-

-

-

-

-

-

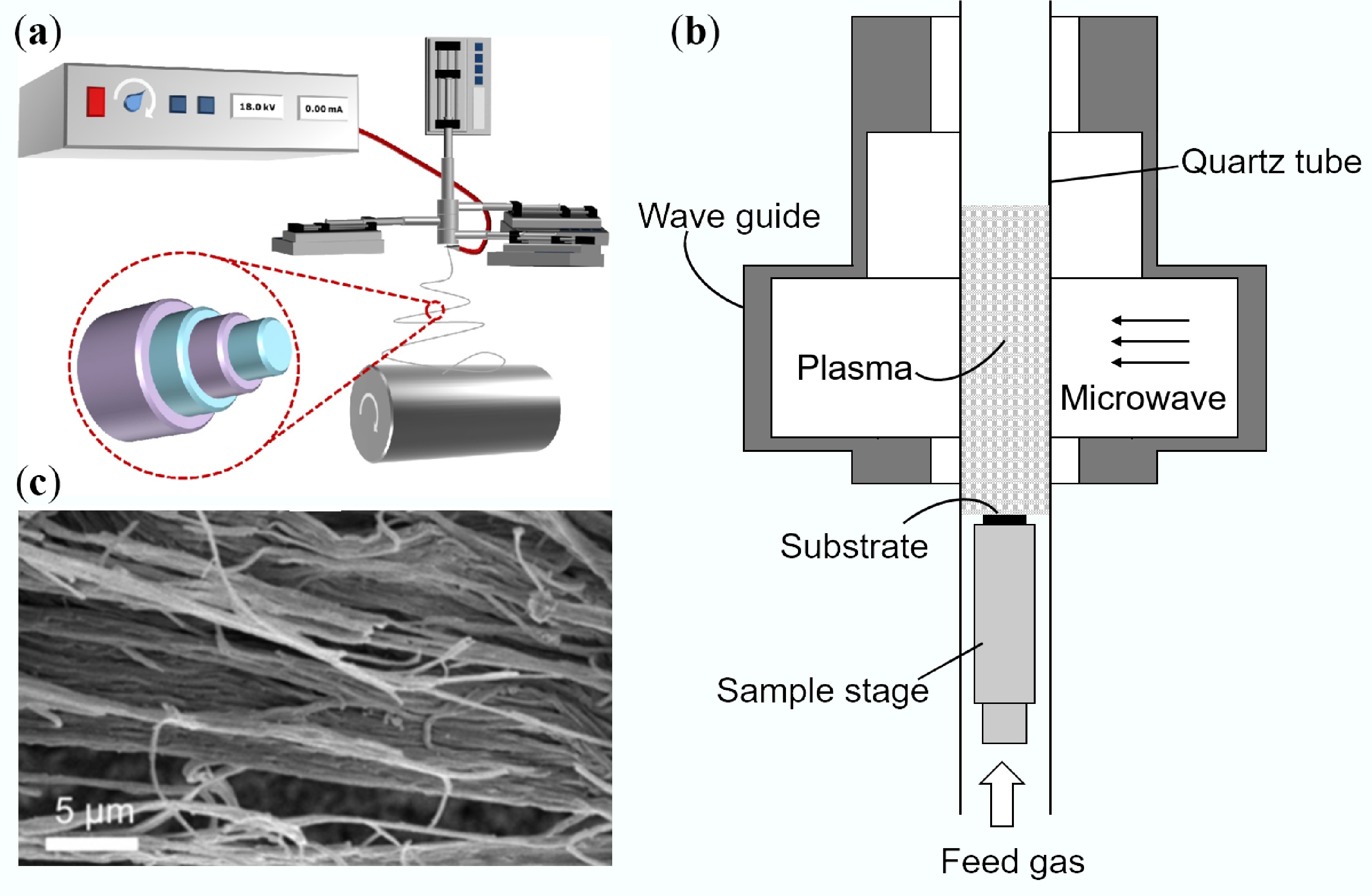

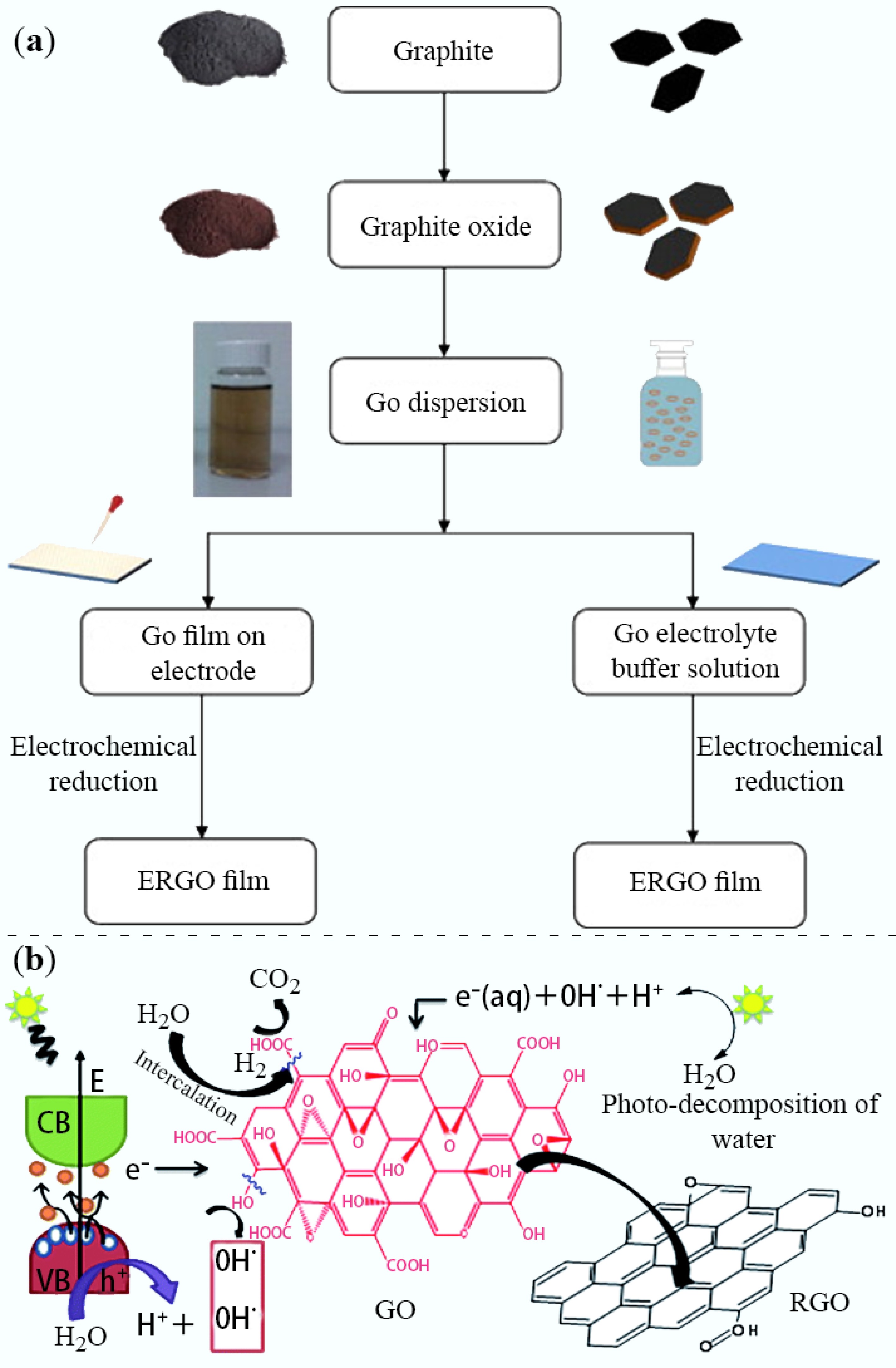

Figure 6.

Synthesis of rGO by microwave-assisted thermal reduction[102].

