-

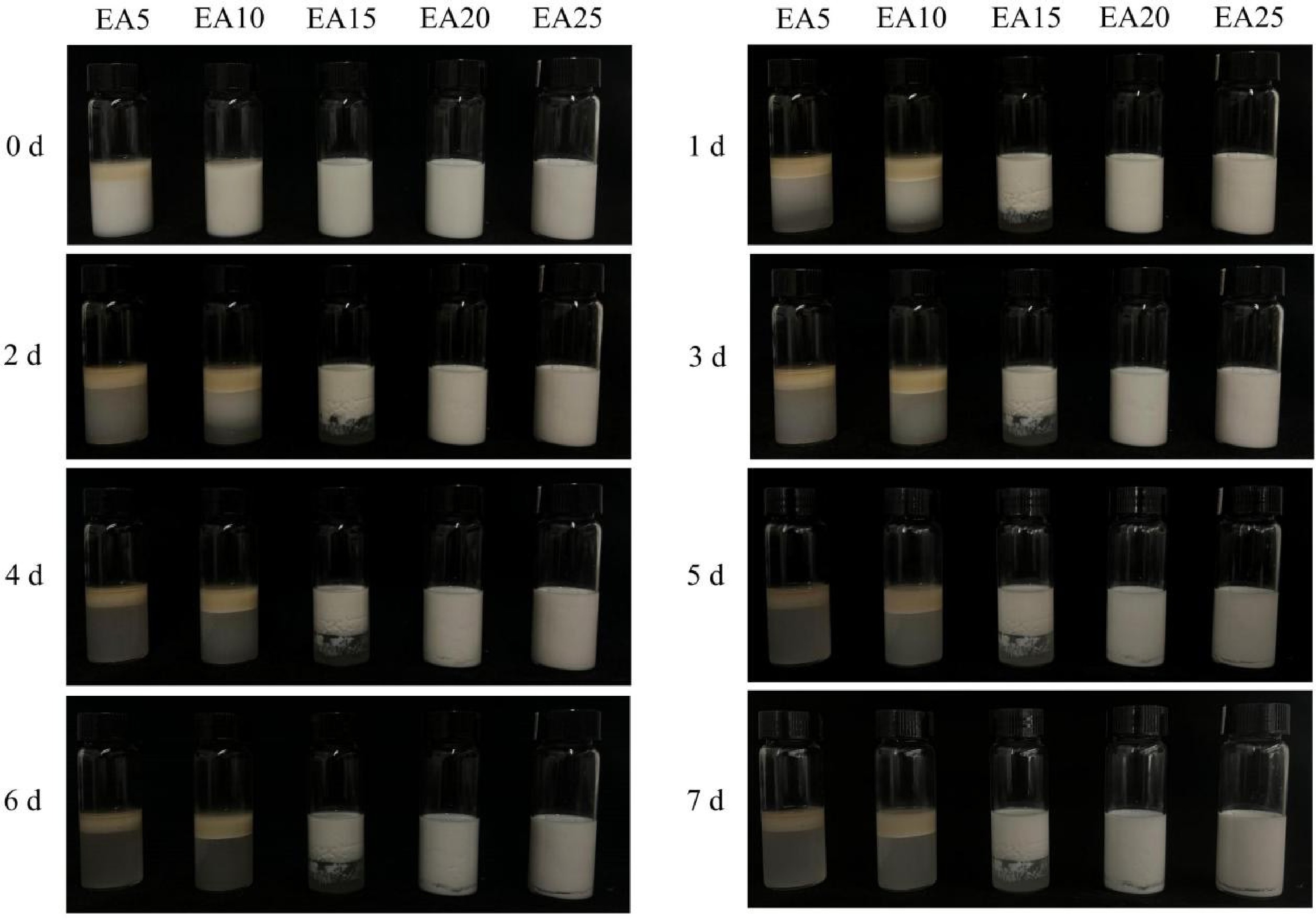

Figure 1.

Emulsion stability at different concentrations of gelatin-gum arabic.

