-

In today's world, there is growing concern about the use of petroleum derivatives in the manufacture of films and coatings within the food sector. Due to this issue, biopolymers derived from biomass are used in film production. These biopolymers primarily proteins, lipids, or polysaccharides, contain at least one element capable of creating a unified three-dimensional structure. These edible films have proven effective in preserving the quality of perishable foods such as meat and fish by reducing microbial growth and improving their sensory characteristics.

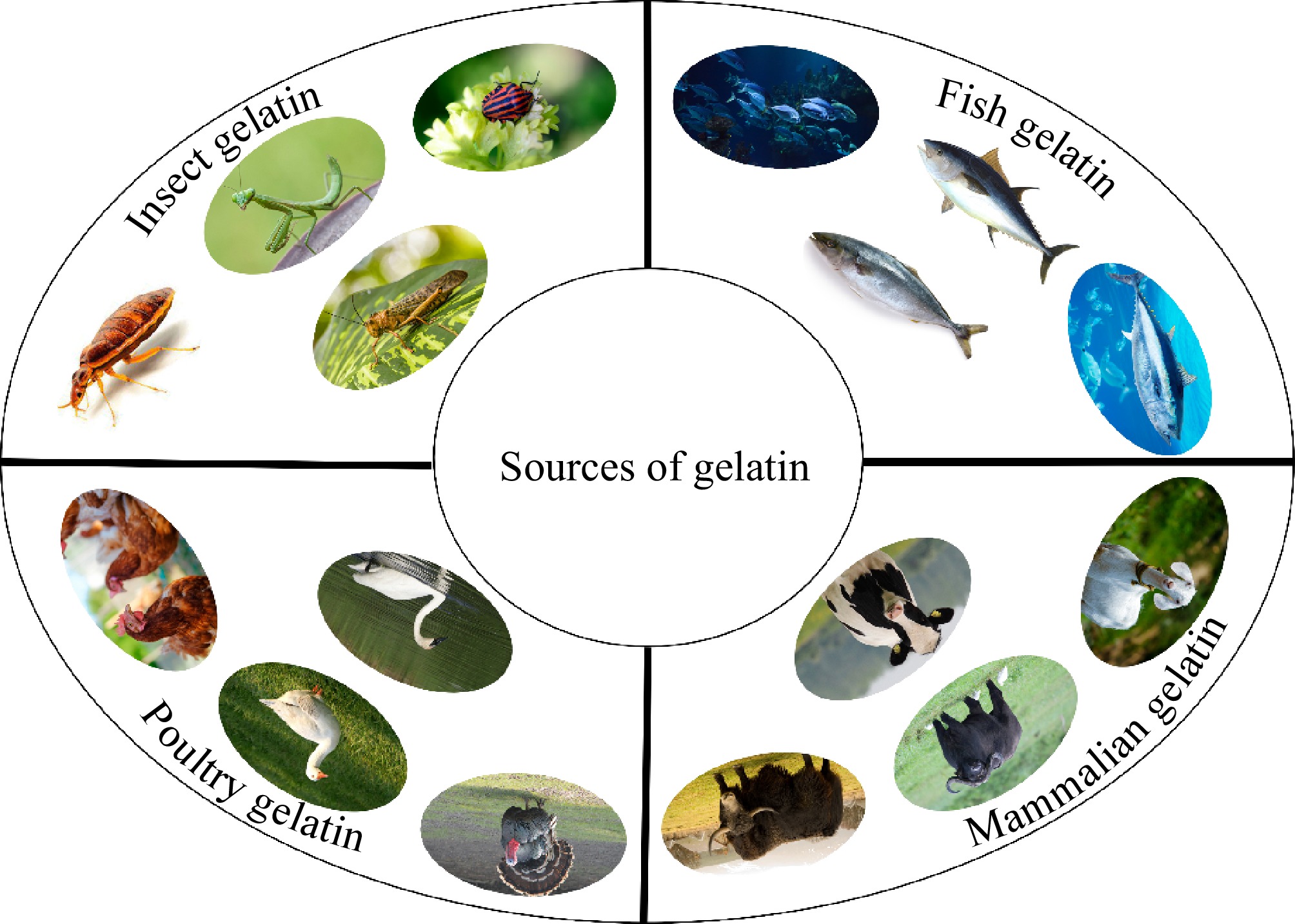

Gelatin is a type of biopolymer produced by breaking down collagen, a connective tissue found in mammals, fish, and poultry[1]. It is mainly obtained from the skin, bones, and hooves of pigs, which are the main source in gelatin production. Other sources include the waste materials of fish, and slaughtered birds such as poultry, and minor sources, which are not of commercial importance (insects and vegetables)[2]. The structural resilience of gelatin arises from its triple helical conformation, which improves its resistance to physical stress. The amino acids, especially tyrosine and tryptophan, absorb ultraviolet radiation, thereby mitigating oxidative degradation by scavenging free radicals and stabilizing the polymer[3]. Additionally, the attributes of the gelatin can be improved through incorporating plasticizers, other polymers, or fillers for efficient use in various industries[4].