-

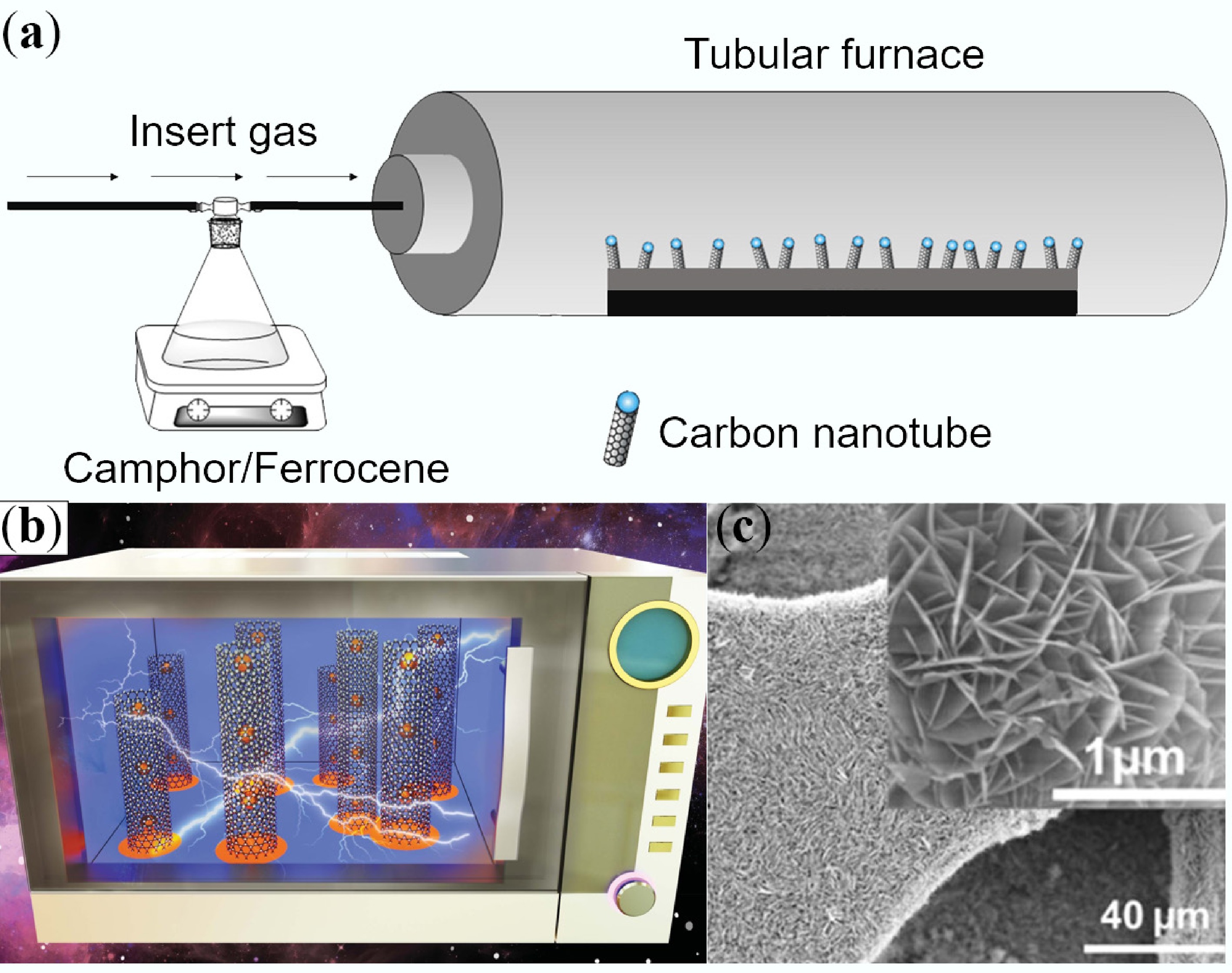

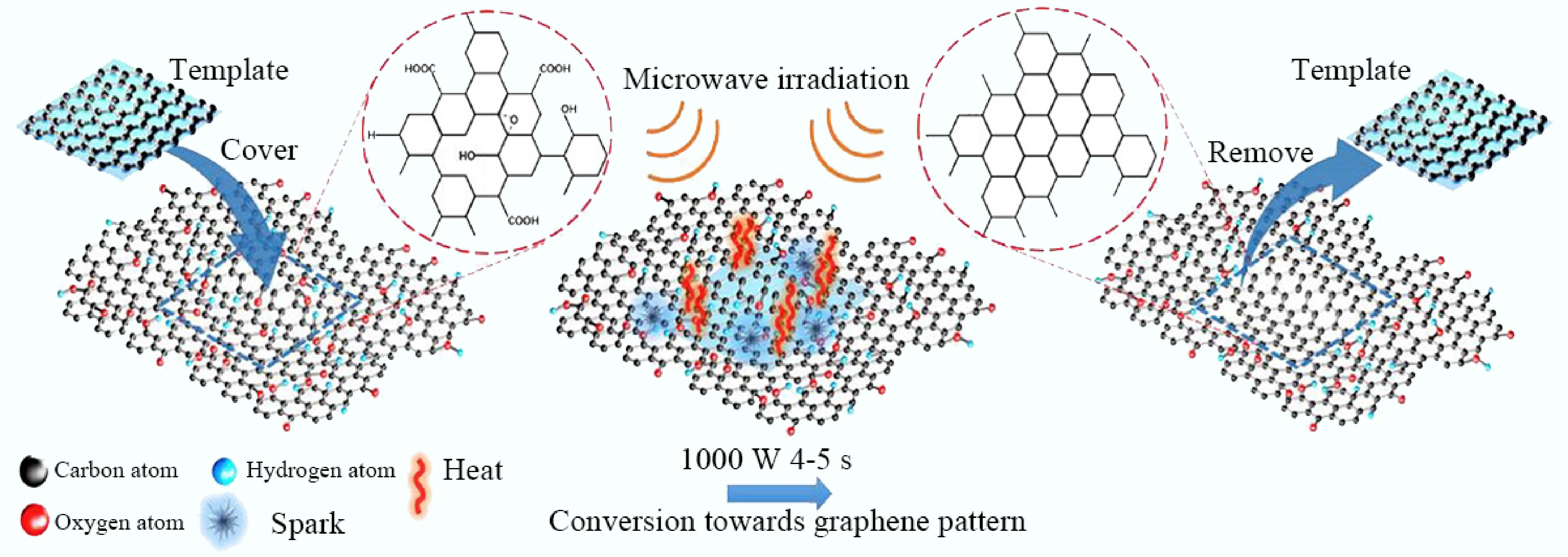

Figure 7.

Synthesis of rGO by microwave-assisted chemical reduction[106].

