-

Figure 1.

Common antimicrobial mechanisms.

-

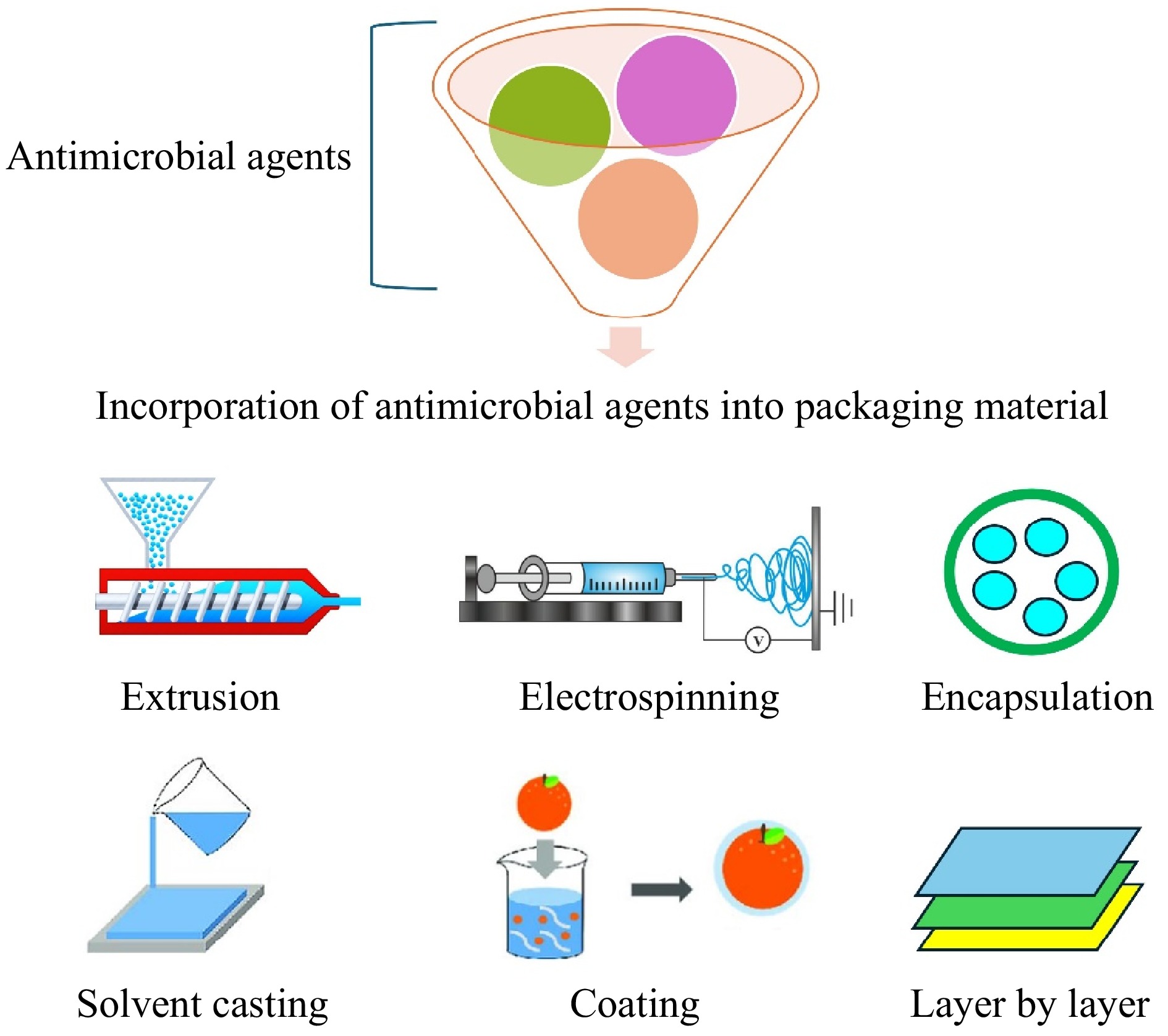

Figure 2.

