-

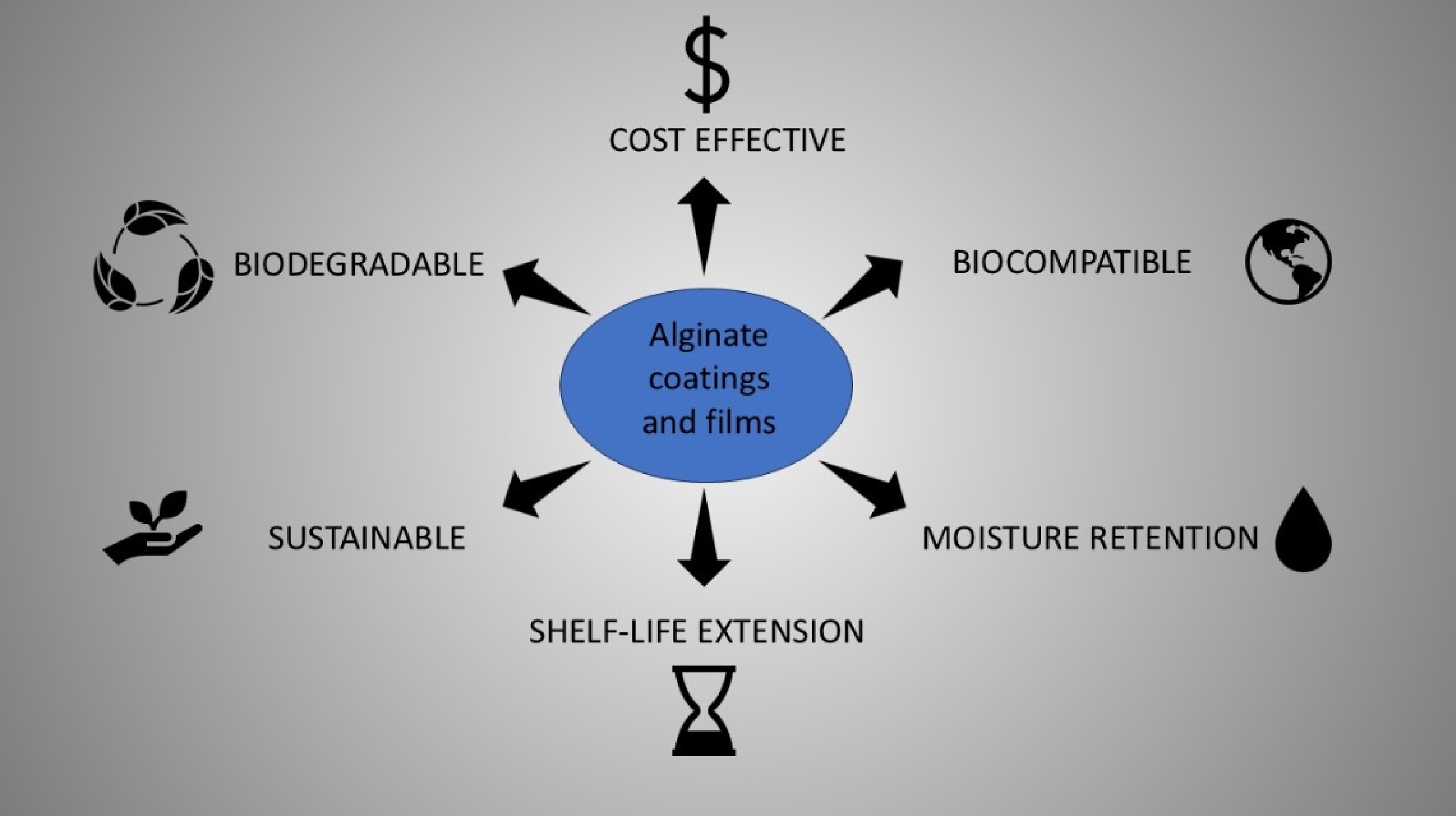

Figure 1.

Schematic representation of the key properties of alginate-based films and coatings.