-

-

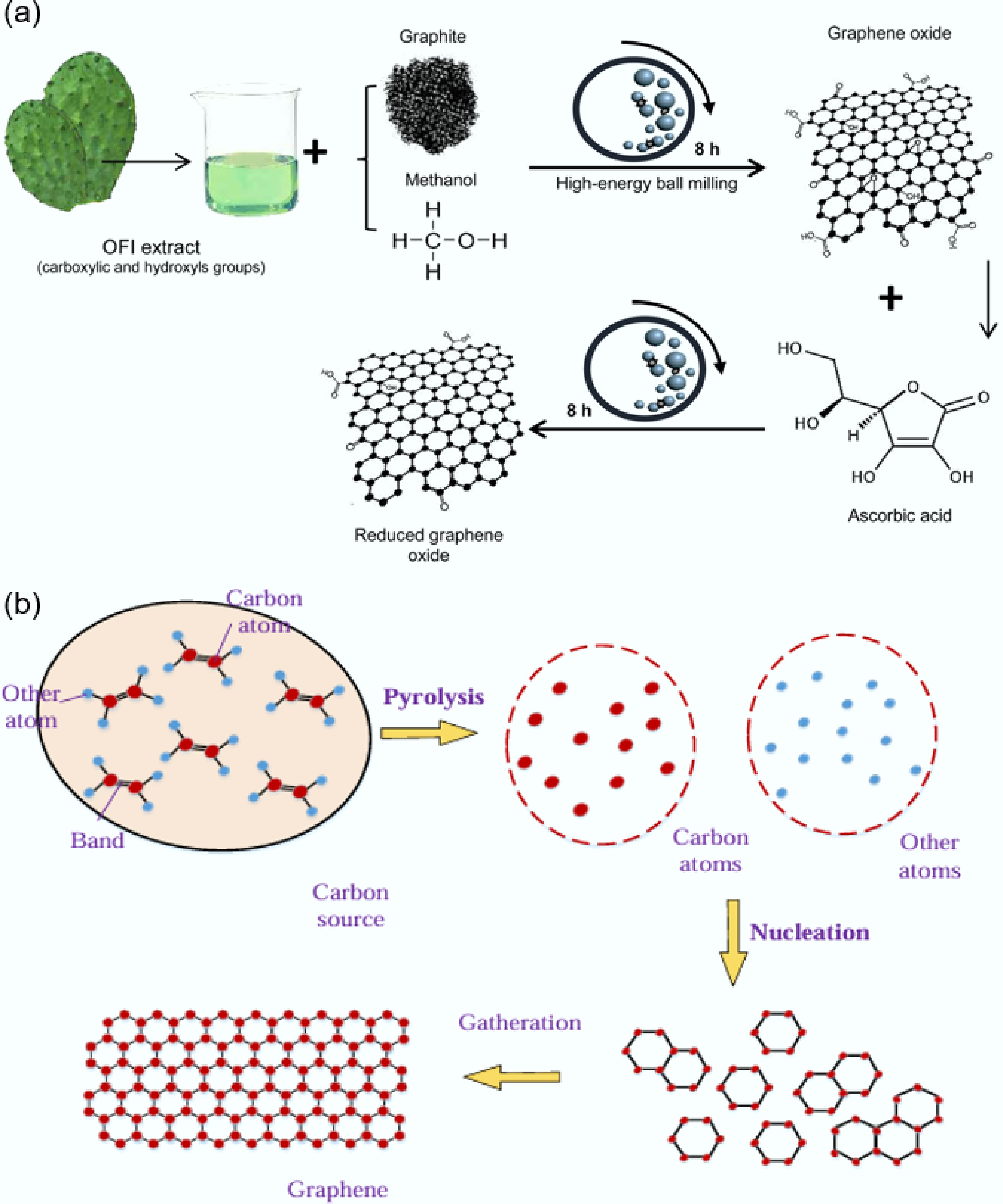

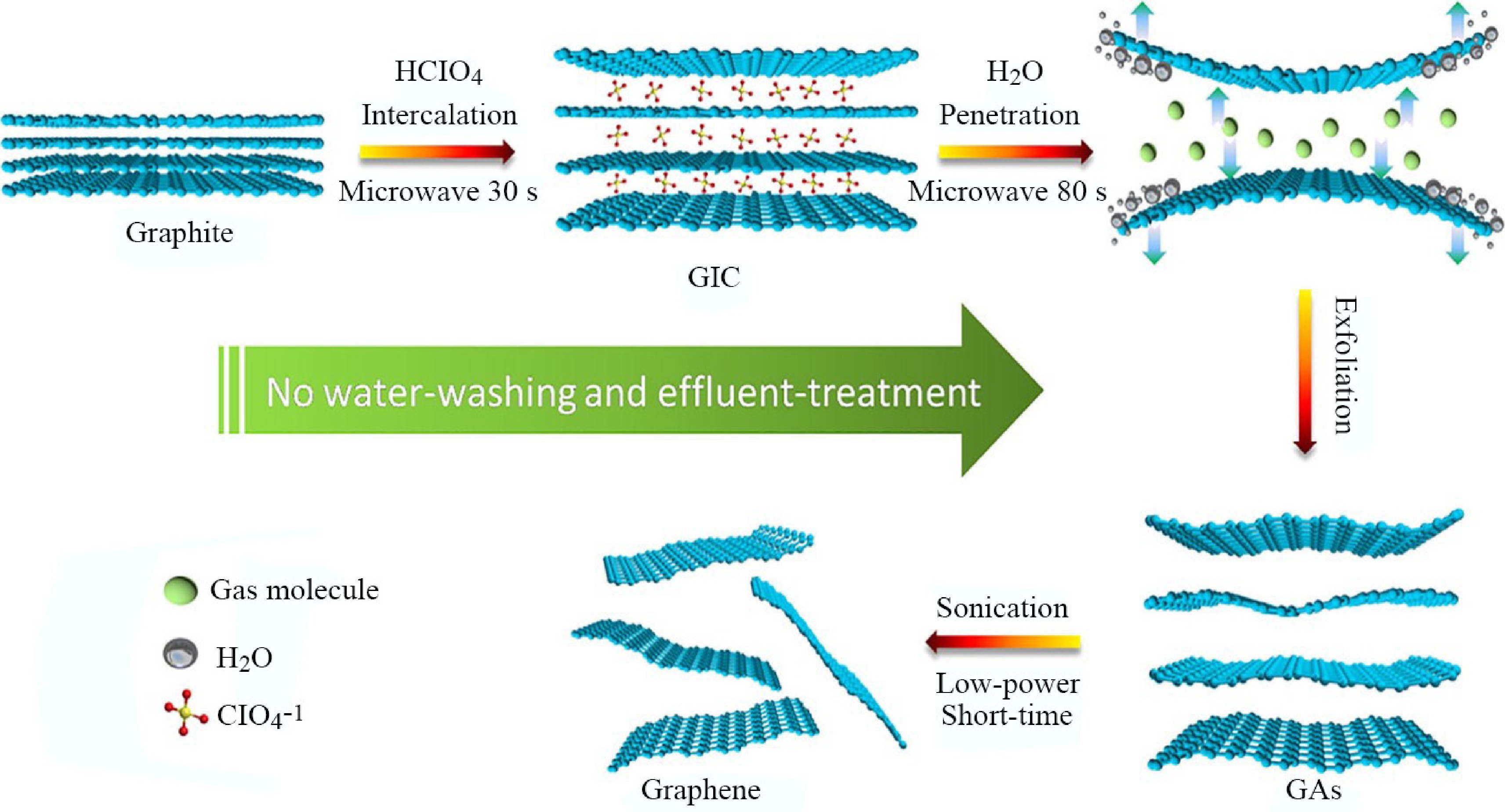

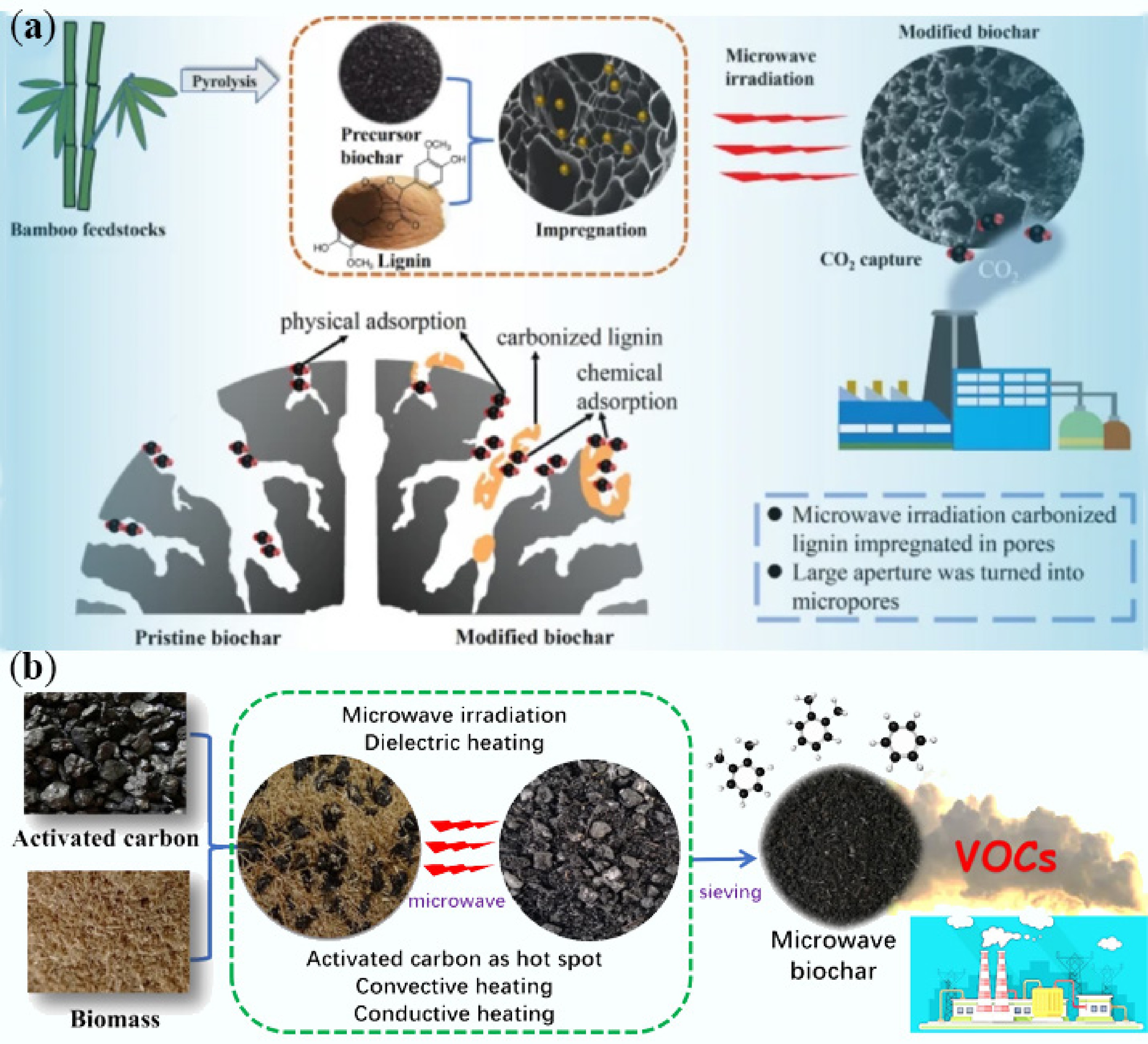

Figure 9.

(a) Schematic diagram of bamboo biochar modification for capturing CO2 by lignin impregnation method and microwave irradiation method[162]. (b) Schematic diagram of the preparation of wheat straw-based microwave biochar catalyzed by granular activated carbon for adsorbing volatile organic compounds[163].

