-

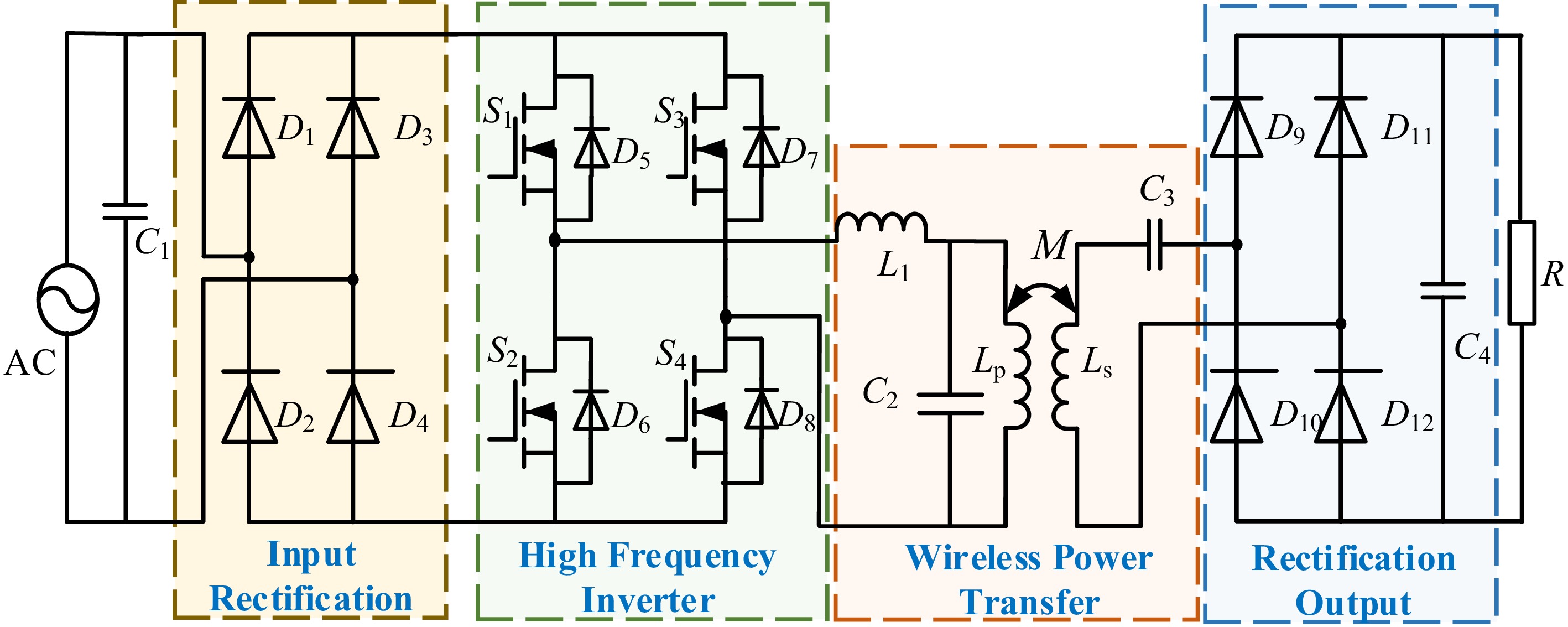

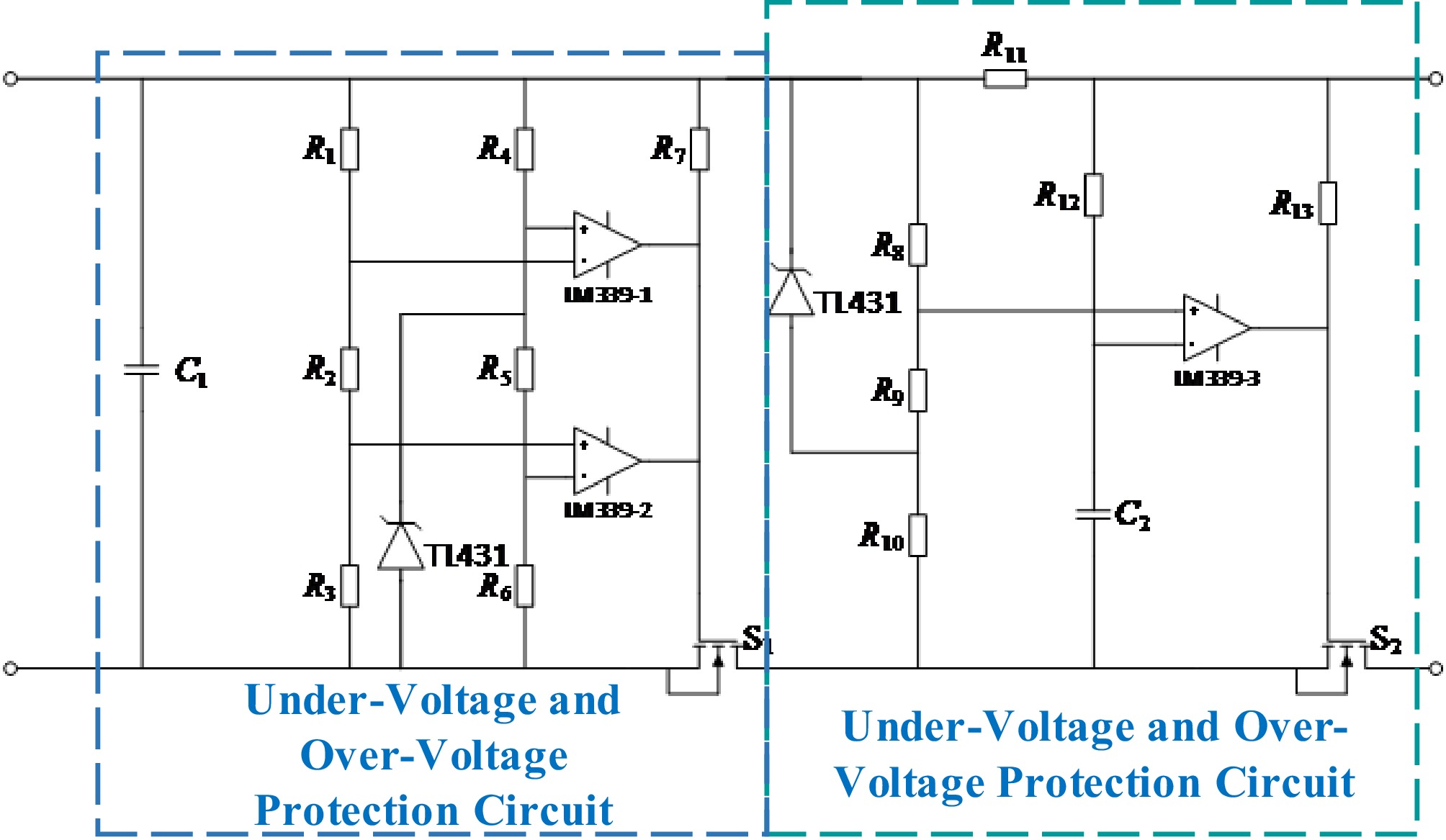

Figure 1.

Main circuit topology.

-

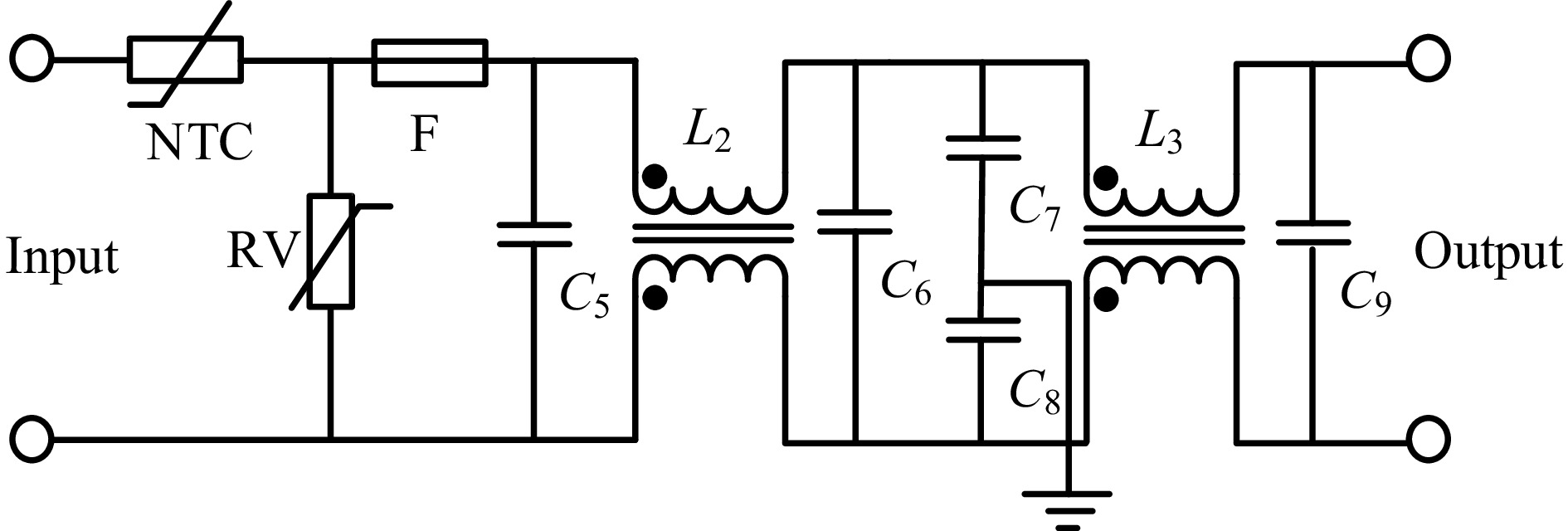

Figure 2.

