-

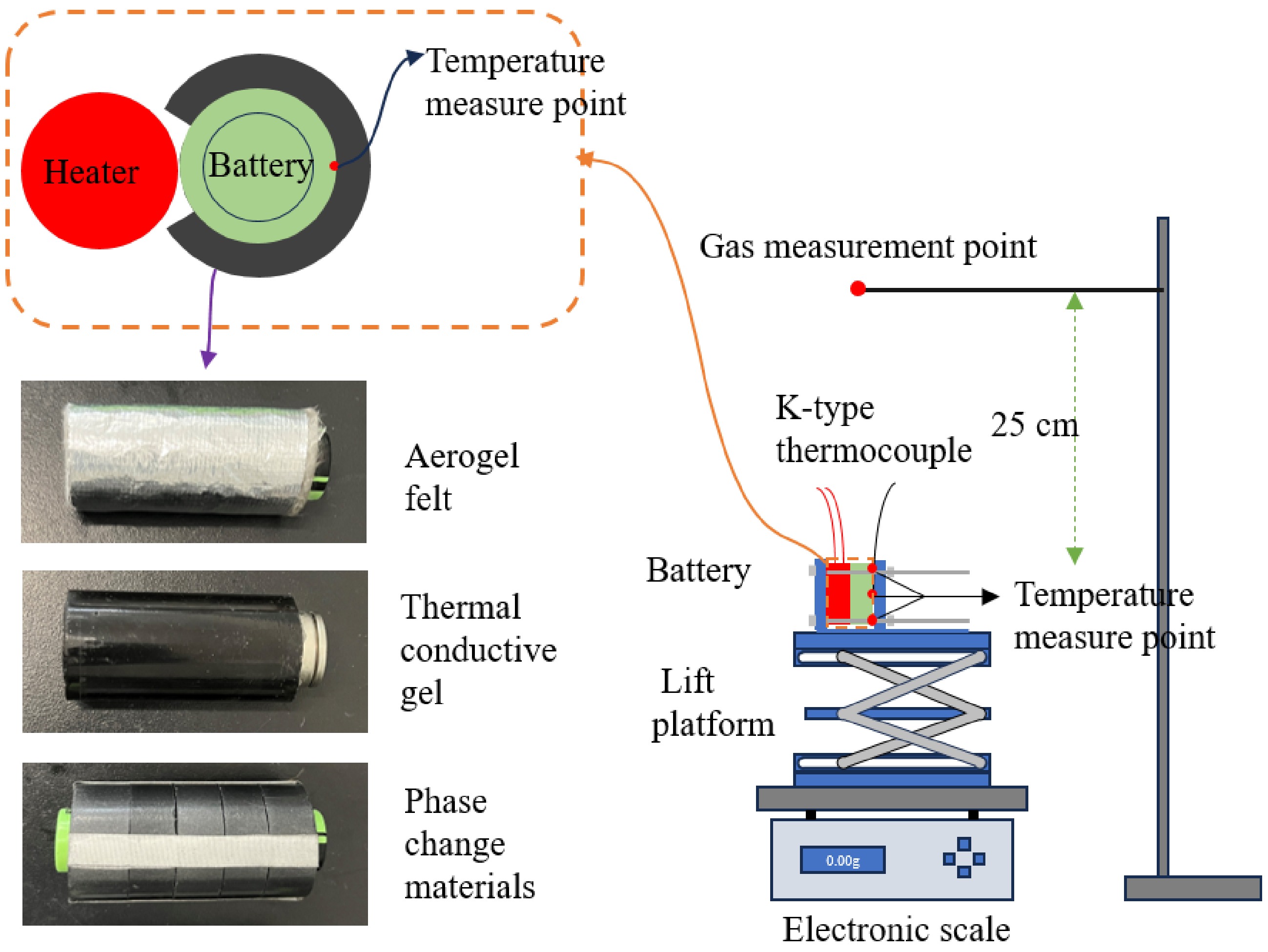

Figure 1.

Schematic diagram of the battery experimental test platform.

