-

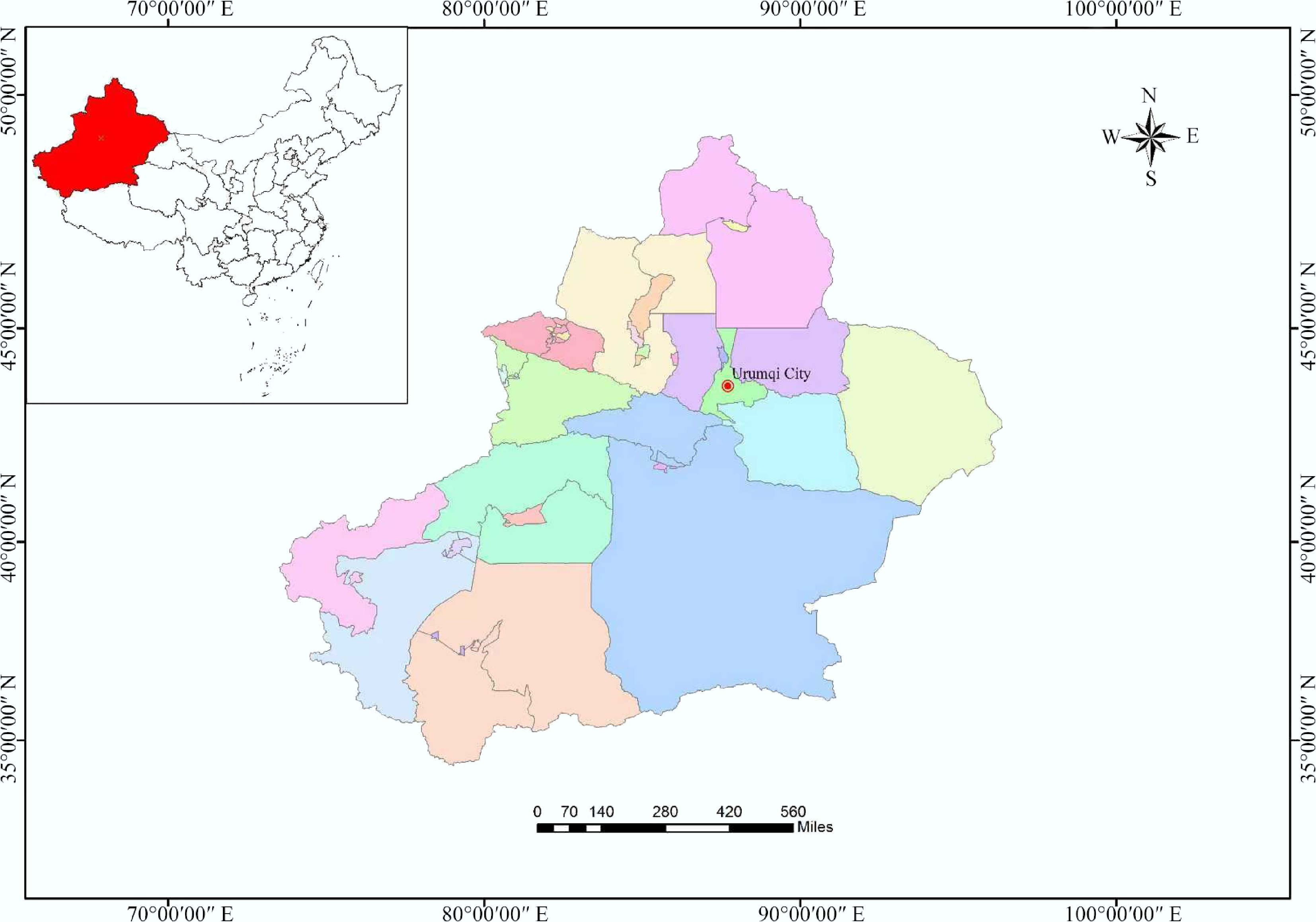

Figure 1.

Map of Xinjiang Province.