Different methods are commonly used for incorporating antimicrobial agents into packaging material for food packaging applications.

-

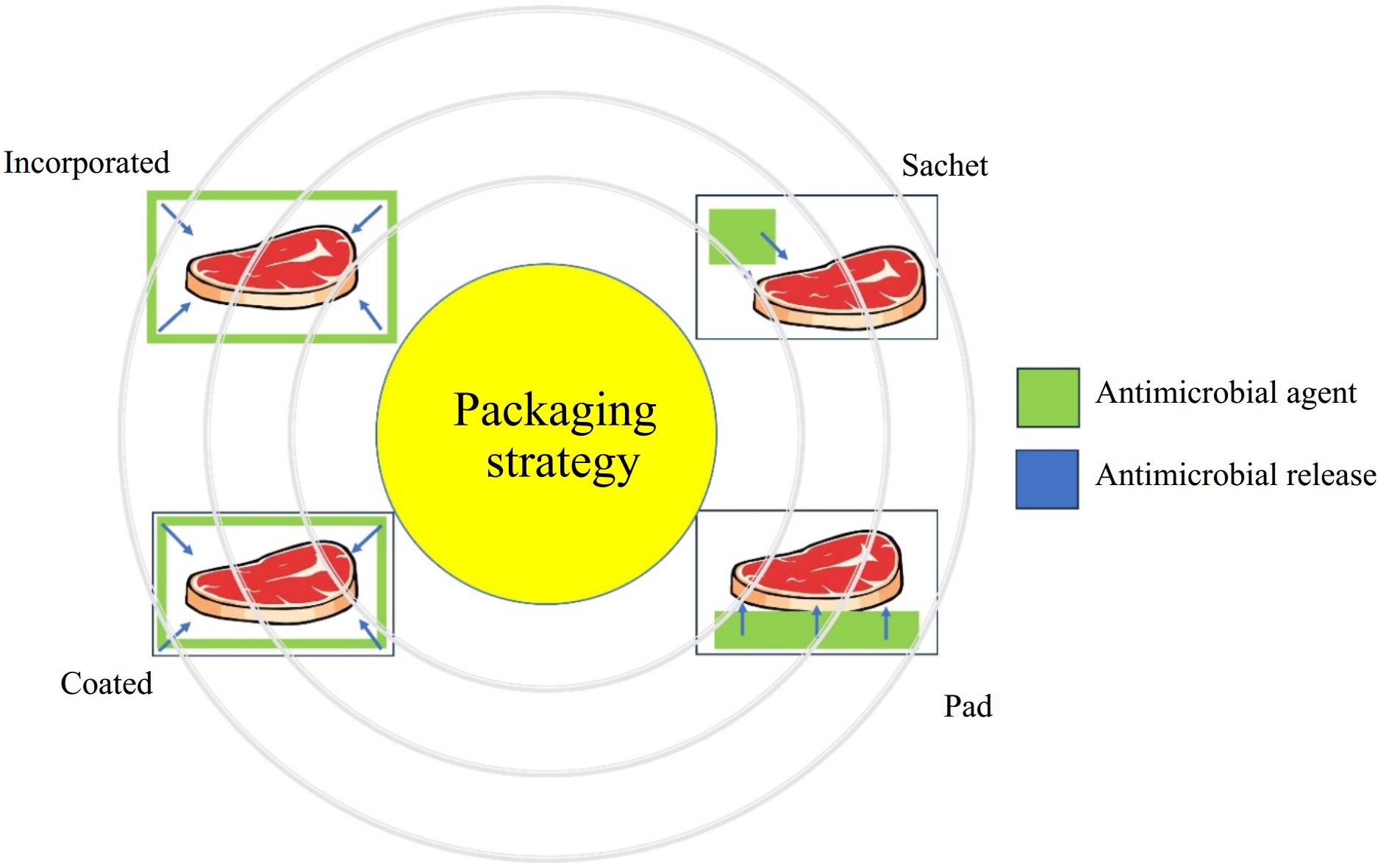

Figure 3.

