-

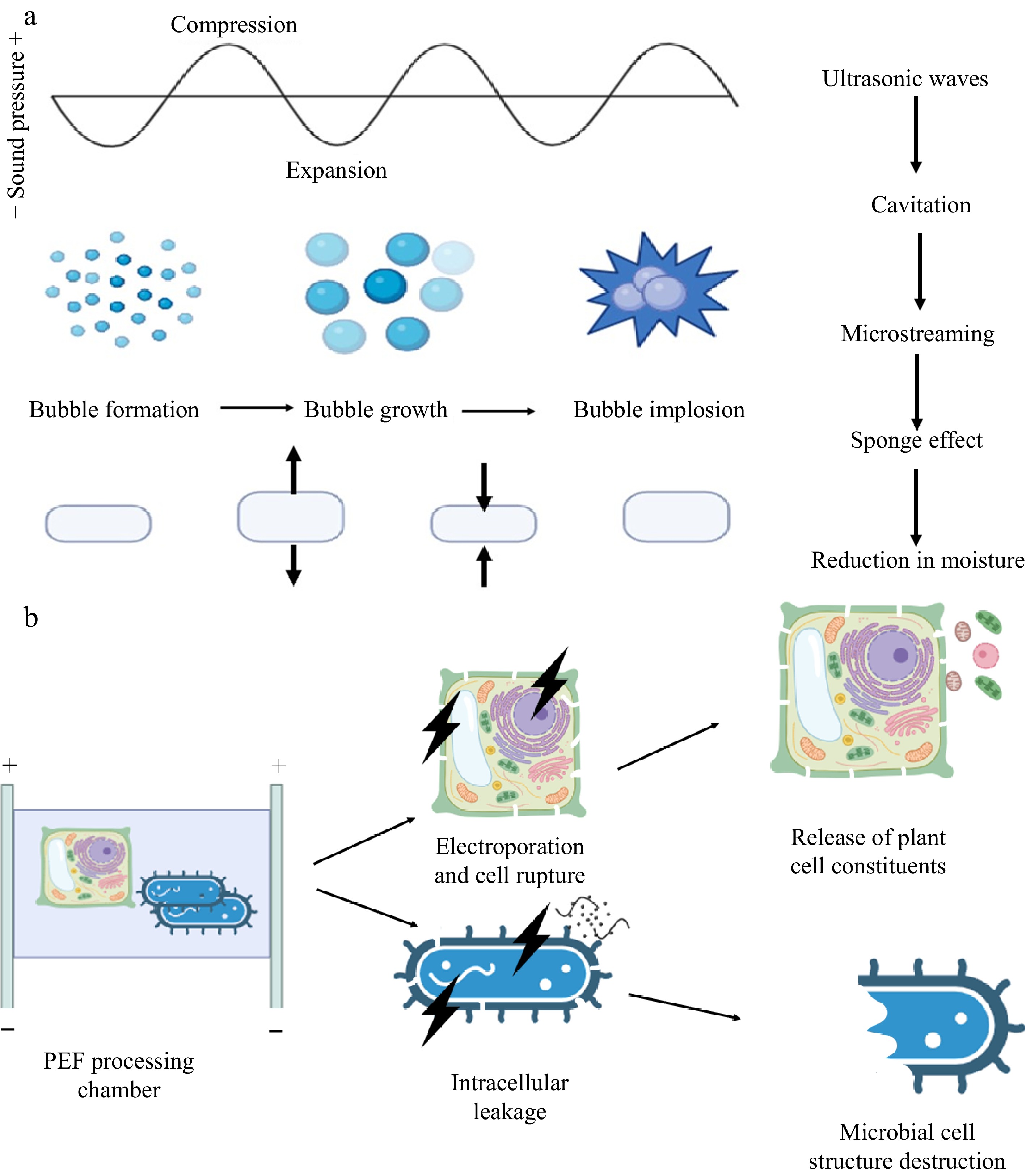

Figure 1.

(a) Cavitation and sponge effect induced by ultrasound. (b) Cellular mechanisms under pulsed electric field treatment.