-

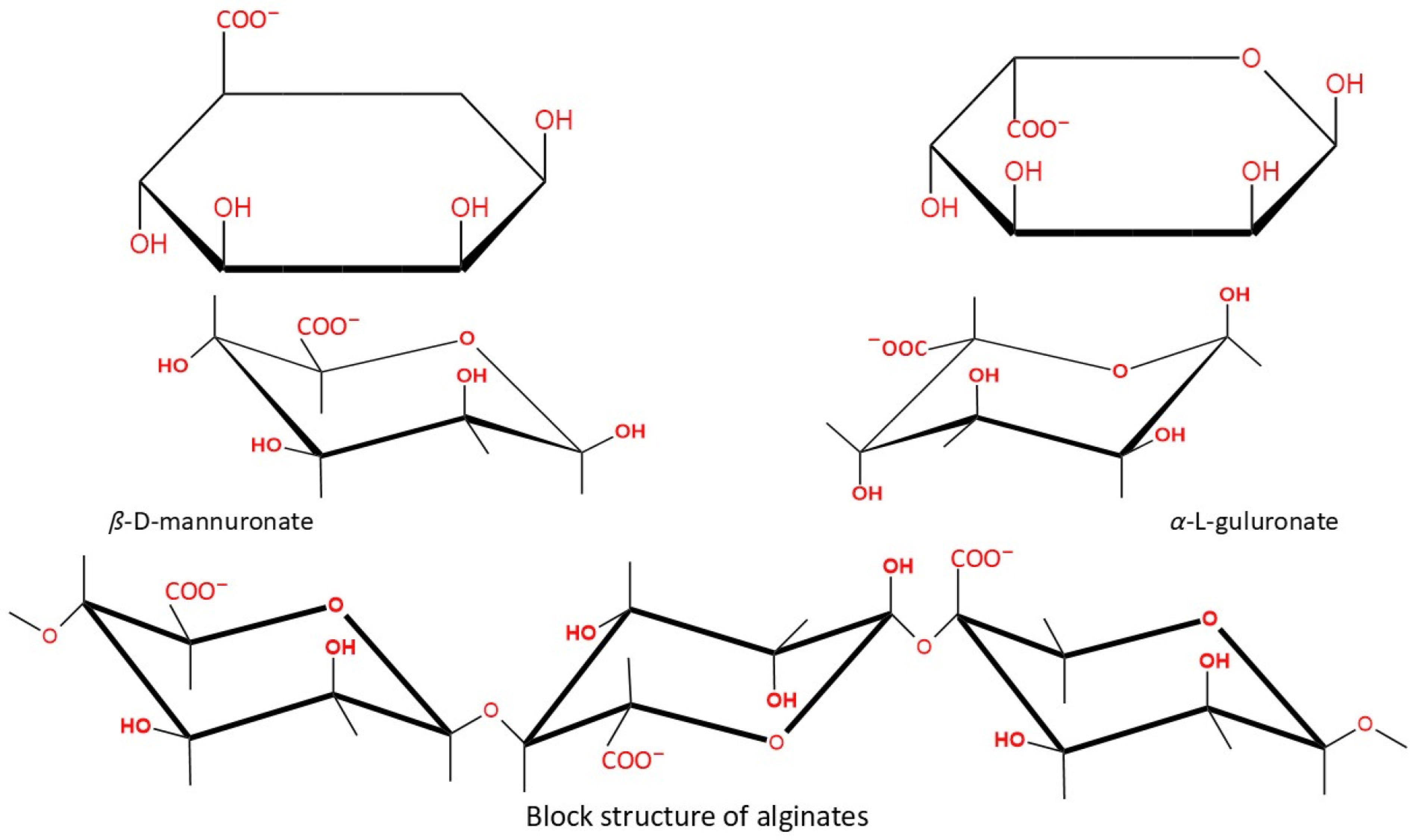

Figure 2.

Monomeric units of alginate (above) and block structure of alginates (below)[18].

