-

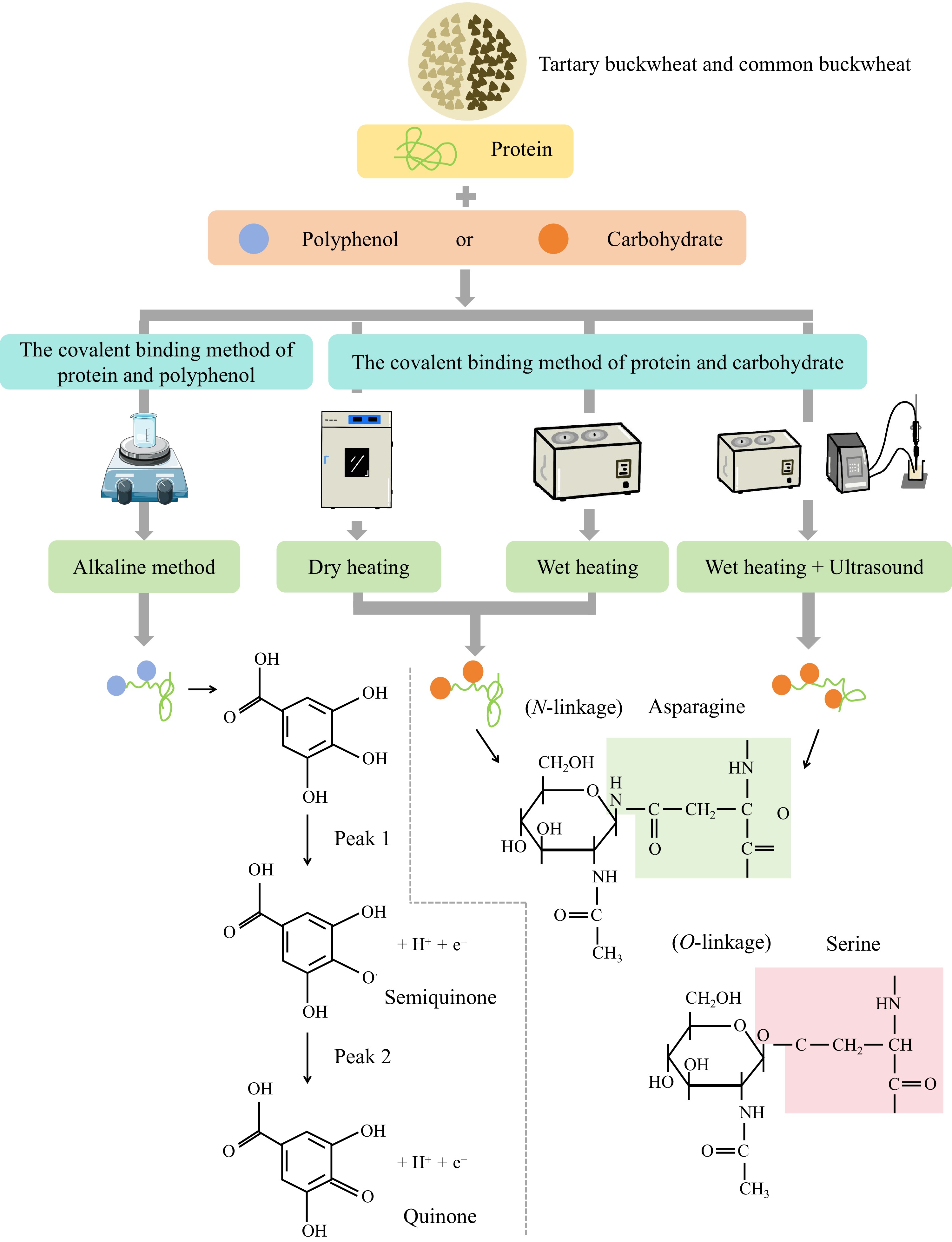

Figure 1.

Formation of covalent protein complexes between buckwheat protein and polyphenols or carbohydrates by different binding methods.