-

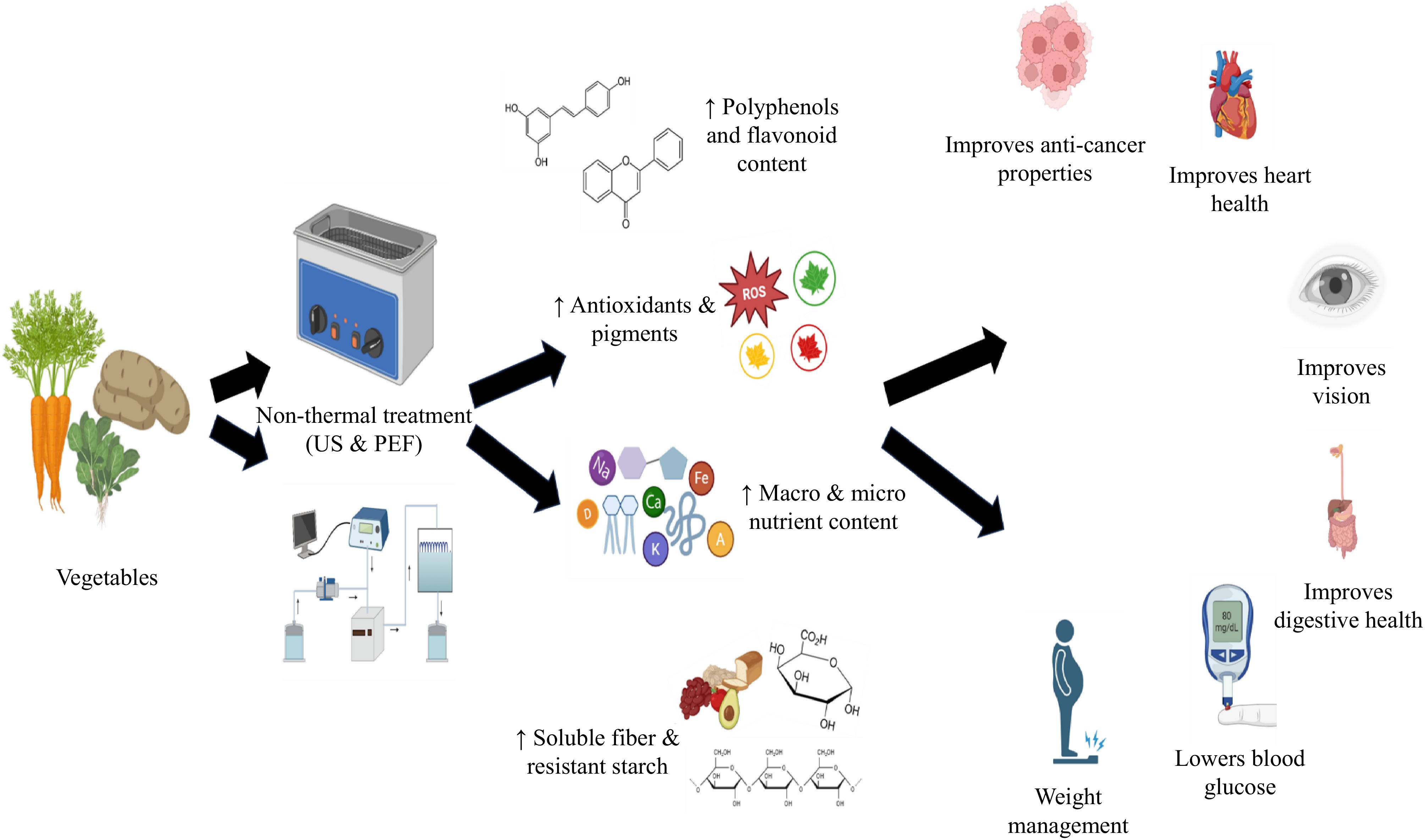

Figure 2.

Potential health benefits of non-thermal processing technologies.

-

Vegetables US conditions Physical changes Chemical changes Reasons Ref. Carrot slices US type: ultrasound bath;

Power: 1.5 kW;

Frequency: 20, 30, and 40 kHz;

Amplitude: N.A.;

Time: 3, 5, and 7 min;

Temperature: 25 °C;

Quantity/speed: 3 mm thick slicesDecreased color parameters with increased treatment time.

Improved more porous structure.Decreased protein content.

Enhanced ash content.

Increased total phenolic and flavonoid content.

Increased the value of β-carotene.Enhanced the nutritional value of carrots, but intensive treatment led to protein denaturation and physical changes. [88,89] Carrot slices US type: ultrasound bath;

Power: 150 W;

Frequency: 40 kHz;

Amplitude: N.A.;

Time: 0–20 min;

Temperature: 50 °C;

Quantity/speed: 5 mm thick slicesDecreased drying time.