-

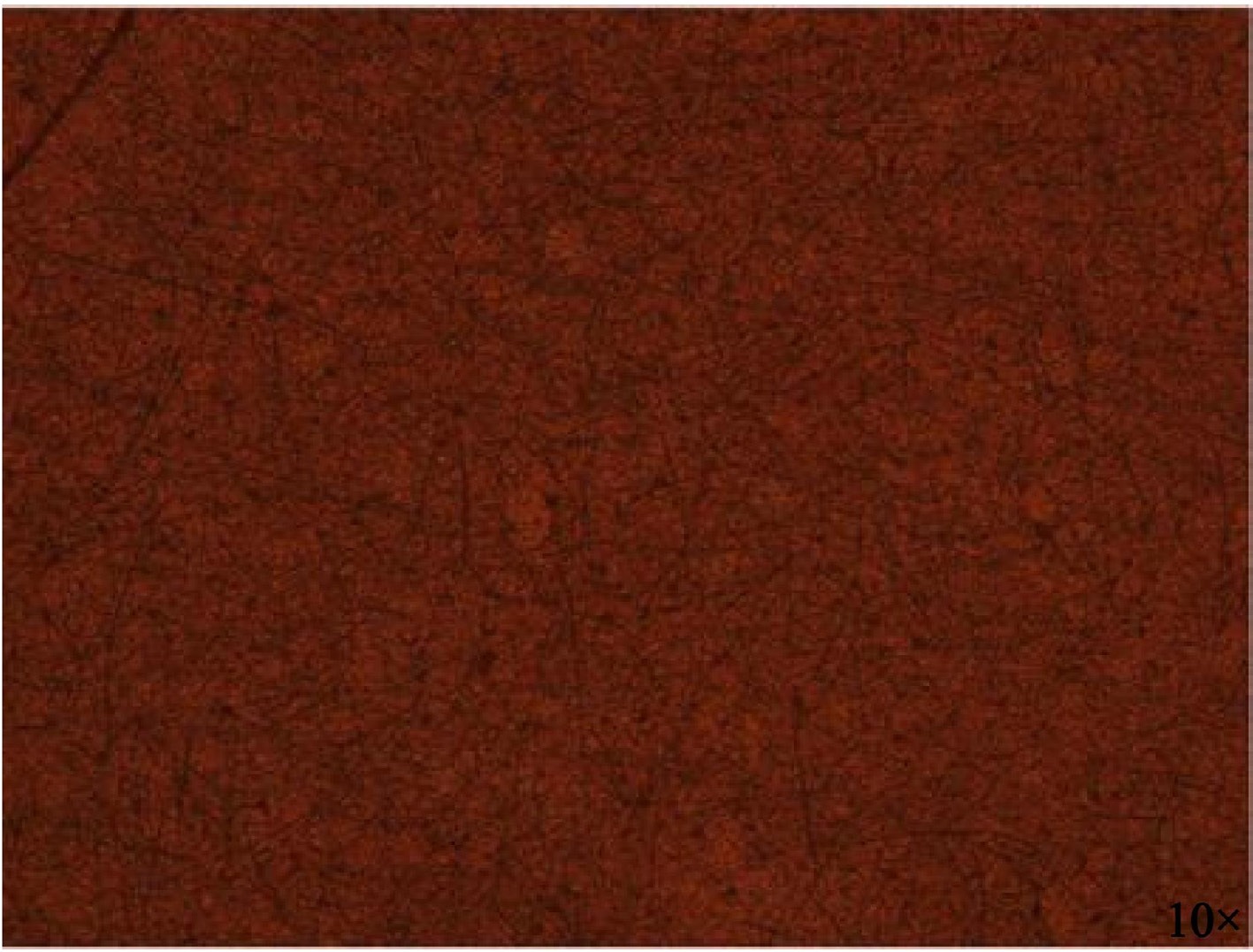

Figure 2.

Spinning fibers observed under a microscope.

