-

Figure 1.

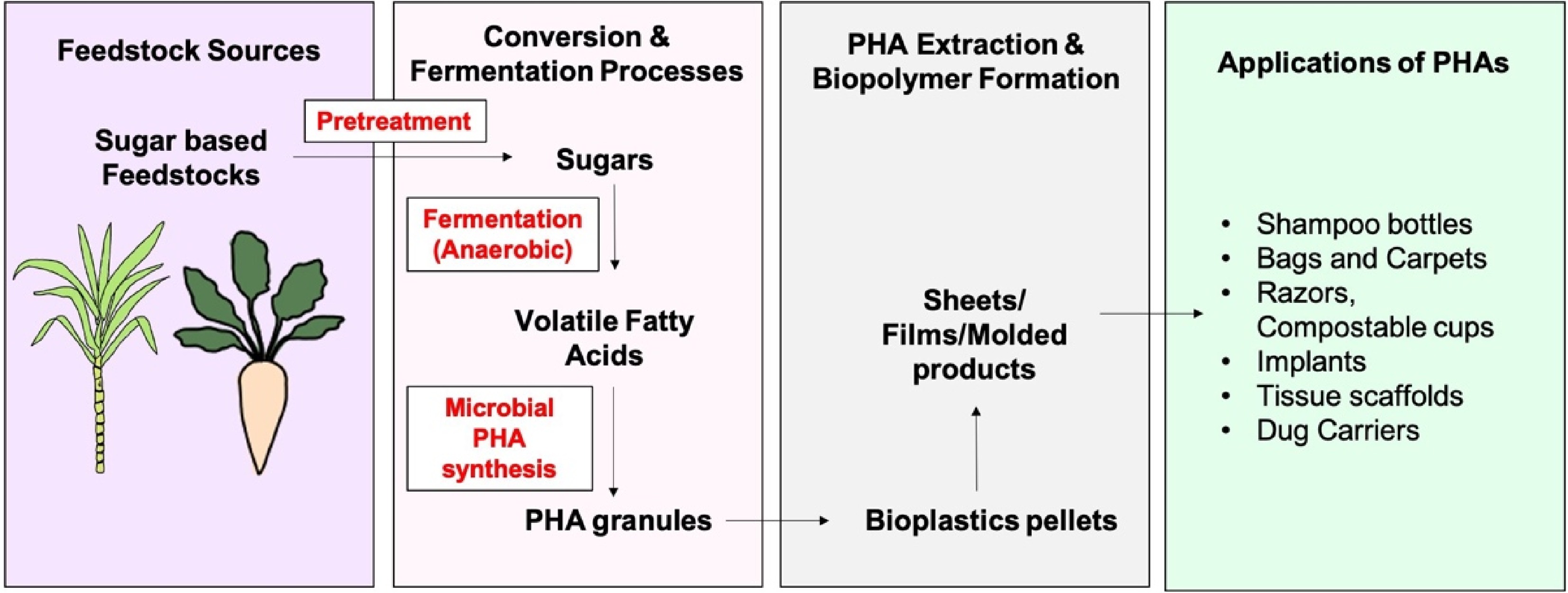

PHAs production from sugar based feedstocks.

-

Figure 2.

Different types of pre-treatment of lignocellulosic biomass.

-

Figure 3.