-

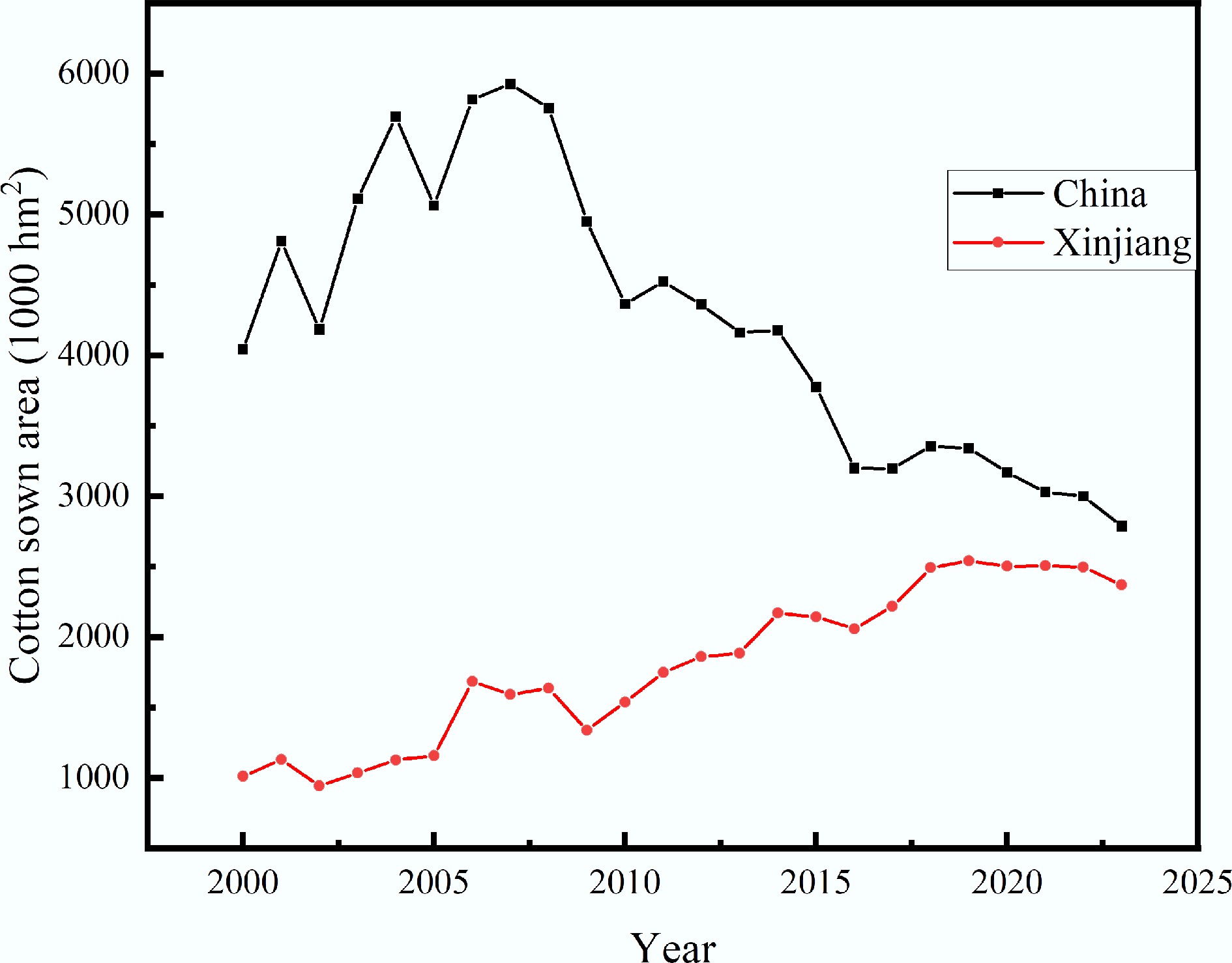

Figure 2.

Changes in cotton planting area from 2000 to 2023.