-

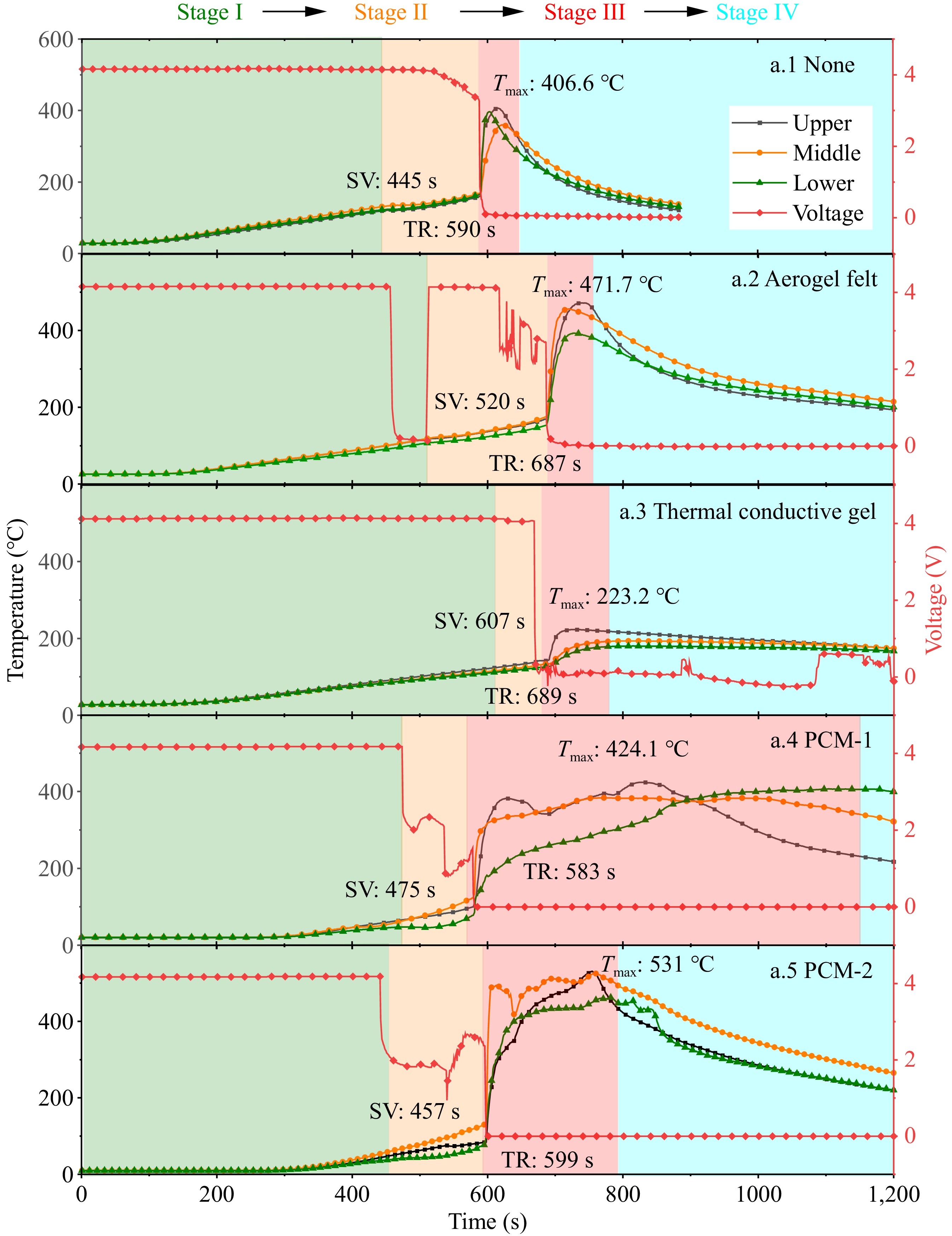

Figure 2.

Temperature and voltage changes during thermal runaway.