-

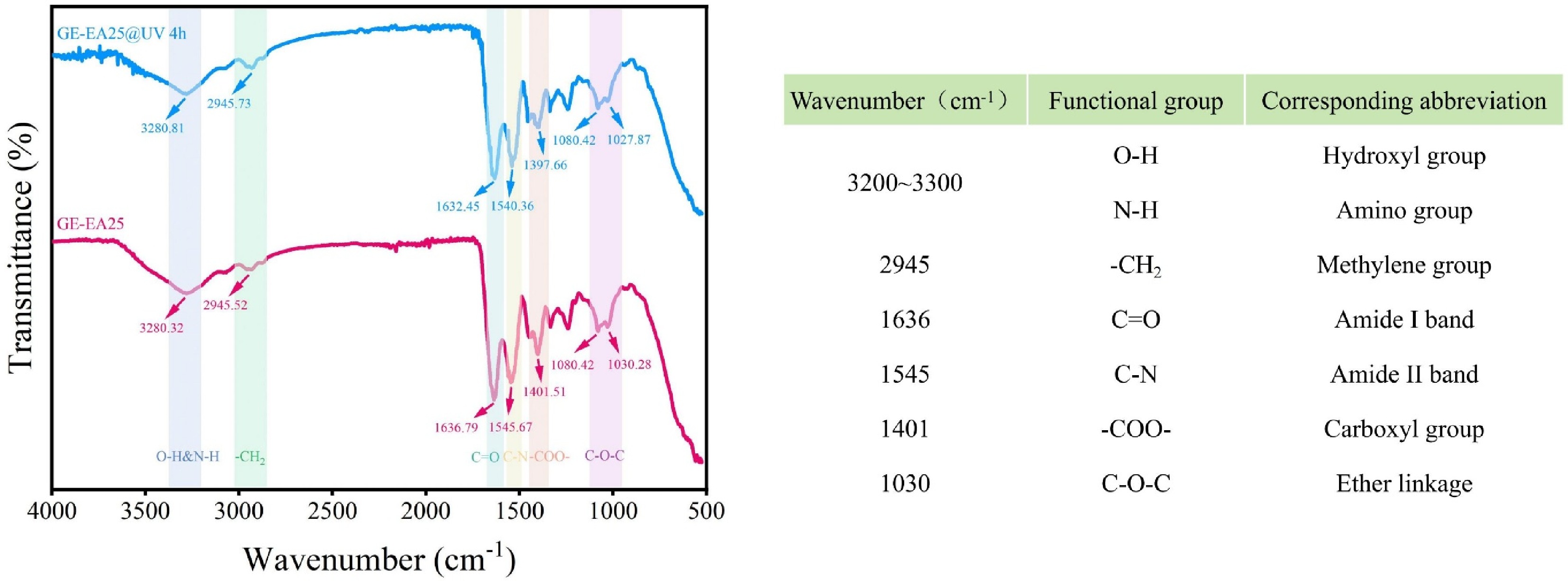

Figure 3.

Effect of UV irradiation on FT-IR of fibrous membranes (GE-EA25: Fiber film prepared with 20% (w/v) gelatin solution as the film-forming matrix and 25% (w/v) concentration of gelatin-gum arabic composite emulsifier; GE-EA25@UV 4 h: GE-EA25 composite fibrous membrane irradiated by UVC for 4 h).