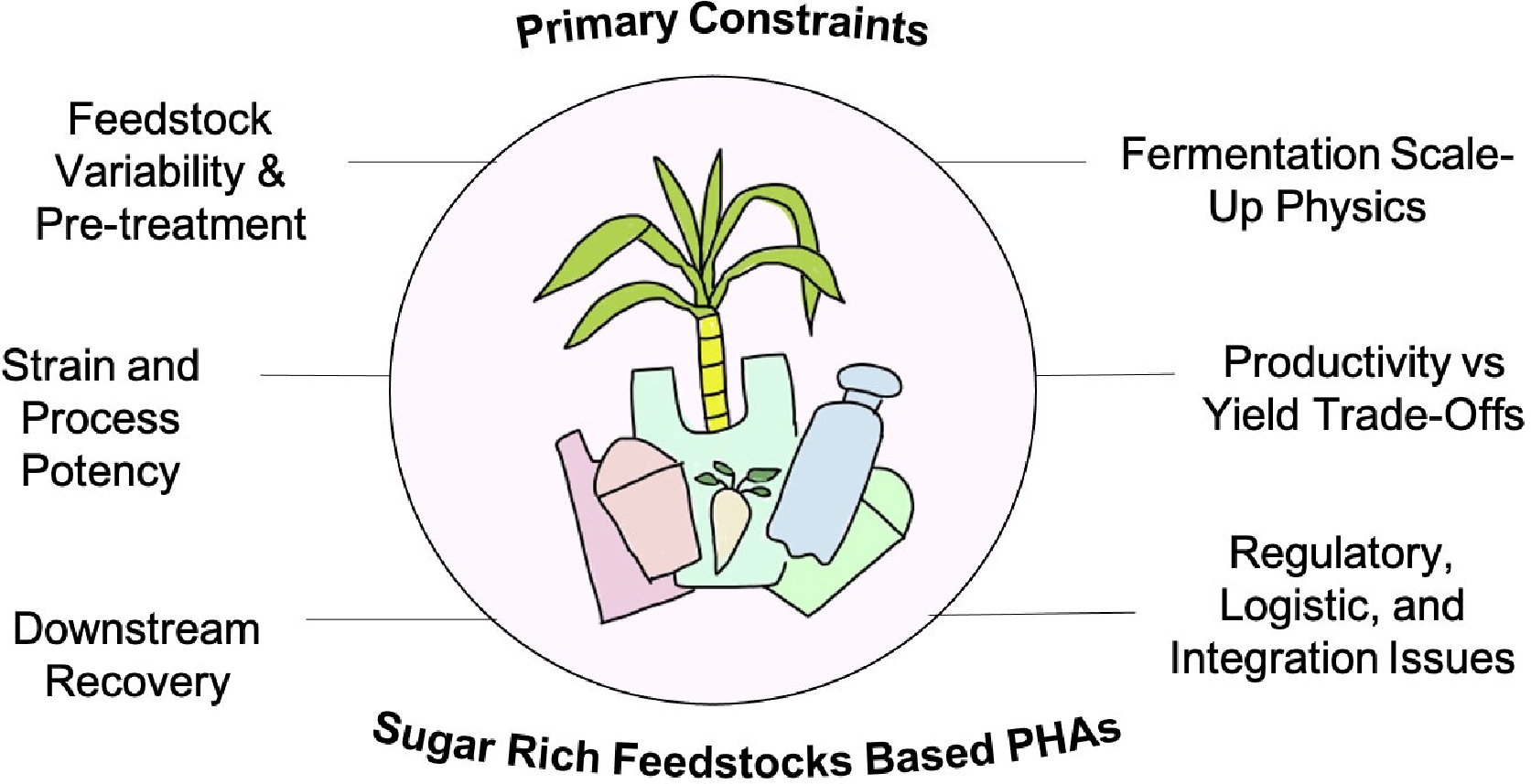

Primary bottlenecks in PHAs production from sugar rich feedstocks.