-

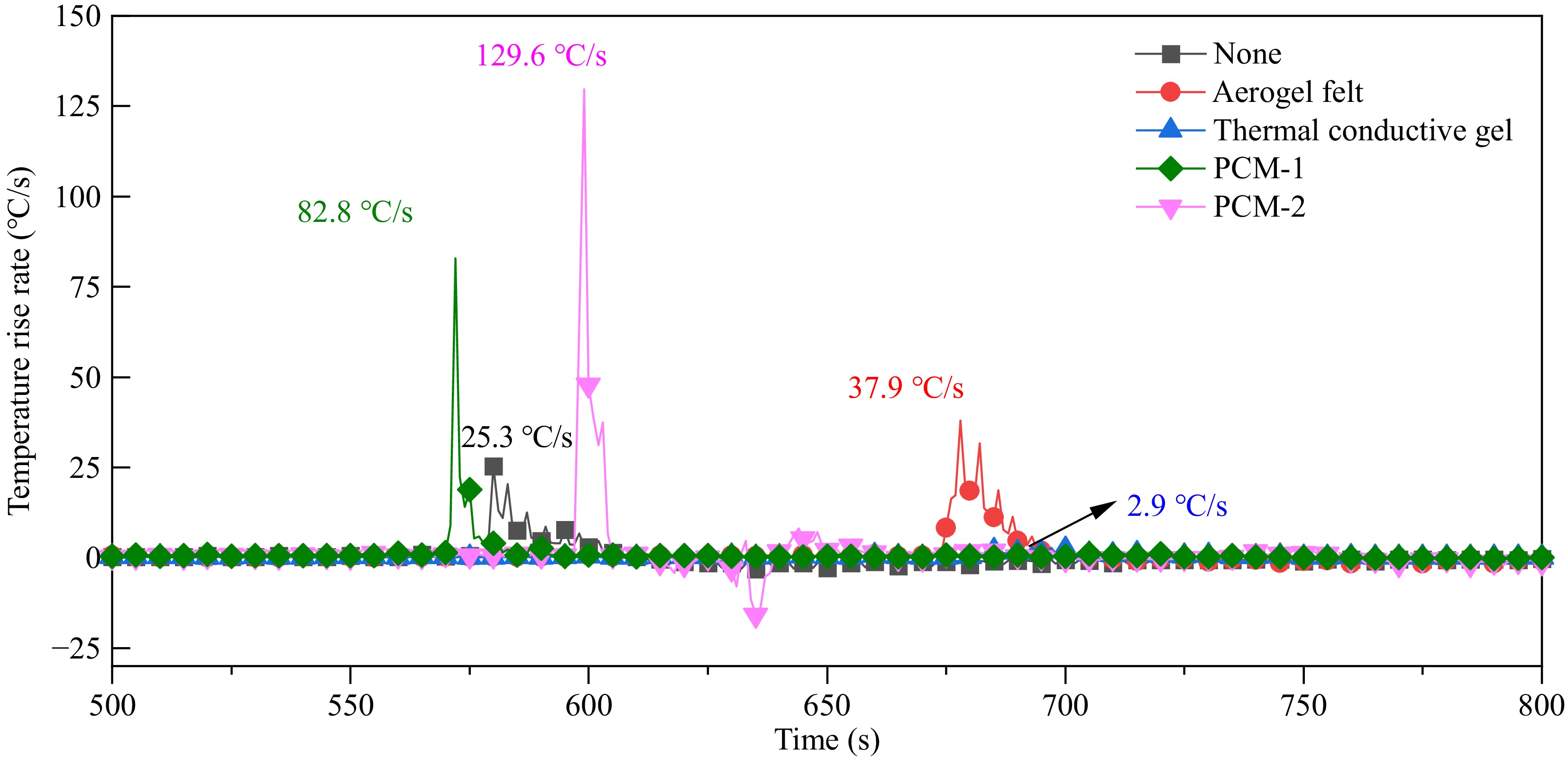

Figure 3.

Temperature rise rate during thermal runaway.