Strategies for antimicrobial packaging development.

-

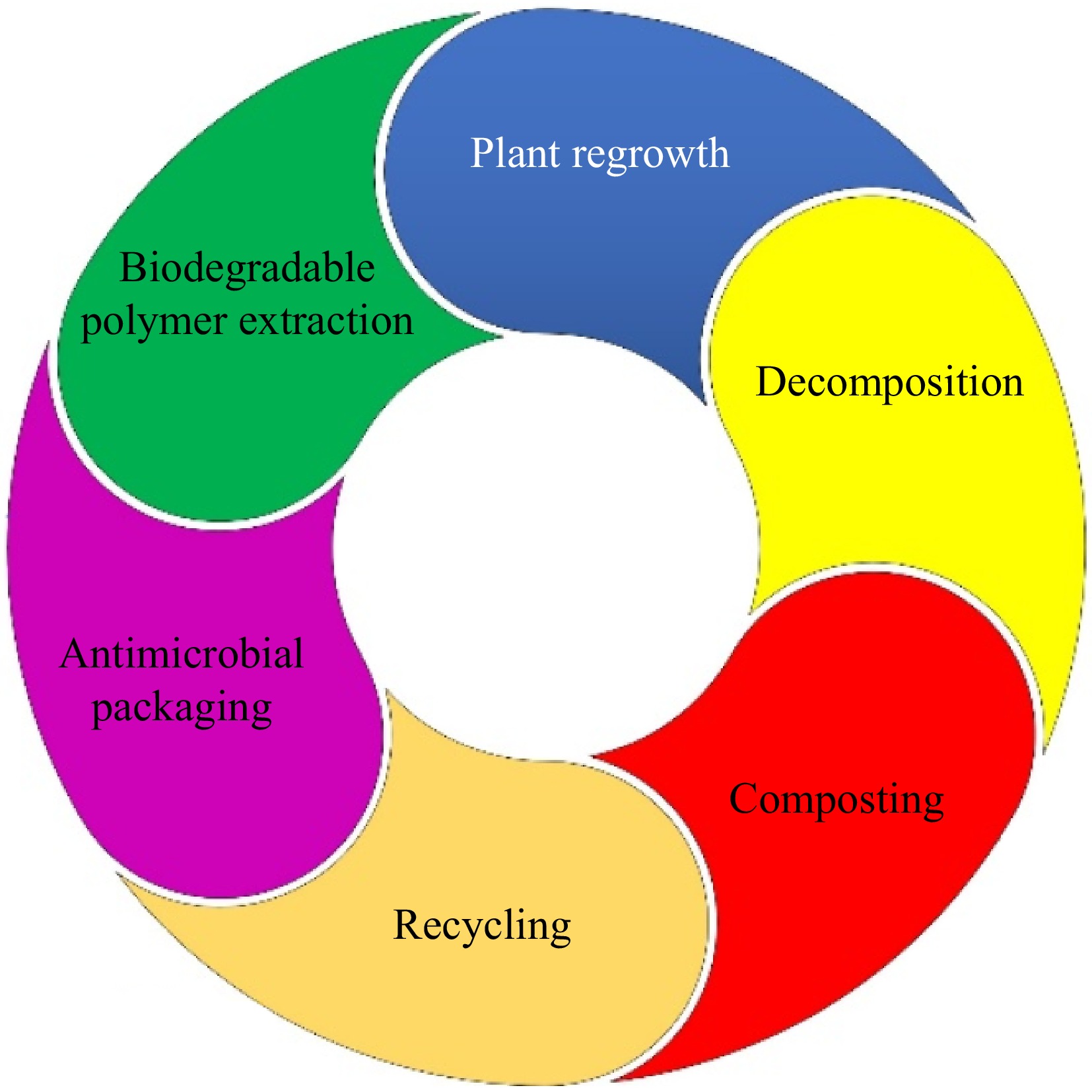

Figure 4.