Changes in color index.

Increase in water diffusivity rate.

Decrease in rehydration with an Increase in treatment time.− US enhanced the bioactive compound release, while prolonged treatment time led to protein denaturation and structural changes. [21,67,68] Carrot slices US type: US vibration disk and infrared drying;

Power: 0–80 W;

Frequency: 20 kHz;

Amplitude: N.A.;

Time: time interval 5 min.

Temperature: N.A.;

Quantity/speed: 5 mm thick slicesIncrease in drying rates.

High water activity.

Positive effect on rehydration ratio.

More porous microstructure.

Increased heat transfer.

Reduction in the ratio of shrinkage.A decrease in vitamin C retention. US assisted drying enhanced porosity and rehydration but a decrease in vitamin C was reported due to thermal sensitivity. [46,51] Carrot cubes US type: ultrasound bath;

Power: 240 W;

Frequency: 35 kHz;

Amplitude: N.A.;

Time: N.A.;

Temperature: 25 °C;

Quantity/speed: 400 gmMinimal changes in quality parameters.

Reduced pH.

No change in texture.Increase in ascorbic acid content.

Increase in cellulose with an increase in treatment time.

Decreased hemicellulose and pectin content.

Loss of carotene content.

Enhanced total phenolic content.

Rise in antioxidant activity.The US enhanced both physical and chemical properties with minimal changes, suggesting that moderate treatment conditions can improve food quality. [29,31,66] Carrot US type: ultrasound bath;

Power: 30 WL−1;

Frequency: 40 kHz;

Amplitude: N.A.;

Time: 5 min;

Temperature: 20 °C;

Quantity/speed: N.A.Decrease in surface cell number.

Positive effect on microbial reduction.Increase in surfactant Tween 20 concentration. The cavitation effect caused by US led to microbial reduction and enhanced surfactant interaction. [69,82] Potato powder US type: ultrasound probe;

Power: 0–5 w/cm3;

Frequency: N.A.;

Amplitude: N.A.;

Time: 15 min;

Temperature: 25 °C;

Quantity/speed: N.A.Improved the gel texture properties.

Enhanced water and oil absorption capacity.Increased content of α-helix.

Enhanced the β-sheet values.

Increased amylose content.US treatment caused a significant enhancement in the overall quality of potato powder, suggesting that moderate treatment conditions can improve food quality. [87,88] Potato US type: ultrasound probe;

Power: 1,200 W;

Frequency: 20 kHz;

Amplitude: N.A.;

Time: 15 min;

Temperature: 20 °C;

Quantity/speed: N.A.Micro-structure disruption. Promote polyphenol oxidase activity inhibition. US enhanced polyphenol oxidase activity inhibition leading to reduced enzymatic browning. [75,78] Potato US type: US freezing system;

Power: 270 W;

Frequency: 20, 28, and 40 kHz;

Amplitude: N.A.;

Time: N.A.;

Temperature: –18 °C;

Quantity/speed: N.A.Enhances freezing rate.

Reduced drip loss.

Increase in cavitation yield.

Decreased firmness of the potato.Reduced calcium content.

Enhanced L-ascorbic acid content.

Decrease in total phenolic content.The cavitation effect led to an enhanced freezing rate, while intensive treatment conditions resulted in mineral and phenolic loss. [73,88] Potato US type: ultrasound bath;

Power: 480 W;

Frequency: 40 kHz;

Amplitude: N.A.;

Time: 10 min;

Temperature: 25 °C;

Quantity/speed: 5 mm thick slicesLowered the color parameters.

Decreased texture properties such as firmness and chewiness.

Reduced pH and soluble solids.Reduction in PPO (polyphenol oxidase) and POD (peroxidase) activity.

Enhanced PAL (phenylalanine ammonia-lyase) activity.

Increased total phenolic content.

Enhanced antioxidant properties.Tissue disruption caused by US led to a reduction in physical properties, while the cavitation effect resulted in enhancement of chemical properties. [72,73,78] Potato US type: ultrasonic probe;

Power: 500 W cm–2;

Frequency: 20 kHz;

Amplitude: 50%–100%;

Time: 2–4 min;

Temperature: 18–23 °C;

Quantity/speed: 140 gEnhanced the lightness color value.