-

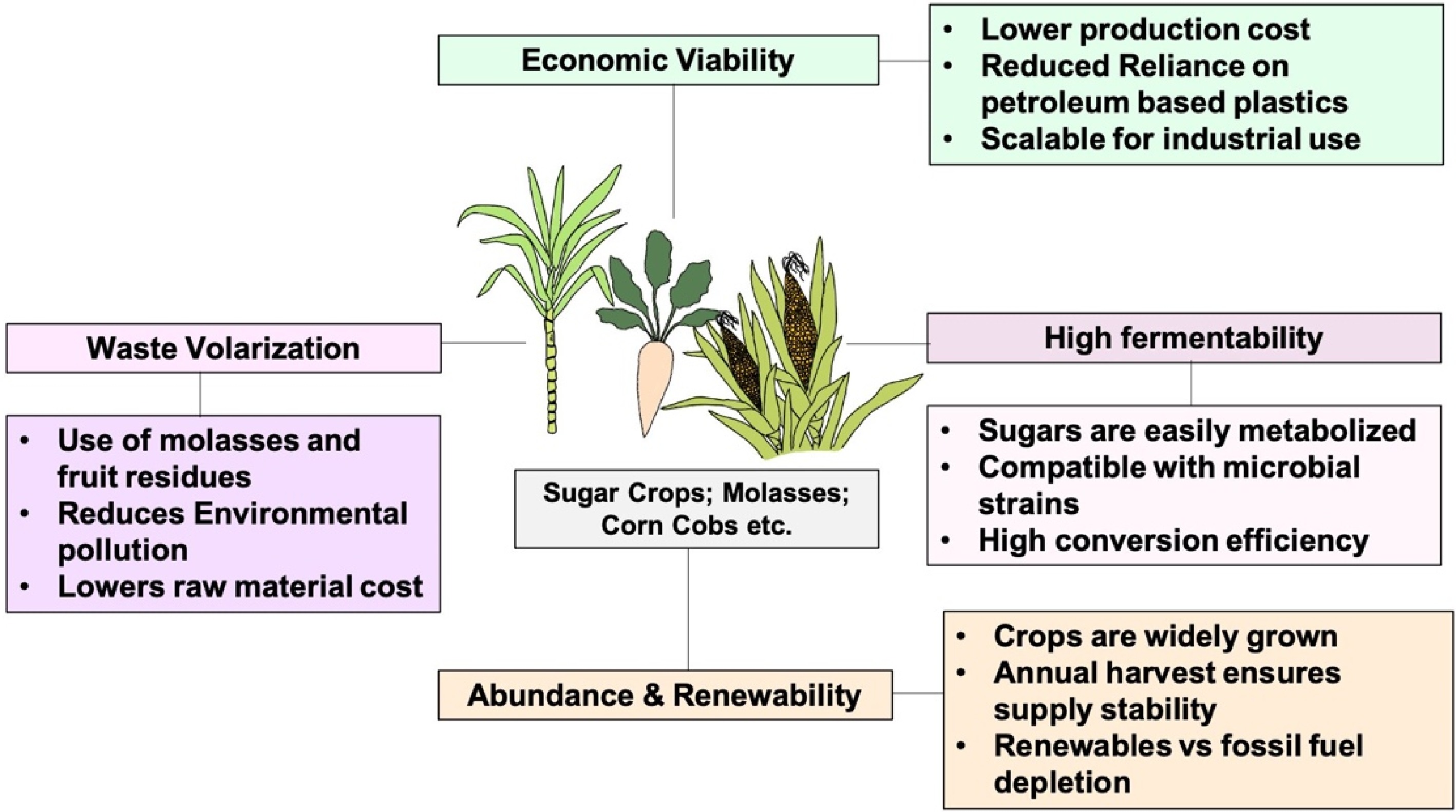

Figure 4.

Advantages of sugar based feedstocks for PHAs production.

-

Figure 5.

Circular route of PHAs bioplastic production from sugar based feedstocks and its applications.