-

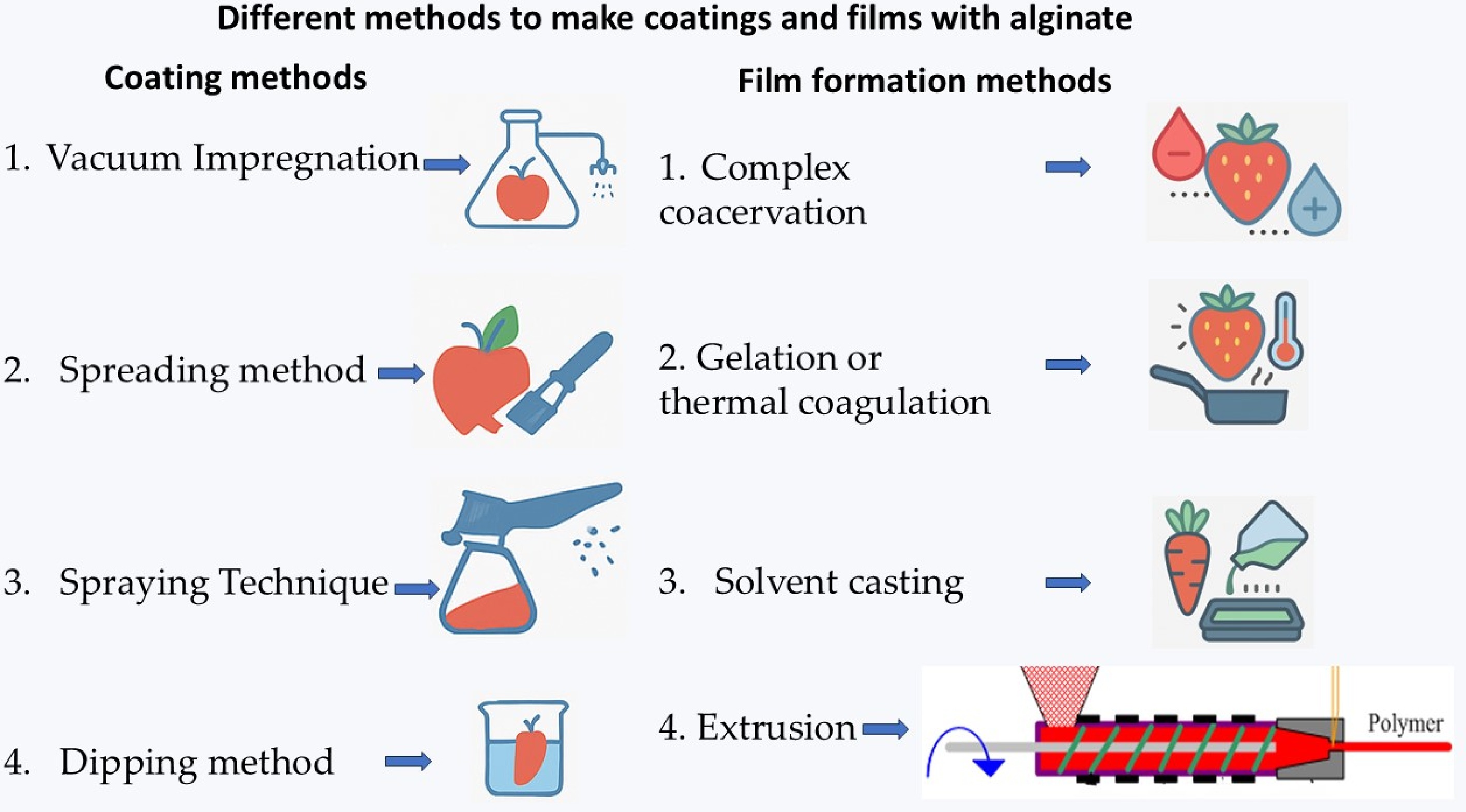

Figure 3.

Different methods to make coatings and films with alginate.