-

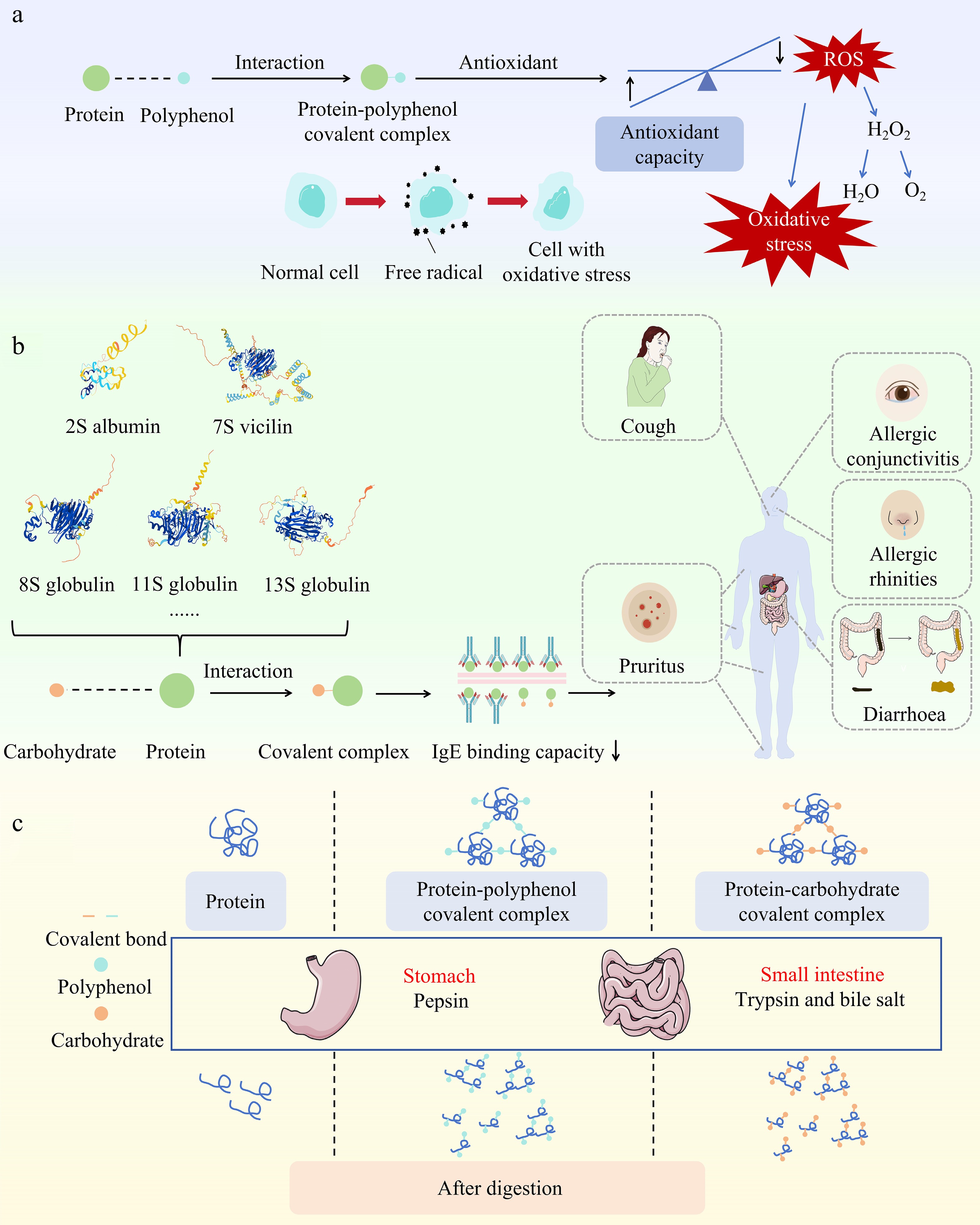

Figure 2.

Biological activities of buckwheat protein covalent complexes. (a) Antioxidant activity of protein-polyphenol covalent complexes, (b) allergenicity of protein-carbohydrate covalent complexes, (c) digestibility of protein-polyphenol and protein-carbohydrate complexes.

