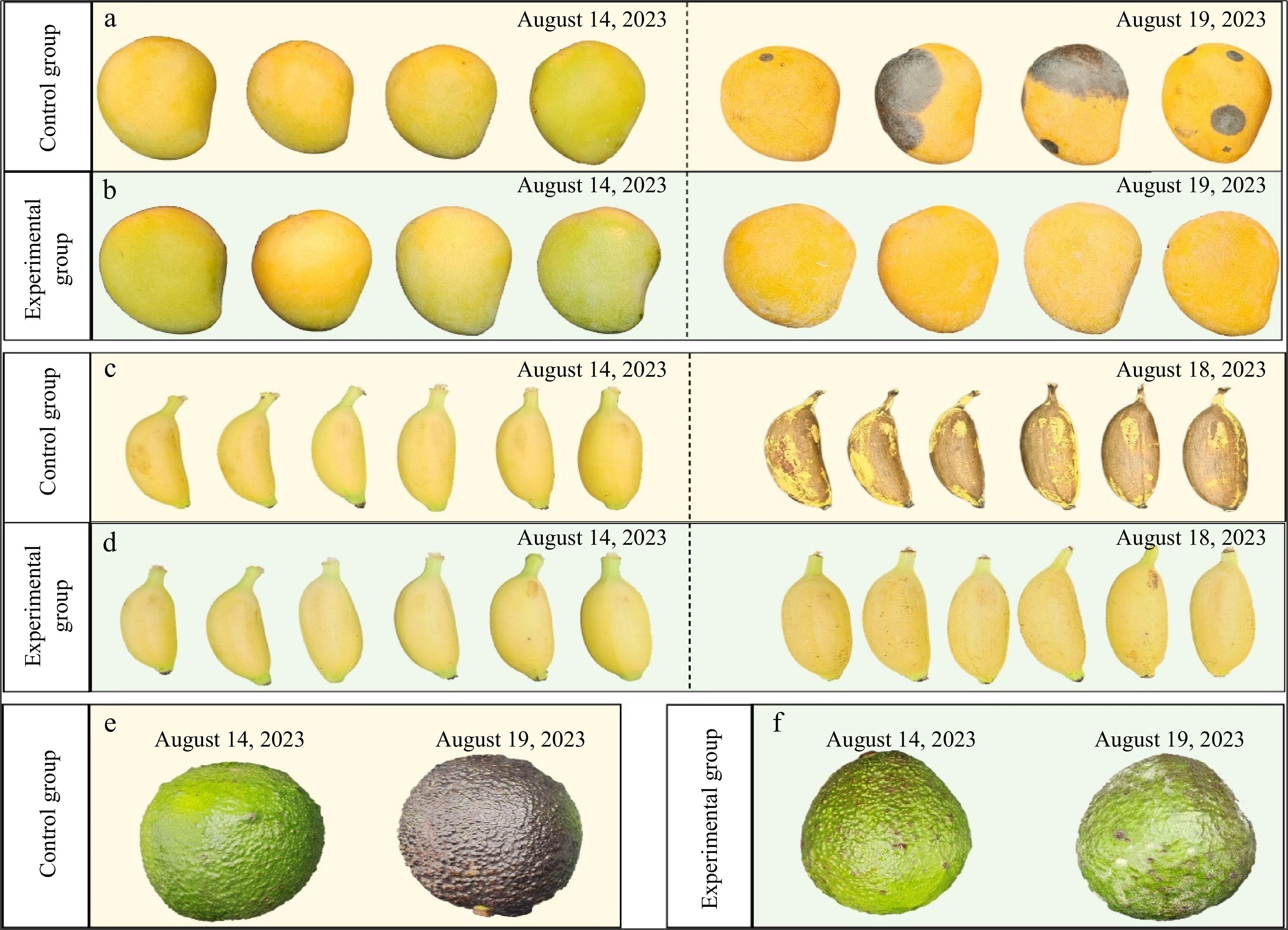

Figure 9.

Citrus peel biomaterials increase the shelf life of fresh fruits[115].

-

Fruit and vegetable

by-productsBioactive compounds Process conditions Agent Optimum yield Ref. Dragon fruit peels and passion fruit peel Pectin 10–12 min, 75 °C,

(153–218) WMethanol and specific pH (2.9–3.0) Red dragon fruit (17.01% ± 0.32%), white dragon fruit: (13.22% ± 1.42%), passion fruit: (18.73% ± 0.06%) [30] Black carrot pomace Antioxidants, anthocyanins, phenolics 5 min, 110 °C,

output 20%, 900 WHot acidic water and

pH 2.5Phenolic compounds (1692 ± 79.4 mg GAE/l) and antioxidants: (60 ± 9.6 MTE/mL) anthocyanins value is (456.8 ± 38.2 mg/L) [34] Longan seeds Pectin 3.5 min, 700 W 50% ethanol as a processing agent Good yield of pectin and 64.95 + 20.56 mg GAE/g dw phenolic contents [35] Peels of lemon, mandarin, and kiwi Pectin 1–3 min, 60–75 °C,

360–600 WNitric acid (HCl) Lemon: 7.31%; mandarin: 7.47%; kiwi: 17.97% [31] Apple, orange and mango peel, carrot pulp Pectin 10–180 min, 90 °C,

50–200 WWater orange peel: 12.9% ± 1.0%; mango peel: 14.7% ± 0.6%; apple pomace: 14.7% ± 0.1%; carrot pulp:

6.3% ± 0.7%[36] Black carrot pomace Phenolics, flavonoids, and anthocyanins 9.8 min, 348.07 W 20% ethanol used as a processing agent Polyphenolic (264.9 ± 10.02) mg GAE/100 mL; flavonoid: (1662.2 ± 47.3) mgQE/L; anthocyanins (753.4 ± 31.6) mg/L [33] Lemon peel Essential oil, pigment 50 min, 20 °C/min, 500 W 80% methanol Essential oil: 2 wt.%; pigment: 6 wt.% [37] Mango peel extract Phenolic compound, antioxidant 360 W for 20 s Ethanol : water ratio of 20:80 The total phenol content and antioxidant activity of the extracts increased significantly [38] Table 1.