Rectification and filtering circuit diagram.

-

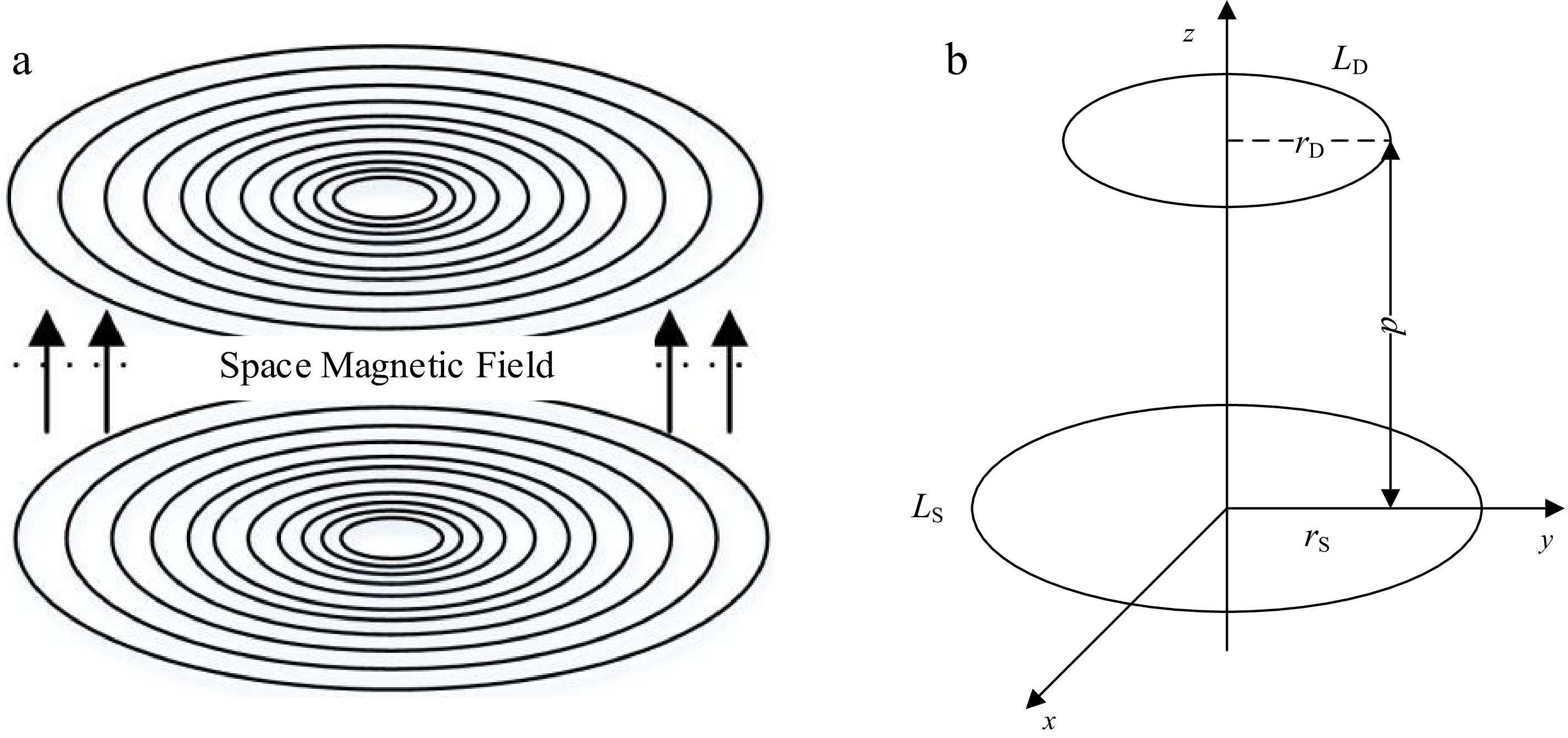

Figure 3.

Diagram of WPT coil. (a) Diagram of planar coil structure. (b) Diagram of parallel coaxial coil spatial structure.

-

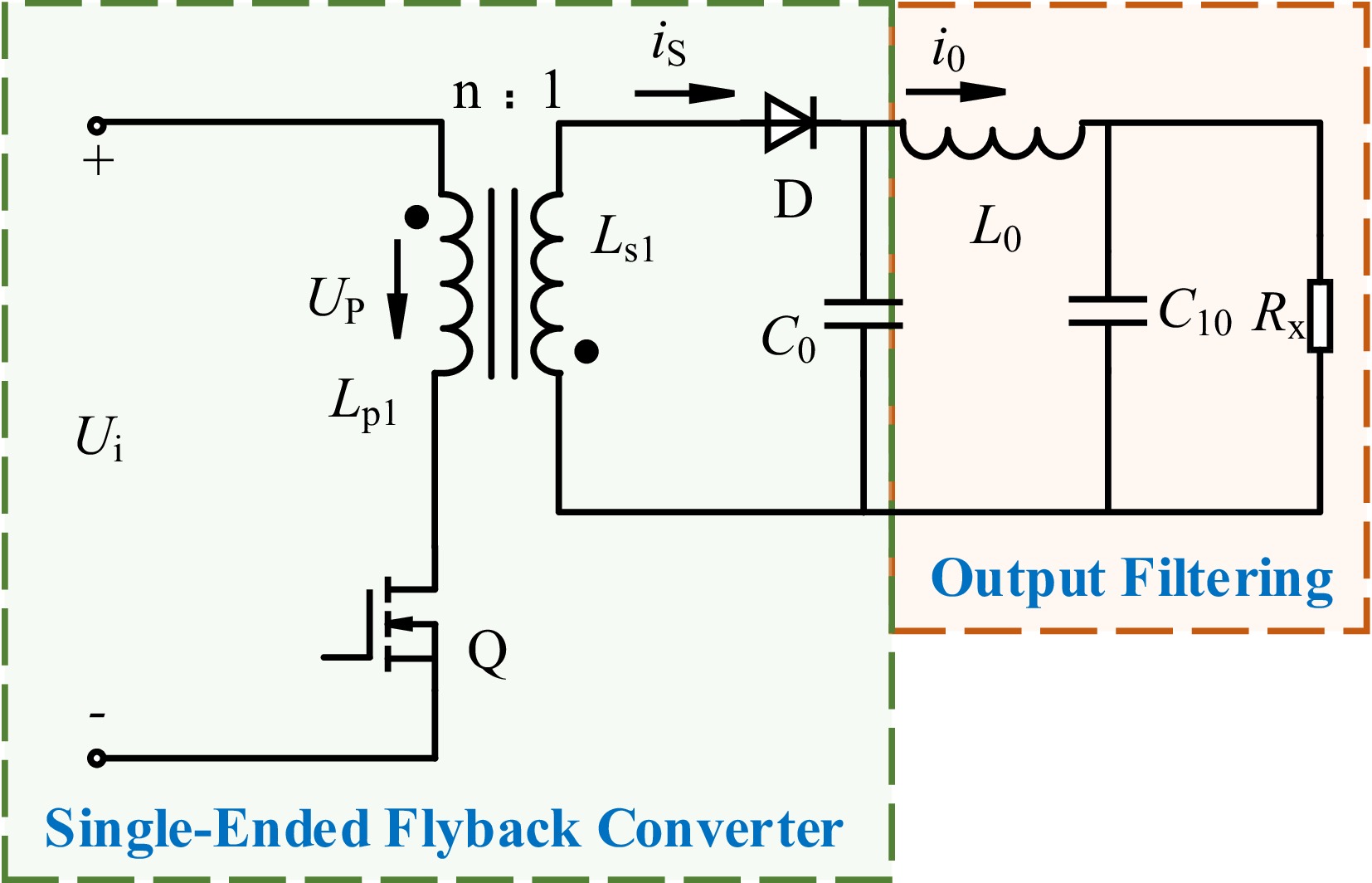

Figure 4.

Single-ended flyback converter with output filtering.

-

Figure 5.

Single-ended flyback converter with output filtering.