-

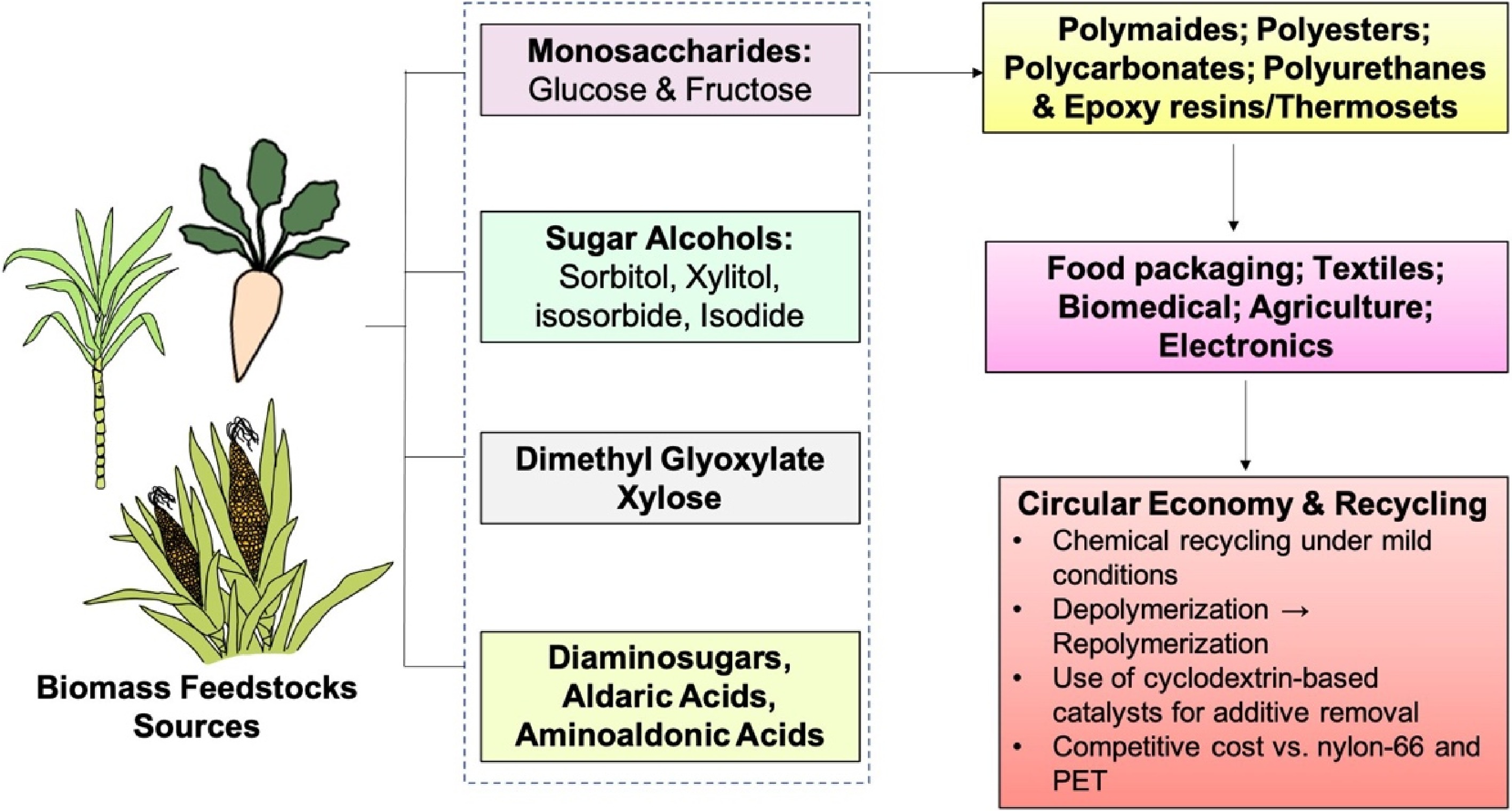

Figure 6.

Sugars based feedstock to smart materials.

-

By-product Concentration of

raw materialInitial treatment of raw material Microbe utilized with

inoculum concentrationPHAs yield (%) Ref. Molasses 80 g/L Acidic treatment Cupriavidus necator 11599 75.64 [35] Molasses 2−10 Not mentioned Enterobacter sp. SEL2 47.4−92.1 [36] Cane molasses + ammonium sulphate 20 g/L Not mentioned Bacillus megaterium BA-019 49.9−55.5 [73] Cane molasses + urea 20 g/L Not mentioned Bacillus megaterium BA-019 49.9–55.5 [73] Molasses 1% Alkaline/acidic pre-treatment; Hydrothermal pre-treatment Cupriavidus necator (DSM 545 strain); 40 mL 27.20 [75] Molasses Not mentioned Not mentioned Bacillus subtilis 62.2 [77] Molasses Not mentioned Not mentioned Escherichia coli 58.7 [77] Molasses 2%−10%

(at even intervals)Sulfuric acid treatment and Tricalcium phosphate treatment B. subtilis (2 mL) 21.09−54.1 [77] Molasses 2–10 Tricalcium phosphate treatment B. subtilis (2 mL) 21.1−54.1 [77] Molasses 2−10 Tricalcium phosphate treatment E. coli 21.1−54.1 [77] Molasses 0−8 Acidic treatment Enterobacter cloacae 36.0–51.8 [78] Molasses − Acidic treatment Enterobacter cloacae (2–16) 44.2–53.7 [78] Molasses 2−10 Not mentioned Bacillus cereus SPV 61.1 [82] Molasses + corn steep liquor 2%−5% Not mentioned Bacillus megaterium 18.3−49.12 [87] Molasses + corn steep liquor 4 or