No change in the ratio of rehydration.Decreased total phenolic and total monomeric anthocyanin content.

Changed antioxidant values.

Reduction in ascorbic acid content.The short duration with intense power of US treatment led to degradation of chemical compounds, suggesting for optimization of conditions to improve overall quality. [75,88] Potato US type: ultrasound bath;

Power: 60 W;

Frequency: 28 ± 0.5 kHz;

Amplitude: N.A.;

Resonance: 0–20 Ω;

Time: 30 min;

Temperature: 25 °C;

Quantity/speed: Ten piecesPromotes the dehydration process.

Reduce drying time.

Decrease in moisture content.

Enlarged micropores.Increase in total phenolic and total flavonoid content with increasing ultrasound power. Prolonged duration and increased power of the US enhanced the quality of the potato. [66,67,88] Spinach US type: jet ultrasound;

Power: 100 W;

Frequency: 40 kHz;

Amplitude: N.A.;

Time: 15 min;

Temperature: 20 °C;

Quantity/speed: N.A.;

Flow: 0.5–2.0 L/minPromoted stomatal closing.

Enhances freshness.Increased abscisic acid signaling.

Enhanced the activity of Ethylene-sensitive 3 Binding F-box proteins 1 and 2.The US enhanced both physical and chemical properties with minimal changes, suggesting that moderate treatment conditions can improve food quality. [91] Spinach US type: N.A.;

Power: 150 W;

Frequency: 40 kHz;

Amplitude: N.A.;

Time: 10, 25, 30 min;

Temperature: 25 °C;

Quantity/speed: N.A.Increase in the capacity of extracts.

Enhanced antibacterial activity.Increase in antioxidant activity.

Increased total phenolic content.Moderate US treatment enhanced the overall quality of spinach. [92] Spinach US type: ultrasound bath;

Power: 400 WL–1;

Frequency: 40 kHz;

Amplitude: N.A.;

Time: 3 min;

Temperature: 23 °C;

Quantity/speed: N.A.Caused reduction in yeasts and molds.

Reduced total bacterial count.– The short duration of the US treatment and the cavitation effect caused microbial reduction in spinach [58,60,99] Broccoli US type: ultrasonic probe;

Power: 400 W;

Frequency: 24 kHz;

Amplitude: 100 µm;

Time: 5 min;

Temperature: 20 °C;

Quantity/speed: 180 gHigh intensity caused cell disruption of the tissue. Increased the extraction of glucoraphanin, 4-hydroxy glucobrassicin, and glucobrassicin.

No change in total ascorbic acid and isothiocyanate content.Moderate conditions of US preserved chemical compounds, while the intensive power led to cell disruption. [93,94] Broccoli US type: N.A.;

Power: 400 W;

Frequency: 24 kHz;

Amplitude: 100 mm;

Time: 10, 20, 30, 60, 120 min;

Temperature: 25 °C;

Quantity/speed: N.A.Ruptured cell wall polysaccharides.

Change in cell structure.Increased phenolic acid compounds.

Enhanced carotenoid content.

Increased chelate soluble pectin and sodium carbonate soluble pectin.

Enhanced carotenoid and phenolic acid compounds.

Increased ascorbic acid content.Extended treatment time led to the release of bioactive compounds and enhanced bioactive content. [93,98] Broccoli US type: ultrasonic vibrating plate;

Power: N.A.;

Frequency: 20 kHz;

Amplitude: N.A.;

Time: N.A.;

Temperature: 20 °C;

Quantity/speed: 3 gReduction in drying time. Reduced Fe2+.

Decreased the content of glucoraphanin.

Enhanced the sulforaphane content throughout the treatment.The US vibrating plating led to reduced drying time, while oxidative reactions led to a reduction in chemical properties. [93,106] Broccoli US type: ultrasonic probe;

Power: N.A.;

Frequency: 23 kHz;

Amplitude: 135 µm;

Time: 1–20 min;

Temperature: 25, 42.5, and 60 °C;

Quantity/speed: 1 g– Promoted myrosinase activation.

Reduction in sulforaphane content.US treatment led to an initial increase in myrosinase, but prolonged treatment conditions led to a reduction of sulforaphane content. [94,106] Table 1.

Effect of ultrasound on whole vegetables.

