-

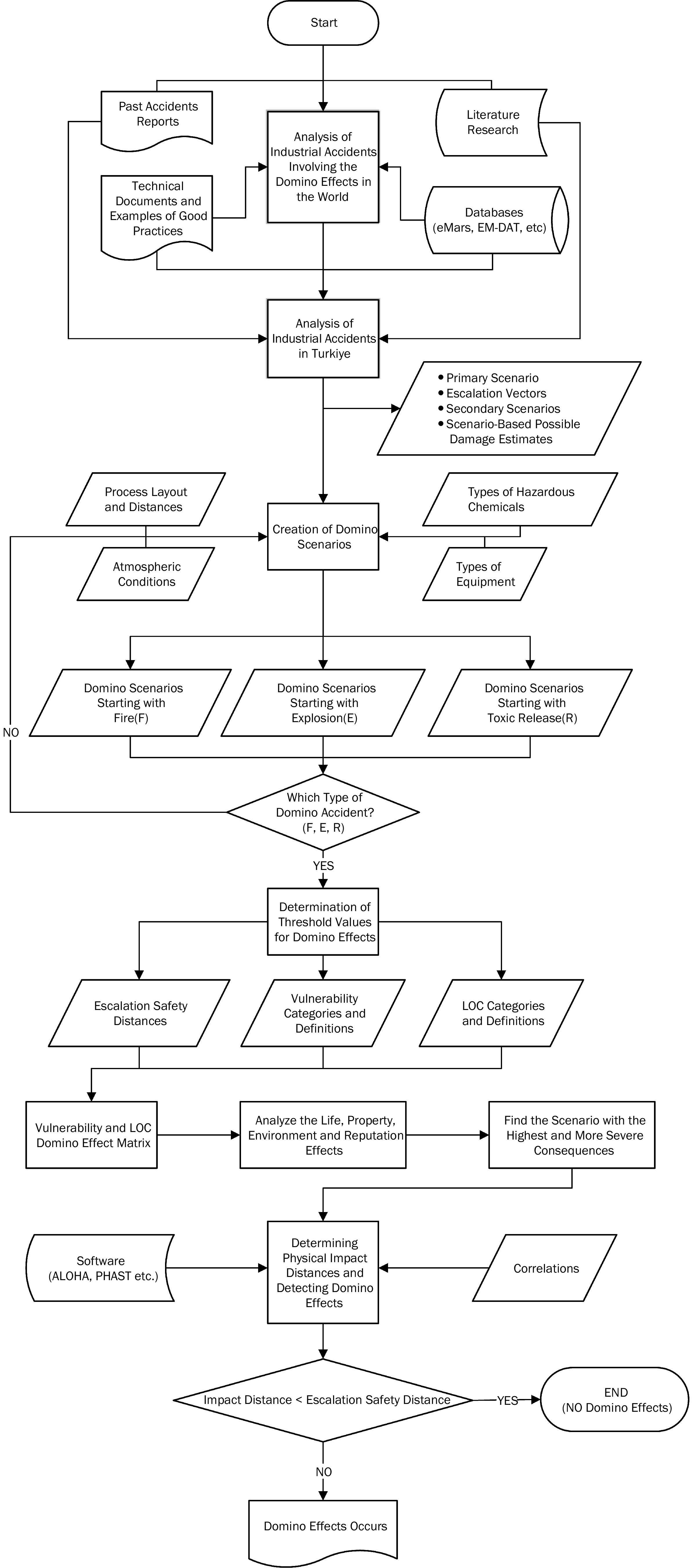

Figure 1.

The flow chart of the proposed methodology.