-

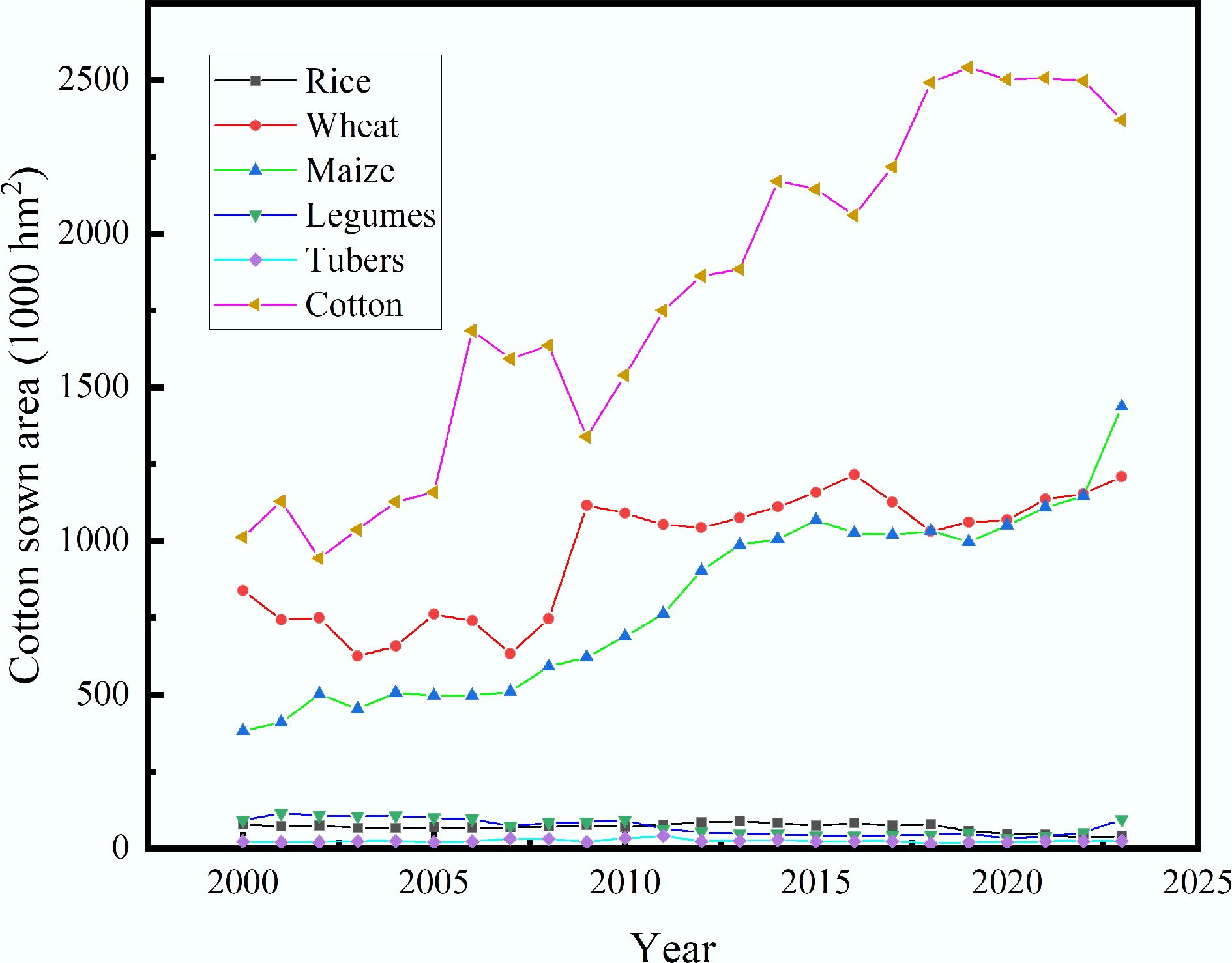

Figure 3.

Cultivated area of major crops in Xinjiang Province.

-

Parameter Value1 Parameter

code2Calculation process Ref. The heat energy generated during biochar production can replace the combustion of