-

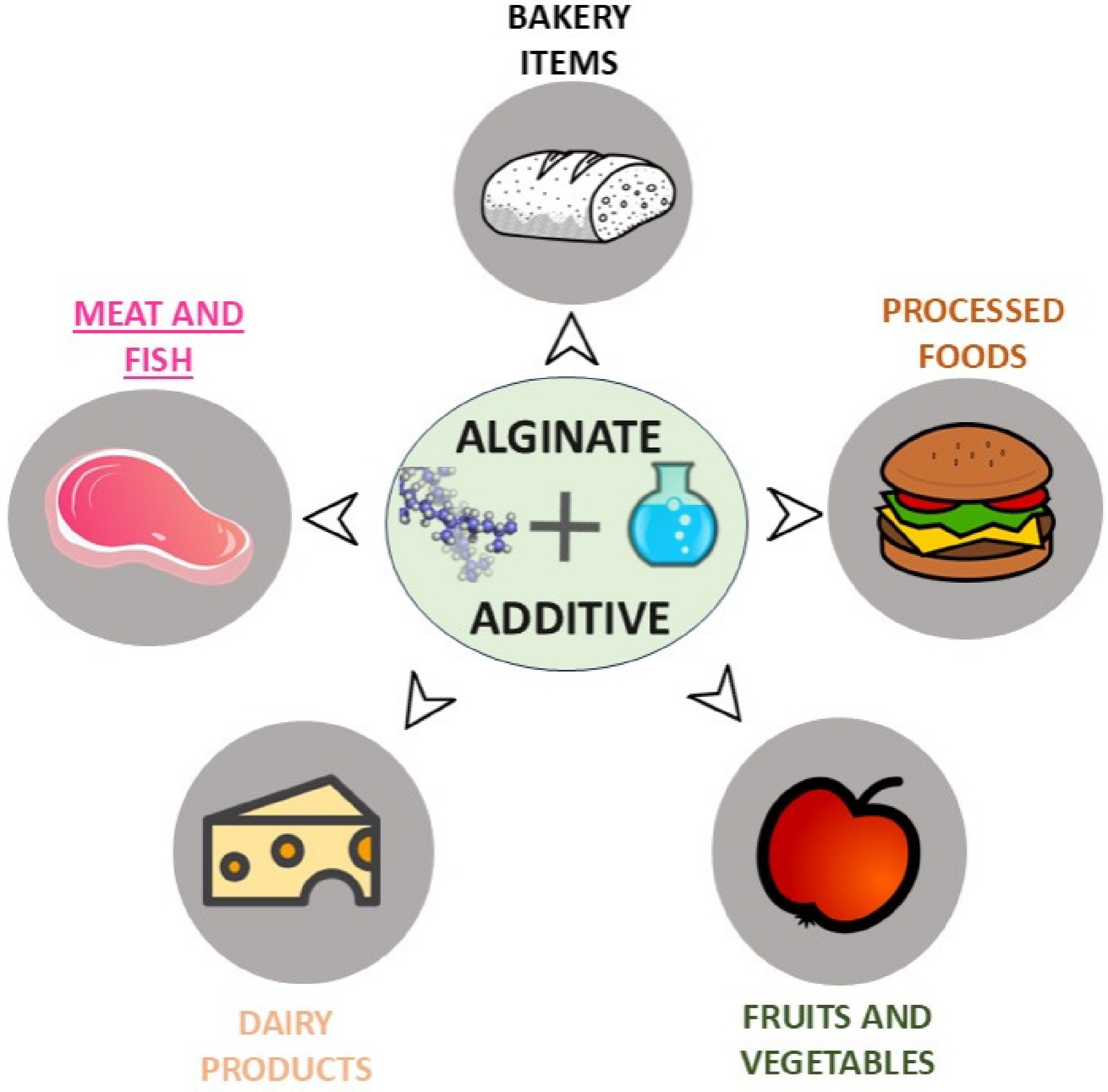

Figure 4.

Application of alginate-based films and coatings in various foods.