-

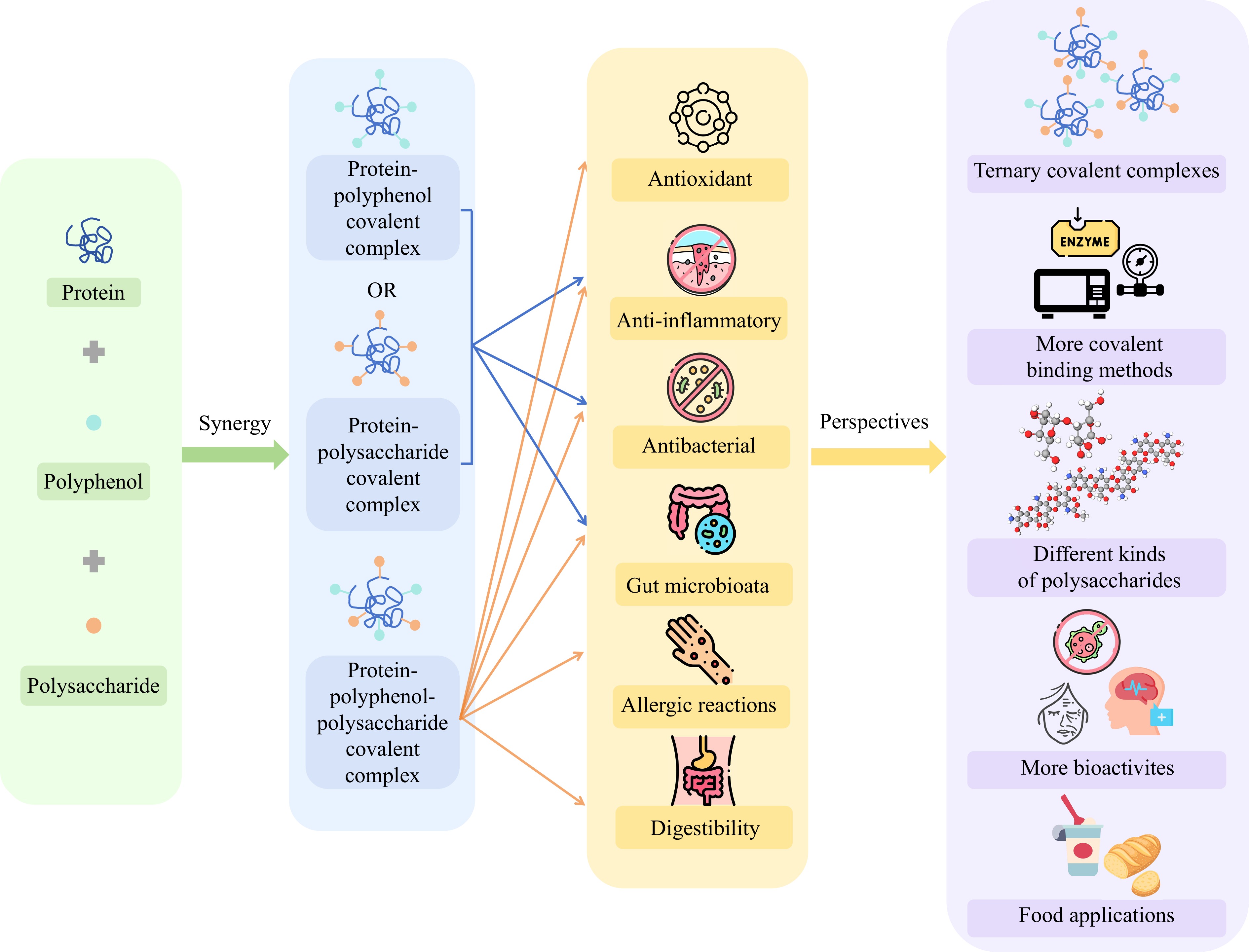

Figure 3.

The research framework of the challenges and perspectives for buckwheat protein covalent complexes.