-

Vegetables Ultrasound conditions Effect on microorganisms Effect on rheological properties Findings Ref. Carrot puree US type: ultrasound bath;

Power: 300 W;

Frequency: 21 kHz & 35 kHz;

Amplitude: N.A.;

Intensity: 0.5 W/cm2;

Time: 30 min;

Temperature: 20–50 °C;

Quantity/speed: 200 g− Enhanced viscosity with increase in extract content.

Increased consistency coefficient K.

Increased flow behaviour with increased frequency in 12 °Brix.No significant change in total soluble solids.

No significant change in color parameters.[59,65] Carrot juice US type: ultrasound bath;

Power: N.A.;

Frequency: 40 kHz;

Amplitude: N.A.;

Intensity: 0.5 W/cm2;

Time: 20–60 min;

Temperature: 20 °C;

Quantity/speed: N.A.Reduced total microbial plate count to 3.23 ± 0.11 log CFU/mL.

Decreased yeast and mold counts by 3.03 ± 0.09 log CFU/mL.Increased the viscosity to 2.23 ± 0.08 cP. Increase in color.

Enhancement in total carotenoid content.

Increase in total soluble solids.[68,76,109] Carrot juice US type: ultrasound probe;

Power: 400 W;

Frequency: 24 kHz;

Amplitude: 120 µm;

Time: 0–10 min;

Temperature: 50, 54 and 58 °C;

Quantity/speed: 500 mReduced E. coli to more than 5 log values. − No change in pH, soluble solids, and acidity.

Negligible increase in carotenoid content.

No major change in phenolic content and ascorbic acid content.[90,110] Carrot juice US type: ultrasound probe;

Power: 525 W;

Frequency: 20 kHz;

Amplitude: 70%;

Time: 5 min;

Temperature: 15 °C;

Quantity/speed: 250 ml− − Enhanced all the quality parameters such as pH, total soluble solids, phenols, and flavonoids. [90,109] Carrot juice US type: ultrasound probe;

Power: 950 W;

Frequency: 20 kHz;

Amplitude: N.A.;

Time: 2–10 min;

Temperature: 4 °C;

Quantity/speed: 200 mlInactivation of pectin methylesterase by 72.55%. Decreased viscosity by 1.27% initially and then increased by 2.29 mPa·s 1.78%. Polyphenol oxidase and pectin methylesterase decreased.

Increase in turbidity.

Decreased carotenoids.[65,90] Carrot juice US type: ultrasound cell;

Power: 271 W;

Frequency: 20 kHz;

Amplitude: N.A.;

Time: 10 min;

Temperature: 30 °C;

Quantity/speed: 25 mlInactivation of aerobic microorganisms by 4.28 log10 cycles. Increased viscosity by 2.29 mPa·s. No change in total soluble solids, pH.

Changed color attributes.[110,109] Carrot juice US type: ultrasound waves;

Power: 1,000 W;

Frequency: 20 kHz;

Amplitude: N.A.;

Time: N.A.;

Temperature: 30 °C;

Quantity/speed: 1,000 ml/10–20 ml per s− − No change in pH, total soluble solids, and total phenolic compounds.

Enhanced color parameters.[69,90,109] Sweet potato juice US type: ultrasound probe;

Power: 0.66 W/cm;

Frequency: 20–100 kHz;

Amplitude: N.A.;

Time: 8 min;

Temperature: probe temperature 550 °C;

Quantity/speed: 200 mlReduction of polyphenol oxidase to 98.7% ± 3.2% and peroxidase activity to 97.8 ± 3.0%. − Increases bioaccessibility of β carotene and antioxidant activity. [74,75,88] Sweet potato paste US type: ultrasound probe;

Power: N.A.;

Frequency: 26 kHz;

Amplitude: 20%, 40%, 60%;

Time: 2, 6, 10 min;

Temperature: 25 °C;

Quantity/speed: N.A.Inhibited the enzymatic activity of peroxidases and polyphenol oxidase to 98%. − Highest anthocyanin content.

Enhanced overall color attributes.

Increased total phenolic content.[95] Spinach juice US type: ultrasonic bath;

Power: 180 W;

Frequency: 40 kHz;

Amplitude: N.A.;

Time: 21 min;

Temperature: 30 °C;

Quantity/speed: 100 mlDecrease in POD Abs min−1 to 31.76% and PPO Abs min−1 to 36.00% activity. Caused a minimal increase in cloud value to 0.218 ± 0.01 and cloud stability to 10.45% ± 0.08%. Increase in flavonoids, phenolics, and anthocyanins.

