-

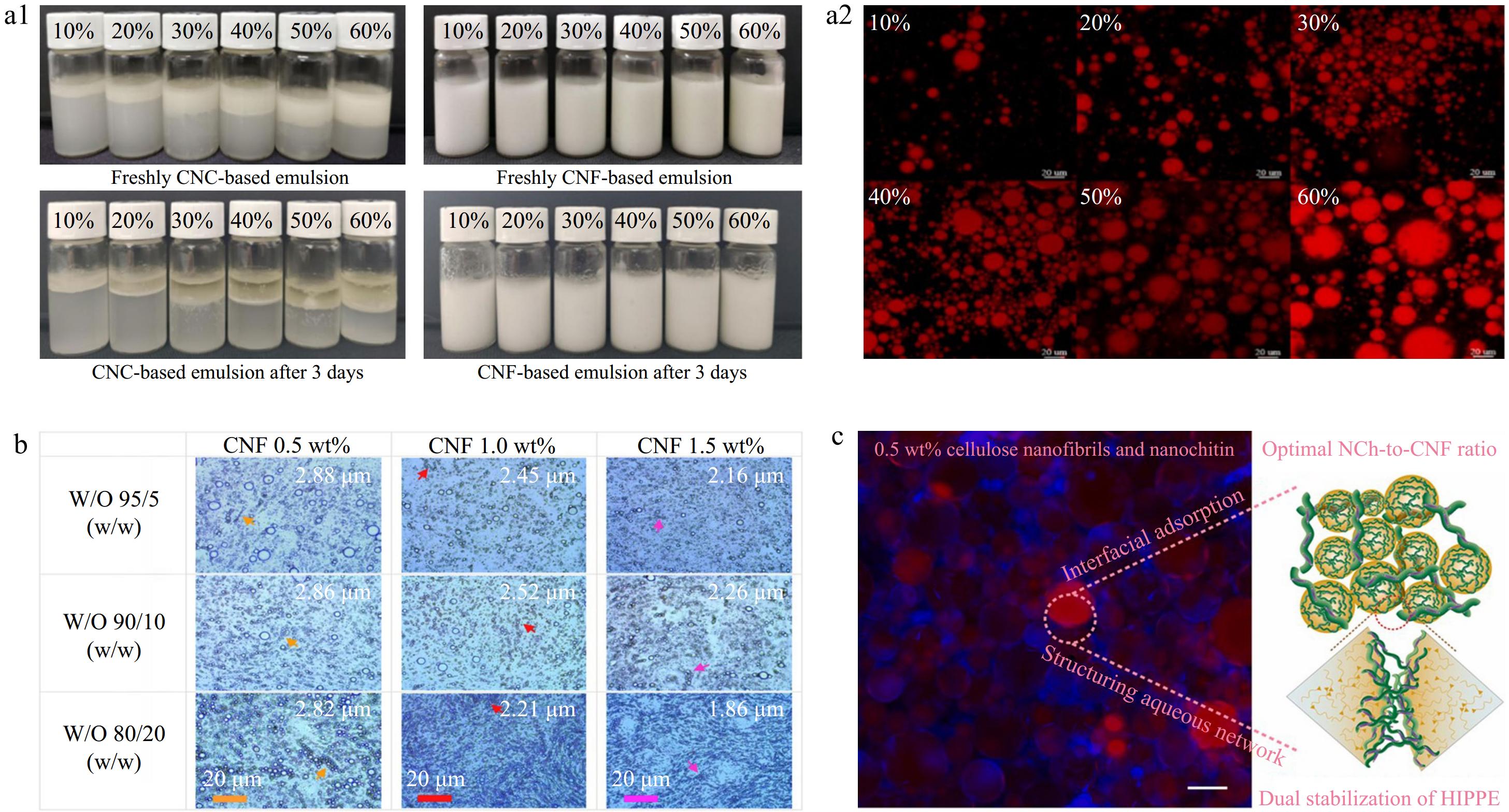

Figure 1.

CNF stabilized Pickering emulsion: (a1) Storage stability of Pickering emulsions prepared by CNF and CNC respectively stabilized with different oil contents. (a2) CLSM images of CNF-based Pickering emulsion (reproduced with permission from Elsevier)[45]. (b) CNF stabilized sesame oil-in-water emulsion oil-in-water morphology (reproduced with permission from Elsevier)[46]. (c) CNF and NCh to obtain a high internal phase Pickering emulsion (reproduced with permission from Elsevier)[47].