Sustainability process of antimicrobial packaging.

-

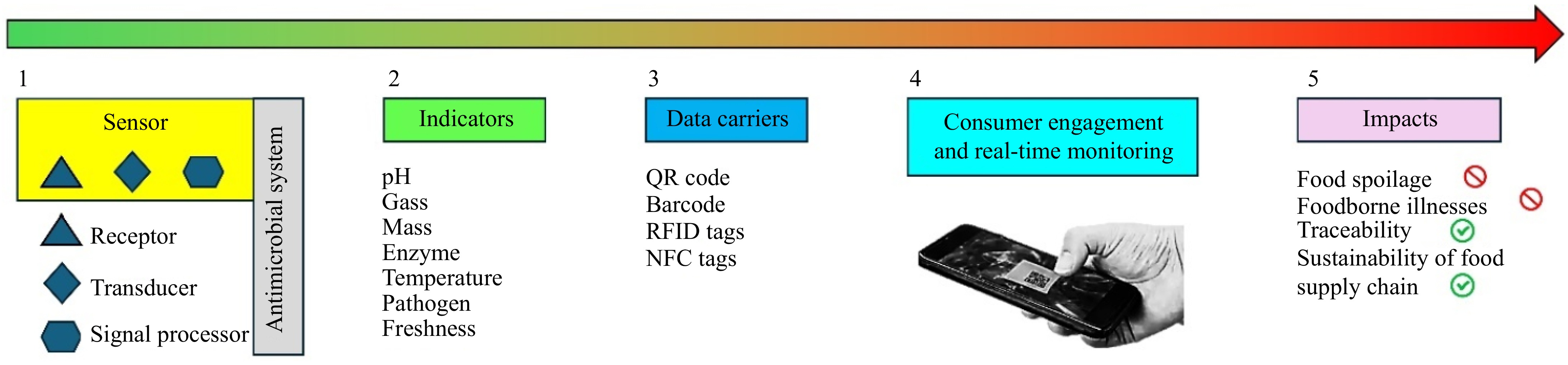

Figure 5.

From smart antimicrobial packaging to sustainability of the food supply chain.

-

Type Antimicrobial agents Efficacy Ref. Plant extract Olive leaf extract Olive leaf extract of Gemlik possesses the highest levels of oleuropein and rutin contents. It shows the highest zone of inhibition against E. coli (16.33 ± 0.33 mm) and against Salmonella typhimurium (16.00 ± 0.00 mm). The studies of thickness, water vapor transmission rate, oxygen transmission rate and antibacterial potential of the packaging sheets prove that olive leaf extract is an effective active functional food packaging. [30] Adina rubella extract Fermented Adina rubella extract, a flowering shrub, for 9 d can inhibit the growth of Listeria monocytogenes by destroying the structure of the cell wall when incorporated into food film, showing great potential for pork packaging. [31] Cannabis sativa L.