Enhanced carotenoid content.

Improved overall chlorophyll content.

Lowered vitamin C content.

Change in color parameters.[60] Spinach juice US type: ultrasonic homogenizer;

Power: 600 W;

Frequency: 30 kHz;

Amplitude: N.A.;

Time: 30 min;

Temperature: 60 °C;

Quantity/speed:100 mlReduction in E. coli, yeast, and molds up to 4 log CFU/ mL. Decrease in viscosity to 1.123 ± 0.2 Pa.sn.

Decrease in yield stress.Enhanced bioactive compounds. [58,60] Spinach juice US type: ultrasound bath;

Power: 200 W;

Frequency: 40 kHz;

Amplitude: N.A.;

Time: 21 min;

Temperature: 30 °C;

Quantity/speed:100 mlReduced activity of E. coli to 1.5 log CFU/mL. Decrease in viscosity by 13.10 mPa·s. Reduction in particle distribution.

Increase in free amino acids (FAA).

Decrease in Fe, Ca, Mn, and Zn content.

Increase in K.[59,65] Broccoli puree US type: ultrasonic sonotrode;

Power: 500 W;

Frequency: 18 kHz;

Amplitude: N.A.;

Time: 7 min;

Temperature: 60 °C;

Quantity/speed: N.A.Decreased the count of Enterobacteriaceae to 2.26 ± 0.12 log CFU/mL. − Increased total polyphenol content.

No change in pH and tritrable acidity.

Reduced the content of glucoraphanin.[98,99] Table 2.

Effect of ultrasound on vegetable juices, thick juices, and purees.

-

Vegetables PEF conditions Physical changes Chemical changes Reasons Ref. Dried carrot Pulse shape: rectangular shape;

Pulse type: monopolar pulses;

Electric field strength: 0.6 kV/cm;

Pressure: 0.3 bar;

Number of pulses: N.A.;

Treatment time: 100 µs;

Temperature: 25–90 °CReduced drying time.

Caused minimal color changes when compared to untreated samples.Increased the extraction of β-carotene. Moderate PEF conditions enhanced quality while preserving color. [100,111] Carrot slices Pulse shape: N.A.;

Pulse type: monopolar pulses;

Electric field strength: 0.6 kV/cm;

Output voltage: 1.5 kV;

Pulse width: 10–1,000 μs (± 2 μs);

Time interval: 10 minDecrease in drying time.

Lowered color parameters.

Moisture ratio was decreased in PEF-treated samples.

Caused restoration of cell forms.− Electroporation enhanced moisture loss, leading to reduced drying time. [101] Carrot Pulse shape: rectangular shape;

Pulse type: bipolar pulses;

Electric field strength: 0.9 kV/cm;

No of pulses: 1,000;

Pulse time: 20 µsDecrease in color attributes.

Increase in yellow color characters.

No change in shear stress.

Increase in cell disintegration index.

Reduction in drying time.− Moderate treatment condition enhanced physical properties, causing minimal changes. [63,61] Carrot slices Pulse shape: N.A.;

Pulses: 4 μs;

Capacitor: 0.1 μF;

Frequency: 0.1 Hz;

Voltage: +5 to +7 kV DC;

Output voltage: +50 VEnhance cell disruption.

Reduced the color parameters regarding lightness value.Increase in phenolic content after 24 h.

Showed high antioxidant potential.Intensive treatment led to degradation in physical properties while enhancing compound extraction. [101,102] Potato chips Pulse shape: N.A.;

Pulse type: N.A.;

Pulse generator: N.A.;

Total energy input: 0.75–1.5 kJ/kg;

Electric field strength: 1 kV/cm;

Pulse width: 6 µs;

Frequency: 24 kVReduced frying time.

No significant changes in texture properties.

Reduced oil uptake.Reduced fat content.

Reduced acrylamide content.

Decreased reducing sugar contents.Moderate PEF treatment enhanced overall food quality and safety. [105,96] Potato (French fries) Pulse shape: N.A.;

Pulse type: N.A.;

Pulse generator: 30 kW;

Total energy input: 2 & 50 kJ/kg;

Electric field strength: 1.1 kV/cm;

Pulse width: 20 µs;

Frequency: 200 HzReduction in frying conditions.

Reduced oil consumption.Lowered the percentage of slowly digestible starch.