fossil fuelsTotal amount of straw feedstock (t) 2.64 × 107 A1 Eq. (2) This study Biogas yield (%) 35% A2 [22] Calorific value of biogas (MJ·kg−1) 6 A3 [23] Electricity conversion coefficient (%) 35% A4 [24] CO2 emissions from power generation (kg·kWh−1) 0.8426 A5 [25] Electricity output during biochar production (kWh) 5.39 × 109 A6 A1 × A2 × A3 × A4/3.6 × 1,000 —3 CO2 emissions reduction from coal substitution (t) 4.54 × 106 A7 A6 × A5/1,000 — Calculation of biochar yield and carbon sequestration rate Biochar yield (%) 30.34% (m), 31.71% (w), 37.5% (c) A8 [26,27] Biochar carbon content (%) 59.76% (m), 62.89% (w), 73.4% (c) A9 [26, 28] The ratio of biochar's stable component (%) 80% A10 [21] C-CO2 conversion coefficient 3.67 A11 — Total biochar produced (t) 8.76 × 106 A12 Eq. (4) This study Amount of carbon sequestered via soil application of biochar (t) 4.62 × 106 A13 Eq. (5) This study Amount of CO2 sequestered via soil application of biochar (t) 1.70 × 107 A14 A13 × A11 — The inhibition of N2O emissions by biochar The rate of N2O emission suppression by biochar (%) 87% A15 [29] N2O emissions (kg·hm−2) 1.86 (m), 1.54 (w), 2.10 (c) A16 [12, 30] Proportion of biochar applied to soil (t·hm−2) 50 A17 [31] Area available for biochar application (hm2) 6.74 × 104 (m), 3.82 × 103 (w),

6.97 × 104 (c)A18 A12 /A17 — N2O-CO2 conversion coefficient 298 A19 [21] The reduction in N2O emissions (t) 241.53 A20 ∑A15 × A16 × A18/1,000 — The reduction in CO2 emissions (t) 7.2 × 104 A21 A20 × A19 — Fertilizer reduction from biochar application (calculated in CO2e) Fertilizer input rate (kg·hm−2) 167.41 (N); 98.66 (P); 35.44 (K) A22 [32] Reduction amount of agricultural fertilizer input (%) 10% (N); 5% (P); 10% (K) A23 [31] CO2e emission amount from fertilizer production (kg) 3; 0.7; 1 A24 [21] CO2e emission avoidance from reduced fertilizer application (t) 8.06 × 103 A25 ∑A18 × A22 × A23 × A24 — Greenhouse gas emissions from the storage and transportation of biochar and feedstock Greenhouse gas emission factor from the storage and transportation of straw (kg·t−1) 27.53 A26 [33] Emissions of CO2e per ton for biochar (kg) 45.32 A27 [34] CO2e emissions from straw feedstock (t) 7.27 × 105 A28 A1 × A26 — Emissions of CO2e attributable to biochar (t) 3.97 × 105 A29 A12 × A27 — Total emissions (CO2e) (t) 1.12 × 106 A30 A28 + A29 Net reduction in greenhouse gas emissions (CO2e) (t) 2.05 × 107 A32 A7 + A14 + A21 + A25–A30 — 1 m, w, and c represent maize, wheat, and cotton, respectively. 2 Parameter codes are assigned to illustrate calculation procedures. 3 — indicates that the relevant data is derived via calculation. Table 1.

Relevant parameters and estimated potential for greenhouse gas mitigation through biochar production from major collectible crop straw resources in Xinjiang, 2023