-

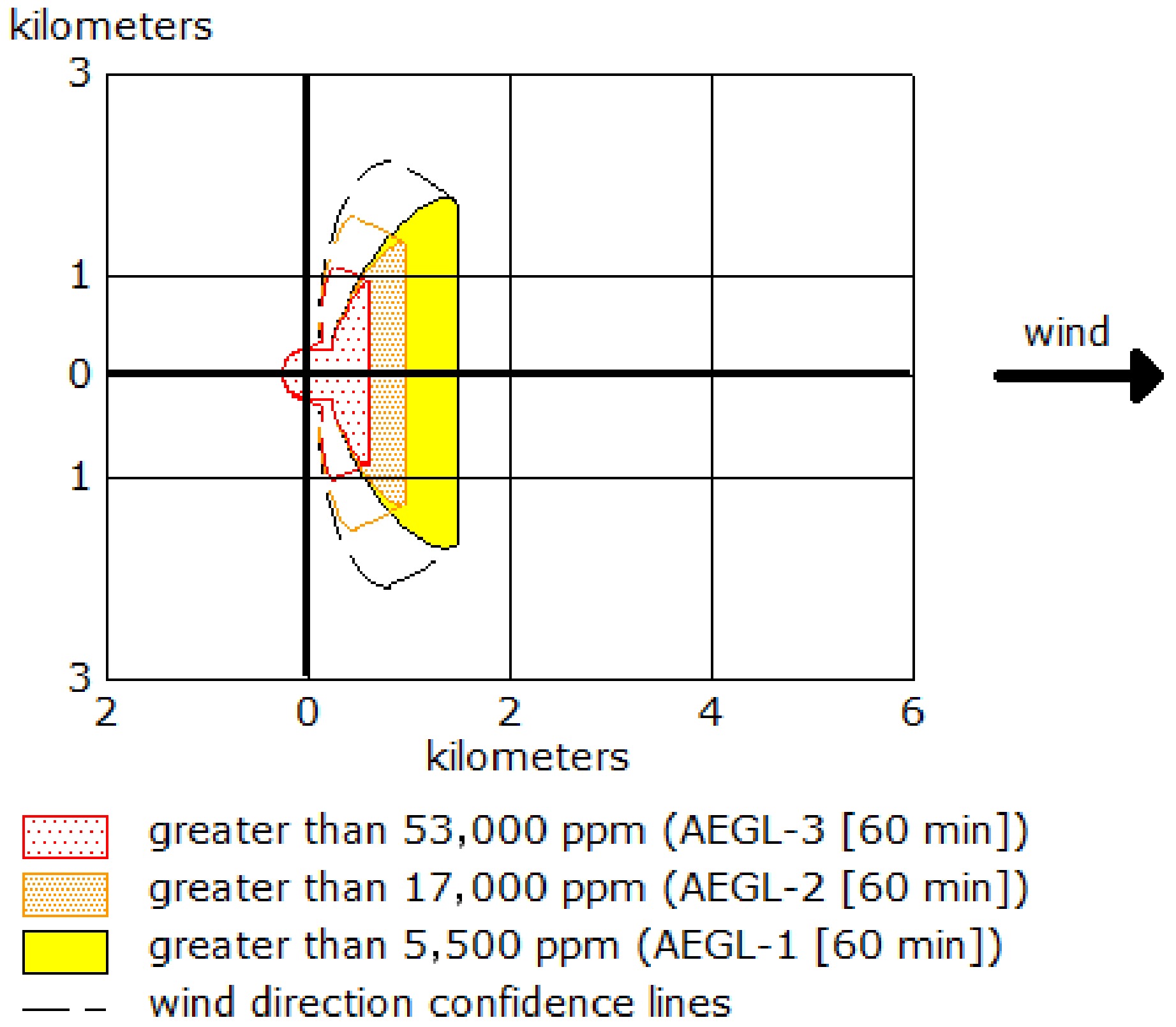

Figure 2.

Primary scenario-threat zones of toxic release.