-

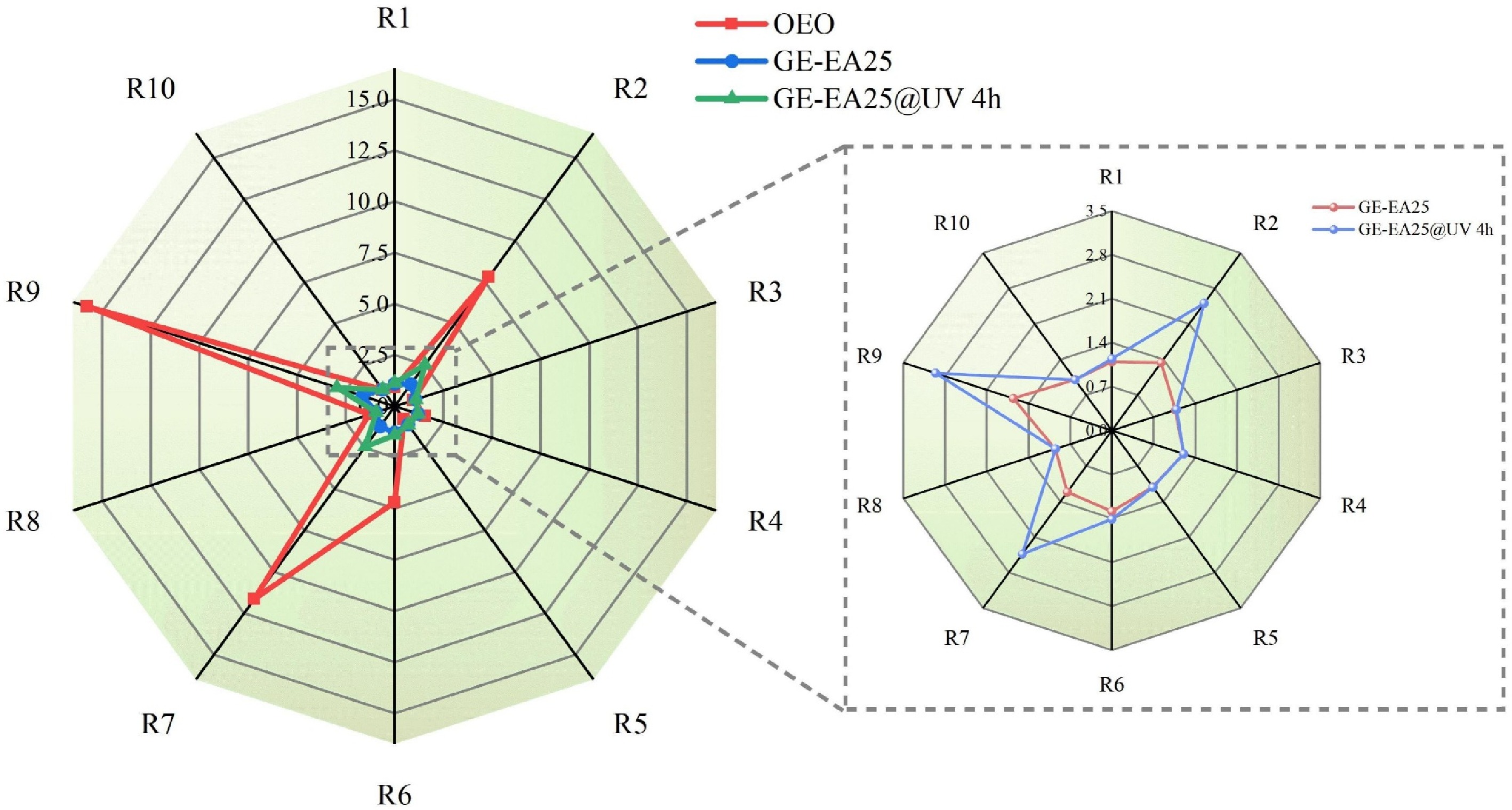

Figure 4.

Effect of UV irradiation on electronic nose of fibrous membranes.

-

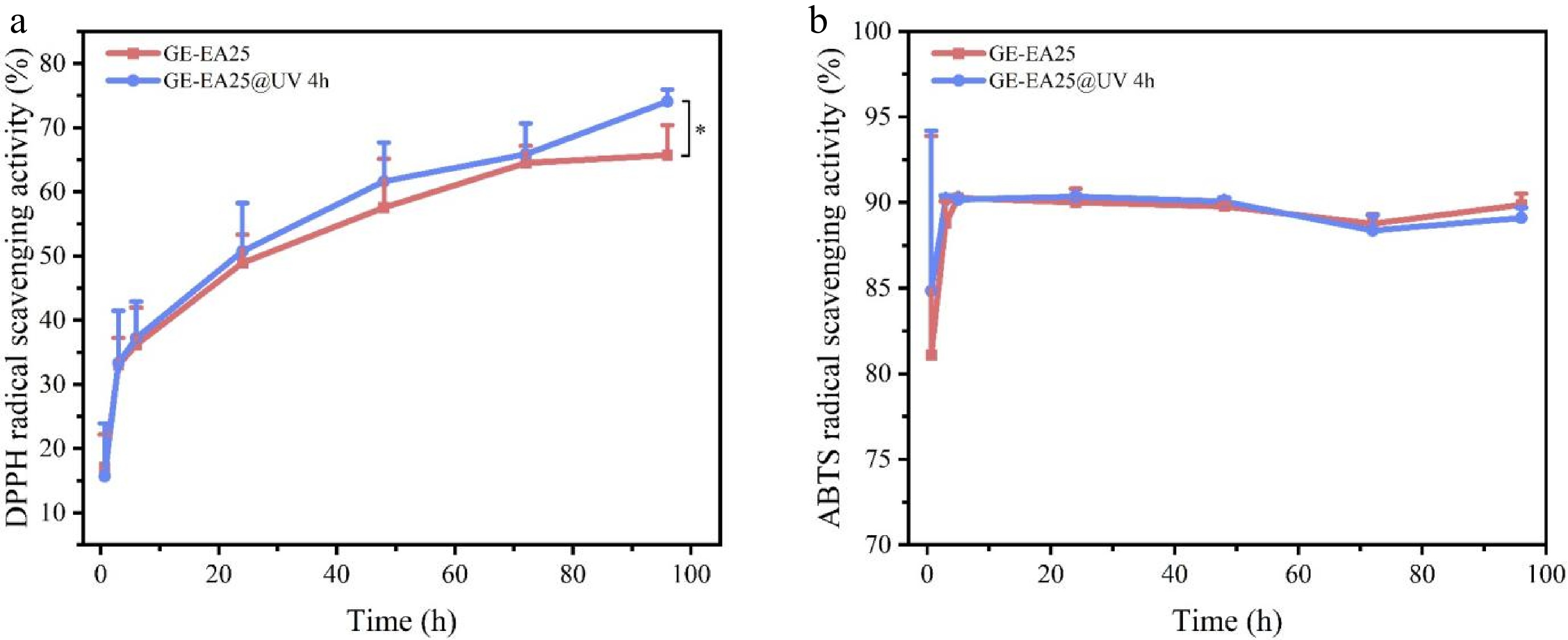

Figure 5.