-

-

-

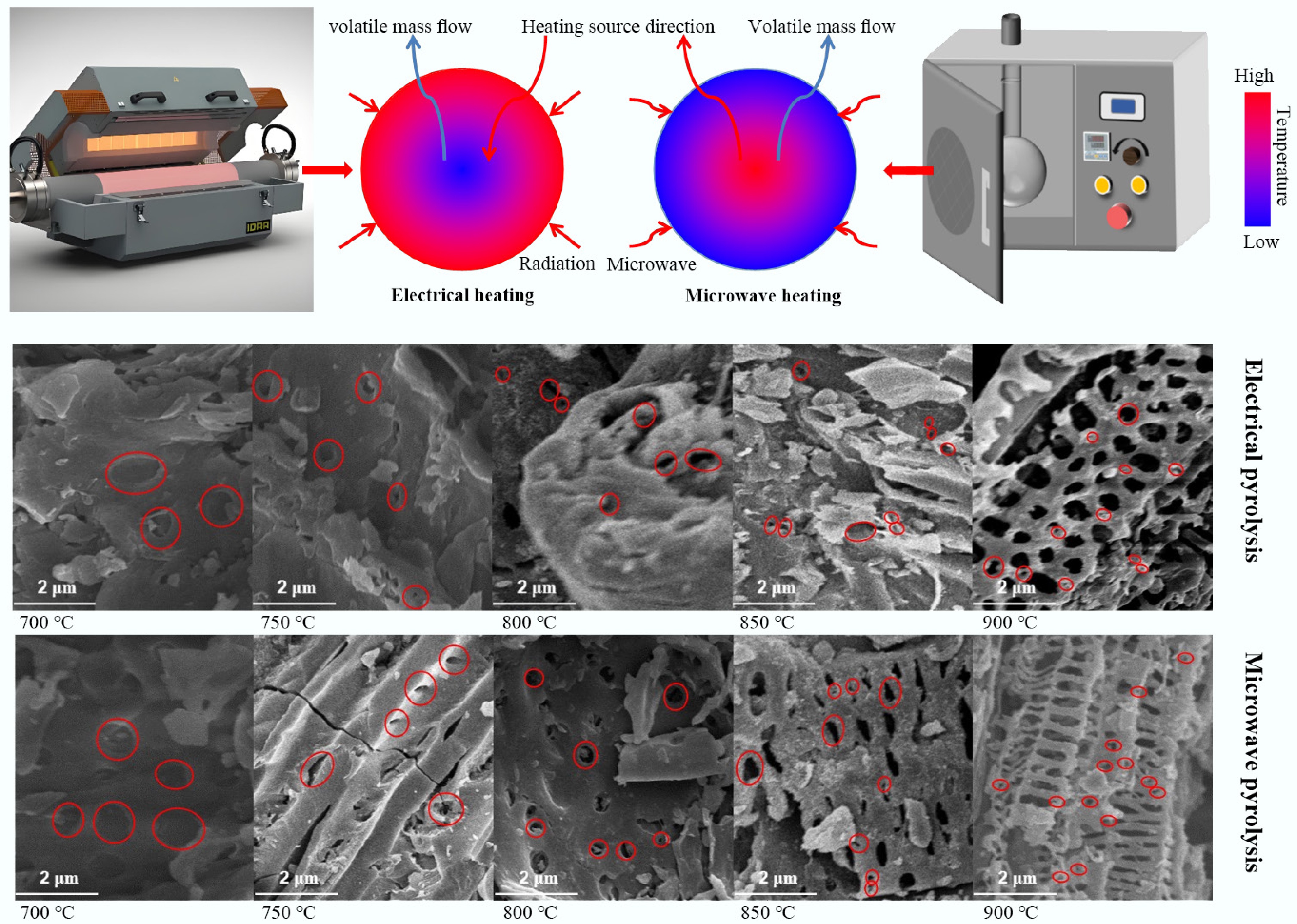

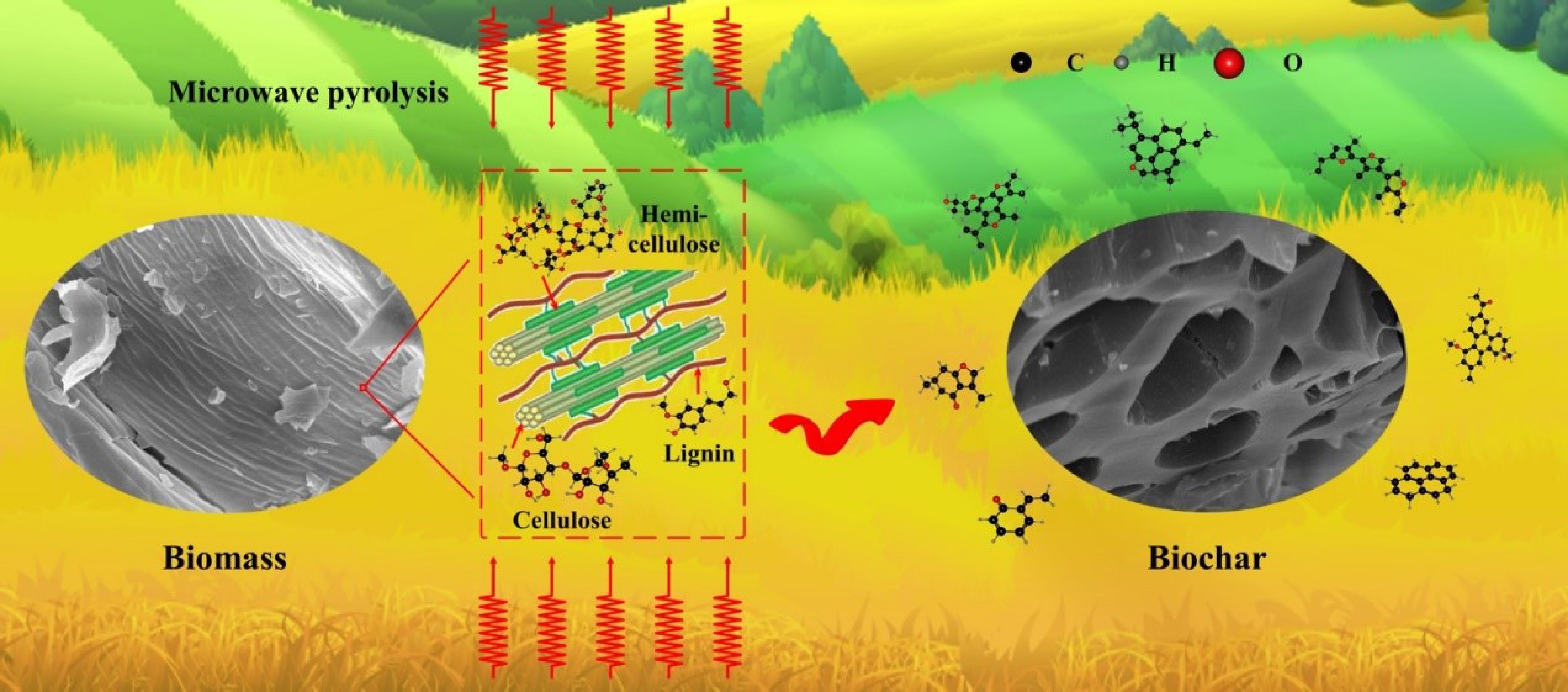

Figure 12.

Schematic diagram of biochar pore-forming mechanism[168].

-

-

Figure 14.

Electromagnetic radiation hazards and application of electromagnetic-wave absorption materials around daily life[209].

-

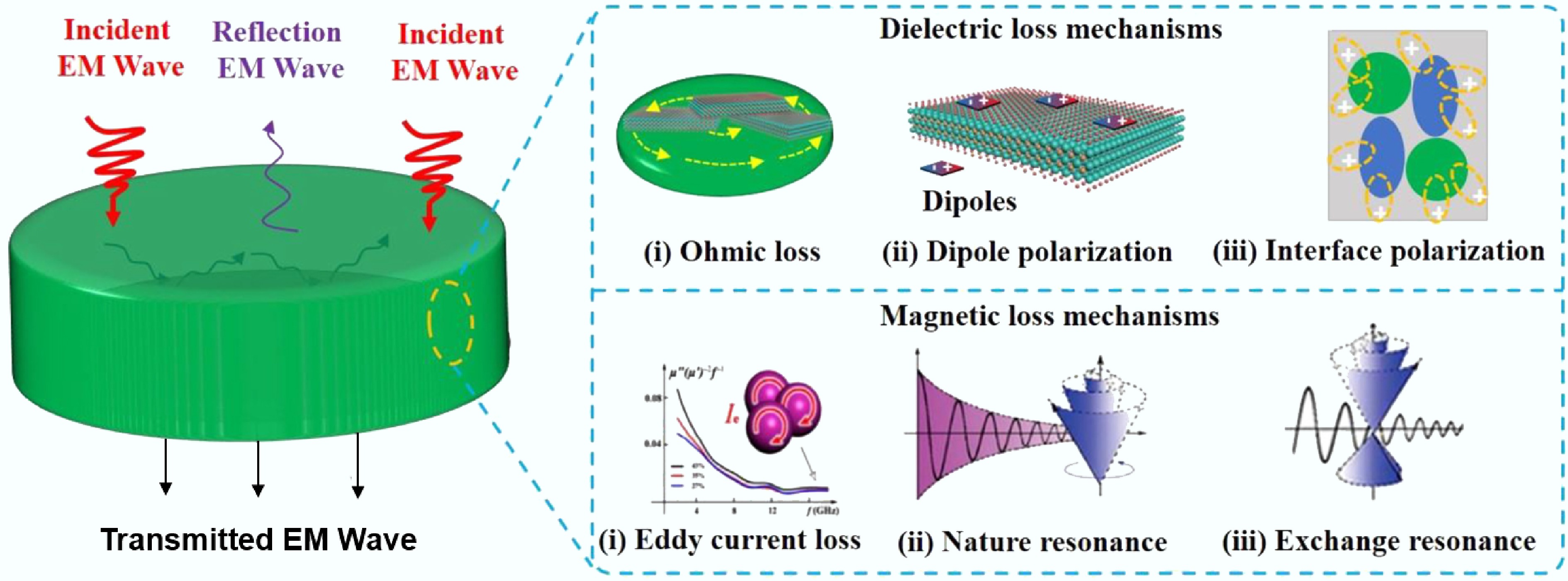

Figure 15.