The utilization of MAE of fruit and vegetable waste for bioactive compounds.

-

Fruit and vegetable

by-productsOrganic compounds Extraction condition Solvent Optimum yield Ref. Skin and seed of grape pomace Polyphenols and antioxidants contents 5 min, 100–160 °C, 10 atm, 250 s nitrogen purge 20%–60% ethanol Phenolic compounds of skin: 1.98 mg GAE/g DW, seed: 12.54 mg GAE/g DW [61] Pomegranate peel Punicalagin and total phenolic content 200 °C 77% ethanol TPC: 164.3 mg GAE/gDW, punicalagin: 17 mg/g DW [62] Olive pomace Total phenolic and flavonoid content, aminooxy acetic acid, 65–180 °C, supercritical CO2 80%–92% ethanol TPC: 280.37 mg GAE/g DE, AOA: 6.88 MTE/g DE [58] Beetroot by-products and residues TPC, aminooxy acetic acid 7.5–12.5 MPa, 3 mL/min, 40 °C 70%–100% ethanol Total phenolic content in leaves: 252 mg GAE/g, AOA: 823 MTE/g [63] Table 2.

Studies of fruit and vegetable by-products PLE extraction for organic compounds.

-

Fruit/vegetable

by-productsBioactive compounds Process conditions Agent Optimum yield Ref. Grape pomace Phenolics, flavonoids 50-190 °C Water Extract phenolic compounds: 29 g/100 g extracts [67] Citrus peel Total flavonoid content 145–175 °C, 15 min Water

TFC: 59,490 g/gdb[68] Dates by product

(seed)Total phenolic content, aminooxy acetic acid, TFC, dietary fiber 120–180 °C for 10–30 min, and 144 °C for 18.4 min Aqueous mixture TPC: (9.97 mg GAE/g), TFC: (3.52 mg QE/g), AOA:(1.67 mg TE/g) and dietary fibers: 29 g/mg [69]

Peel of kiwifruit

Aminooxyacetic acid, total phenolic and flavonoid content120–160 °C for 5–30 min, and 160 °C for 20 min Aqueous mixture TPC: (51.24 mg GAE/gdw), TFC:

(22.49 mg CE/gde),

AOA: (269.4 mM TE/gdw)[70] Tamarind seed Xyloglucan component, TPC, aminooxy acetic acid 100–200 °C (175 °C), 5.03–13.55 min Water Xyloglucan (62.28%),

TPC: (14.65–42.00 gGAE/g), and AOA: (1.93–3.20 MTE/g)[71] Table 3.

Progress studies of fruit and vegetable waste involving SWE extraction.

-

Fruit/vegetable by-products Packaging film/

coating materialProperties of films Ref. Mulberry leaf Pectin Improve mechanical properties, effectiveness as barriers, antibacterial and antioxidant activity, extending storage life. [114] Citrus peel Pectin, cellulose nanofibrils Bioplastics have flexibility, gas barrier properties, antimicrobial activity, and an extended shelf life for bananas and mangoes. [115] Red pomelo peel pectin Casein, egg albumin The reduction of water vapour permeability and the increase in strength tension have enhanced film thermal stability. [92] Skin and seeds of pumpkin Protein, pectin improved mechanical and barrier properties [116] Palmyrah fruit fiber Cellulose nanofiber, starch Starch films with improved tensile strength, reduced water vapour transmission, and excellent biodegradability. [117] Fruit pectin Rubus chingii Hu. Pectin, Tara gum Increased water resistance, thickness, and mechanical properties. [118] Oil palm fruit bunch carboxymethyl cellulose Biodegradable microcarriers with enhanced mechanical stability, swelling properties, and biodegradability are applicable for therapeutic and industrial uses. [118] Orange peel Fish gelatin, pectin Increased resistance to spoilage, better preservation for cheese packaging. [119] Pumpkin seed Pea starch Enhance gas permeation resistance and stretchability while reducing tensile strength, and moisture absorption. Adding pumpkin seed starch improved water repellency and decreased film spreading out. [120] Berry leaf Material used sodium alginate Enhanced physicochemical characteristics, increased phenolic compounds, greater yield strength, and reduced length. [121] Bagasse extract Gelatin The shelf life of frozen beef is prolonged using active films. These functional films influence adequate physical and barrier properties, effectively inhibiting the oxidation of beef lipids and proteins. [122] Kiwifruit peel Pectin The film with watermelon peel pectin had superior tensile strength and Young's modulus. Increasing the kiwi peel extract concentration increased film turbidity, elongation, and water vapour permeability. [123] Pineapple peel Alginate /peel extract The preservation of bovine red meat colour was effectively attained through improved antioxidant and antibacterial properties. [103] Grape seed Pectin/seed extract Extended storage durability, enhanced physical attributes, increased antimicrobial activity and oxidative stress, and reduced sourness. [124] Sesame pulp Starch/pulp Reduction in spoilage indicators, and improved shelf life of beef under extremely low temperatures. [125] Table 4.

Fruit and vegetable by-product polymers for increased properties of packaging materials.

Figures

(9)

Tables

(4)