-

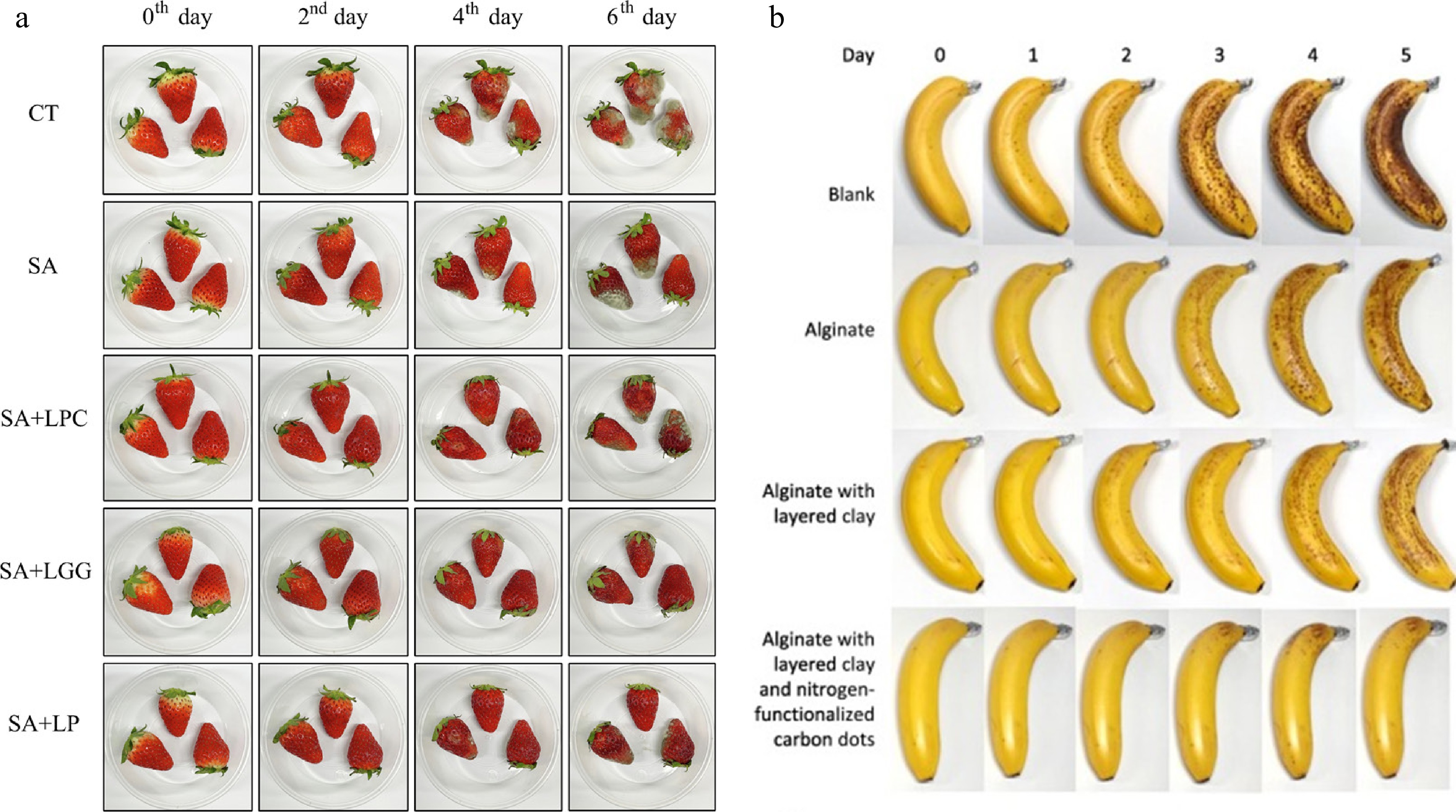

Figure 5.

Alginate-based film and coating for fruit packaging. (a) Lactic acid bacteria-reinforced alginate-based edible coating on strawberry[48]. CT, control; SA, sodium alginate; LPC, Lactobacillus paracasei; LPG, Lactobacillus rhamnosus; LP, Lactobacillus plantarum. (b) Nitrogen-functionalized carbon dots (NCDs) and layered clay-loaded alginate coating on banana[99]. Images reprinted with permission from Elsevier.