-

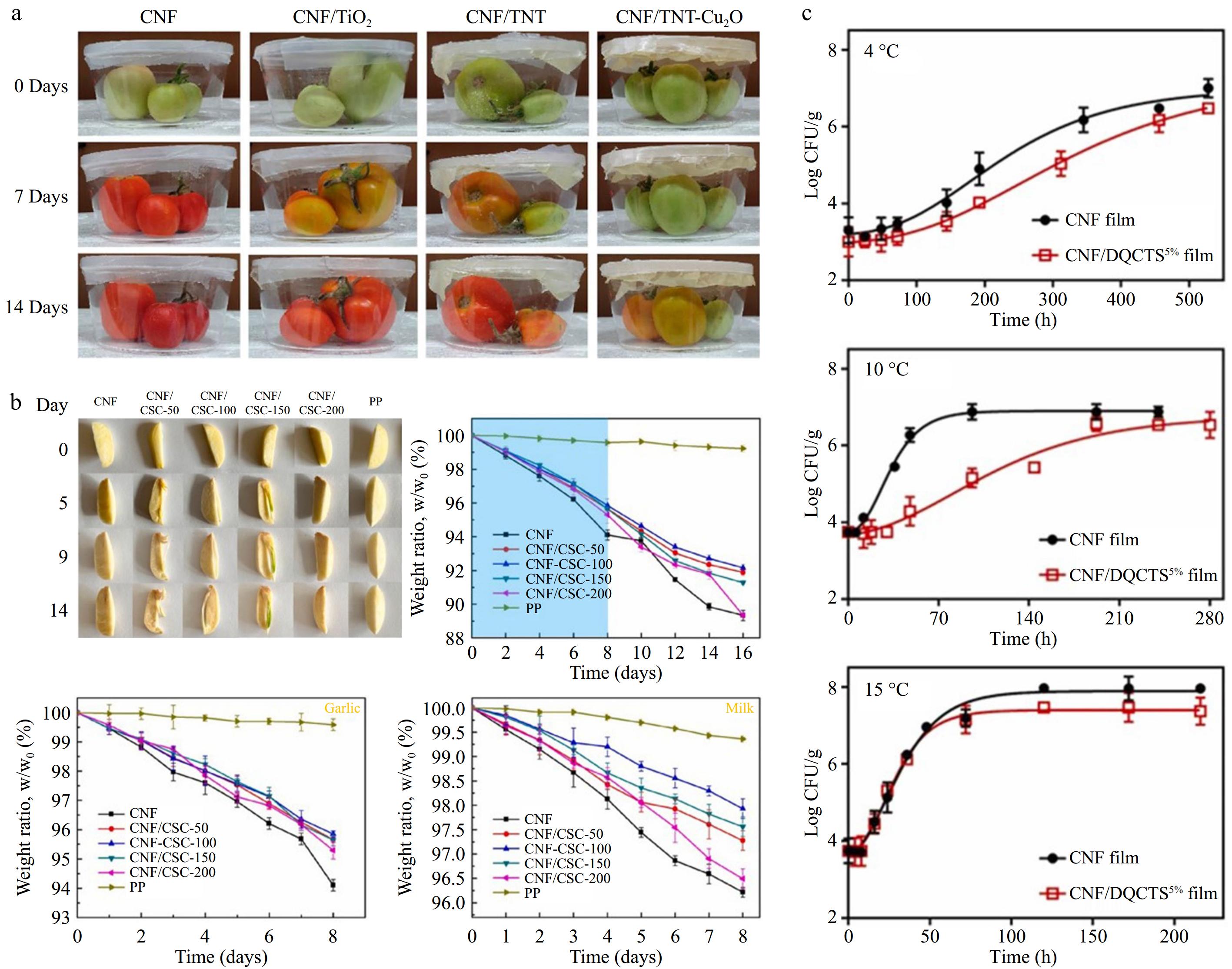

Figure 2.