-

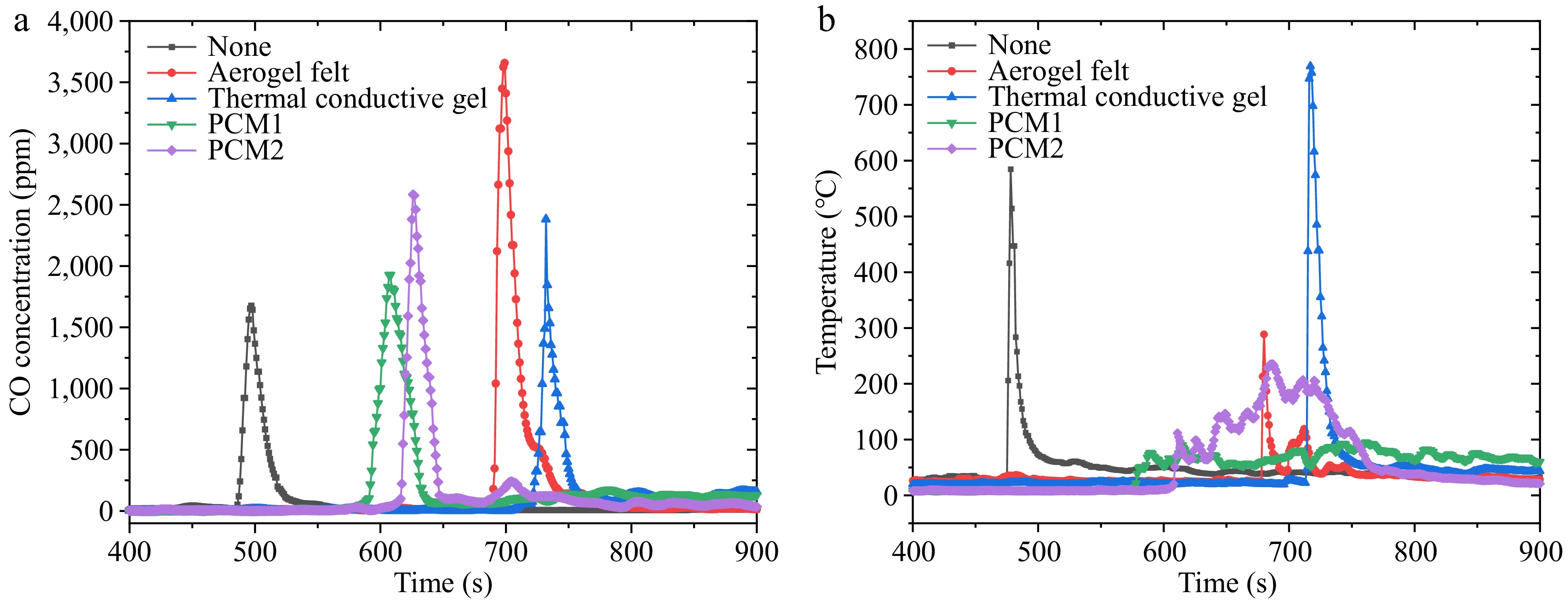

Figure 4.

CO concentration and gas temperature changes during thermal runaway.