-

Types of buckwheat Complex Reaction conditions Ref. Tartary buckwheat Protein-rutin, protein-myricetin, and protein-quercetin Alkaline method: pH 9.0, 1.0 h, 600 rpm [22] Tartary buckwheat flour Protein-myricetin, protein-Hanabiratakelide C, protein-quercetin, protein-kaempferol, protein-phloretin,

protein-norathyriol and protein-rutinAlkaline method: NaOH (0.1 M), pH 10.0, 2.0, 6.0, 8.0, & 10.0 h, 800 rpm [23] Tartary buckwheat flour Protein-rutin and protein-quercetin Alkaline method: pH 9.0, 24 h, aerobic conditions [24] Tartary buckwheat bran Protein-rutin Alkaline method: NaOH (0.5 M), pH 9.0, 230 rpm, 24 h, aerobic conditions [25] Tartary buckwheat Protein-polysaccharide Dry heating: 70 °C for 3 d or 160 °C for 15 min [26] Tartary buckwheat Protein-glucose Wet heating: 60 °C, 5 h [27] Common buckwheat flour Protein-xylose, protein-fructose, protein-glucose,

protein-dextran, and protein-maltodextrinWet heating: pH 6.5, 60 °C [28] Common buckwheat flour Protein-dextran Dry heating: 60 °C, 79% relative humidity for 2 weeks [29] Common buckwheat Protein-dextran Wet heating: 70 °C for 40 h;

Ultrasound treatment: 70 °C, ultrasound intensity 544.59 W/m2 for 80 min[30] Table 1.

Methods and reaction conditions of buckwheat protein covalent complexes.

-

Plant Complex Reaction conditions Characterization Ref. Soy Protein-ferulic acid (1:1.28 w/w) Alkaline method: pH 9.0 (2 M NaOH), 12 h;

Microwave: 600 W, 40 °C, 5 minCD, Fluorescence spectroscopy [49] Soy Protein-ferulic acid (1:1.28 w/w) Alkaline method: pH 9.0 (0.2 M NaOH), 12 h;

Microwave: 600 W, 40 °C, 4 min− [50] Rice Protein-dextran (1:3 w/w) Microwave heating SDS-PAGE, FTIR, CD, Fluorescence spectroscopy [51] Soy PI-D-allulose, PI-fructose, and PI-glucose (1.6:1 w/w) Wet glycation method: pH 7.0 and 10.0;

Microwave: 210 W, 90 °C for 4 minFree amino group, HPLC, FTIR, TD-NMR [52] Soy PI-lactose

(1:2 w/w), PI-soluble starch (1:5 w/w)Wet heating: 90 °C for ≤ 400 min;

Microwave: 1,000 W, 90 °C for 1.5 minFree amino groups, SDS-PAGE, FTIR, UV-VIS, AA analysis [53] Watermelon seed Protein-glucose (1:1 w/w) Wet heating: pH 10.0 (0.1 M NaOH), 90 °C for 1 h;

Microwave: 100, 150, 200, 250, & 300 W, 25 kHz, 90 °C for 10, 20, 30, 40, & 60 minFTIR, CD, Fluorescence spectroscopy, SEM, molecular weight distribution [54] Rice dreg Protein-sodium alginate

(1.88:1 w/w)Wet heating: 50 °C for 30 min;

Microwave treatment: 600 W for 11 minFTIR, CD, UV-VIS, AA analysis, molecular weight distribution [55] Hemp PI-gallic acid and

PI-catechin (66.7:1 w/w)Alkaline method: pH 9.0 (1 M NaOH) for 1 h;

Ultrasound treatment: 400 W for 20 minFree amino group, free SH groups, FTIR, Fluorescence spectroscopy [56] Quinoa Protein-chitosan Ultrasound treatment: 700 W, 20 kHz;

TGase (10 or 20 U/g): incubated at 50 °C, 30 min, and heated at 85 °C, 10 minFTIR, SEM, DSC [57] Grain Glutenin-Proanthocyanidin, Glutenin-catechin, and Glutenin-curcumin (50:1 w/w) Ultrasound treatment: 105.86 W/cm2 for 20 min using free radicals induced by ultrasound Free amino group, free SH groups, FTIR, Fluorescence spectroscopy [58] Soy PIs-cyanidin-3-galactoside