CNF can be used in food active packaging: (a) CNF-based film delays tomato ripening at 25°C (reproduced with permission from the American Chemical Society)[53]. (b) CNF-based film at room temperature for fresh garlic preservation test, solid food (garlic) and liquid food (milk) water loss over 8 d (reproduced with permission from Elsevier)[54]. (c) Antimicrobial effect of CNF-based film as raw salmon packaging: growth status of Listeria monocytogenes in CNF- and CNF/DQCTS-based film packaging of raw salmon at different temperatures (reproduced with permission from Elsevier)[55].

-

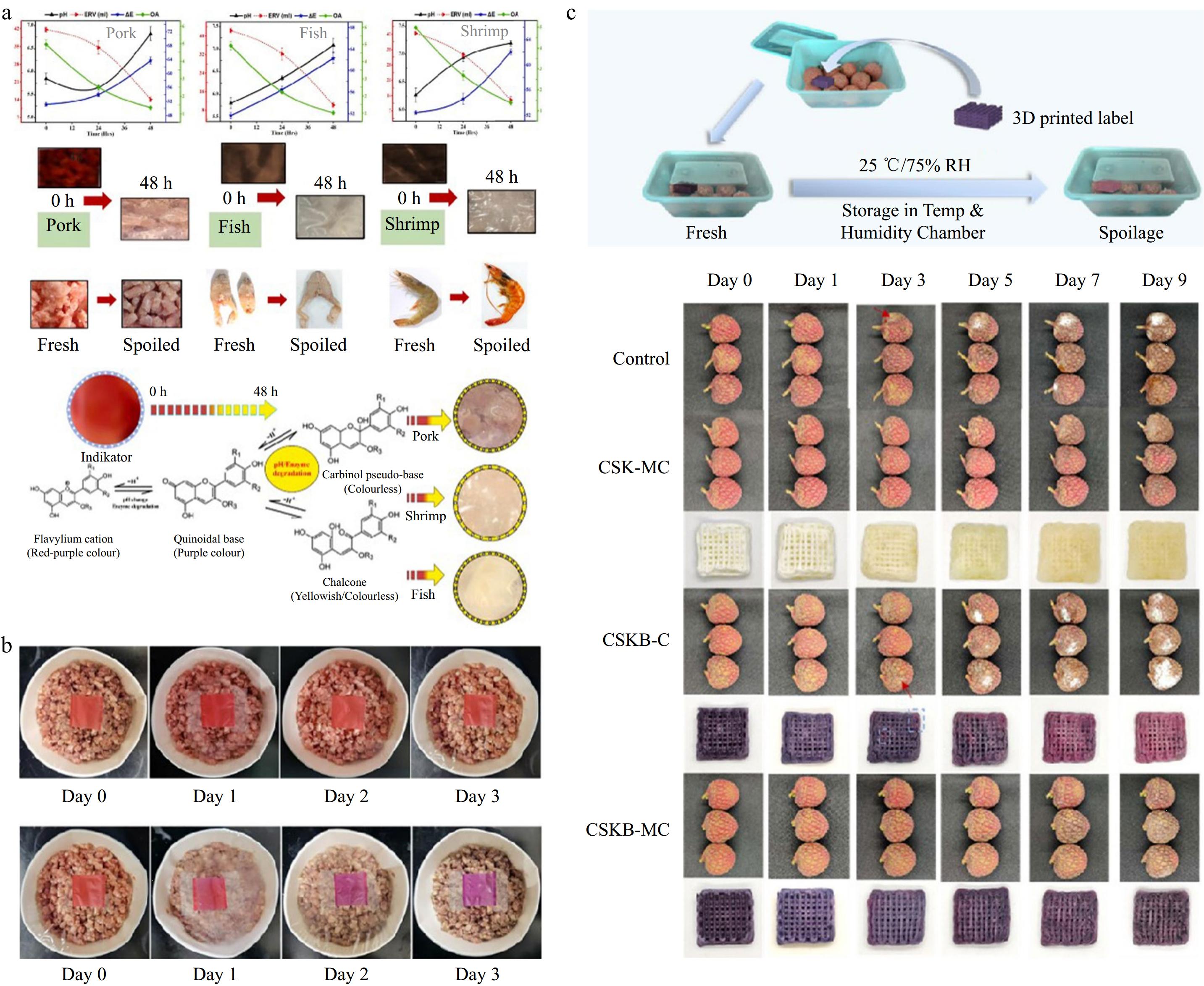

Figure 3.