Schematic diagram of electromagnetic wave absorption mechanisms[221].

-

-

-

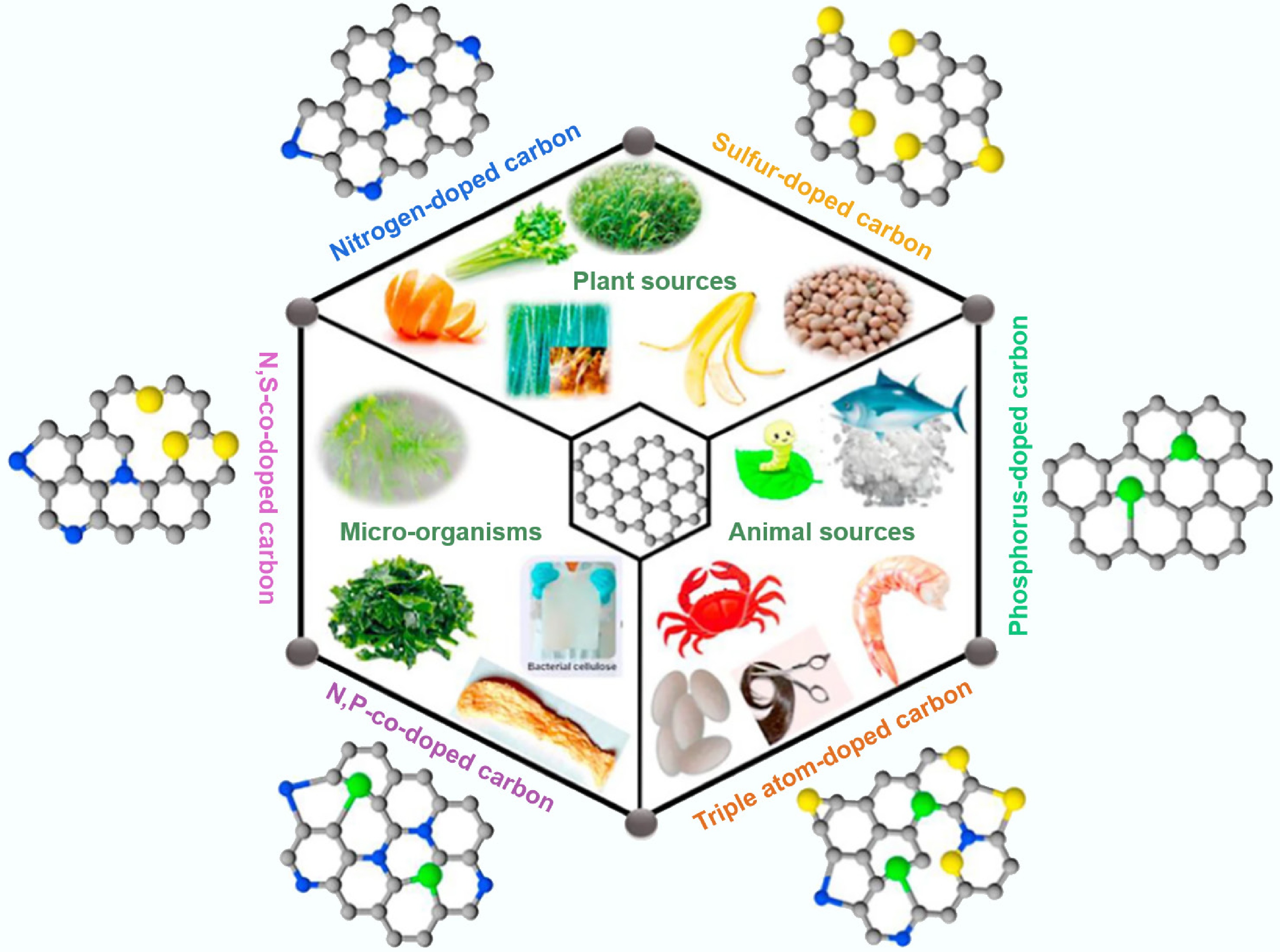

Figure 18.

Various self-doped biomass-derived carbon materials as a supercapacitor electrode[277].

-

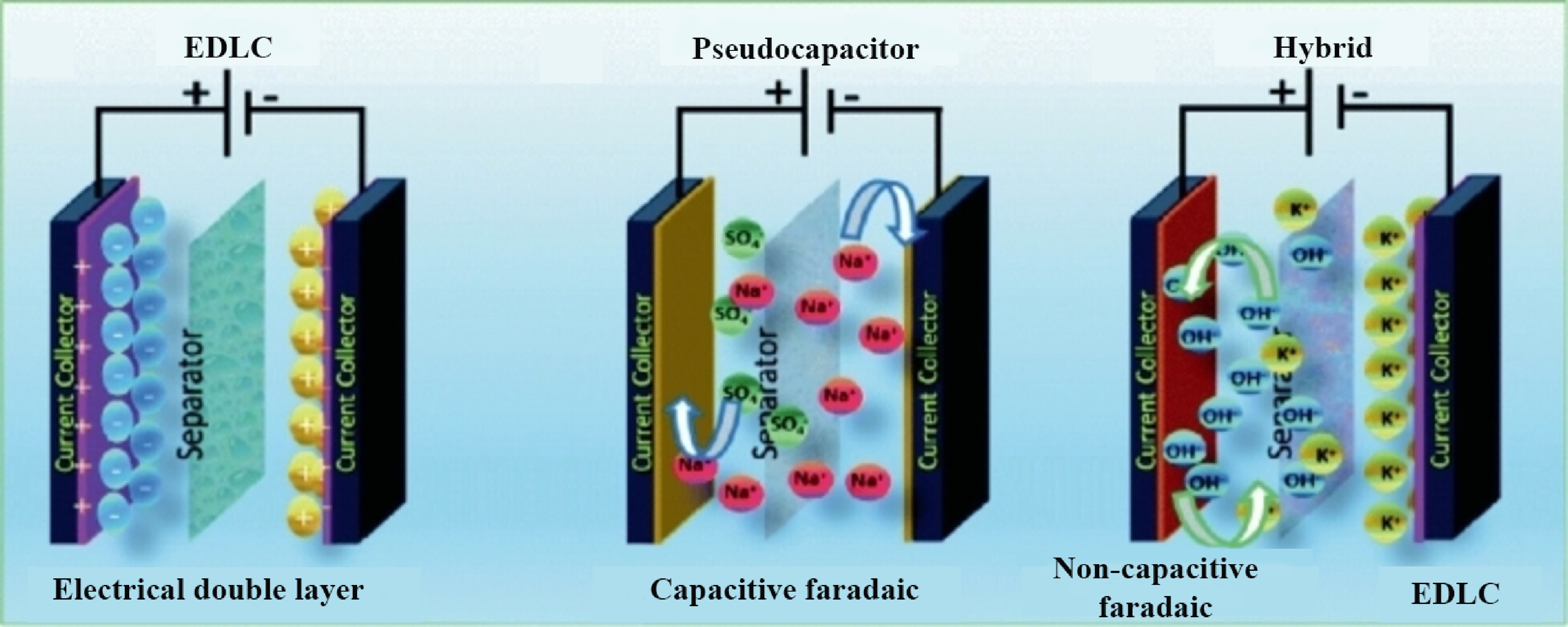

Figure 19.

Types of supercapacitors - EDLC, pseudo capacitor, hybrid[311].