-

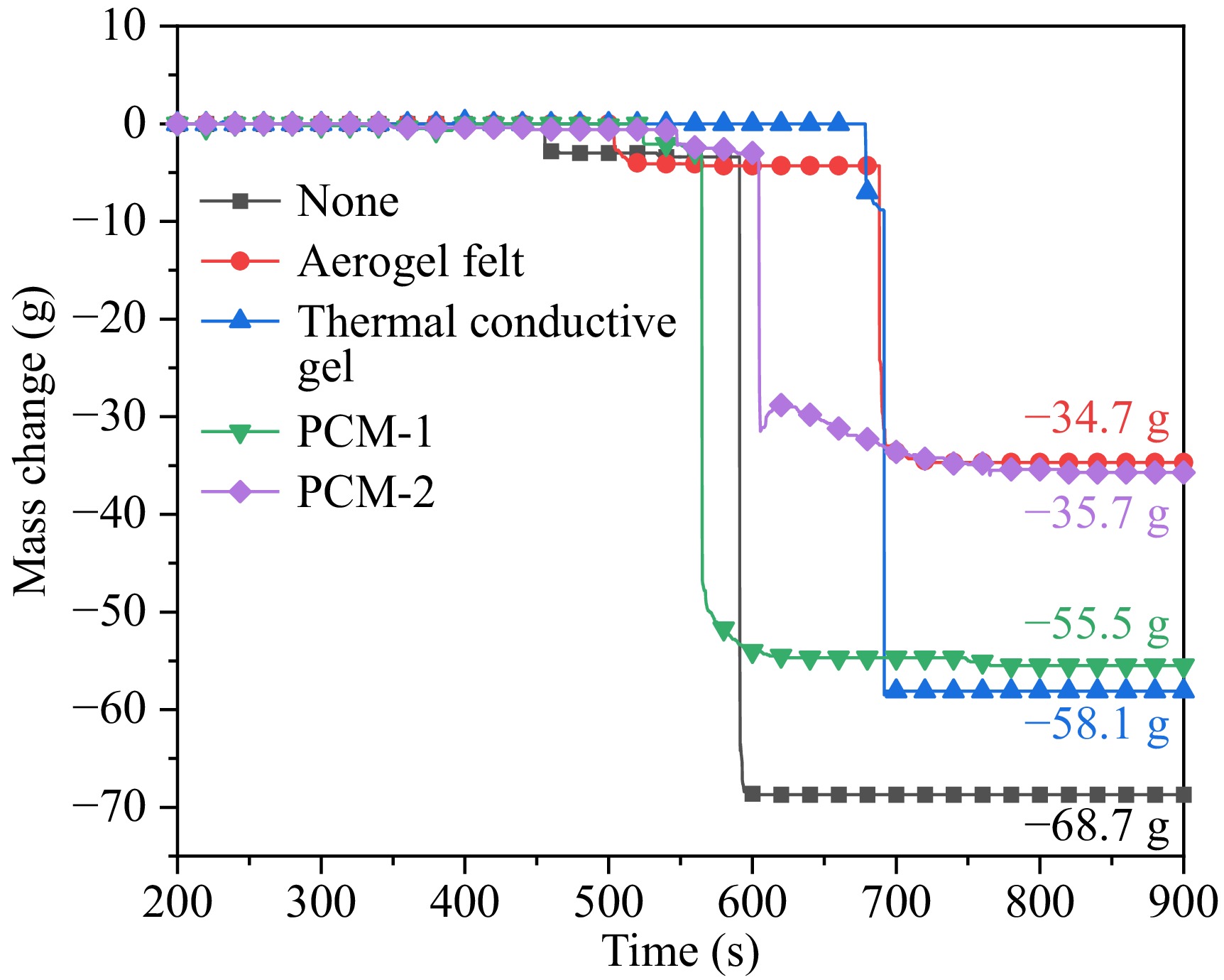

Figure 5.

Mass changes during thermal runaway.