seeds extract2.5 [wt%] Cannabis sativa L. seeds extract incorporated into apple and citrus-based pectin food film successfully inhibit S. aureus, S. typhimurium, and L. monocytogenes. Cannabidiol, a phenolic compound found in the seed may alter cell membrane permeability, inhibit RNA synthesis, and inactivate bacterial proteins, giving the extract antibacterial properties. [32] Organic acid Lactic acid Polyvinyl alcohol film incorporated with lactic acid (PVA/LA) exhibits the highest bacterial inhibition, which is largely due to its capacity to modify the local pH and alter the permeability of the microbial layer by disrupting bacteria–substrate interaction. The composite film has attractive properties and can be considered as a food packaging material with low environmental impact based on polyvinyl alcohol. [33] Sorbic acid Sorbic acid-incorporated polypropylene (PP) films for packaging fresh yufka dough, a Turkish flatbread, regulate the moisture content of the dough, preventing it from being spoiled. At 6% sorbic acid concentration, the film decreases the log cycles of E. coli and S. aureus and shows a greater inhibition zone against Aspergillus niger (6.70 ± 0.48 mm). [34] Citric acid Keratin from chicken feathers reinforced with citric acid-modified cellulose nanocrystals (CNC-CA) film possesses a promising antimicrobial activity against E. coli and S. aureus. The film has a great tensile strength and elongation at a break of 209%, aside from being biodegradable, successfully extends the shelf-life of blueberries for 5 d at room temperature. [35] Enzyme Lysozyme Chitosan-lysozyme composite films and coatings remarkably decrease the growth of L. monocytogenes, E. coli, Pseudomonas fluorescens, and mold in mozzarella cheese than laminated films and coatings. [36] Nanoenzyme Biomimetic artificial bovine serum albumin (BSA) nanoenzyme chelated with copper ions (CuBSA) successfully kills more than 95% viable bacteria. The nanoenzyme delays the oxidative browning of freshly cut fruit slices and prevents the growth of bacteria on figs and apples. [37] Phage endolysin The incorporation of endolysin from E. coli EO157:H7 phage JN01 and eucalyptus leaf essential oil liposome into gelatin packaging is effective against E. coli O157:H7 and S. enteritidis. These suggest that this packaging successfully prevents microbial growth on fresh Pacific white shrimp (Penaeus vannamei) that are prone to microbial spoilage during cold storage. [38] Peptides Bacteriocin When used as Minas Frescal cream cheese packaging, a chitosan/agar-agar bioplastic film incorporated with bacteriocin contributes to the increase of microbiological stability, showing a reduction of 2.62 log CFU/g, contributing a gradual release of the active compound into the food during the storage time. [39] Nisin Nisin, an antimicrobial peptide from Lactococcus lactis subsp. lactis that is loaded into zein/polyethylene oxide (PEO) film has a significant increase in the antibacterial activity against S. aureus, L. monocytogenes, S. typhimurium, and E. coli, which is probably due to the membrane permeability alteration. The strong antibacterial activity of the fabricated nisin-loaded electrospun mats successfully prolongs the shelf-life of chicken breast in storage, proven as a promising antibacterial packaging material. [40] Casein Milk-derived antimicrobial peptides αs2-casein151-181 and αs2-casein182-207, are incorporated into whey protein-based edible films for cheese packaging. They have a similar antibacterial activity against B. subtilis and a much greater activity against E. coli when compared to nisin-containing cheese packaging films. It is a promising packaging for soft cheese, inhibiting yeasts and molds as well as controlling the growth of other psychotrophic bacteria at refrigerated temperatures. [41] Nanomaterial A combination of

silver and zinc oxide nanoparticlesThe antimicrobial efficiency of starch/PBAT nanocomposite films with AgNPs and ZnONPs reaches more than 95% within 3 h of contact. [42] Nanocellulose Corn cob nanocellulose combination with essential oil that is incorporated into polylactic acid (PLA) film, reinforces its matrix and prevents food with high water content from being spoiled. When tested against Fusarium oxysporum f. sp. Cubense, the nanocellulose composite bags completely inhibit the mycelial growth. [43] Titanium carbide

MXene nanofillersTi3C2 MXene nanofillers-reinforced chitosan/gelatin/polyvinyl alcohol (PVA) composite films (CGPF-Mxs) at a concentration of 0.75% alters the permeability of cell membrane by binding the amino ions on chitosan with teichoic acid and lipopolysaccharide in the cell wall. It has an inhibition rate of up to 98.53% against S. aureus and 82.91% against E. coli and could be considered as packaging for cooked meat products. [44] Table 1.

Antimicrobial agents are commonly used in food packaging.

Figures

(5)

Tables

(1)