-

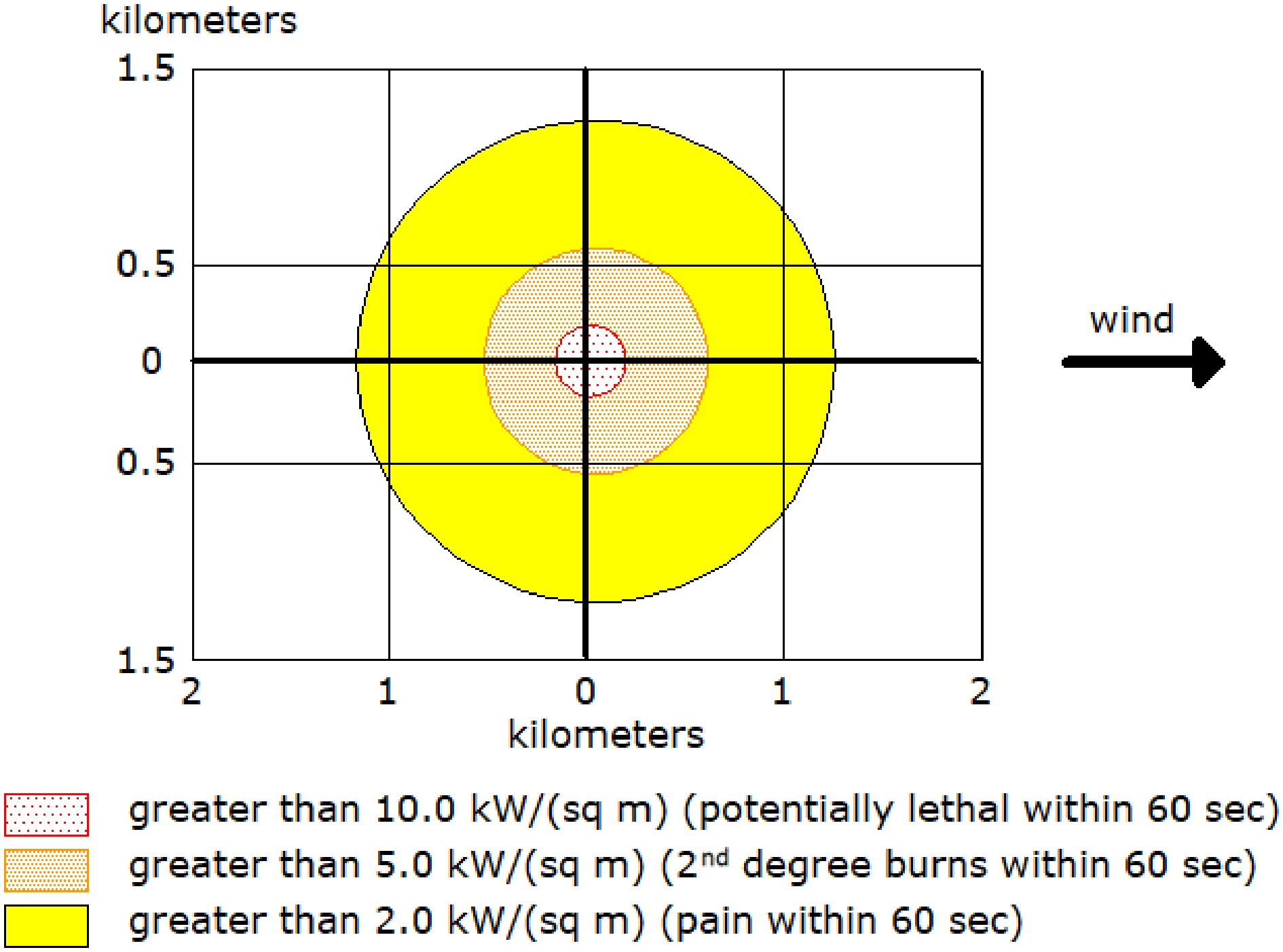

Figure 3.

Threat zones of primary scenario-jet fire.