-

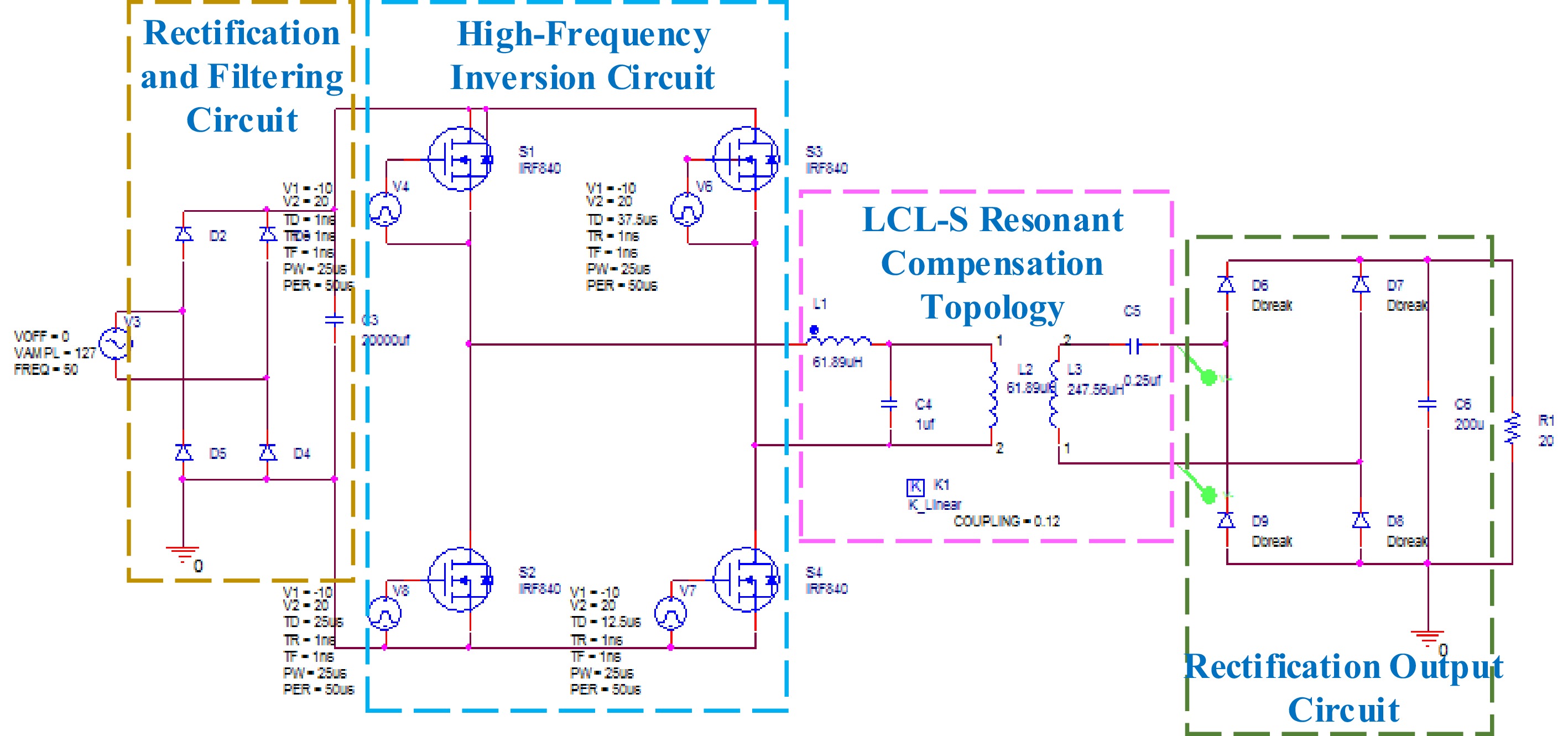

Figure 6.

Diagram of main circuit simulation.

-

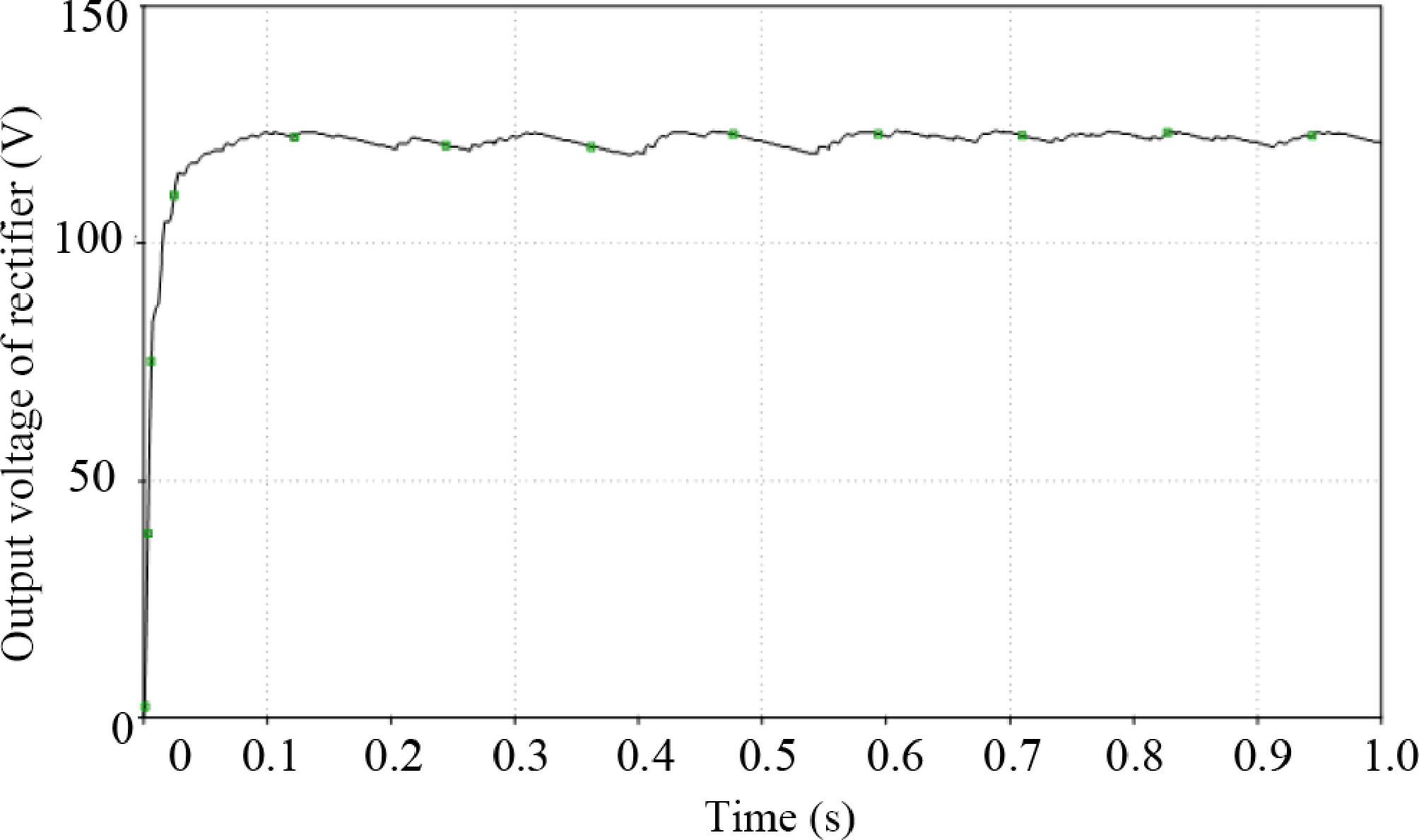

Figure 7.

Waveform of rectified output voltage.

-

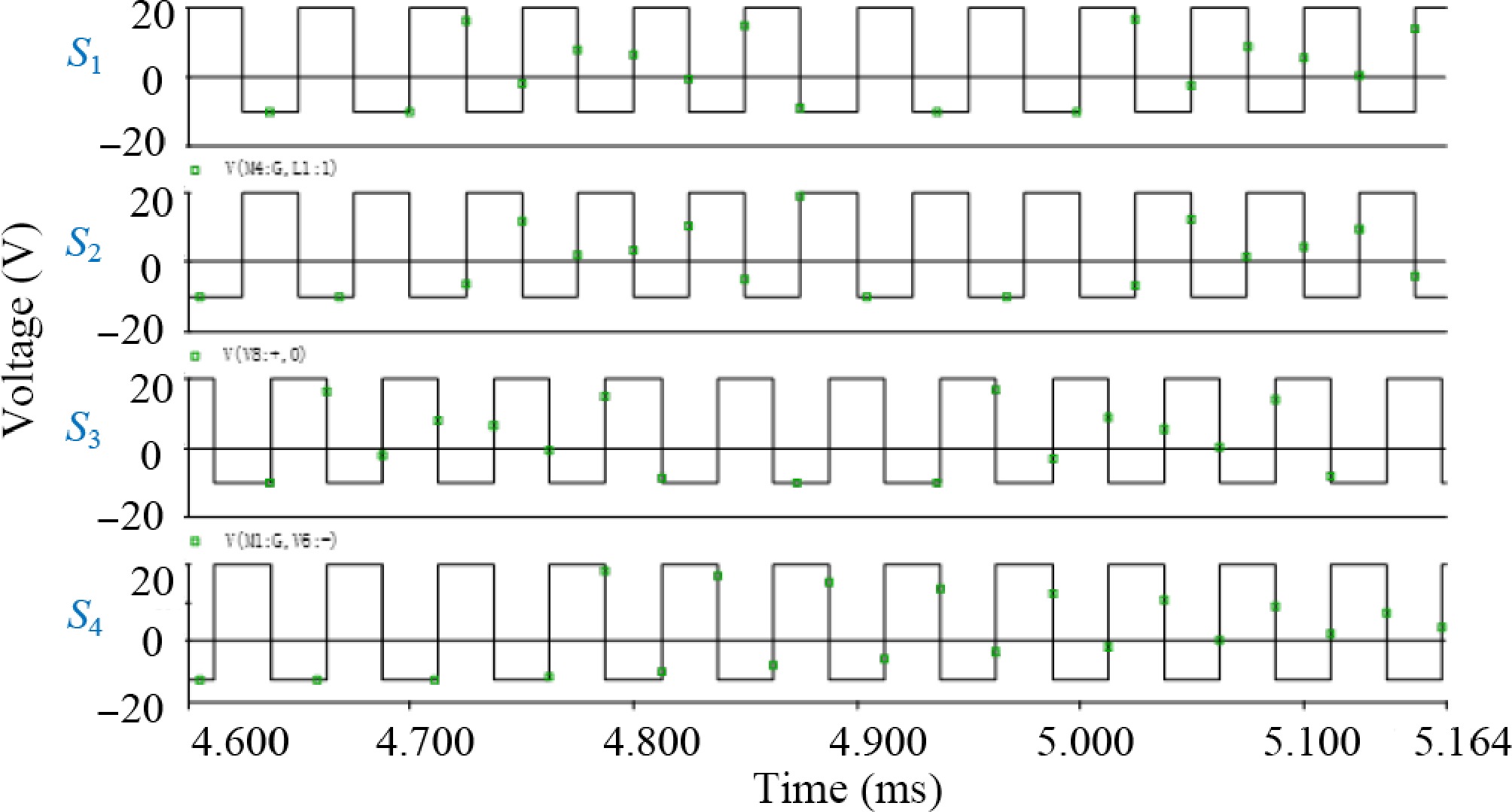

Figure 8.

Waveform of phase shift control pulse.