CNF can be applied to smart packaging: (a) Smart nanocomposite films based on CNF/cabbage anthocyanins/cabbage biowaste can detect changes in the quality of fish, pigs, and shrimps. (Reproduced with permission from Elsevier)[56]. (b) CNF film compounded with carotene pigment extract can detect the freshness of minced pork by color change (reproduced with permission from Elsevier)[57]. (c) CNF-based 3D printed label that can detect the freshness of lychee by color change (reproduced with permission from Elsevier)[58].

-

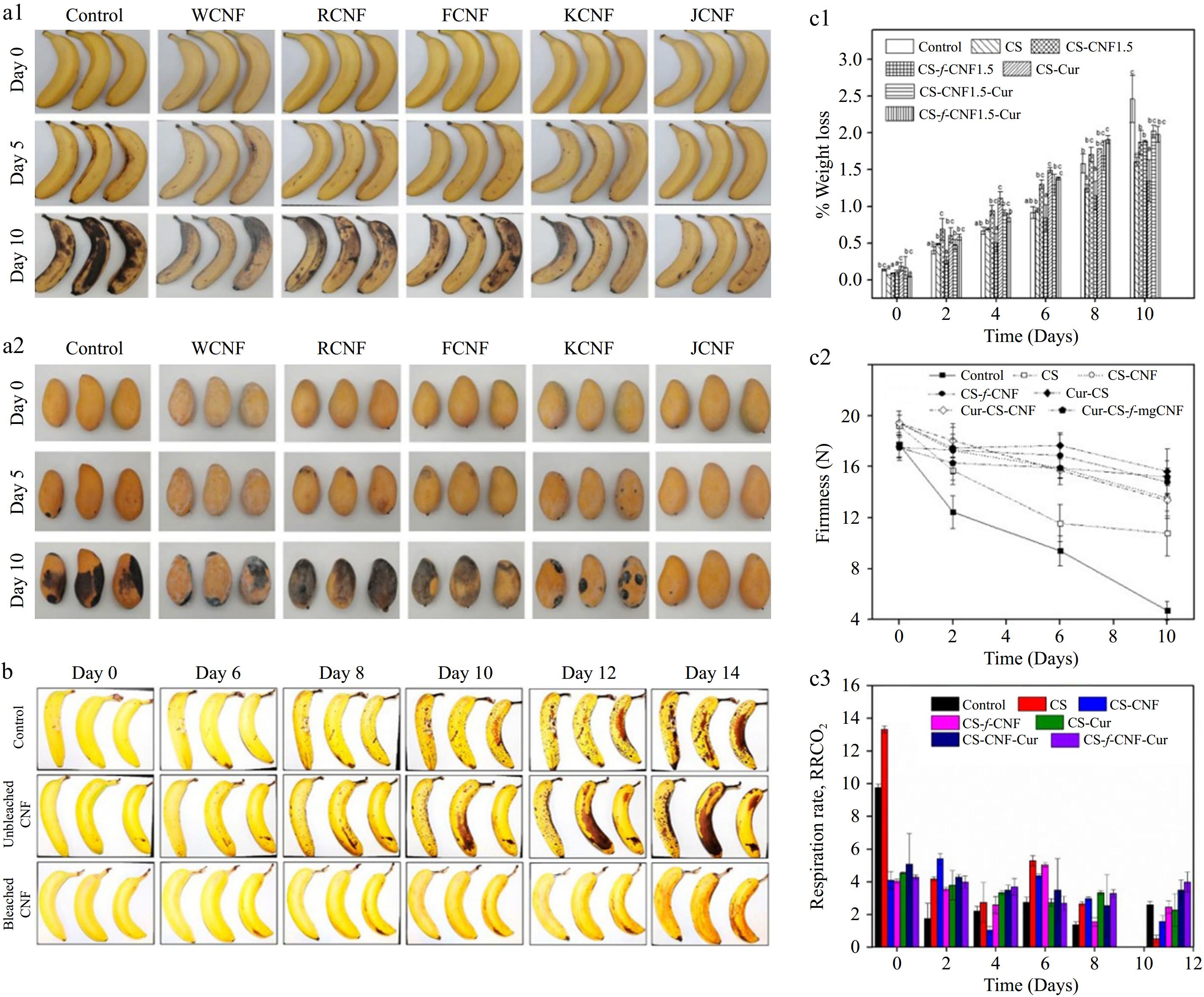

Figure 4.