-

-

Technology Heating mechanism Key advantage Inherent limitation Conventional pyrolysis External conduction/

convectionMature technology, simple setup High energy consumption, slow heating Microwave-assisted pyrolysis Volumetric heating via dielectric loss Rapid and selective heating, high energy efficiency, superior product performance, excellent microstructure control Potential hotspots, specialized equipment needed, scalability challenges Low-temperature catalytic carbonization Catalytic lowering of activation energy Lower operating temperature, potential for targeted reactions Catalyst cost and deactivation, limited feedstock adaptability Molten salt electrolysis Electrochemical reduction in molten salt Utilize CO2 or wastes as feedstock, direct conversion High energy input, corrosive environment, complex operation Plasma activation Ultra-high temperature from ionized gas Extremely fast reactions, can handle refractory materials Very high energy consumption, expensive equipment Table 1.

Comparison of different pyrolysis technologies for sustainable carbon material production

-

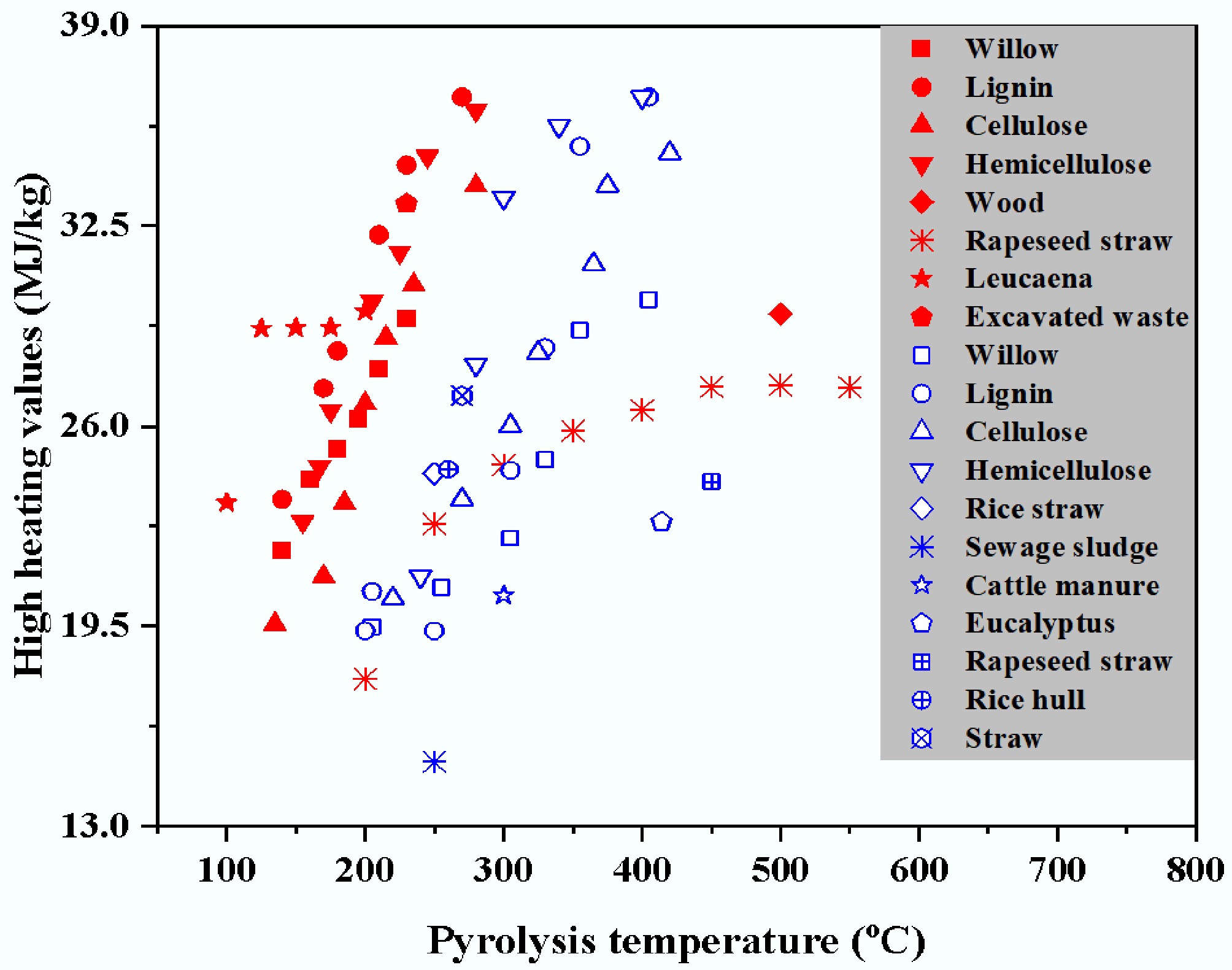

Feedstock Pyrolysis condition Yield (wt%) HHV (MJ/kg) Ref. Algae 400–600 °C 10.8–13.4 18.6–21.7 [134] Canola straw 300–500 °C 29.8–41.9 22.3–24.5 [135] Corn stalk 400–600 °C 24.8–36.4 18.3–22.1 [134] Corn stover 500–900 °C 28.0–40.0 18.1–29.8 [136] Manure pellet 300–500 °C 66.7–76.4 4.1–4.7 [135] Palm kernel shell 500–700 °C 33.0–38.0 23.0–26.0 [137] Pigeonpea stalk 500 °C 31.0 30.7 [138] Pinewood 400–600 °C 19.3–33.1 23.2–27.3 [134] Saccharum bagasse and Waste cooking oil 200–300 °C 59.6–86.7 16.1–24.5 [139] Sawdust 300–500 °C 24.7–45.3 25.9–32.3 [135] Sewage sludge 450–600 °C 33.0–62.3 6.5–8.7 [140] Waste oily sludge 250–650 °C 70.0–70.4 15.4–16.2 [141] Wheat straw 300–500 °C 31.0–43.3 25.6–26.9 [135] Cassava stem 550–750 W 70.0–77.0 19.2–20.6 [142] Corn stalk 900–1,500 W 30.9–41.1 23.0–31.7 [143] Indian coal 420–560 W 61.9–69.6 15.3–16.8 [144] Indian coal and rice husk 420–560 W 45.7–61.2 12.0–14.6 [144] Palm kernel shell 500–700 W 79.0–86.0 23.5–28.4 [145] Rice husk 420–560 W 34.8–38.3 12.1–12.6 [144] Wood pellets 2,000–3,000 W 26.2–32.4 30.6–31.8 [146] Chlorella sp. 15–60 min 50.1–66.7 25.4–27.3 [147] Chlorella vulgaris 15–25 min 35.4–44.8 23.1–26.2 [148] Nannochloropsis oceanica 15–60 min 49.6–75.1 23.8–26.4 [147] Sewage sludge 5–15 min 70.0–87.0 27.2–28.4 [145] Sewage sludge 30–60 min 30.2–56.5 13.6–16.8 [149] Sugarcane bagasse 20–30 min 30.1–60.4 19.9–24.7 [150] Waste oily sludge 60–120 min 68.6–70.8 15.3–16.0 [141] Table 2.

Yields and HHVs of biochars obtained under different microwave pyrolysis conditions