-

Method of production Type of

protection offered

(coating/film)Advantages Disadvantages Ref. Vacuum impregnation Coating • Produces higher quality foods especially in terms of texture and quality

• Efficient mass transfer

• Uniform coating

• Better retention of structural integrity• Not compatible with all food products

• Chances of product leaching

• Specialised equipment is needed

• Expensive equipment in terms of capital cost and maintenance

• Complex process parameters[37−39] Spreading Coating • Simple and basic method

• Reduced risk of cross-contamination

• Excellent applicability for viscous solutions• Labour-intensive

• Dependent on the skill of the person carrying out the process

• Feasibility issues for large production batches

• Difficult to achieve uniformity during application

• For foods with nonuniform shapes, it is difficult to achieve a uniform coating[37−39] Spraying techniques Coating • Have the potential to be used as a method of application in multilayered coatings• Uniform coverage• Cost-efficiency and good scalability • Only low-viscosity solutions could be applied in this format

• High-end equipment requirement

• Loss of coating material[37−39] Dipping techniques Coating • Complete coating of the food

• Easiest and simple form of coating

• Best method for the incorporation of additives

• Can be applied to a wide range of products• Thickness of the applied coating is not under control

• Chances of contamination of dipping solution

• Can cause undesirable changes[37−39] Complex coacervation Film • Encapsulation efficiency is high in this method

• Mild processing conditions could lead to excellent quality

• Good control over the release of compounds into the food

• Film properties are highly customisable• Material and equipment cost is very high

• Limited scope for scalability

• Process control is complex

• Operating conditions are narrow[40,41] Gel formation Film • Good film strength

• Mild processing conditions

• Excellent adhesive properties• Chances of microbial growth are high

• Sophisticated equipment is needed

• Chances of potential quality changes[40,41] Solvent casting Film • Low cost and simple operation

• Fabricated film has better quality

• Mild processing conditions• Drying time is long

• Chances of solvent residues becoming entrapped in the film

• Bubble formation is possible if the mixture is not homogenised well

• Shape limitation in fabrication of the film[40,41] Extrusion Film • Scalability of this technique is high

• Unlike the solvent casting method, the solvent is not used in the film

• Good mechanical properties of the film

• Multilayer film formation• High capital cost is needed

• Limited control over the processing parameters and the thickness of the film formed

• Material limitations, as not every polymer could not withstand the temperature and pressure conditions in the extruder[40,41] Table 1.

Comparison of the different methods of film and coating formation.

-

Formulation Mechanical properties Barrier properties Ref. Alginate with submicron linseed oil coating It increased the mechanical strength of the film. Water vapour barrier properties improved from 2.20 to 2.92 g·mm−1·m−2·d−1·kPa−1 [42] Tannic acid (30%)/Ca2+