-

Parameter Value Parameter

code1Calculation Ref. The heat energy generated during biochar production can replace the combustion of fossil fuels Total amount of cotton stalk (t) 9.29 × 106 B1 Eq. (2) This study Biogas yield (%) 35.82% B2 [38] Calorific value of biogas (MJ·kg−1) 10.9 B3 [39] Electricity conversion coefficient (%) 35% B4 [24] CO2 emissions from power generation (kg·kWh−1) 0.8426 B5 [25] Electricity output during biochar production (kWh) 3.53 × 109 B6 B1 × B2 × B3 × B4 / 3.6 × 1,000 —2 CO2 emissions reduction from coal substitution (t) 2.97 × 106 B7 B6 × B5/1,000 — Calculation of biochar yield and carbon sequestration rate Biochar yield (%) 37.5% B8 [27] Biochar carbon content (%) 73.4% B9 [28] The ratio of biochar's stable component (%) 80% B10 [21] C-CO2 conversion coefficient 3.67 B11 — Total biochar produced (t) 3.48 × 106 B12 Eq. (4) This study Amount of carbon sequestered via soil application of biochar (t) 2.04 × 106 B13 Eq. (5) This study Amount of CO2 sequestered via soil application of biochar (t) 7.5 × 106 B14 B13 × B11 — The inhibition of N2O emissions by biochar The rate of N2O emission suppression by biochar (%) 87% B15 [29] N2O emissions (kg·hm−2) 2.10 B16 [30] Proportion of biochar applied to soil (t·hm−2) 50 B17 [31] Area available for biochar application (hm2) 6.97 × 104 B18 B12 /B17 — N2O-CO2 conversion coefficient 298 B19 [21] The reduction in N2O emissions (t) 127.34 B20 ∑B15 × B16 × B18/1,000 — The reduction in CO2 emissions (t) 3.79 × 104 B21 B20 × B19 — Fertilizer reduction from biochar application (calculated in CO2e) Fertilizer input rate (kg·hm−2) 167.41 (N); 98.66 (P); 35.44 (K) B22 [32] Reduction in fertilizer input (%) 10% (N); 5% (P); 10% (K) B23 [31] CO2e emissions amount from fertilizer production (kg) 3; 0.7; 1 B24 [21] CO2e emission avoided through reduced fertilizer application (t) 3.99 × 103 B25 B18 × B22 × B23 × B24/1,000 — Greenhouse gas emissions from the storage and transportation of biochar and feedstock Greenhouse gas emission factor from the storage and transportation of straw (kg·t−1) 27.53 B26 [33] Emissions of CO2e per ton for biochar (kg) 45.32 B27 [34] CO2e emissions from cotton stalk (t) 2.56 × 105 B28 B1 × B26 — Emissions of CO2e attributable to biochar (t) 1.58 × 105 B29 B12 × B27 — Total emissions (CO2e) (t) 4.14 × 105 B30 B28 + B29 Net reduction in greenhouse gas emissions (CO2e) (t) 1.01 × 107 B31 B7 + B14 + B21 + B25–B30 — 1 Parameter codes are assigned to illustrate the calculation procedures. 2 — indicates that the relevant data is derived via calculation. Table 2.

Relevant parameters and estimated potential for greenhouse gas mitigation through biochar production from all collectible cotton straw resources in Xinjiang in 2023

-

Parameter Value Parameter

code1Calculation Ref. The heat energy generated during biochar production can replace the combustion of fossil fuels Total amount of mulch film feedstock (t) 2.03 × 105 C1 Eq. (3) This study Biogas yield (%) 42% C2 [22] Calorific value of biogas (MJ·kg−1) 38.6 C3 [23] Electricity conversion coefficient (%) 35% C4 [24] CO2 emissions from power generation (kg·kWh−1) 0.8426 C5 [25] Electricity output during biochar production (kWh) 3.2 × 108 C6 C1 × C2 × C3 × C4/

3.6 × 1,000—2 CO2 emission reduction from coal substitution (t) 2.7 × 105 C7 C6 × C5/1,000 — Calculation of biochar yield and carbon sequestration rate Biochar yield (%) 1.65% C8 [22] Biochar carbon content (%) 8.91% C9 [22] The ratio of biochar's stable component (%) 80% C10 [21] C-CO2 conversion coefficient 3.67 C11 — Total biochar produced (t) 3.35 × 103 C12 Eq. (4) This study Amount of carbon sequestered via soil application of biochar (t) 2.39 × 102 C13 Eq. (5) This study Amount of CO2 sequestered via soil application of biochar (t) 8.76 × 102 C14 C13 × C11 — The inhibition of N2O emissions by biochar The rate of N2O emission suppression by biochar (%) 87% C15 [29] N2O emissions (kg·hm−2) 2.10 C16 [30] Proportion of biochar applied to soil (t·hm−2) 50 C17 [31] Area available for biochar application (hm2) 67 C18 C12 / C17 — N2O-CO2 conversion coefficient 298 C19 [21] The reduction in N2O emissions (t) 0.122 C20 C15 × C16 × C18/1,000 — The reduction in CO2 emissions (t) 36.48 C21 C20 × C19 — Fertilizer reduction from biochar application (calculated in CO2e) Fertilizer input rate (kg·hm−2) 167.41 (N); 98.66 (P); 35.44 (K); C22 [32] Reduction in fertilizer input (%) 10% (N); 5% (P); 10% (K) C23 [31] CO2e emissions from fertilizer production (kg) 3; 0.7; 1 C24 [21] CO2e emissions avoided through reduced fertilizer application (t) 3.83 C25 ∑C18 × C22 × C23 × C24/1,000 — Greenhouse gas emissions from the storage and transportation of biochar and feedstock Greenhouse gas emission factor from the storage and transportation of mulch film (kg·t−1) 21 C26 [33] Emissions of CO2e per ton for biochar (kg) 45.32 C27 [34] CO2e emissions from mulch film feedstock (t) 4.26 × 103 C28 C1 × C26 — Emissions of CO2e attributable to biochar (t) 1.52 × 102 C29 C12 × C27 — Total emissions (CO2e) (t) 4.41 × 103 C30 C28 + C29 Net reduction in greenhouse gas emissions (CO2e) (t) 2.67 × 105 C31 C7 + C14 + C21 + C25–C30 — 1 Parameter codes are assigned to illustrate calculation procedures. 2 — indicates that the relevant data is derived via calculation. Table 3.