CNF can be used as a spray coating for food preservation: (a) Mitigation effect of different CNFs sprayed on the surface of (a1) bananas, and (a2) mangoes on their decay. (Reproduced with permission from the American Chemical Society)[59]. (b) Freshness of bleached and unbleached carrot CNF sprays for bananas (reproduced with permission from the American Chemical Society)[60]. (c) f-CNF enhanced chitosan edible coating for kiwifruit preservation: (c1) Weight loss. (c2) Texture analysis. (c3) Respiration rate of edible coated kiwifruit products stored at 10 °C (reproduced with permission from Elsevier)[61].

-

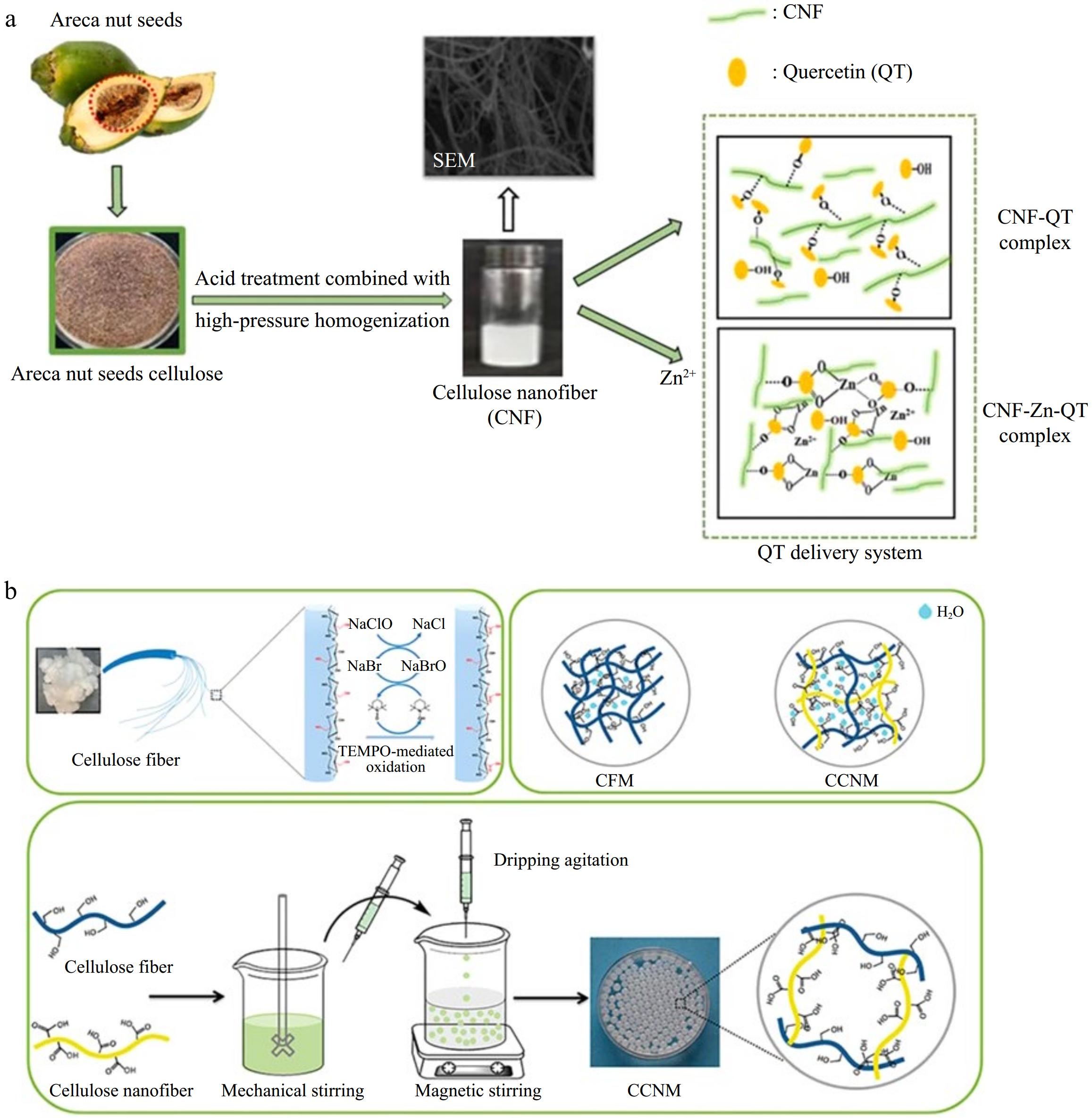

Figure 5.

Application of CNF in the sustained-release delivery system: (a) CNF-based quercetin (QT) delivery system (reproduced with permission from Elsevier)[66]. (b) CNF-based macrogels as probiotic sustained-release delivery carriers (reproduced with permission from the American Chemical Society)[67].

-

Method Principle Disadvantage High-pressure homogenization Pass the cellulose dispersion through the homogenization valve's tiny flow channel several times under high pressure (> 150 MPa)[37]. Strong peeling and shearing forces generated by the dispersion reduce the fibrillation of the cellulose. The reliability of the equipment is low, the maintenance work is complex, the preparation of homogenization is time-consuming, the energy consumption is high[38], and the size of CNF particles are too large to use directly[39]. Micro-Jet Similar to the high-pressure homogenization method, the cellulose dispersion is subjected to a huge shear force when passing through a zigzag flow channel under ultra-high pressure (> 300 MPa) and quickly ejects from a narrow valve port of 100−400 μm[40]. Under extremely high pressure, CNF's crystallinity will diminish, and as the number of processing steps grows, cellulose's creep flexibility and the fiber network structure tend to relax[41]. Milling The grinding process mainly uses a fixed groove disc and the mechanical force of a planetary mill or grinding disc to rub and shear the cellulose fibers and decrease the size of the fiber particles[42]. Fibrillation is achieved by narrowing the gap between the grinding discs and reducing the particle size of CNF. Production efficiency is limited because the distance between the discs must be continuously changed during the process. It