-

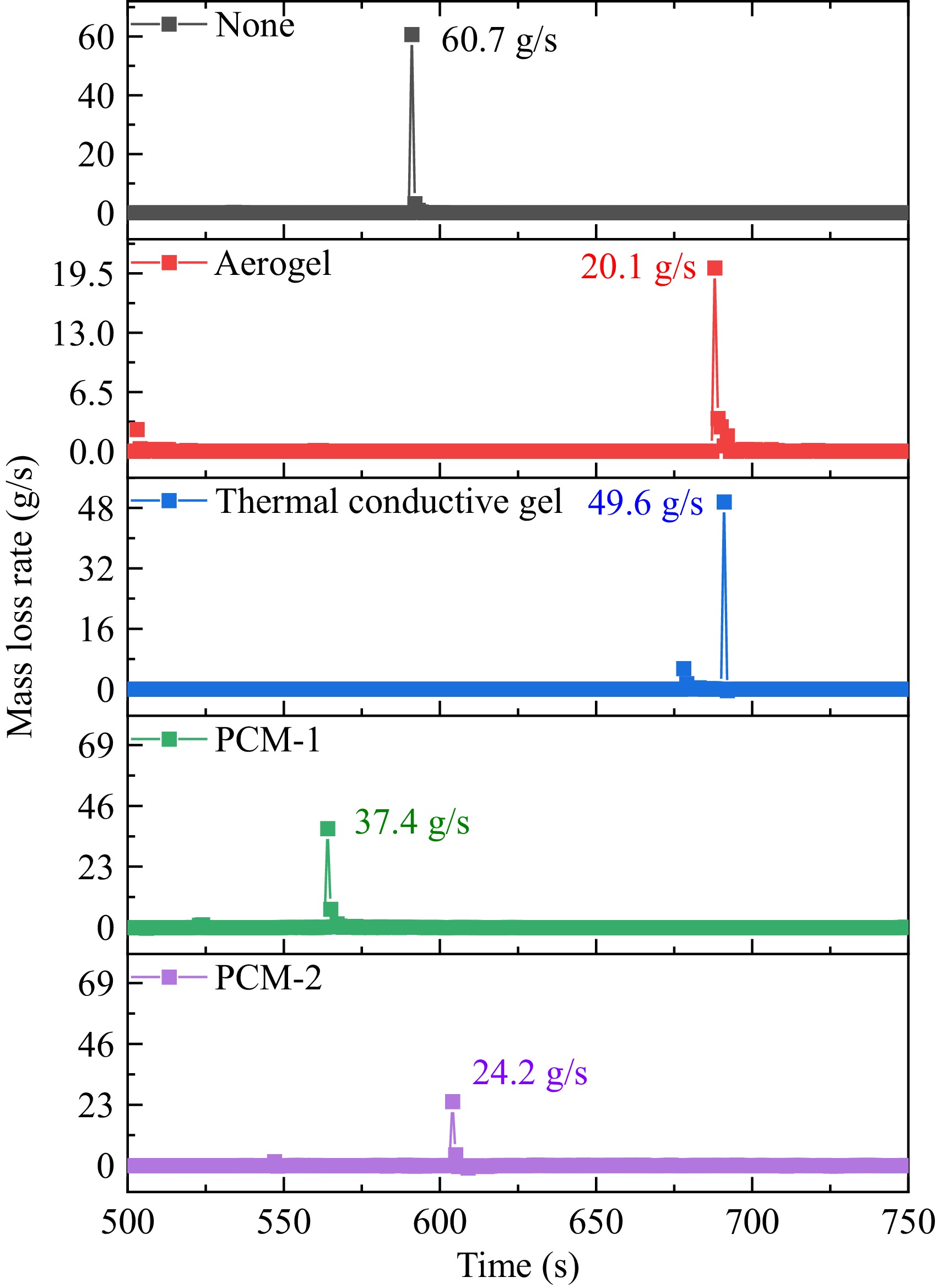

Figure 6.

Mass loss rate changes during thermal runaway.