-

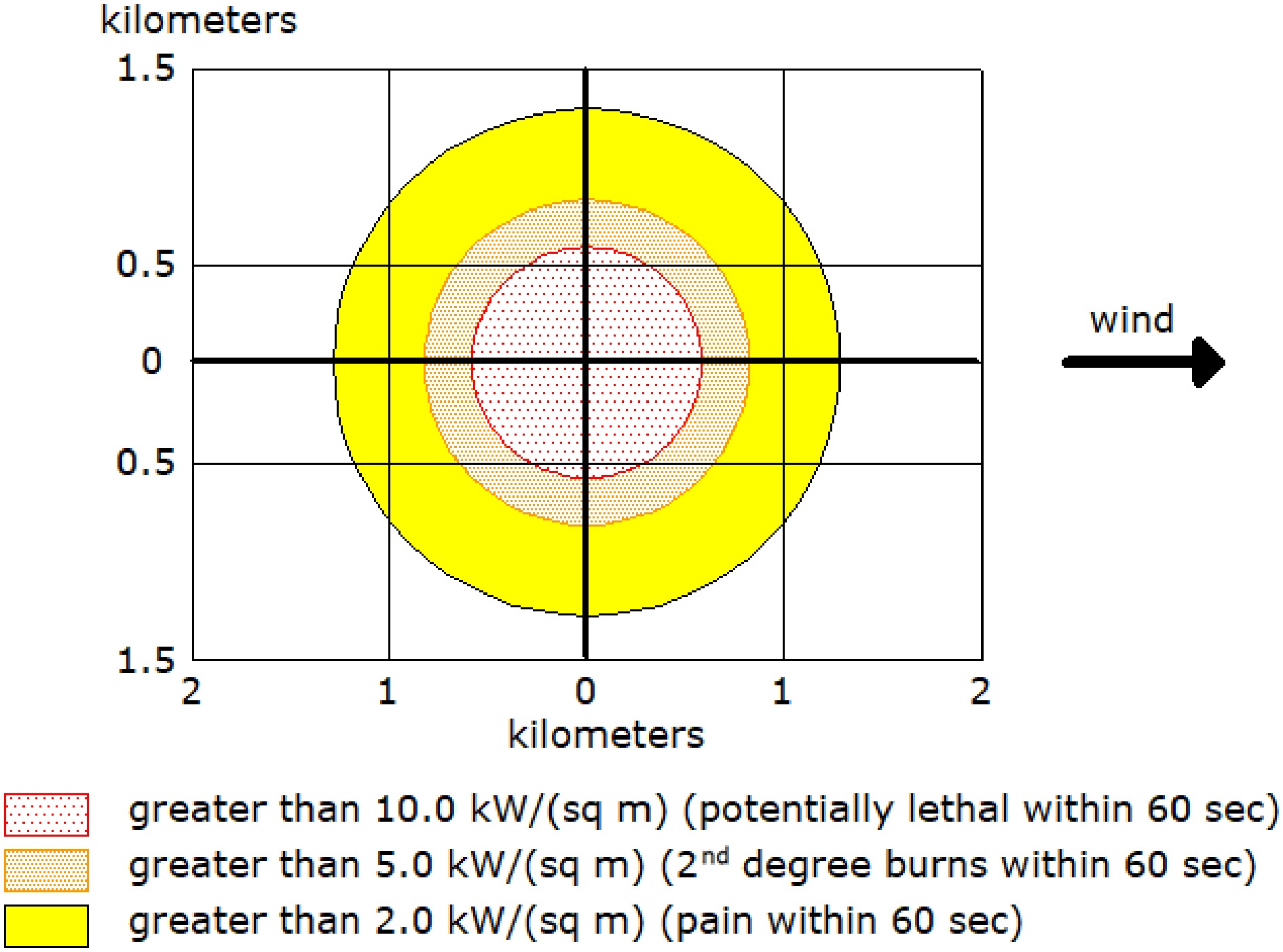

Figure 4.

Threat zones of the primary scenario-BLEVE.