(200:1 w/w)Ultrasound treatment: 105.86 W/cm2 for 20 min using free radicals induced by ultrasound FTIR, SDS-PAGE, UV-VIS [59] Soy Protein-gallic acid (50:1 w/w, 25:1 w/w, 12.5:1 w/w, 6.25:1 w/w) Laccase (1.6 U/mL): 25, 40, 50, 60 °C, 4 h SDS-PAGE, UV-VIS, FTIR, CD, Fluorescence spectroscopy [60] Oat Globulin-procyanidin B2 (molar ratio is 1:1 or 10:1) Laccase (5 U/g): 37 °C for 0, 1, 2, 4 h CD and SEC [61] Red bean seed apoRBF protein-oligochitosan (1:4 w/w) TGase (6,000 U): incubated at 42 °C for 2 h, and thermally treated at 90 °C for 3 min HPLC, UV-VIS, FTIR, CD, DSC, TEM, DLS, Molecular weight analyses, SDS-PAGE, Fluorescence spectroscopy [62] Soy Soy PI-oligochitosan (1:3 w/w) TGase (10 U/g): 37 °C for 3 h FTIR, CD, SDS-PAGE, HPLC [63] Pea PI-chlorogenic acid (5.64:1 w/w) Laccase (80 U/g): 75 °C for 0, 2, 4, 6, 8, 12, 24 h SDS-PAGE, HPSEC, CD, Fluorescence spectroscopy [64] Inca peanut Albumin-para-hydroxybenzoic acid, albumin-protocatechuic acid, albumin-gallic acid, and albumin-epigallocatechin gallate (5:1 w/w) Laccase (2 U/mL): 30 °C for 24 h Free amino groups, thiol group, Tyr groups, FTIR, CD, Fluorescence spectroscopy, SEM [65] Rice Protein-ferulic acid, protein-gallic acid and protein-tannin acid (20:1 w/w) Laccase (polyphenol: enzyme 2:1) incubated in room temperature, 24 h Free amino groups, free and total SH content, Tyr content FTIR, fluorescence [66] Soy PI-chlorogenic acid (1:7 w/w) Laccase (chlorogenic acid: laccase 4:1) incubated in the dark for 2 h FTIR, SDS-PAGE, UV-VIS, Fluorescence spectroscopy [67] Soybean PI-oligochitosan (molar ratio is 1:3) TGase (10 U/g): 37 °C for 3 h SDS-PAGE, CD [68] Soy Protein-anthocyanins (58.82:1 w/w, 40:1 w/w, 20:1 w/w) Laccase (10 U): stir for 24 h FTIR, Fluorescence spectroscopy, UV-VIS [69] Pea Protein-xylo-oligosaccharides (3:1 wt%) Wet heating: pH 9, 70 °C, 20 min;

High pressure homogenization: 80 MPa three timesFTIR, CD, SDS-PAGE [70] Wet heating: pH 9, 70 °C, 21 min;

High pressure homogenization (80 MPa) three times.

Ultrasound treatment: 400 W at 70 °C for 20 minFTIR, SDS-PAGE, Fluorescence spectroscopy Soy PI-Galacto-Oligosaccharides (3:1 w/w) Wet heating: pH 8, 70 °C, 10 min;

High pressure homogenization: 70 °C under 80, 100, 120, and 140 Mpa,10 minFree amino groups, SH content, SDS-PAGE, FTIR, CD, Fluorescence spectroscopy [71] Lotus seed PI-dextran (1:2 w/w) Dynamic high pressure microfluidization: 40, 80, 120, & 160 MPa;

Wet heating: 70 °C for 2 hFTIR, Fluorescence spectroscopy [72] Soy PI-chitosan (3:1 w/w) TGase (10 U/g): 40 °C for 1 h;

Microfluidic treatment: 300, 400, 500, & 600 MPa once or twiceFree SH content analysis, SDS-PAGE, FTIR, Fluorescence spectroscopy [73] Soybean PI (2% w/v)-flaxseed gum (2% w/v) High hydrostatic pressure: 60 °C for 3 days under 0.1, 100 200 and 300 MPa Free AA content, FTIR, CD, SDS-PAGE, nano-HPLC-MS/MS [74] Pea PI-Epigallocatechin-gallate (20:1 w/w) Pulsed electric field: 120 mL/min, < 30 °C, 10 kV/cm, 0.8 ms;

Alkaline: pH 9, 25 °C with oxygen for 24 hFree SH group, free amino group, SDS-PAGE [75] Table 2.

Methods, reaction conditions, and characterization of other plant protein covalent complexes.

Figures

(3)

Tables

(2)