-

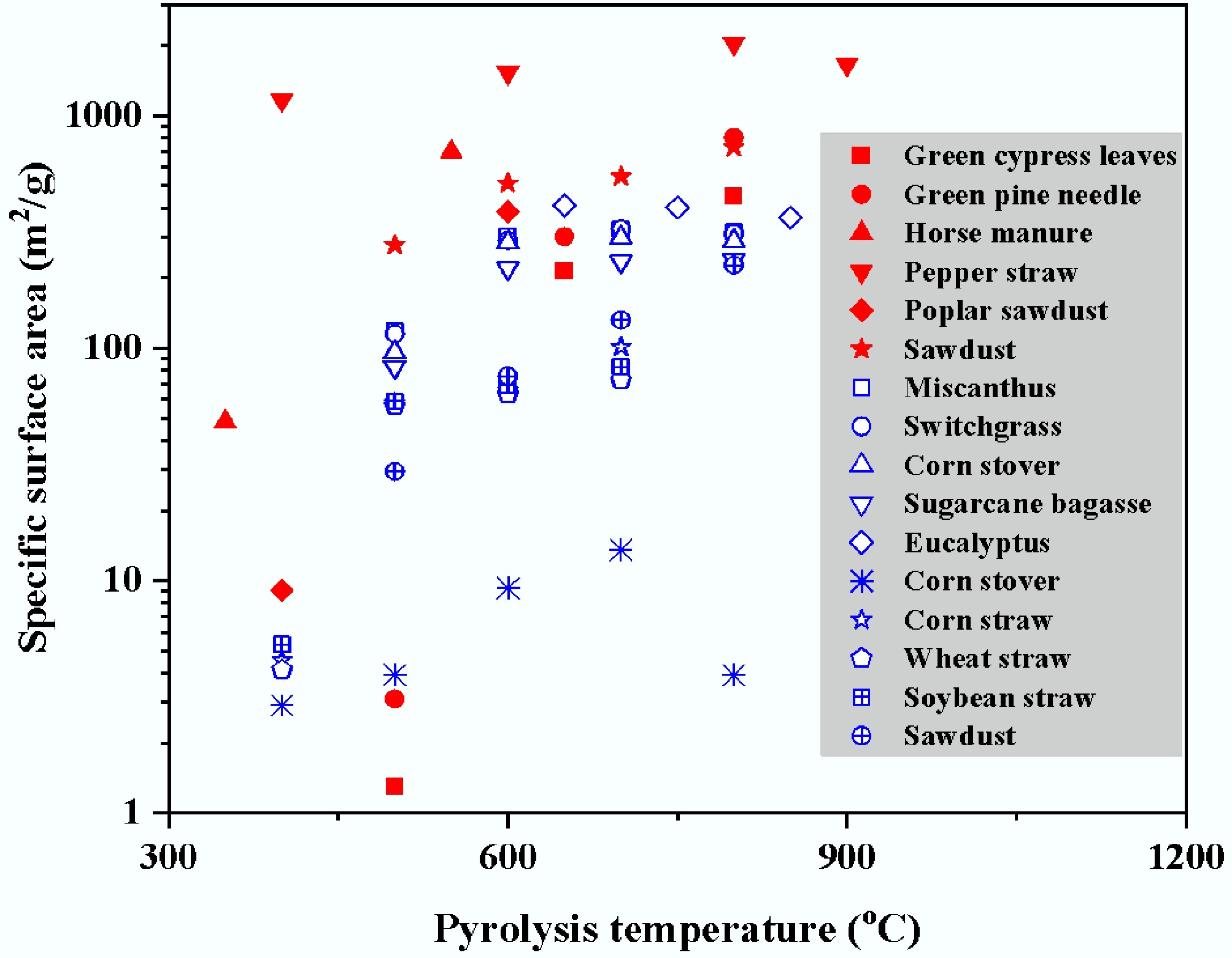

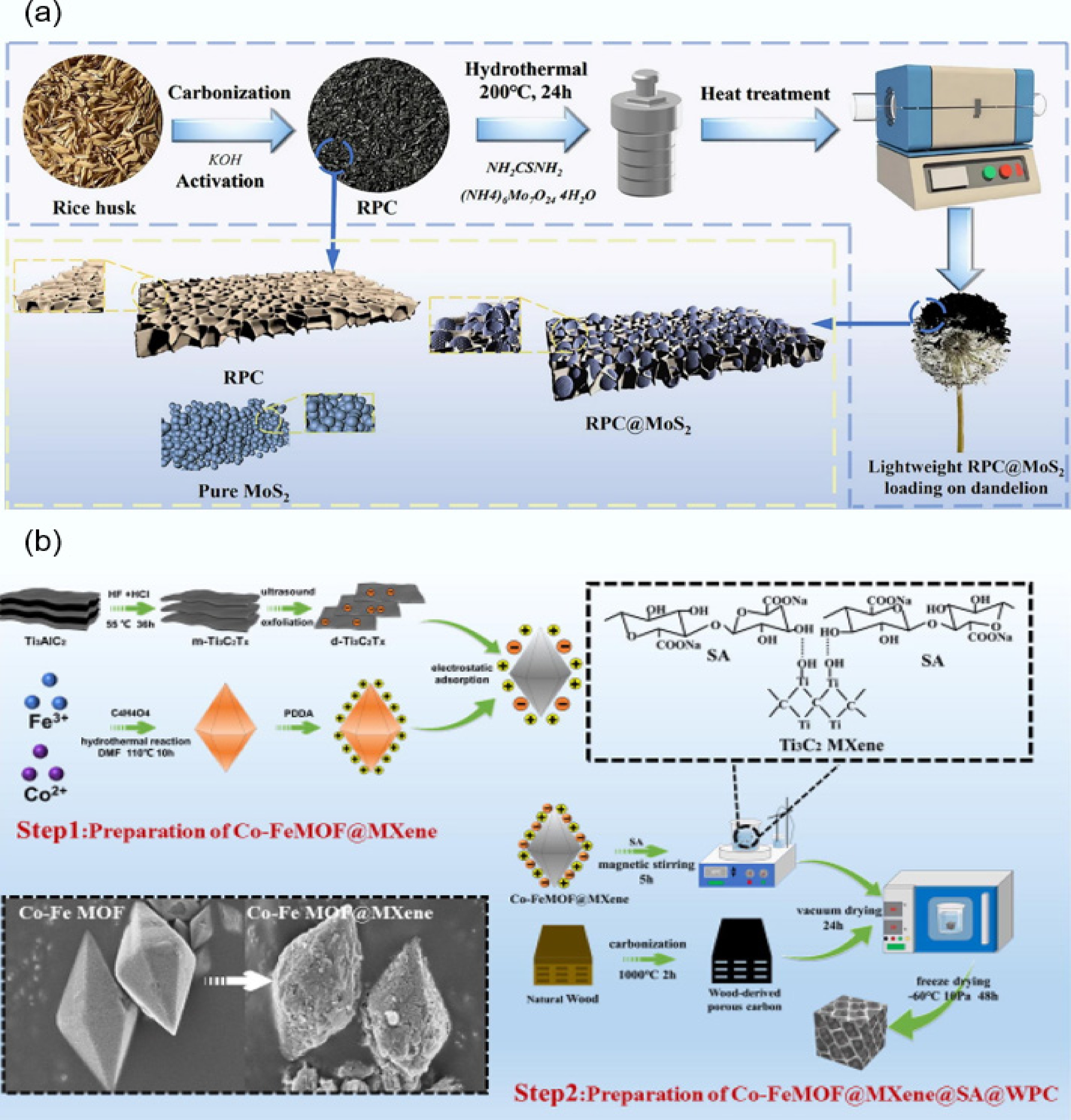

Feedstock Pyrolysis condition SSA (m2/g) PV (cm3/g) Ref. Biosolids 400–800 °C 54.60–148.71 0.119–0.150 [182] Corn stalk 700–900 °C 26.52–323.33 0.041–0.196 [168] Green cypress leaves 500–800 °C 1.30–452.10 0.060–0.338 [173] Green pine needle 500–800 °C 3.10–805.90 0.181–0.475 [173] Horse manure 350–550 °C 48.30–698.40 0.047–0.302 [153] Peanut shell 700–950 °C 10.76–67.29 0.011–0.084 [168] Pepper straw 400–900 °C 1,162.68–2,038.61 0.470–0.870 [174] Poplar sawdust 400–600 °C 9.10–385.00 0.040–0.200 [175] Poplar wood chip 450–650 °C 47.43–71.30 [183] Rice husk 700–900 °C 21.67–237.81 0.025–0.168 [168] Sawdust 500–800 °C 276.30–729.20 0.126–0.361 [176] Sludge 400–600 °C 12.58–99.07 0.037–0.182 [184] Sludge + cotton stalk 400–600 °C 8.19–57.40 0.024–0.103 [184] Solid digestate 300–500 °C 37.50–207.50 0.082–0.224 [185] Sugar cane bagasse 350–550 °C 3.11–25.14 0.003–0.020 [186] Waste crustaceous shell 400–800 °C 164.00–258.00 0.076–0.119 [187] Activated sludge 400–1,000 W 167.00–323.00 [188] Corn stalk 100–600 W 0.68–325.23 0.012–0.127 [111] Corn stalk 400–600 W 97.22–296.76 0.096–0.202 [168] Corn stover 500–1,800 W 0.59–43.18 0.003–0.017 [189] Cow dung 300–1,000 W 50.58–126.99 0.045–0.119 [190] Cow dung 300–1,000 W 18.13–113.81 0.000–0.082 [190] Hemp stem 500–1,800 W 1.15–69.38 0.003–0.019 [189] Palm kernel shell 550–750 W 100.00–270.00 0.030–0.110 [191] Peanut shell 400–600 W 11.37–35.66 0.011–0.041 [168] Rice husk 300–1,000 W 1.36–172.04 0.003–0.123 [192] Rice husk 400–600 W 52.33–182.80 0.054–0.122 [168] Rice straw 150–250 W 31.60–122.20 0.034–0.083 [177] Waste bamboo chopsticks 200–450 W 166.00–414.00 0.008–0.120 [193] Wheat straw 100–600 W 1.22–312.62 0.020–0.162 [163] Wheat straw 100–600 W 13.47–190.35 0.002–0.131 [194] Young durian fruit 450–800 W 6.66–19.33 0.017–0.038 [195] Activated sludge 3–10 min 176.00–310.00 [188] Biosolids 10–30 min 39.67–148.81 0.102–0.169 [182] Canola seed 4–10 min 8.00–97.00 [196] Corn stalk 60–180 min 28.31–268.78 0.070–0.188 [168] Cow dung 5–20 min 2.22–50.58 0.000–0.045 [190] Cow dung 5–20 min 71.51–113.81 0.067–0.082 [190] Cow dung 5–20 min 74.10–95.50 0.065–0.081 [190] Enteromorpha 10–30 min 473.44–693.65 [197] Enteromorpha 10–30 min 995.69–1,403.83 [197] Municipal sewage sludge 90–150 min 47.99–51.70 [160] Peanut shell 60–180 min 4.68–26.70 0.008–0.030 [168] Pulp and paper mill sludge 60–120 min 398.00–570.00 [198] Reed canary grass 7–28 min 457.00–517.00 [199] Rice husk 5–15 min 63.43–172.04 0.052–0.123 [192] Rice husk 60–180 min 22.32–190.47 0.024–0.160 [168] Spent brewery grain 20–30 min 1,011.00–1,072.00 [200] Wheat straw 3–15 min 254.00–312.62 [163] Table 3.