Effect of UV irradiation on antioxidant properties of fibrous membranes. (a) DPPH; (b) ABTS.

-

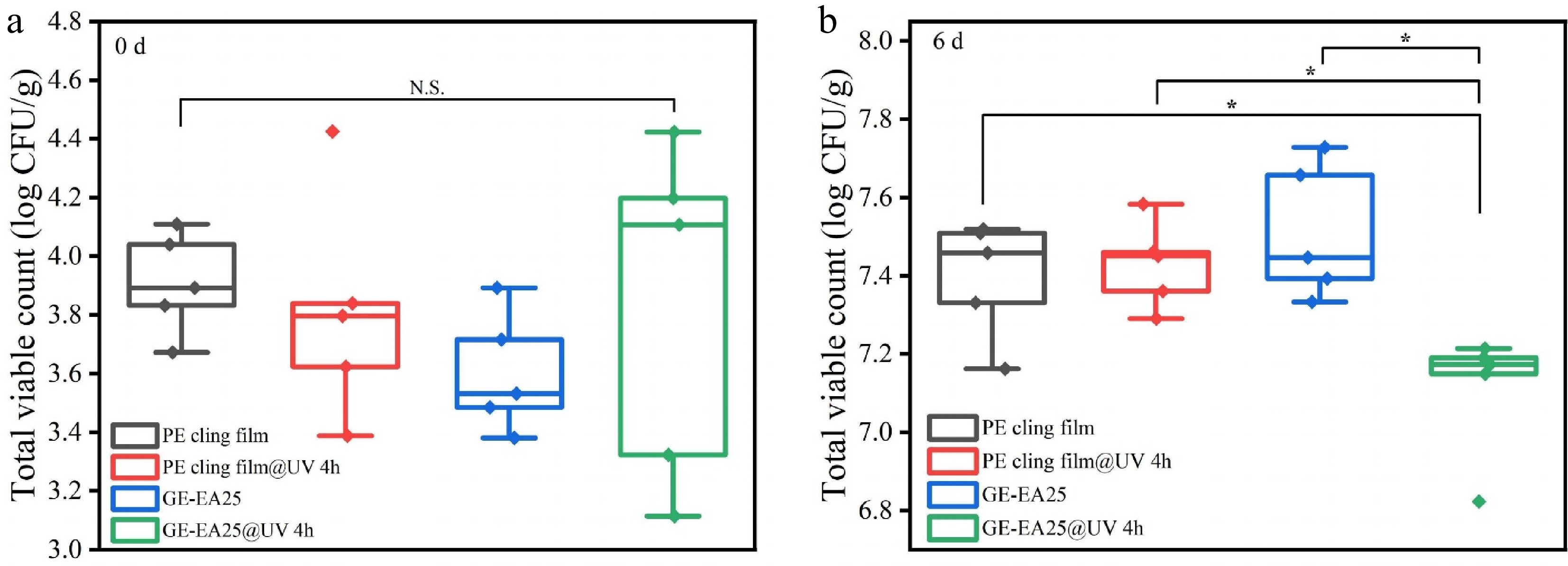

Figure 6.

Variations in total viable counts of chilled chicken breast.

-

Array ID Sensor name Sensitive components R1 W1C Aromatic compounds R2 W5S Nitrogen oxides R3 W3C Ammonia compounds R4 W6S Selective to hydrides R5 W5C Short-chain alkanes and aromatic compounds R6 W1S Methyl compounds R7 W1W Inorganic sulfides R8 W2S Alcohols, aldehydes and ketones R9 W2W Aromatic compounds and organic sulfides R10 W3S Long-chain alkanes Table 1.

Performance description of electronic nose sensors.

-

Spinning solution Feed rate (mL/h) Spinning voltage (kV) Spinning state EA20 0.15~0.35 16~20 Dense jet flow but ejected material was powdery EA25 0.15~0.35 16~20 Dense jet flow but ejected material was powdery GE-EA20 0.15~0.35 16~20 Inadequate fiber stretching at nozzle, droplet spraying occured, with powdery output GE-EA25 0.15 16 Inadequate fiber stretching at nozzle 18 Insufficient stretching velocity resulted in non-continuous spinning 20 Insufficient stretching velocity resulted in non-continuous spinning 0.35 16 Insufficient nozzle stretching led to droplet spraying 18 Continuous spinning was achieved with stable fiber formation 20 Continuous spinning was realized with fiber formation, yet the jet stream remained unstable Table 2.

Electrospinning state under different conditions.

Figures

(6)

Tables

(2)