-

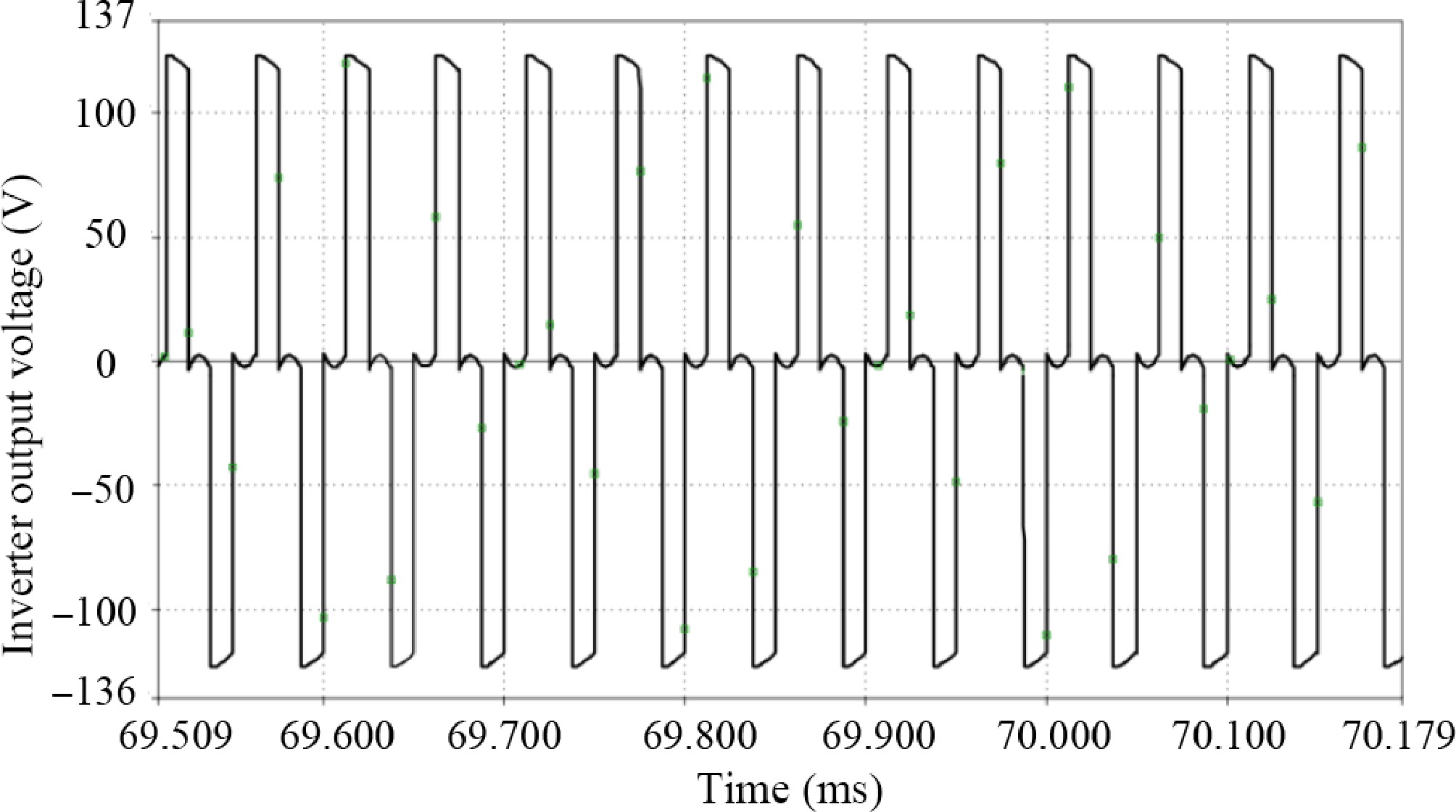

Figure 9.

Waveform of inverter circuit output.

-

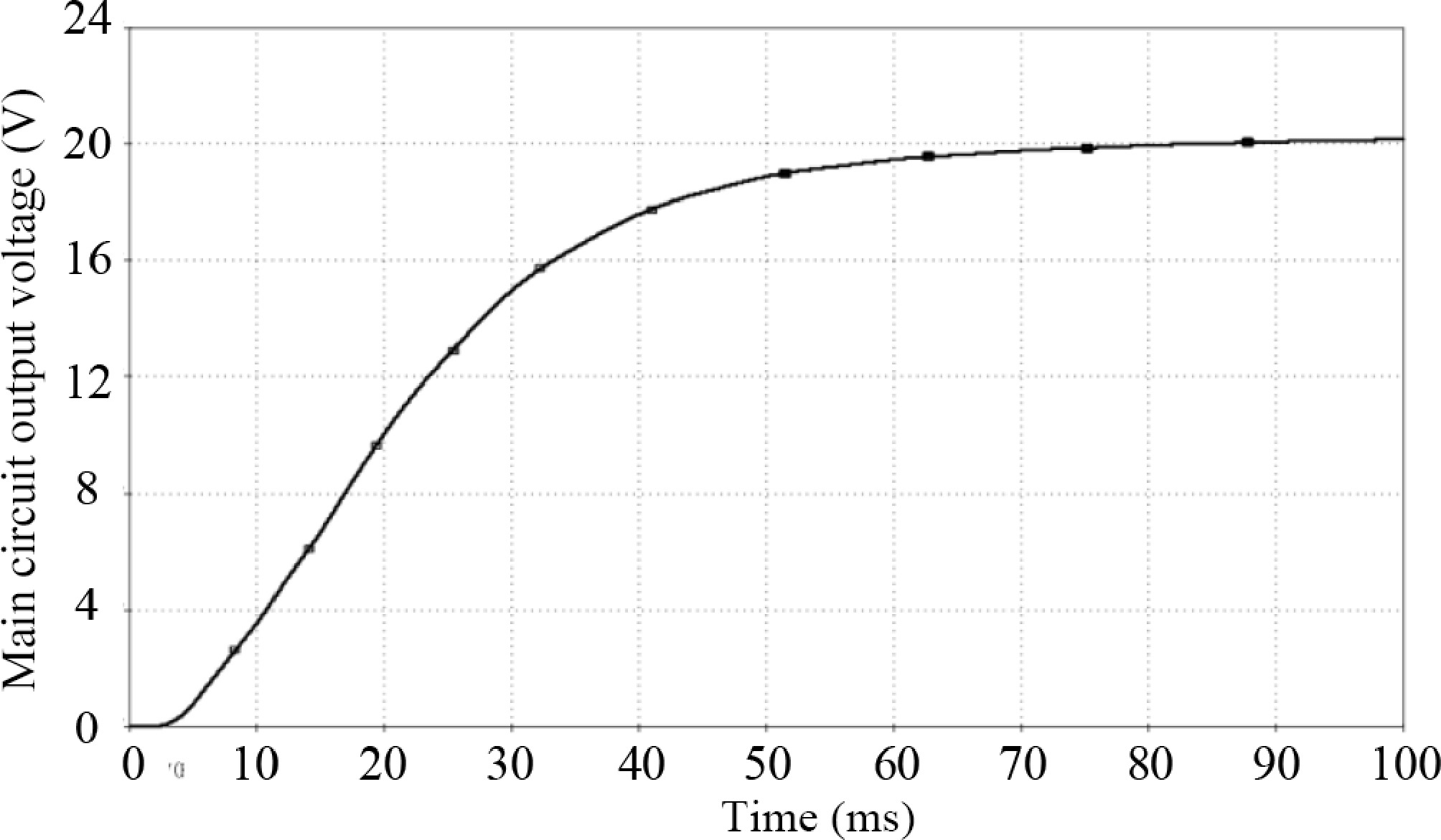

Figure 10.

Waveform of main circuit output.