SSAs and PVs of biochars obtained under different microwave pyrolysis conditions

-

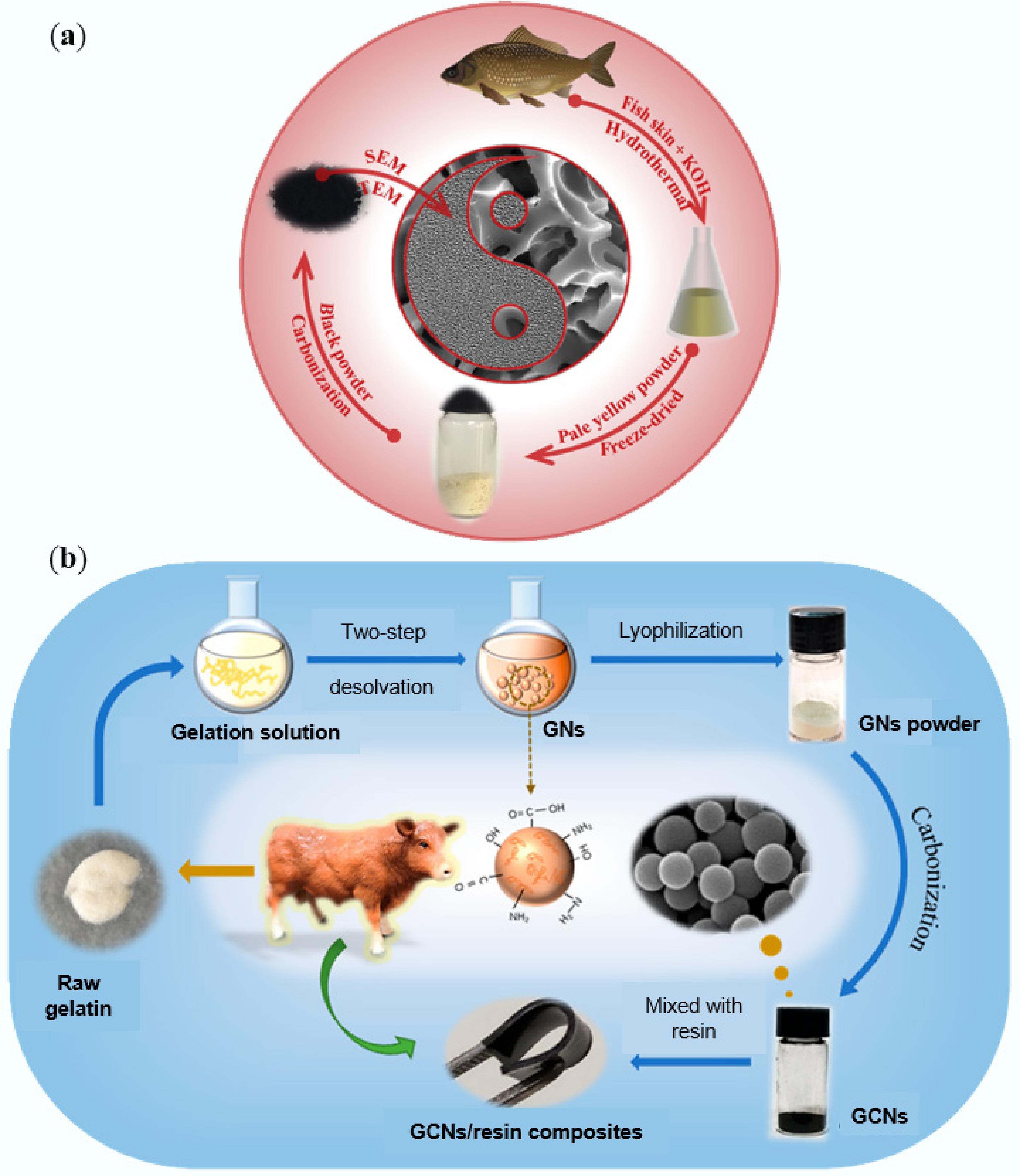

Material Pyrolysis condition RLmin (dB) EAB (GHz) Ref. Apple 600–900 °C, 2 h –72.6 5.3 [228] Bacterial cellulose 800 °C, 2 h –53.3 4.2 [229] Bamboo fiber 900 °C, 2 h –75.2 4.6 [230] Cellulose 640–700 °C, 2 h –49.2 8.2 [231] Cellulose dispersion 600–900 °C –55.4 2.4 [232] Coconut shell 450–650 °C –48.9 7.9 [233] Coconut shell 1,100 °C, 4 h –54.2 4.2 [234] Coffee grounds 650–800 °C, 1–4 h –52.7 6.4 [235] Cotton fiber 800 °C, 1 h –60.9 6.1 [236] Dried teak wood 800 °C, 2 h –64.7 5.3 [237] Gelatin 600–800 °C, 2 h –50.9 3.5 [238] Kelp 700 °C, 1 h –75.0 4.8 [239] Loofah sponges 600–900 °C, 2 h –66.8 5.5 [240] Peanut shell 1,100 °C, 2 h –66.4 3.5 [241] Pine needle 700–900 °C, 2 h –56.3 3.4 [242] Pine nut shell 170 °C, 14 h –57.4 6.4 [243] Rice husk 800 °C, 2 h –68.1 5.0 [244] Rose 1,000 °C, 1 h –47.9 4.1 [245] Tremella 600 °C, 1 h –77.9 8.5 [246] Walnut shell 750 °C, 2 h –67.6 5.4 [247] Water chestnut 600 °C, 2 h –60.8 6.0 [248] Wheat straw 800 °C, 1.5 h –54.0 6.0 [249] Almond wood shell 1,000 °C, 2 h –37.9 7.0 [250] Dried ballonflower 900 °C, 4 h –47.0 5.5 [251] Laver 650 °C, 2 h –35.7 12.3 [252] Soybean dregs 900 °C, 1 h –18.5 4.8 [253] Tremella 650 °C, 1 h –34.6 8.8 [254] Table 4.

Comparative study of biocarbon-based microwave absorption materials

-

Raw material Preparation condition SSA

(m2/g)Current density (A/g) Capacitance

(F/g)Ref. Aloe vera 700 °C, 1 h 1,890 0.5 410 [282] Anthracite 900 °C, 2 h 2,814 0.5 325 [283] Castor shell 800 °C, 4 h 1,527 1 365 [284] Cellulose 650 °C, 2.5 h 1,588 0.5 288 [285] Chili straw 800 °C, 1 h 2,768.5 1 352 [24] Crab shells/

rice husks700 °C, 3 h 3,557 0.5 474 [286] Crop straw 800 °C, 1 h 1,058.4 1 317 [287] Corn gluten meal 500 °C 3,353 0.5 488 [288] Corn stalk 800 °C, 2 h 2,054 0.5 461 [289] Corn stover 820 °C, 1 h 1,432.9 0.1 246 [290] Cotton seed husk 700 °C, 1 h 1,694.1 0.5 238 [291] Cotton stalk 800 °C, 2 h 1,964.5 0.2 254 [292] Cotton stalk 1,000 °C 327 1 1,214 [293] Kapok wood 700 °C, 1 h 2,909.8 0.2 380 [294] Moringa leaves 800 °C, 2 h 1,327 50 234 [295] Peanut shell 800 °C, 1 h 1,138 0.2 447 [296] Rice husk 800 °C, 2 h 3,263 0.5 315 [297] Rice straw 700 °C, 1 h 3,333 0.1 400 [298] Rice straw 850 °C, 2 h 2,537 0.5 324 [299] Sargassum 800 °C, 20 min 1,367.6 1.0 531 [26] Shaddock endotheliums 750 °C, 1 h 1,265 0.2 550 [300] Sisal 750 °C 2,289 0.5 415 [301] Bagasse 700 °C, 1 h 2,296 0.5 180 [302] Rice husk 600 °C, 1 h 454.6 0.5 130.3 [303] Sword bean shell 700 °C, 2 h 2,282 1.0 264 [304] Tea leaves 1,200 °C 911.9 1 167 [305] Withered rose 800 °C, 1.5 h 1,911 0.5 208 [306] Table 5.

Preparation methods of biochar, electrolyte, and application in supercapacitors

Figures

(20)

Tables

(5)