-

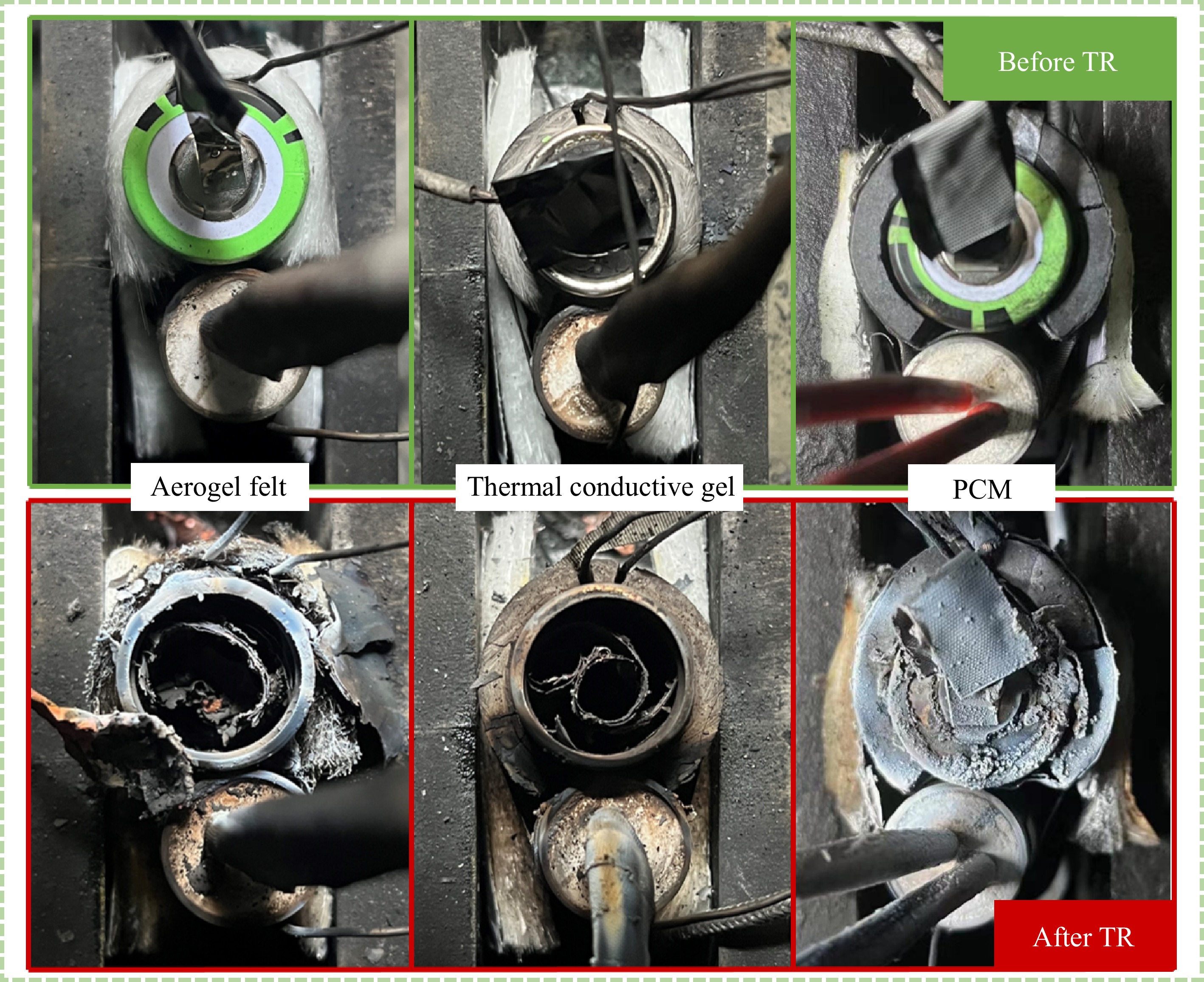

Figure 7.

Battery and material appearance before and after thermal runaway under different protection materials.