-

Year Place Facility/unit Death Injury Other known effects 1951 Port Newark, United States LPG storage/propane 0 14 Seventy three tanks were destroyed, shrapnel impacts destroyed a filling station and ruptured a groundwater main 1954 Lake Port, United States Storage area/LPG 4 − − 1966 Feyzin, France Refinery storage tank/propane 18 81 Five spherical tanks were destroyed 1972 Rio de Janeiro, Brazil Refinery storage area/LPG 37 53 − 1984 Mexico City, Mexico Storage tank/LPG 650 6,400 Severe damage to nearby homes, ${\$} $ 1984 Romeoville, United States Refinery/absorption column/

propane, butane17 31 Damage to the electrical power supply system and fire extinguishing systems 1986 Petal, United States Pipeline/LPG − 12 Residents within a 2-mile radius were evacuated 1990 St Peters, Australia Gas tank/LPG − − − 1997 Visakhapatnam, India HPCL refinery/LPG 60 − ${\$} $ 2000 Texas, United States Tanker/propane 2 1 200 people were evacuated 2001 ConocoPhillips, Humber Refinery UK Refinery/deethanizer/propane, butane − − − 2009 Viareggio, Italy Freight train/LPG 15 > 50 A flash fire broke out, covering the railway area, streets, and houses close to the railway line 2009 Karachi, Pakistan Chipboard production factory 3 5 − 2009 Pawana, India Darshan Chemicals 2 9 − 2009 Columbus, USA Columbus chemical industries − 3 − 2009 La Mesa, USA Saltwater disposal factory − 1 − 2009 Okhla, India Foam production factory 1 8 The entire factory was destroyed 2009 Gazipur Bangladesh Knife-making factory/LPG 3 15 − 2009 Agra, India Fireworks at a commercial complex − − The fire spread to nearby shops, some of which were evacuated 2009 Yanshi City, China Luoran Co. Ltd/chemical dye production 5 > 108 Residents within a 1 km radius were evacuated 2009 Ulyanovsk, Russian Federation Army depot/ammunition 2 > 10 3,000 people were evacuated 2009 Jaipur, India Petroleum products 13 > 200 500,000 people evacuated; ${\$} $ 2013 − Fire and explosion in crude distillation unit (Petrochemical) − 3 More than €2 million in property damage 2018 Czech Republic Fire and explosion in crude distillation unit (Petrochemical) 6 2 On-site property damage more significant than €2 million Off-site property damage greater than €0.5 million 2021 France Releasing natural gas into the atmosphere 1 > 6 On-site property damage more significant than €2 million Off-site property damage greater than €0.5 million 2023 Romania Gasoline discharge pipeline (Petrochemical) 1 6 On-site property damage more significant than €2 million Off-site property damage greater than €0.5 million -

Year Place Incident Loss 1997 Kırıkkale-MKE Explosion in an ammunition factory Evacuation of the city and significant property damage 1999 Izmit-TUPRAS Fuel storage tanks fire ${\$} $ 2002 Kocaeli- AKCAGAZ Fire and explosion at LPG filling facility Three were injured, and 3 million liras of property were damaged 2004 Mersin-ATAS Tank full surface fire The 50 m diameter tank has become unusable 2007 Izmir-Aliaga Paint and varnish factory fire − 2011 Batman LPG filling facility explosion Three deaths and extensive property damage 2014 Manisa-Soma Explosion in the electrical panel and subsequent fire Three hundred one miners lost their lives 2017 Izmir-Aliaga An explosion occurred due to gas compression during work inside a naphtha tank in the TUPRAŞ Refinery, which had been under maintenance for a long time and was being prepared to be put into operation Four people lost their lives. Two people were injured, one seriously 2017 Bursa An explosion and subsequent collapse occurred in the steam boiler of

the textile factory dye workshopFive people lost their lives. Sixteen people were injured 2020 Sakarya An explosion occurred at the Coskunlar Fireworks Factory due to the

use of equipment that is not suitable for explosive environmentsSeven people lost their lives. One hundred twenty-seven people were injured 2023 Ankara A fire broke out in the dynamite mixer workshop of the Rocket and Explosives Factory belonging to the Machinery and Chemical Industry

in the Elmadag district of Ankara, and then an explosion occurredFive people lost their lives -