Increased the percentage of resistant starch.Overall quality of fries has enhanced when treated with moderate PEF treatment conditions. [103] Potato chips Electric field strength: 1 kV/cm

Specific energy input: 1 kJ/kg

Pulse energy: 450 J

Capacitors: 0.5 μF

Discharge voltage: 30 kV

Frequency: 2 Hz

pulse width: 40 μsIncreased diffusion rate.

Enhanced frying behavior.Reduced the content of acrylamide. PEF enhanced cell permeability, thereby enhancing the overall quality of chips. [102,103] Potato slices Pulse shape: N.A.;

Pulse type: N.A.;

Electric field strength:1 kV/cm;

Pulse width: 20 µs;

Pulse frequency: 50 Hz and 150 kJ/kgNo change in lightness color parameters. − Moderate treatment conditions maintain the quality of potato slices without changing physical properties. [103] Spinach Pulse shape: N.A.;

Pulse type: N.A.;

Electric field strength: 2.8 kV/cm;

Pulse width: 1 μs;

Frequency: 30 Hz;

Capacitance: 0.218 μF;

Specific energy input: 27.1 kJ/kgThe rate of drying increased.

Change in moisture content.

Surface shrinkage was more inhibited.

Increased the color attributes.Prevented elution of L-ascorbic acid. Moderate PEF enhances drying efficiency and enhances chemical compounds. [99] Baby spinach leaves Pulse shape: rectangular pulses;

Pulse type: bipolar;

Amplitude: 350 V;

Pulses: 500;

Pulse width: 200 μs;

Pulse space: 1,600 μs;

Frequency: 500 HzImproved freezing tolerance. Increase in sucrose and fructose accumulation post-harvest.

A decrease in glucose accumulation.Electroporation and moderate stress enhanced sugars. [84,99,105] Broccoli stalks Pulse shape: N.A.;

Pulse type: N.A.;

Interelectrode distance: 11.0–29.7 cm;

Electric field strength: 8.00 kJ/kg, 2.50 kJ/kg, 0.5–2 kV/cmRuptured the membrane of broccoli stalks. Change in volatile profile, such as dimethyl sulfide and ethyl acetate. An increase in electric field strength gradually led to cell rupture and changed the volatile compound profile. [106] Chinese cabbage Electric field strengths: 1.0, 1.5, 2.0, and 2.5 kV/cm;

Pulse generator: 5 kW;

Pulse width: 20 µs;

Frequency: 50 Hz;

Voltage: 400 V;

Current: 25 A;

Temperature: 25 °CChanged color attributes.

Decrease in texture qualities.Increased pH.

Enhanced acidity and salinity.A change in electric field strength gradually led to pigment release and texture degradation. [112] Table 3.

Effect of pulsed electric field on whole vegetables.

-

Vegetables PEF conditions Effect on microorganisms Effect on rheological properties Findings Ref. Carrot juice Electric field strength: 3.5 kV/cm;

Passes: 5 times− − Exhibits highest carotenoid and phenolics.

No change in pH and total soluble solids.[67] Carrot puree Capacitor: 0.1 µF;

Frequency: 0.1 Hz;

Pulses: 3.5 kV cm−1− Viscosity increased minimally to 1.48 ±

0.04 mPa·s.Increased carotenoid and phenolic bioaccessibility.

Improved bioaccessibility of caffeic acid derivatives and ferulic acid derivatives.

Change in microstructure.

No change in pH and total soluble solids.

Minimal change in color attributes.[107] Carrot puree Pulse frequency: 10 Hz;

Pulse type: bipolar pulse;

Voltage: 1–4 kV;

Pulses: 100, 300, 500, 1,000 and 2,000;

Pulse width: 20 µs;

Specific energy input: 1.5–576 J/kg− − High level of polyacetylene content.

Increase in FaDOH, FaDOAc, and FaOH.

Increase in sucrose, β−glucose, α−glucose, and fructose levels.[113] Carrot mash Electric field strength: 0.8 kV/cm;

Voltage: 4 kV;

Pulse energy: 4 J;

Capacity: 0.5 µF;

Pulse width: 10 µs;

Input: 0.5 kJ/kg;

Time: 0.5 ms− Increase in viscosity. Increase in juice yield.

Improved cell disintegration.

Decrease in TSS content and increase in TDS content.