-

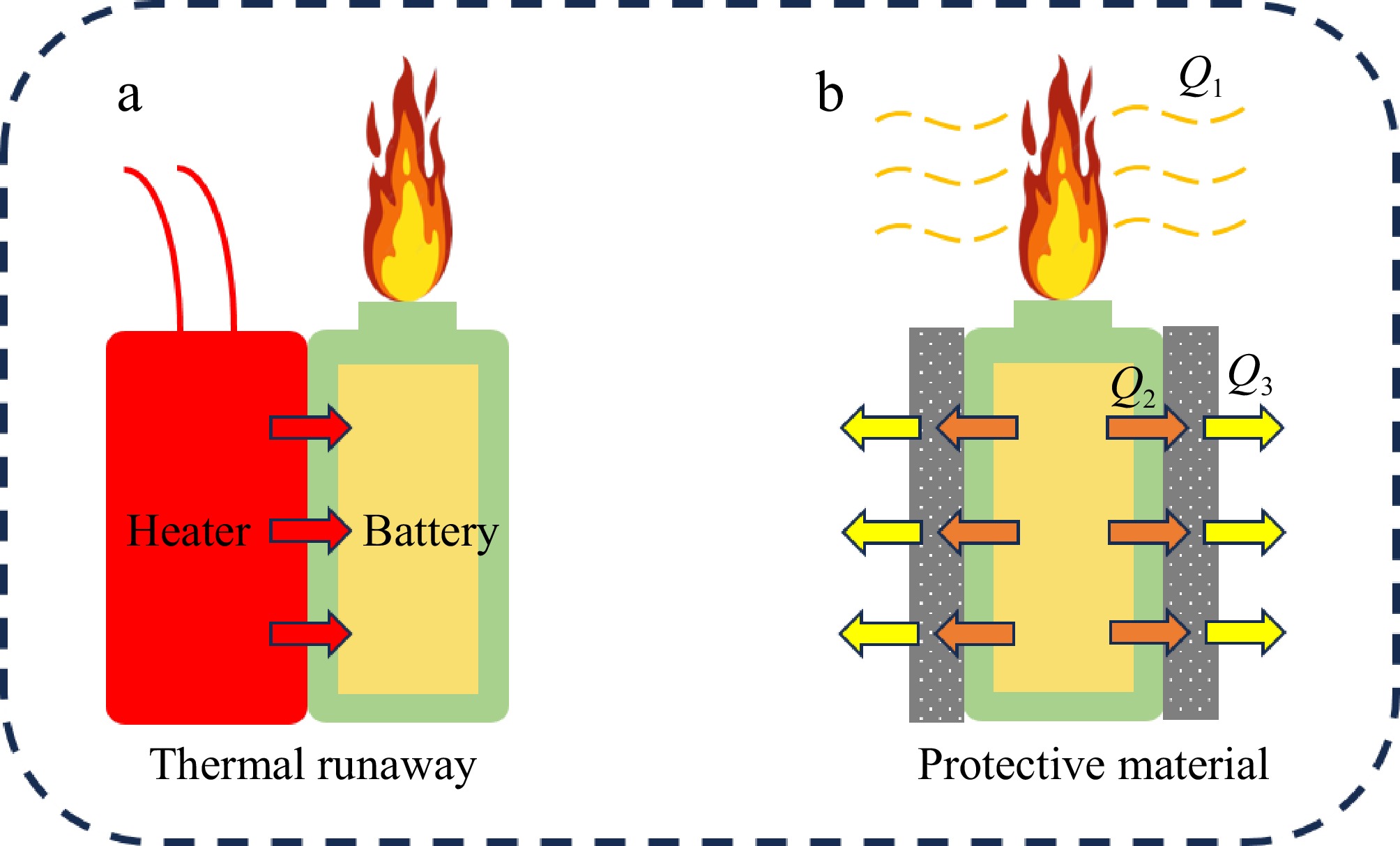

Figure 8.

Schematic diagram of thermal runaway heat transfer in battery.

-

Parameter Value Battery Panasonic NCR 21700T Capacity 4,800 mAh Voltage 3.7 V (discharge cut-off voltage 3.0 V, maximum charge voltage 4.2 V) Dimensions Φ 18 × 65 mm Anode Graphite Cathode NCA Electrolyte Solvents, salts, and additives Table 1.

Composition of 21700T lithium-ion battery.

-

Sample Mass content (wt%) PA EG Graphene DOPO PCM-1 93 7 0 0 PCM-2 85 5 8 2 Table 2.

Mass content of the components in the obtained CPCMs.

-

Protective material Safety valve

rupture time (s)Thermal runaway

occurs time (s)None 445 590 Aerogel felt 520 687 Thermal conductive gel 607 689 PCM-1 475 583 PCM-2 457 599 Table 3.

Starting time of safety valve rupture and thermal runaway.

Figures

(8)

Tables

(3)