Primary scenario Escalation vector Expected secondary scenario Domino scenarios starting with fire Pool fire Radiation and flame impingement Jet fire, pool fire, BLEVE, or toxic release Jet fire Jet fire, pool fire, BLEVE, or toxic release Fireball Tank fire Flash fire Flame impingement Tank fire Domino scenarios starting with an explosion Mechanical explosion (ME) Fragments and overpressure Jet fire, pool fire, flash fire, fireball, BLEVE, toxic release, VCE, ME, CE VCE Jet fire, pool fire, flash fire, fireball, BLEVE, toxic release, VCE, ME, CE Closed explosion (CE) Overpressure Jet fire, pool fire, flash fire, fireball, BLEVE, toxic release, VCE, ME, CE BLEVE Overpressure and flame impingement Jet fire, pool fire, flash fire, fireball, BLEVE, toxic release, VCE, ME, CE Domino scenarios starting with toxic release Toxic Release − − Table 3.

Possible domino scenarios that may occur in chemical organizations.

-

Primary scenario Escalation vector Expected secondary scenario Equipment category Threshold value Safety distance Fireball Thermal radiation Tank fire Atmospheric 100 kW/m2 (protected element) Fireball radius + 25 m Pressurized − − Jet fire Thermal radiation Jet fire, pool fire, BLEVE, toxic release Atmospheric 8 kW/m2 (unprotected element) Flame length + 50 m Pressurized 35 kW/m2 (protected element) Flame length + 25 m Flash fire Thermal radiation Jet fire, pool fire, flash fire, fireball, tank fire, BLEVE, toxic release, VCE, ME, CE Atmospheric 8 kW/m2 (unprotected element) Maximum flammable distance (determined by consequence analysis) Pressurized 35 kW/m2 (protected element) Pool fire Thermal radiation Jet fire, pool fire, BLEVE, toxic release Atmospheric 8 kW/m2 (unprotected element) Pool border + 50 m Pressurized 35 kW/m2 (protected element) Pool border + 15 m Vapor cloud explosion (VCE) Overpressure

(F ≥ 5; Mf ≥ 0,35)Jet fire, pool fire, flash fire, fireball, tank fire, BLEVE, toxic release, VCE, ME, CE Atmospheric 22 kPa (unprotected element) R = 1.75 m Pressurized 45 kPa (protected element) R = 1.35 m Mechanical explosion (ME) Overpressure Jet fire, pool fire, flash fire, fireball, tank fire, BLEVE, toxic release, VCE, ME, CE Atmospheric 22 kPa (protected element) R = 1.80 m Pressurized 45 kPa R = 1.20 m Fragmentation 500 m Fragment distance Closed explosion (CE) Overpressure Jet fire, pool fire, flash fire, fireball, tank fire, BLEVE, toxic release, VCE, ME, CE Atmospheric 22 kPa (protected element) 20 m away from the vent Pressurized 45 kPa 20 m away from the vent BLEVE Overpressure Jet fire, pool fire, flash fire, fireball, tank fire, BLEVE, toxic release, VCE, ME, CE Atmospheric 22 kPa (unprotected element) R = 1.80 m Pressurized 45 kPa (protected element) R = 1.20 m Fragmentation Any one 500 m Fragment distance Toxic release − − − − − F: expected death number; Mf: Mach number. Table 4.

Proposed escalation safety distances.

-

Health and safety effects Property damage Loss of environment Loss of reputation VC1 Major injury: A life-altering injury to employees, subcontractors, or the general public within the facility. Minor damage: ${\$} $ ${\$} $ Significant: ERPG-2 visible and impactful leakage off-site.

Public concern and media attentionSignificant: Damage to neighboring facilities and immediate community (impacting finances and quality of life), local media attention VC2 On-site/off-site death: One or more off-site deaths or multiple on-site deaths or mass off-site serious injuries Severe or catastrophic damage: > ${\$} $

the facility or off-siteDisaster: > ERPG-3 Leaky international media attention that will have catastrophic effects off-site Severe: Harm to all stakeholders of the firm, international media attention Table 5.

Vulnerability categories and definitions.

-

LOC Category Definition LOC1 Small loss Partial inventory loss or total inventory loss over a time interval of more than 10 min LOC2 Serious loss Partial inventory loss or total inventory loss within a time interval of 1 to 10 min LOC3 Disaster Instant total inventory loss in less than 1 min Table 6.