double-crosslinked alginate

Tensile strength increased by 22.54%Sodium alginate film containing 30% tannic acid performed the best in terms of WVP with an increase of 25.36% over that of the pure sodium alginate film. [43] Sodium alginate–aloe vera gel Aloe vera significantly improves the mechanical strength. The tensile strength was increased. The tensile stress increased from 20.84 to 25.72 N·mm−2. The same trend was observed in the elongation at break (EAB), which increased from 0.86% to 2.56%. The incorporation of aloe vera was noted to decrease the WVP of alginate films. The WVP of the control film (sodium alginate) was measured to be 1.35 × 10−10 gm−1·s−1·Pa−1 but it decreased progressively, reaching a minimum of 1.13 × 10−10 gm−1·s−1·Pa−1 with a 50% concentration of aloe vera gel. [44] Alginate and glycerol Tensile strength increases from 59.9 ± 5.7 (pure alginate) to 71.0 ± 15.5 (alginate with 20% glycerol) but decreases when the glycerol amount is increased from 20%. Glycerol increases the oxygen permeability rate and water vapour transmission rate (WVTR) compared with pure alginate. [45] Alginate and sorbitol It decreases tensile strength but increases the value of elongation at break from 10 (pure alginate) to 27 (alginate with 50% sorbitol) Sorbitol slightly decreases the oxygen permeability rate and increases the WVTR at high concentrations compared with pure alginate. [45] Alginate and gallnut extract (GE) An increase in tensile strength and breaking at elongation was achieved by increasing the concentration of GE from 0 wt% to 25 wt% (on a sodium alginate basis) in sodium alginate films in the ranges of 48%–103% and 135%–185%, respectively. An increase in the GE content from 2.5 wt% to 50 wt% resulted in a reduction in WVP in the polyester complex films of 28.5%–50.1% in comparison with neat sodium alginate films. [46] Alginate and seaweed powder Without an additive, the tensile strength for pure alginate films was 95.14 ± 12.96. Adding 10%, 30%, and 50% of seaweed filler reduced the tensile strength to 56.47 ± 6.83, 51.54 ± 3.81, and 46.27 ± 4.59 MPa, respectively. The alginate film had a WVTR value of about 136.89 ± 8.24 g·m−2·h−1. There was a huge decrease in the WVTR at 10% loading of the seaweed filler, down to 123.05 ± 4.97 g·m−2·h−1. A similar observation was made with 30% seaweed, where the WVTR decreased significantly to 112.86 ± 2.79 g·m−2·h−1. [47] Alginate and plasma-activated water (PAW) Alginate film formed in PAW possessed a high tensile strength that amounted to 147.49 ± 16.74 MPa. The alginate film composed from PAW exhibited a WVTR of 119.41 ± 4.6 g·m−2·h−1, which was observed to decrease by 13% compared with that prepared in distilled water under similar conditions. [47] Table 2.

Comparative analysis of the mechanical and barrier properties of alginate-based films with various additives.

-

Additive Amount of additives Benefits Application on food Ref. Ascorbic acid, citric acid 0.5% (w/v) ascorbic acid,

1% (w/v) citric acidIts antioxidant activities were slightly enhanced, and it showed promise in helping to maintain the texture and minimising browning chemical reactions. Fresh-cut Fuji apples [73] Lemongrass essential oil 0.3% (w/v) Extended the life of the product with antimicrobial activity. Fresh-cut pineapple [74] Pomegranate peel extract 1% (w/v) Showed antifungal effects, preservation of sensory quality, and delayed spoilage. Fresh-cut capsicum [75] Oregano essential oil 2.0% (w/w) and 2.5% (w/w) Indicated antimicrobial properties and improved safety. Cut low-fat cheese [76] Vitamin C 5% (w/w) Brought about a decrease in the degree of chemical spoilage, inhibited bacterial growth, slowed down water loss, and improved the overall sensory values. Refrigerated bream fish [53] Eugenol and citral essential oils Eugenol, 0.20 (w/v) and 0.10%; citral, 0.15% (w/v) Improved the quality of crops for a better shelf life. Arbutus fruit [77] Calcium chloride 2% (w/w) This created a protective coating on the fruit, thereby inhibiting

transpiration and respiration rates. The edible coating also delayed the rate of increase in the total soluble solid content and pH of cut fruits by retaining citric acid.Strawberry [78] Thyme essential oil 0.3 (w/v) and 0.5% (w/v) Thyme essential oil slows the growth of yeasts and molds, leads to a longer shelf storage life, and maintains the freshness of natural characteristics. Pistachios [77] Ascorbic acid 1% (w/v) Retard the ripening process caused by hormone-induced changes such as change in colour and firmness loss. Strawberries [79] Table 3.

Additives in the production of alginate-based functional films for applications in food packaging.