-

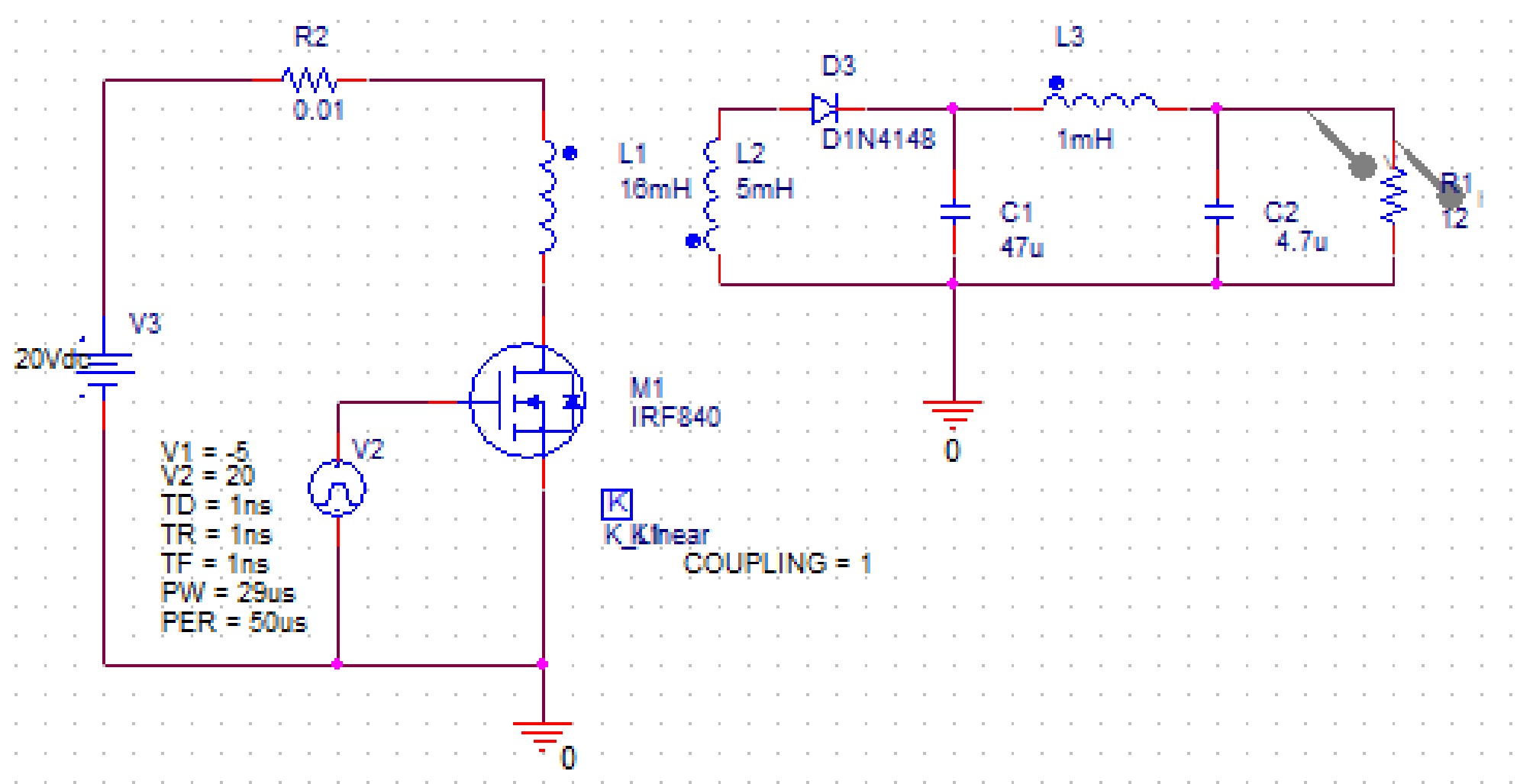

Figure 11.

Single-ended flyback DC-DC converter.

-

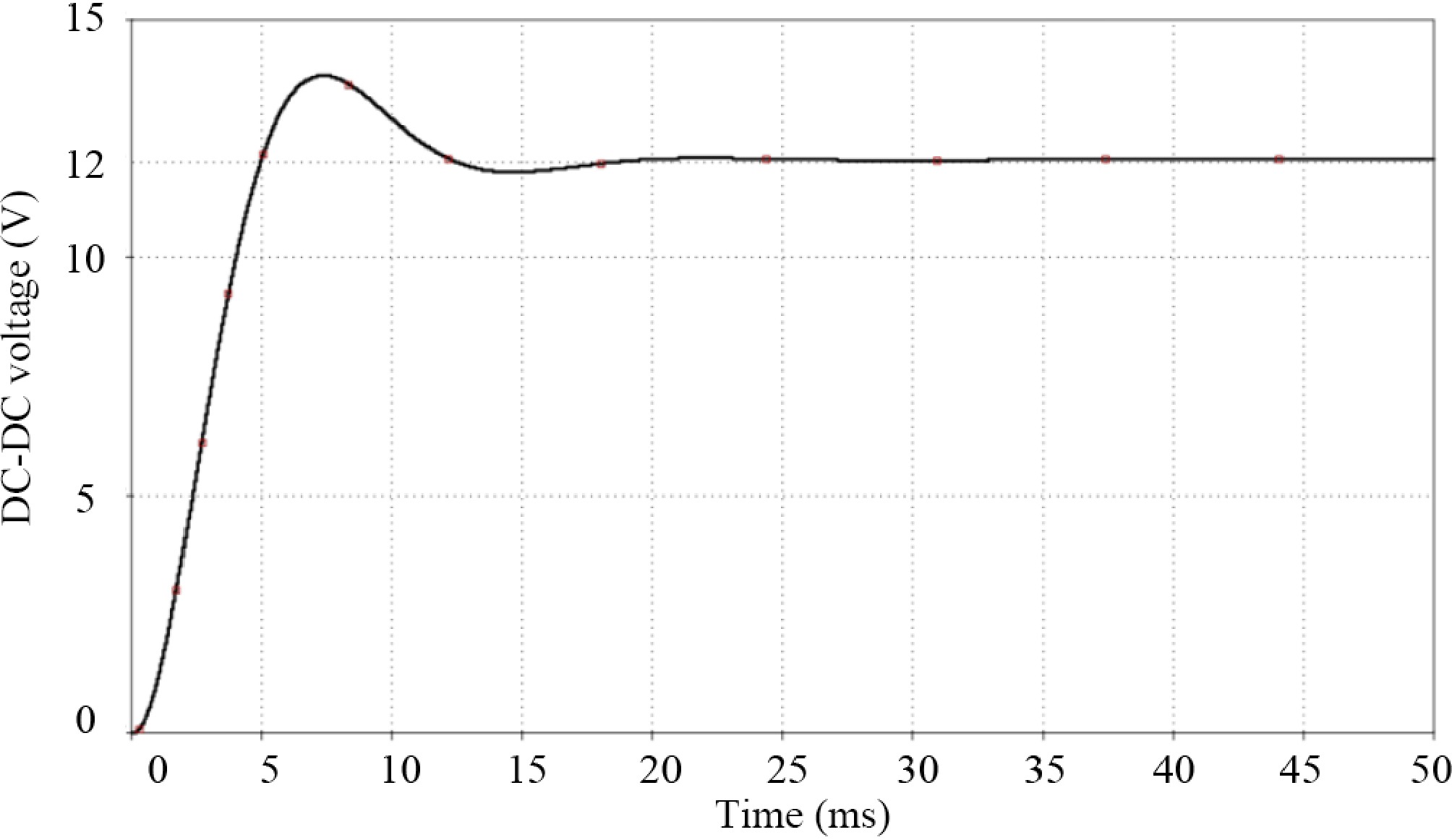

Figure 12.

Result of DC-DC voltage regulation simulation.

-

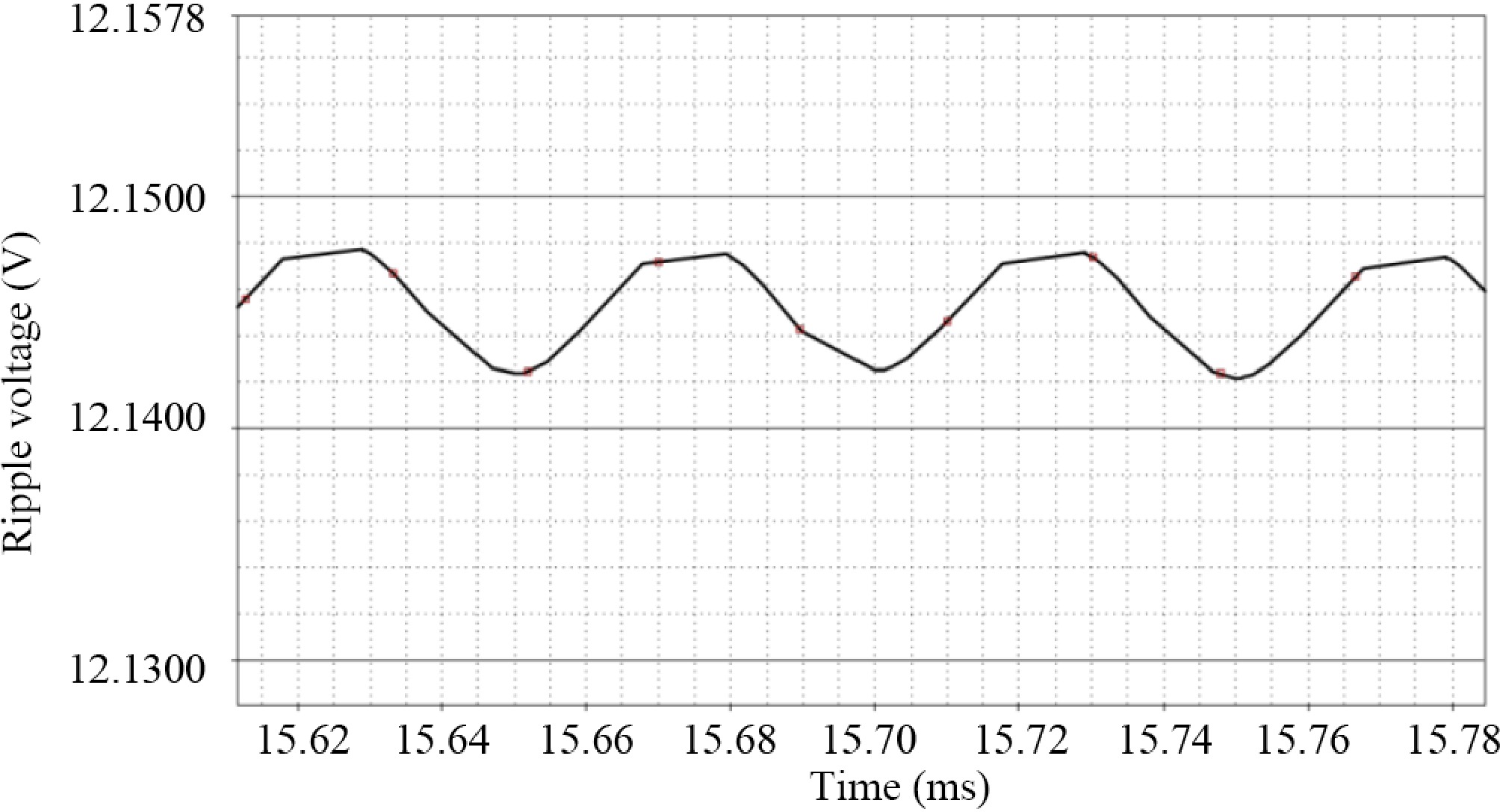

Figure 13.

Waveform of output voltage ripple.