is challenging to modify the distance between the discs because the cellulose is too small. When spinning at high speeds, two grinding discs may clash, introducing quartz or metal chips; The grinding disc's surface has a specific number of grooves that make it easy for cellulose to become embedded during the grinding process, producing uneven cellulose scale[43]. Table 1.

Principle and disadvantages of different mechanical methods for the preparation of CNF.

-

Method Principle Advantage Hydrolysis of organic acids[83] Organic acid hydrolysis of cellulose raw materials can reduce its particle size, and can hydrolyze the amorphous region of cellulose, improve the crystallinity of the final product, and can also graft functional groups such as carboxyl and ester groups on the fiber surface. CNF can be synthetically prepared by adjusting the hydrolysis conditions, and the organic acids after the reaction can be recovered with high efficiency by rotary evaporation or crystallization Periodite oxidation pretreatment[12, 84,85] By increasing the anionic charge density on the surface of cellulose fibers to reduce hydrogen bonds, periodic acid oxidation pretreatment combined with sodium hypochlorite oxidation or sodium bisulfite reduction can enrich the surface of microfibrils inside cellulose with carboxyl or sulfonic acid groups, thereby increasing the electrostatic repulsion of microfibrils against each other The electrostatic repulsion of the microfibrils against each other is increased, which greatly improves the nano-efficiency of the mechanical treatment process, thereby reducing energy consumption, and the periodate can be recovered efficiently during the pre-treatment process. Eutectic solvent pretreatment[36, 83] Deutscible solvent (DES) is a two-component or three-component eutectic mixture composed of a hydrogen bond acceptor and a hydrogen bond donor with a certain stoichiometric ratio. The functionalization of cellulose surface groups can be achieved by adding modification reagents. The physicochemical properties of DES are similar to those of ionic liquids, but they are less expensive to prepare, less toxic, biodegradable, and greener than ionic liquids. In addition, DES can achieve efficient recycling through a simple recycling process. Table 2.

The principles and advantages of the emerging pretreatment methods.

Figures

(5)

Tables

(2)