Relevant parameters and estimated potential for greenhouse gas mitigation through biochar production from all recyclable mulch film in Xinjiang, 2023

-

Parameter Value Parameter code1 Calculation Ref. The heat energy generated during biochar production can replace the combustion of fossil fuels Total amount of cotton straw and mulch film feedstock (t) 1.02 × 106 D1 Eqs (2) and (3) This study Biogas yield (%) 32% D2 [38] Calorific value of biogas (MJ·kg−1) 21 D3 [38] Electricity conversion coefficient (%) 35% D4 [24] CO2 emissions from power generation (kg·kWh−1) 0.8426 D5 [25] Electricity output during biochar production (kWh) 6.66 × 108 D6 D1 × D2 × D3 × D4/3.6 × 1,000 —2 CO2 emissions reduction from coal substitution (t) 5.62 × 105 D7 D6 × D5/1,000 — Calculation of biochar yield and carbon sequestration rate Biochar yield (%) 22% D8 [38] Biochar carbon content (%) 69.91% D9 [22] The ratio of biochar's stable component (%) 80% D10 [21] C-CO2 conversion coefficient 3.67 D11 — Total biochar produced (t) 2.24 × 105 D12 Eq. (4) This study Amount of carbon sequestered via soil application of biochar (t) 1.25 × 105 D13 Eq. (5) This study Amount of CO2 sequestered via soil application of biochar (t) 4.6 × 105 D14 D13 × D11 — The inhibition of N2O emissions by biochar The rate of N2O emission suppression by biochar (%) 87% D15 [29] N2O emissions (kg·hm−2) 2.10 D16 [30] Proportion of biochar applied to soil (t·hm−2) 50 D17 [31] Area available for biochar application (hm2) 4.48 × 103 D18 D12 / D17 — N2O-CO2 conversion coefficient 298 D19 [21] The reduction in N2O emissions (t) 8.18 × 103 D20 ∑D15 × D16 × D18/1,000 — The reduction in CO2 emissions (t) 2.44 × 106 D21 D20 × D19 — Fertilizer reduction from biochar application

(calculated in CO2e)Fertilizer input rate (kg·hm−2) 167.41 (N); 98.66 (P); 35.44 (K) D22 [32] Reduction in fertilizer input (%) 10% (N); 5% (P): 10% (K) D23 [31] CO2e emissions from fertilizer production (kg) 3; 0.7; 1 D24 [21] CO2e emissions avoided through reduced fertilizer application (t) 256.35 D25 ∑D18 × D22 × D23 × D24 — Greenhouse gas emissions from the storage and transportation of biochar and feedstock Greenhouse gas emission factors from the storage and transportation of straw and mulch film (kg·t−1) 27.53, 21 D26 [33] Emissions of CO2e per ton for biochar (kg) 45.32 D27 [34] CO2e emissions from cotton straw and mulch film feedstock (t) 2.66 × 104 D28 D1 × D26 — Emissions of CO2e attributable to biochar (t) 1.02 × 104 D29 D12 × D27 — Total emissions (CO2e) (t) 3.68 × 104 D30 D28 + D29 Net reduction in greenhouse gas emissions (CO2e) (t) 3.43 × 106 D31 D7 + D14 + D21 + D25–D30 — 1 Parameter codes are assigned to illustrate calculation procedures. 2 — indicates that the relevant data is derived via calculation. Table 4.

Relevant parameters and estimated potential for greenhouse gas mitigation through biochar production from all recyclable mulch film and cotton straw at a ratio of 1:4 in Xinjiang, 2023

Figures

(3)

Tables

(4)