-

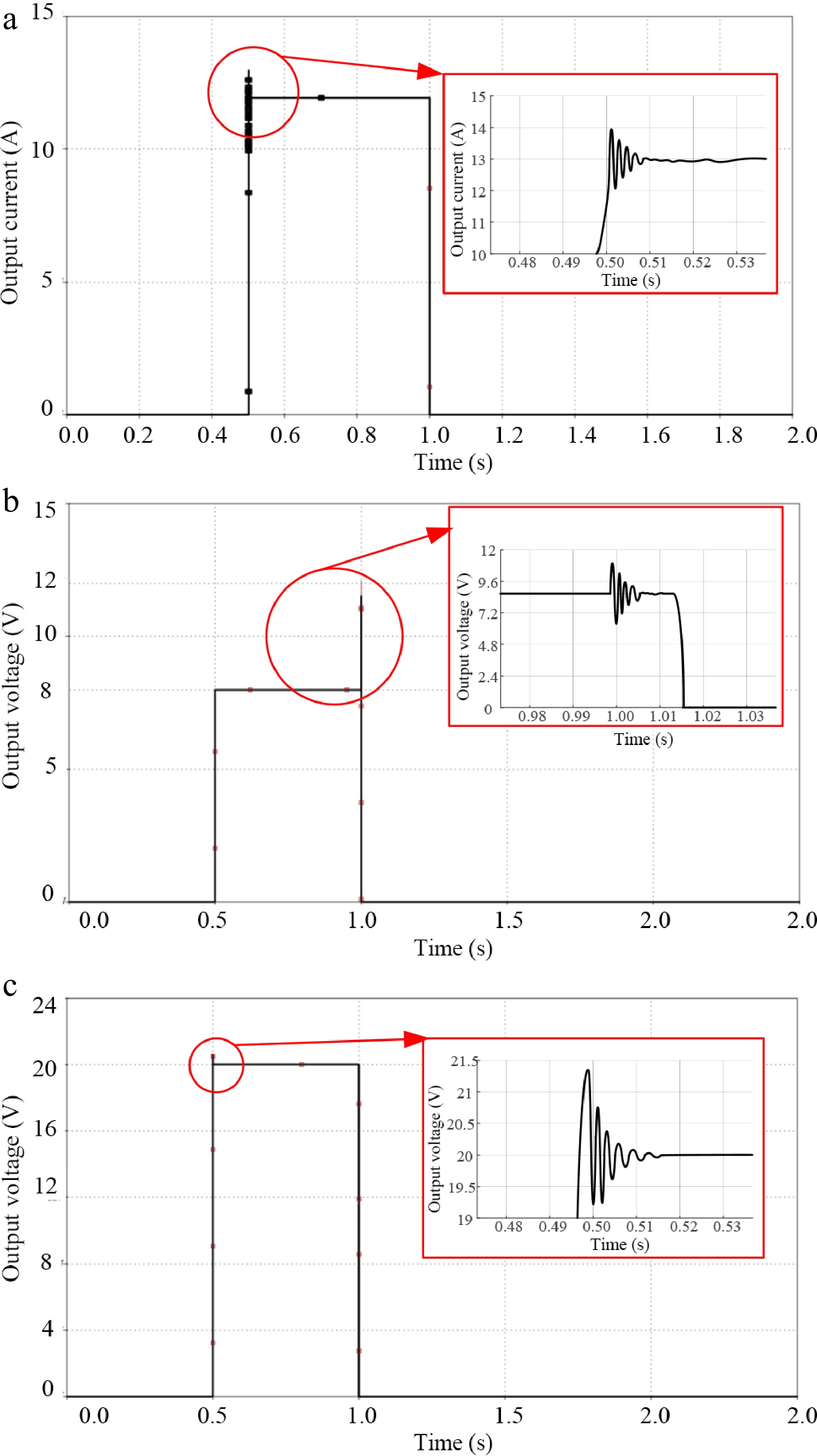

Figure 14.

Results of the protection circuit experiment. (a) Overcurrent protection simulation result. (b) Undervoltage protection simulation result. (c) Overvoltage protection simulation result.

-

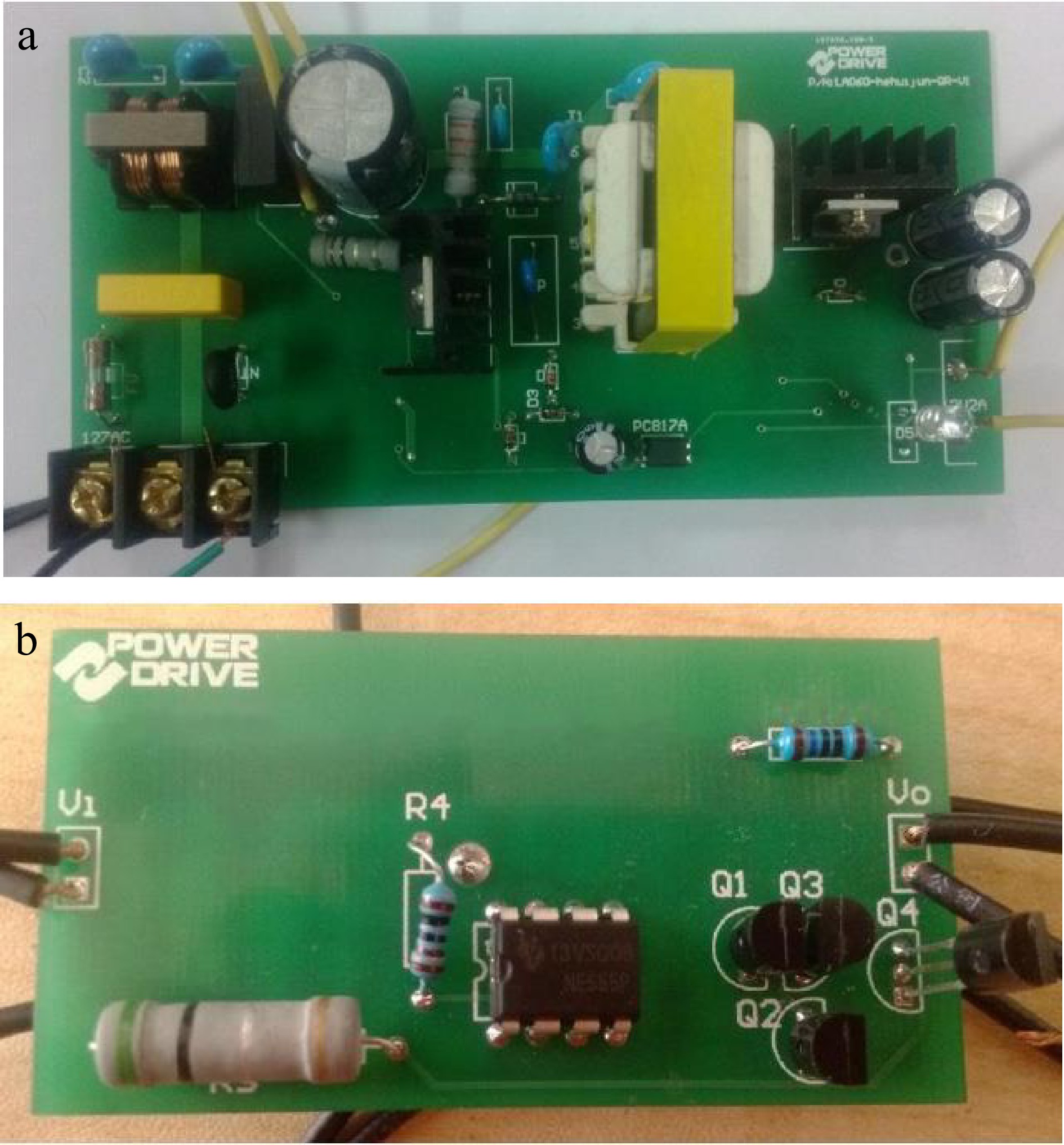

Figure 15.

Prototype of the improved clamping-based single-stage flyback converter. (a) Single-stage flyback converter. (b) Improved clamping-based protection circuit.