Decreased the pH level.[101,108] Spinach juice Electric field strength: 9 kV/cm;

Frequency: 1 kHz;

Pulse width: 80 µs;

Time: 335 µs;

Temperature: 30 °CDecreased polyphenol oxidase to –44.00% RC (relative change) and peroxidase enzyme activity to –43.52%. − Flavonoids were increased.

Phenolics were increased.

Anthocyanins exhibited an increase.

Significant increase in carotenoid content.

Enhanced concentration of chlorophyll.

No variation in color attributes.[60,62] Spinach juice Electric field strength: 20 kV/cm and 20 kV/cm Reduced aerobic microbial growth to less than 1 log CFU/mL. Lowered flowability. No decrease in lutein content.

Inhibited the degradation of pigments.[58] Spinach juice Frequency: 1 kHz;

Pulse width: 80 µs;

Flow rate: 60 ml/min;

Temperature: 30 °C;

Time: 335 µs;

Electric field strength: 9 kV/cmDecreased polyphenol oxidase by 56% and peroxidase enzyme activity by 78.82%. Enzymatic reduction of Peroxidases and polyphenol oxidase. − [102,105,110] Spinach juice Electric field strength: 9 kV/cm;

Frequency: 1 kHz;

Pulse width: 80 µs;

Time: 335 µsLowered microbial activation by 1.25 log CFU/mL. Decreased viscosity to 1.32 ± 0.06 mPa·s. Electrical conductivity is enhanced.

No change in pH and titrable acidity.

Increase in free amino acids.

Decrease in Mn content and increase in K content.[58] Table 4.

Effect of pulsed electric field on vegetable juices, thick juices, and purees.

-

Vegetables US conditions PEF conditions Findings Ref. Carrot US type: immersive sonication

Frequency: 21 kHz

Power: 180 W

Time: 20 min

Temperature rise: 2.4 ± 0.2 °C

US type: contact sonication

Frequency: 24 kHz

Power: 250 W

Time: 20 min

Temperature rise: 5.4 ± 0.6 °COutput voltage: 30 kV

Capacitance: 0.25 µF

Pulse width: 7 µs

Time: 20 s

Time interval: 2 sImproved electric conductivity.

Reduced drying time.

Retention of total carotenoid content.

Increased redness value.

Decreased yellowness value.[114] Sweet potato chips US type: ultrasonic probe

Power: 180 W

Frequency: 53 kHz

Temperature: 25 °C

Time: 30 minNo of pulses: 50

Electric field strength: 1 kV/cm

Input energy: 9.47 ± 0.5 kJ/kg

Voltage: 1.5 kV

Frequency: 2 Hz

Pulse width: 20 µs

Time: 0.2 sReduced oil uptake of chips.

No significant difference in color and texture parameters.

Increased reducing sugar content.

Reduced acrylamide content.[96] Potato US type: ultrasonic probe

Power: 1,000 W

Energy: 40 kJ/kg

Amplitude: 25 µm

Time: 180 sNo: of pulses: 12

Electric field strength: 1 kV/cm

Input energy: 1 kJ/kg

Voltage: 30 kV

Frequency: 2 Hz

Pulse width: 40 µs

Time: 480 µsIncreased number of bubbles while frying.

Reduced fat content.

Reduction in acrylamide content.[115] Spinach juice US type: ultrasonic bath

Power: 180 W

Frequency: 40 kHz

Time: 21 min

Temperature: 30 °CFlow rate: 60 ml/min

Electric field strength: 9 kV/cm

Frequency: 1 kHz

Pulse width: 80 µs

Time: 335 µs

Temperature: 30 °CIncreased total phenolic and flavonoid content.

Improved chlorophyll content.

Preserved antioxidants.

Inactivation of enzymes.

Increased carotenoids.

Enhanced anthocyanins.[66] Spinach juice US type: ultrasonic bath

Power: 200 W

Frequency: 40 kHz

Temperature: 30 ± 2 °C

Time: 21 min

Flow rate: 0.5 L/minElectric field strength: 9 kV/cm

Frequency: 1 kHz

Pulse width: 80 µs

Temperature: 30 ± 2 °C

Time: 335 µsIncrease in total free amino acids.

Enhanced mineral content.

Reduction in microbial inactivation.[68] Table 5.

Synergistic effect of pulsed electric field (PEF) and ultrasound (US) on whole vegetables and their juices.

Figures

(2)

Tables

(5)