-

Polymer Functional additive Food system Key effects Ref. Alginate Black cumin Chicken breast meat Showing higher antimicrobial activity against Escherichia coli. Fewer colour changes were observed in chicken breast during storage for 5 d at 4 °C. [82] Sodium alginate Mentha spicata essential oil and cellulose nanoparticles Raw silver carp (Hypophthalmichthys molitrix) fillets Packaging inhibits the development of mesophilic and psychrotrophic bacteria for 7 d, improving the storage life of minced beef compared with the control, whereas the coatings used for silver carp fillets increased the shelf life by 14 d versus the control. [83] Sodium alginate Pimpinella saxifrage essential oil Cheese Coating with sodium alginate containing Pimpinella saxifrage essential oil at amounts between 1% and 3% resulted in reduced weight loss, maintenance of colour and pH, and increased resistance to oxidation and bacterial growth in coated cheese. [24] Alginate Chitosan and red beet anthocyanin extract Chicken fillet An edible film of sodium alginate with chitosan and red beetroot anthocyanin extract showed was studied for its antimicrobial efficacy against foodborne pathogens, pH indicator responsiveness, and applicability in the smart packaging of chicken fillets. [84] Alginate Calcium lactate and trans-cinnamaldehyde Fresh-cut watermelon Multilayered antimicrobial alginate coatings were effective in increasing the storage life of fresh-cut watermelon from 7 to 12–15 d, improving fruit firmness and colour retention, and significantly reducing weight loss. [30] Alginate Eugenol and citral Strawberry Alginate incorporated with essential oils provided better coatings and an improvement in bioactive, nutritional attributes, and retardation of microbial spoilage. [77] Alginate Clove, cinnamon, coriander, caraway, marjoram, and cumin Fish fillet In suppression of the growth of Listeria monocytogenes, the essential oils were ranked in descending order as marjoram, clove, cinnamon, coriander, caraway, and cumin. [85] Alginate Cinnamon, clove, and lemongrass Apples The coatings used for the apple pieces sustained their physicochemical characteristics for more than 30 d, reduced the respiration rate, and decreased the E. coli population by about 1.23 log colony-forming units (CFU(/g on Day 0 while prolonging the microbiology-related shelf life of apples by at least 30 more days than the controls. [86] Alginate Sunflower oil and lemongrass essential oil Fresh-cut pineapple Lemongrass oil was found to exert antifungal activity by efficiently acting against fungi like Penicillium expansum, Aspergillus niger, and Rhizopus spp. It enhances the microbial quality and the storage life of fresh-cut pineapple. [74] Alginate/carboxyl methyl cellulose Clove essential oil Carp fillet The texture, smell, and colour of fresh silver-treated fillets did not show any noticeable change for up to 16 d compared with the control fillets, although the silver-treated fillets recorded significantly lower scores for bacterial action, total volatile nitrogen bases, and lipid oxidation rate compared with the control fillets. [87] Sodium alginate Cinnamon Pears and apples Suppression of mycelial development and ochratoxin A synthesis in Aspergillus carbonarius. [88] Alginate Aloe vera and garlic oil Tomato Alginate-based coatings possess antimicrobial properties against pathogens, improved resistance to dehydration through increased moisture retention, and enhanced mechanical strength, thereby extending the storage life of foods and preserving their qualities. [89] Sodium alginate Oregano, cinnamon, savory oils Beef muscle After 5 d of storage, cinnamon and oregano essential oils were recognized as the most potent against Salmonella typhimurium in terms of their effect when combined with a hydrocolloid-based edible film versus the initial treatment without any oils. [90] Sodium alginate Thyme (Thymus vulgaris) and oregano (Origanum vulgare) Fresh-cut papaya It decreased the rate of deterioration in the physicochemical properties, promoted microbiological food safety, and achieved the highest sensory scores for fresh-cut papaya stored for 12 d at 4 °C. [91] Alginate Carvacrol and β-cyclodextrin White mushroom Microencapsulated carvacrol–sodium alginate films exhibit better antimicrobial properties against foodborne pathogens, mechanical strength enhancement, and moisture barrier capabilities, and it should be considered suitable for application in active food packaging. [92] Table 4.

Application of alginate-based packaging in the preservation of different foods.

Figures

(5)

Tables

(4)