-

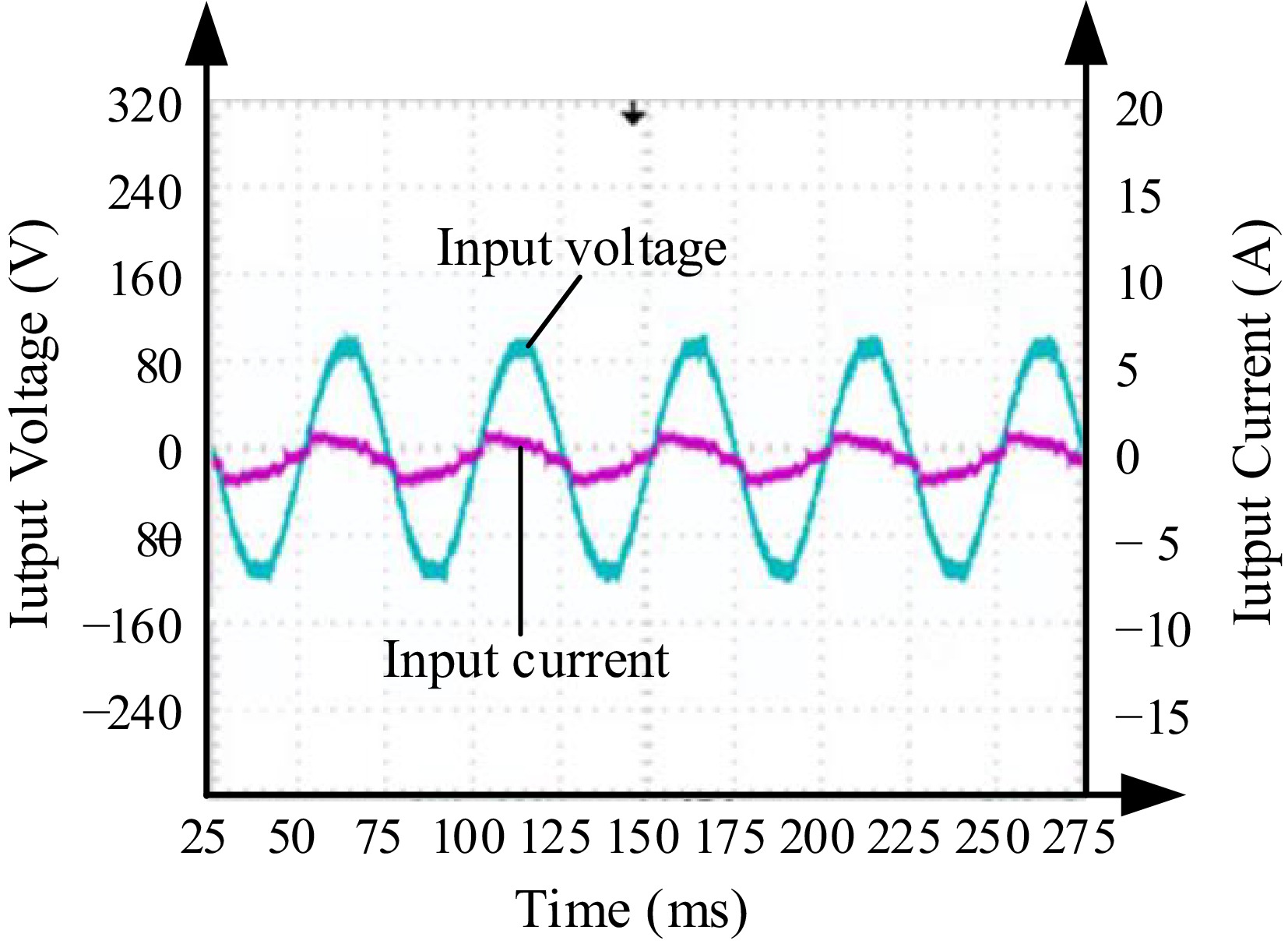

Figure 16.

Waveform of the input voltage and current.

-

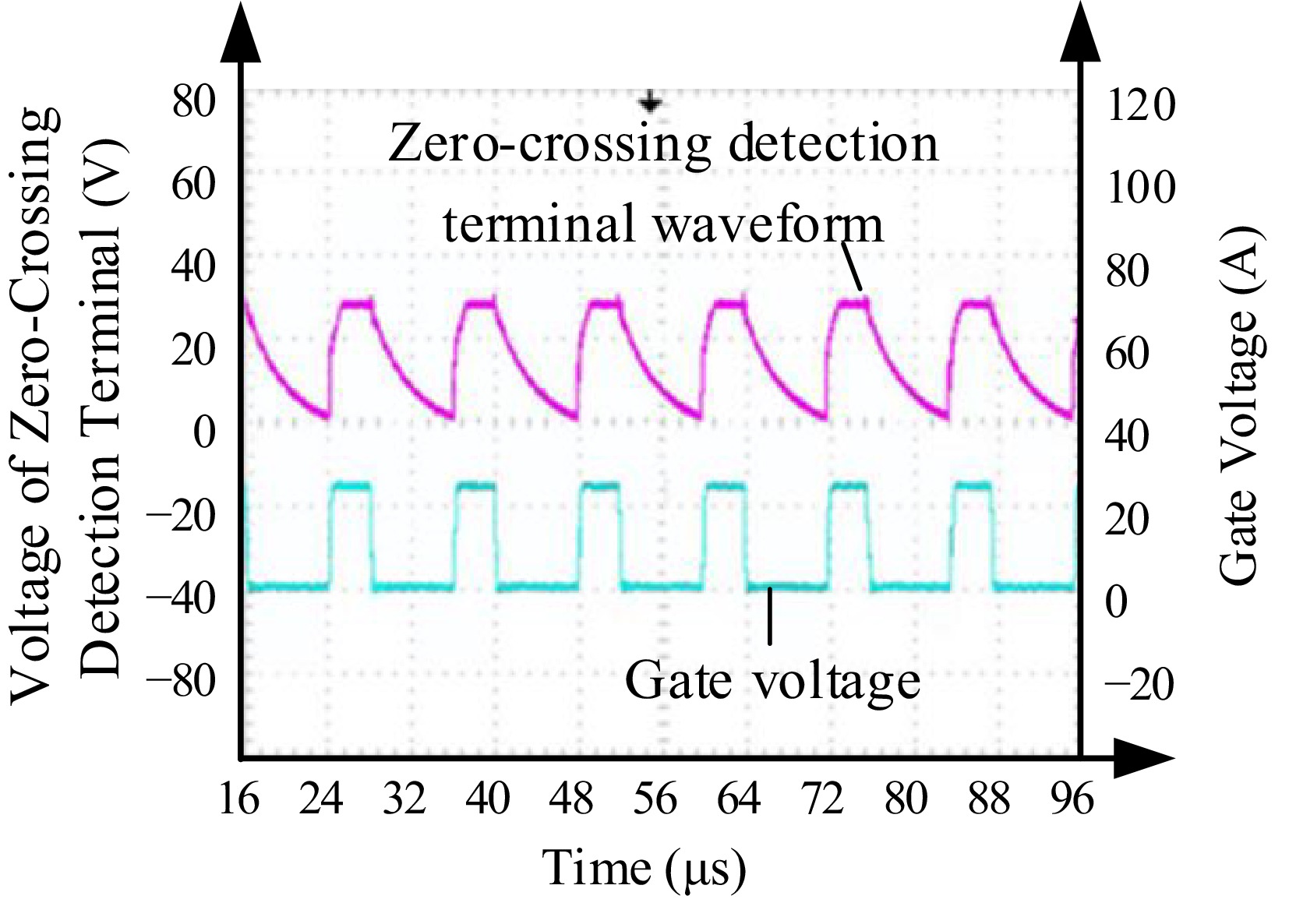

Figure 17.

Waveform of the gate voltage and the zero-crossing detection terminal.

-

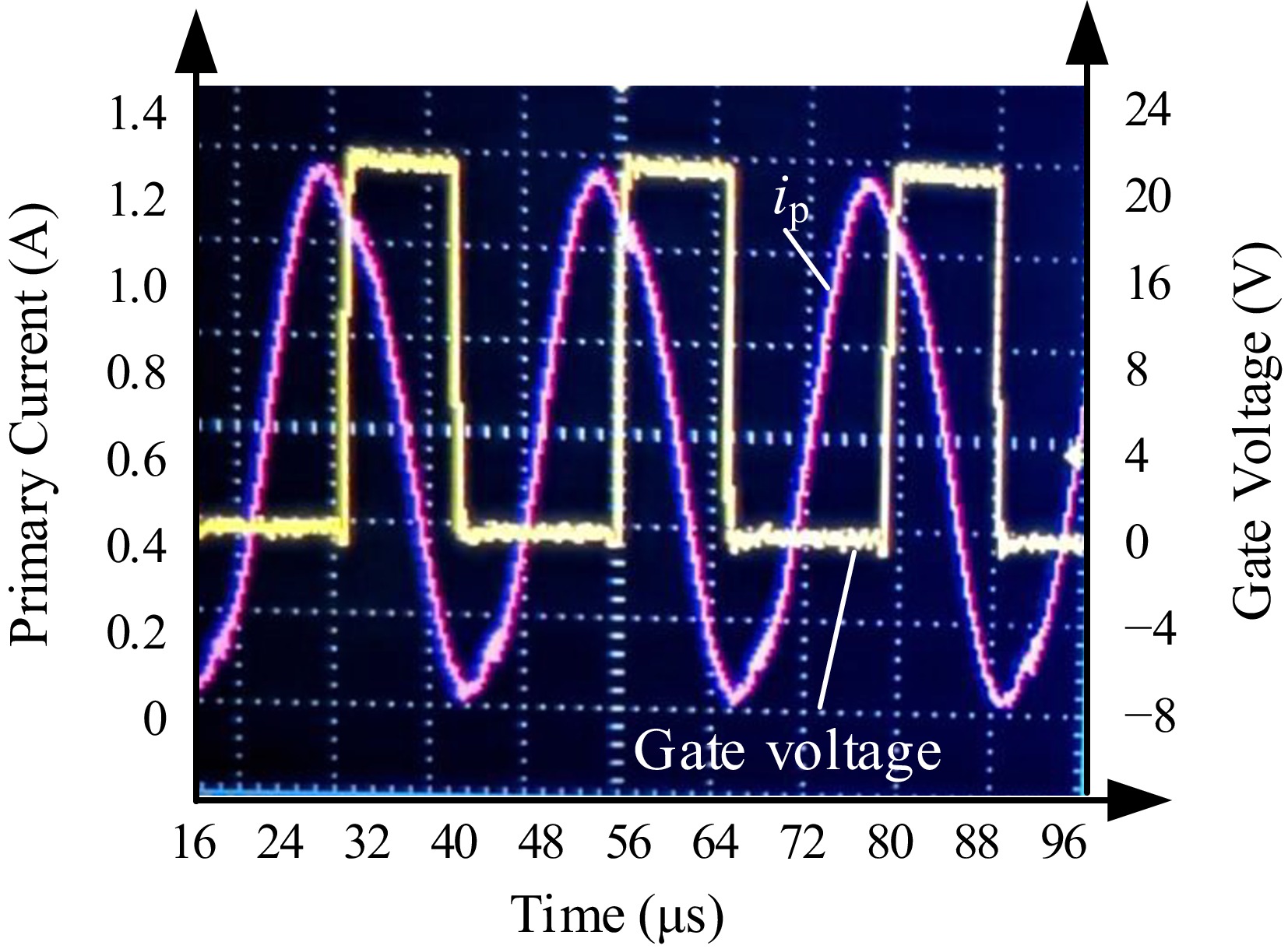

Figure 18.