LOC categories and definitions.

-

Atmospheric Pressurized VC1 VC2 VC2 LOC1-flammable Small pool fire (low) Small jet fire (high) LOC1-toxic Evaporating puddle (low) Boiling puddle, jet toxic release (high) LOC2-flammable Pool fire, flash fire, VCE (high) Jet fire, flash fire, VCE (high) LOC2-toxic Evaporating puddle, toxic release (high) Boiling puddle, jet toxic release (high) LOC3-flammable Pool fire, flash fire, VCE (high) BLEVE/fireball, flash fire, VCE (high) LOC3-toxic Evaporating puddle, toxic release, (high) Boiling puddle, toxic release (high) Table 7.

Proposed vulnerability and LOC domino accident matrix for atmospheric and pressurized equipment (secondary scenario-based).

-

Scenario Correlation BLEVE WTNT = 0.021(P.V/ɣ-1)(1-(PO/P)ɣ-1/ɣ) dn = d/(βWTNT)1/3 Vapor cloud explosion R = d/(E/Po)1/3 Fragment distance For tanks with a capacity of less than 5 m3: I = 90 M0.33 For tanks with a capacity greater than 5 m3: I = 465 M0.1 Pool fire $ D=\sqrt{4\ x\ surfac\ earea\ of\ pool/}\pi $ Flash fire H = 20h((S2/gh)(ρf-a/ρa)2x(wr2/(1-w)3)1/3 Toxic release $ R=(R_0^2+1.2(g_0V_0)^{1/2}t)^{1/2} $ Jet fire L/dor = (5.3/Cst-vol) $ \left(\left(\dfrac{\text{Tad}}{\text{αstTcont}}\right)(Cst+\left(1-Cst\right)\left(\dfrac{Ma}{Mv}\right)\right)^{1/2} $ L/dor = (15/cst-vol)(Ma/Mv)1/2 $ s = \dfrac{6.4\pi {d}_{or}{u}_{j}}{4{u}_{av}} $ Dj = 0.29(In((L+s)/x)))1/2 * Reference[41] was used in creating the table. Table 8.

Correlations for determining physical impact distances.

-

Gases MJ/m3

(molar mass)Flammability percentage limits in air by volume Specific gravity

(air = 1)Air required to burn

1 m3 of gasIgnition temperature

(°C)Lower Upper Propane 93.70 2.15 9.60 1.52 24 493–604 Butane 122.9 1.90 8.50 2.00 31 482–538 -

Property Condition Average Air Temperature 16 °C Wind speed 2 m/s Cloudiness Partly cloudy Surface roughness Urban Humidity Middle Relative humidity 70% Wind direction South Atmospheric stability class D Measurement height At human level Inversion None * f: flash fraction; Mf: mass of liquid. Table 10.

Atmospheric conditions[40].

-

Tank type and orientation Cylindrical, horizontal Tank diameter 3.5 m Tank length 18.7 m Tank volume 180 m3 Chemical phase Liquid Tank temperature 16 °C Tank pressure 5 atm Chemical mass in tank 89,405 kg Tank filling 85% Table 11.

Data used for source selection in ALOHA software.

-

Parameter Baseline assumption

(average conditions)Extreme assumption

(worst-case)Escalation threshold 37.5 kW/m2

(fixed literature threshold

for severe steel damage)37.5 kW/m2 Safety buffer 50 m 50 m Ambient temperature 20 °C 40 °C

(maximum historical temperature)Wind speed 5 m/s 1.5 m/s

(stagnant/maximizes flame length)Table 12.

Model Inputs and Assumptions.

-

Scenario Calculated impact distance (DImpact) Proposed safety distance

(DSafety = DImpact + 50 m)Baseline Case 55 m 105 m Extreme Case 66 m

(Increase due to higher vapor pressure and reduced dispersion)116 m Difference 11 m 11 m Table 13.

Sensitivity of the required distance to thermal effects.

Figures

(4)

Tables

(13)