1%−6%, 0%−6%Pretreated with activated

charcoal (1:1) for 2 hBacillus megaterium ATCC 6748 35 [93] Molasses + corn steep liquor 4% (w/w); 4% (v/v) 43 Molasses 1% Not mentioned Bacillus thuringiensis IAM12077 23.81 [95] Bagasse 1% Bacillus thuringiensis IAM12077 9.68 [95] Molasses 10 and 40.0 g/L Acidic treatment Pseudomonases aregunoisa NCIM No. 2948 62.44 [96] Molasses − Sulfuric acid treatment Bacillus thurigenisis HA1 61.6 [97] − − Cupriavidus necator DSM 428 24.33 [98] − − Mixed microbial culture 57.5 [99] Molasses 0.0–0.5 g/L Not mentioned Alcaligenes eutrophus DSM 545 18–26 [100] Molasses 2–10 Not mentioned Bacillus flexus strain AZU-A2 88.0 [101] Table 1.

Production of PHAs from sugarcane by-products.

-

By-product Concentration of

raw materialInitial treatment of

raw materialMicrobe utilized with inoculum concentration PHA yield (%) Ref. Beet molasses 40% Acid and enzymatic

hydrolysisCupriavidus necator B-10646 wild strain 80 [37] Beet molasses 5% w/v Not mentioned Azotobacter cinelandii UWD 75–85 [88] Beet juice 1 L Not mentioned Alcaligenes latus (ATCC 29714) 38.66 [103] Cane molasses + beet molasses 3% Not mentioned Bacillus megaterium strain L9 41 [105] Beet molasses + sugar beet waste water 1%–15%

(with odd intervals)Not mentioned Bacillus megaterium AUMC b 272 27.20–32.92 [106] Beet molasses 5% w/v Not mentioned Azotobacter vinelandii UWD (4% w/v) 65–73 [107] Sugar beet pulp 6% Recombinant endoglucanase (rCKT3eng) Haloarcula sp. TG1 17.8 [108] Pressed sugar beet pulp Not mentioned Acidification Pseudomonas citronellolis 38 [109] Pseudomonas putida KT2440 31 Table 2.

Production of PHAs from sugar beet by-products.

-

Other sugar rich feedstocks Concentration/weight of

raw materialInitial treatment of

raw materialMicrobe utilized with inoculum concentration PHA yield (%) Ref. Hydrolyzed citrus pulp Not mentioned Dilute acid hydrolysis Bacillus sp. strain COL1/A6 54.6 [2] Corn cob hydrolyzate 0.2, 0.5, and 1 g Acid hydrolysis Bacillus spp. BM 37 36.16 [119] Apple pulp waste 1:3 v/v deionized water Not mentioned Pseudomonas citronellolis NRRL B-2504 30 [123] Apple pulp waste 1:3 v/v deionized water Not mentioned Co-culture of Cupriavidus necator DSM 428 and Pseudomonas citronellolis NRRL B-2504 52 [124] Apple pulp waste 1:3 v/v deionized water Not mentioned Co-culture of Cupriavidus necator DSM 428 and Pseudomonas citronellolis NRRL B-2504 48 [124] Banana peels 20 g Not mentioned Zobellella sp. DD5 34.38 [125] Corn oil waste 20–50 mg Acidic treatment Pseudomonas sp. strain DR2 Up to 37.34 [126] Coir pith 3% Hydrolysis Azotobacter beijerinickii 48.9 [127] Ground orange juicing waste 10 mL Gas chromatography Cupriavidus necator H16 73 [128] Jackfruit seed hydrolysate 0.2 mL Enzymatic hydrolysis Bacillus sphaericus NCIM 5149 49 [129] Oil palm empty fruit bunch Not mentioned Enzymatic hydrolysis B. megaterium R11 51.6 [130] Apricots 10 g Enzymatic hydrolysis Pseudomonas resinovorans 1.4 [131] Table 3.

Comparison of PHAs yield through different sugar rich feedstocks utilizing various microbial strains.

Figures

(6)

Tables

(3)