Waveform of inverter control voltage and WPT system primary current.

-

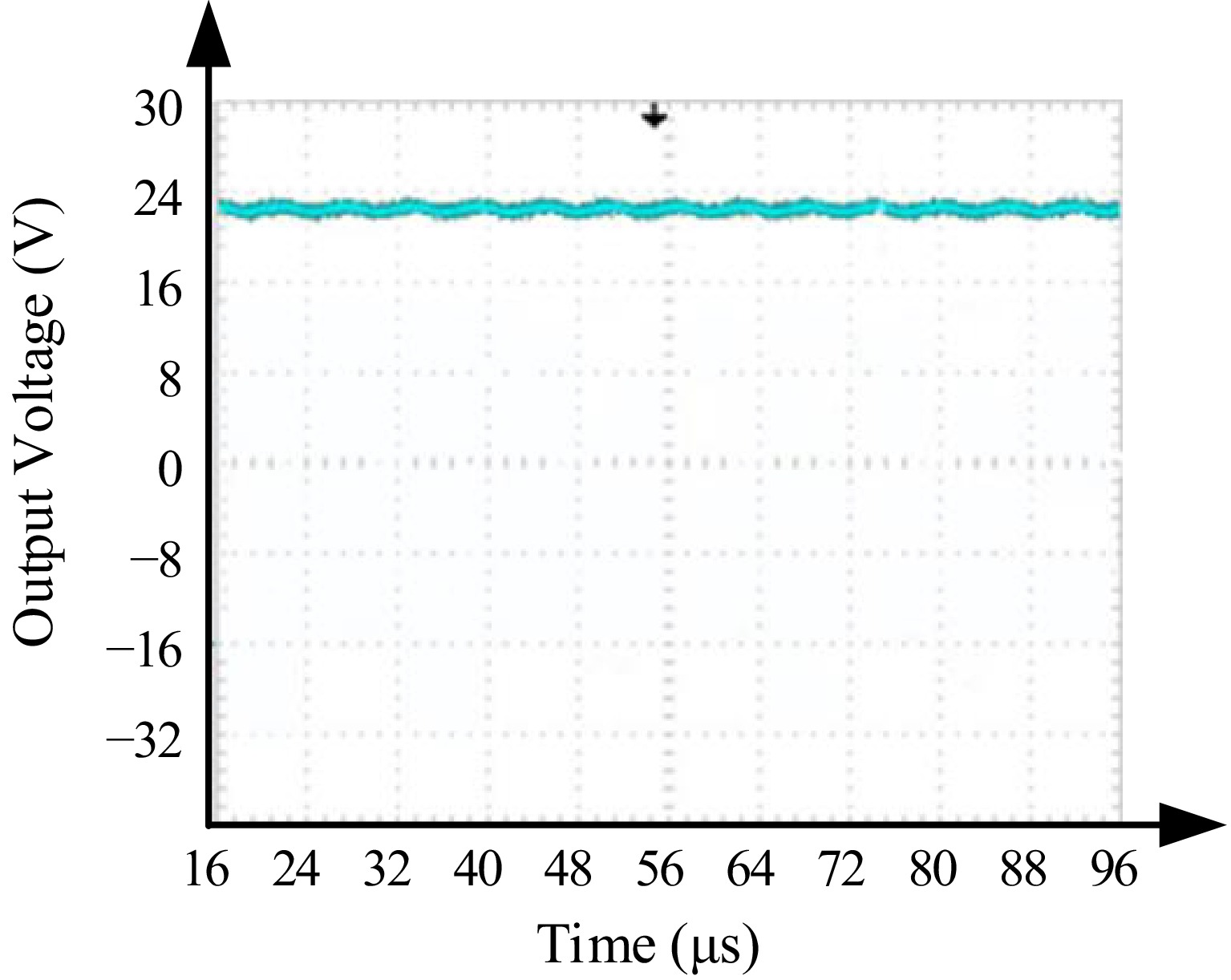

Figure 19.

Waveform of the output voltage.

-

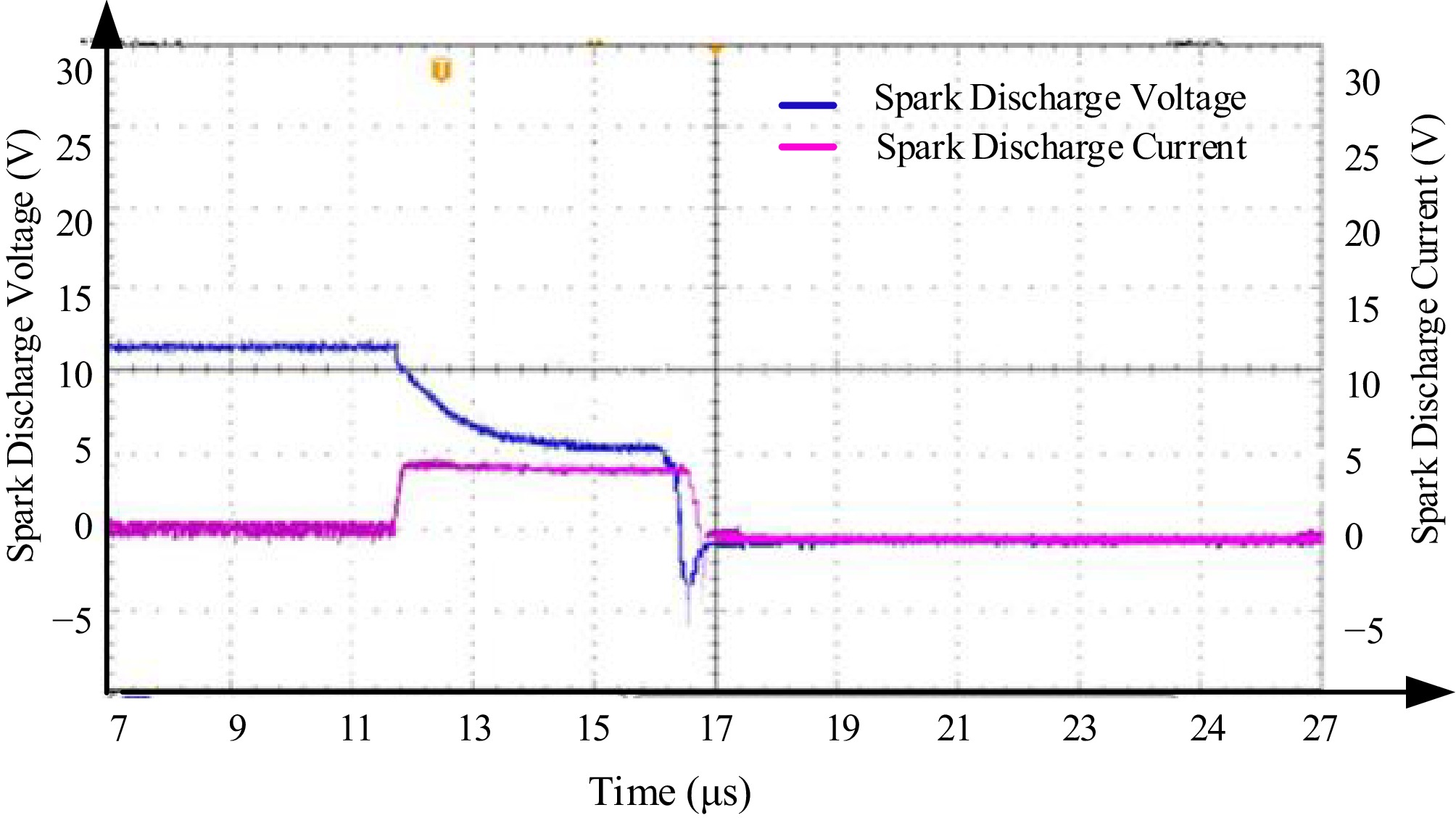

Figure 20.

The waveform of the ameliorated cutoff experiment.

-

Parameter Single-ended fly-back converter Full-bridge converter Efficiency Moderate (85%−90%) High (90%−95%) Cost Low High Complexity Low High Failure points Few Multiple Suitability for harsh environments High Moderate Table 1.

Comparison of the single-ended flyback converter with a full-bridge converter.

-

Parameter Value Parameter Value Vinmax 150 V R4 5 kΩ IBF 0.14 A R5 and R6 1 kΩ UDS 200 V R7 10 kΩ ID 6 A R8 1.3 kΩ Ui 20 V R9 3.3 kΩ Uo 12 V R10 1 kΩ Dmax 0.545 R11 0.7 kΩ R1 9.7 kΩ R12 10 kΩ R2 1 kΩ R13 1 kΩ R3 1.3 kΩ Cp 1 μF La and Lp 61.89 μH Cs 0.25 μF Ls 247.56 μH C1 47 μF L3 1 mH C2 4.7 μF C3 0.25 μF C4 200 μF Table 2.

System parameter configuration table.

-

Technology Safety and reliability Output of voltage and power Ref. Laser power converters (LPC) Emphasis on efficiency and safe conversion technology Conversion efficiency: 33.8%, laser power input: 1 mW [17] Hybrid front-end converters, ultracapacitors, sodium-based batteries Ensures reliable operation and harmonic reduction Energy storage capacity: 3 MJ, peak power: 24 MW, load cycle: 10–60 s [18] Single-ended flyback converters, voltage regulation, protection circuits Intrinsically safe design, rapid response to anomalies Output voltage: 12 V, ripple: < 120 mV, protection response: 5 µs This article Table 3.

Comparison between WPT system and other mining power systems.

Figures

(20)

Tables

(3)