-

Figure 1.

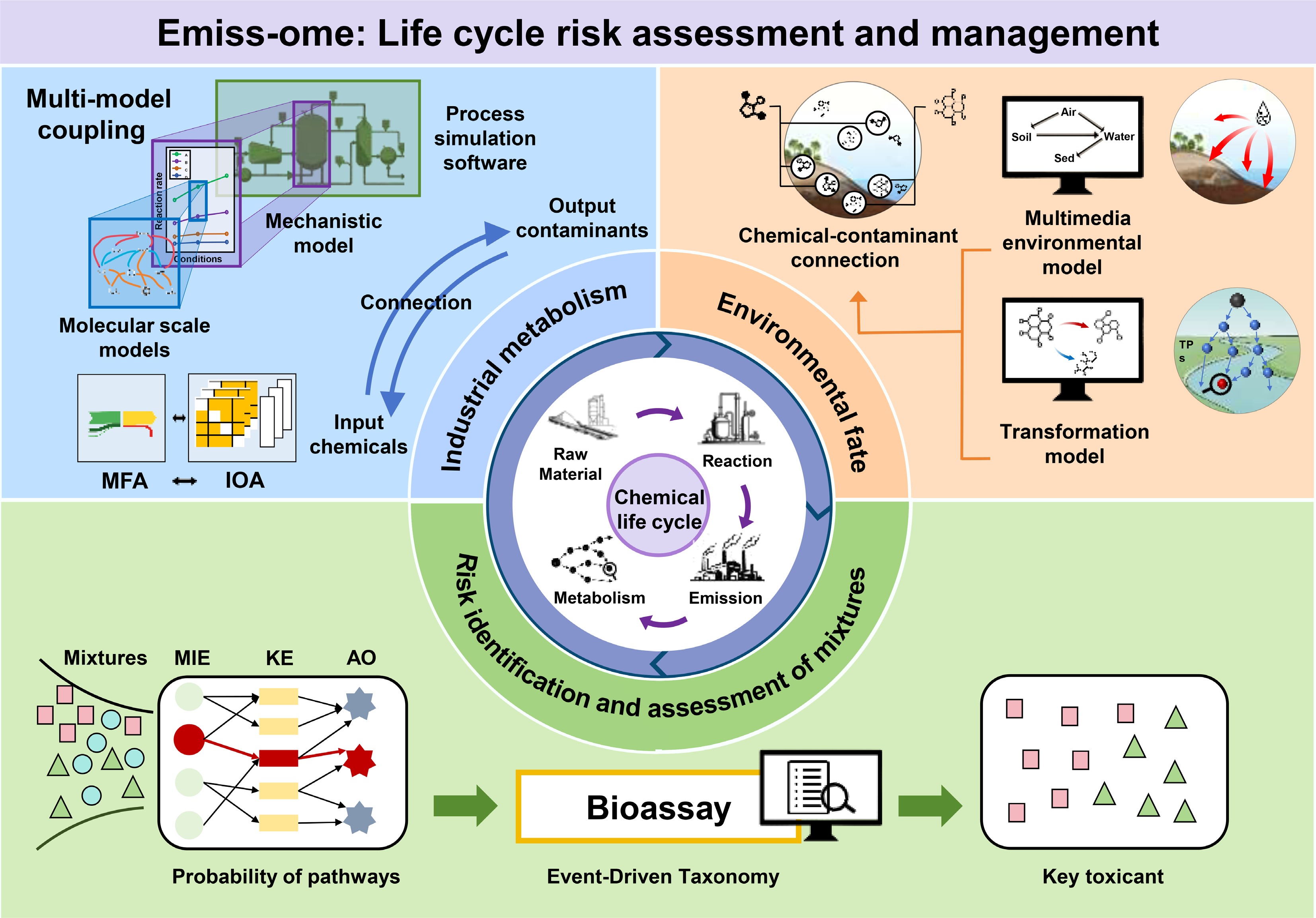

Integrated concepts and methodologies for life cycle risk assessment of industrial chemicals synergizing industrial-environmental metabolism and key toxicant identification in mixtures.

-

Life cycle stage Current limitations Tentative solutions Remaining challenges Industrial metabolism • Complex industrial reactions and transformations obstruct linkage of source chemicals to terminal pollutants

• Models assume idealized conditions, ignoring operational variability• Multi-model integration to quantify material flows across sector transformations

• Coupling molecular-scale models with intrinsic kinetics and process simulation to resolve industrial 'black boxes'• Limited industrial reaction data causes prediction-reality discrepancies

• Validation challenges in cross-scale model integrationEnvironmental fate and transport • Coupled environmental transport/transformation impedes quantitative tracking of terminal pollutants

• Existing models treat transport and transformation as separate processes• Application-specific multimedia models to clarify chemical transport

• Apply transformation models integrating reaction rules, machine learning, and experimental data for environmental metabolites• No integrated frameworks for simultaneous transport-transformation modeling

• Limited joint assessment of dynamic environmental processesRisk of mixtures • Traditional key toxicant identification ignores contaminant interactions, failing to capture mixture effects • Adverse Outcome Pathway (AOP) network construction for toxicity pathway elucidation

• Quantitative AOP for key event relationships and dominant pathway probability

• Event-driven taxonomy (EDT) for high-risk toxicant identification• Limited AOP data (incomplete pathway coverage and lack of quantitative interaction data)

• Constrained cumulative risk evaluation for complex mixturesTable 1.

Limitations, solutions, and challenges identified for enabling the life cycle management of industrial chemicals

Figures

(1)

Tables

(1)