Industries with a major utilization of gelatin are the food, cosmetics, pharmaceutical, photo, and technical industries (e.g., match production, paper manufacturing, and adhesives). Gelatin exhibits several functional properties such as hygroscopicity, gel-forming capability, moisture barrier efficacy, film-forming aptitude, foam-generating capacity, and emulsifying behavior, that enable its utilization across multiple industrial sectors[5]. Within the food industry, gelatin is widely utilized as a multifunctional additive, providing solidification, emulsification, and viscosity enhancement in baked goods and confectionery items[6]. It is an important additive in the meat industry as it reduces the rancidity, and tainting of the meats, and microbial contamination[7]. Gelatin is used as a stabilizer and texturizer in the dairy industry[1].

One of the developments with the gelatin are the modification in the crosslinks, mixing with other biopolymers, and the inclusion of nanoscale additives for the improvement of its protective and structural properties[7]. The microbial activity in gelatin films is enhanced through the use of nanofillers such as silver nanoparticles, while thermal stability and water resistance are improved through nanofillers like zinc oxide nanoparticles[8]. This adaptable and eco-friendly natural polymer possesses significant promise for edible packaging applications. The unique properties, along with the ability to undergo modifications, which enhance functionality through the addition of active ingredients and other biopolymers, makes it ideal for edible films and coatings. As the world progresses towards natural, nutritious, and environmentally friendly packaging, gelatin is expected to expand as it serves as an innovative solution for food preservation along with sustainability.

Despite these promising characteristics and the potential for modification, several inherent limitations of gelatin-based films have been identified, which present challenges for their widespread application and necessitate further research[9]. For instance, unmodified gelatin films often exhibit poor water vapor barrier properties, limiting their effectiveness in extending the shelf life of moisture-sensitive foods. Furthermore, their relatively low mechanical strength and susceptibility to degradation in humid environments pose hurdles for certain packaging applications requiring robust structural integrity[10]. Concerns regarding the variability of properties across different gelatin sources, such as bloom strength and species origin, and the scalability of complex modification processes also persist, affecting consistency and commercial viability[11]. Addressing these limitations is crucial for the wider adoption of gelatin as a truly versatile and sustainable packaging material.

Thus, gelatin has potential in the field of edible active food packaging, and extensive research has already been carried out on this topic. Unlike existing reviews, a comprehensive comparison of gelatin from conventional sources, the emerging alternatives, and their key challenges were discussed. The work highlights the properties and many applications in the preservation of fruits, vegetables, and meat. The key novelty points that were covered include production scalability, advanced technologies used in the production of films and coatings, and the sustainable practices linking the packaging to the circular economy.

-

Partially hydrolyzing collagen is carried out to obtain gelatin. It is predominantly found in connective tissues, tendons, bones, and skin of vertebrates and invertebrates. The most predominant sources in large scale food industry are pig skin and cow hides. It was first used in the 1930s as an initial ingredient to make gelatin. In the effort to shift from pig and cow gelatin, fish gelatin manufacturing has expanded in recent years[12]. The useable materials include scales, viscera, fins, bones, muscle fragments, skin, and heads. The primary disadvantage are less stable rheological properties than those of gelatin that comes from mammals[13]. Forty-six percent of the world's gelatin originates from mammalian sources such as pig skin and cowhide, 23% from bones, 29% from hooves, and 1% from marine sources.

Mammalian gelatin

-

A variety of species including cows, goats, buffalo, and yak, are used in the production of gelatin. Mammalian collagen and gelatin are from the cartilage, tendons, skeleton, skin and hides from cows and pigs. Because of its filmogenic qualities, and higher gel viscosity and gel strength, it is more often used than any other source of gelatin for the making of films[14]. Imino acid (proline and hydroxyproline) is the most abundant amino acid present in the gelatin obtained from the skin of buffalo, yak, and cattle followed by glycine. Tyrosine and histidine are the least prevalent. Gelatin extracted from bovine skin using bromelain has the highest percentage of all the amino acids. 29.80% imino acid, 25.88% glycine, 17.05% hydroxyproline, 12.75% proline, 9.11% arginine, and 8.16% glutamic acid are present in this gelatin. Gelatin strength was highest for bovine skin (475.26−631.90 g), followed by buffalo skin (239.44−293.4 g), and the lowest was for cattle hide (44.37−166.93 g), and bovine heart (54.19−268.84 g). Gelatin from buffalo hide have a viscosity of 23.02 cP, whereas for buffalo skin it has a viscosity value of 17.92−22.17 cP. Lowest viscosity values are for cattle hide (3.67−8.0 cP)[15].

Poultry gelatin

-

The agro food industry, which has seen the fastest growth rate, is the poultry processing industry. The processing of poultry yields products and waste that include heads, feathers, gizzards, liver, and skin of turkey, goose, chicken, duck, and Guinea fowl, which contain a dry matter of 32% with protein of 51%, fat of 41%, and ash content of 6.3%[16]. One neglected by product of the poultry processing industry are chicken feet. Collagenous substances, found in chicken feet, are considered an excellent source of gelatin. Chicken skin gelatin has a higher gel strength and an increased elastic and viscous modulus because of its α-helix and β-sheet design[14].

Fish gelatin

-

Fish skin and bones have collagen content and is used in the making of fish gelatin. The fish species that are used include Cirrhinus mrigala, Catla catla, Channa striatus, Labeo rohita Claris batrachus, Aluterus manoceros, and Pangasius sutchi[17]. The gelatin obtained from fish is translucent, water soluble, colourless, and has good filmogenic qualities[13]. For markets that are concerned with bovine spongiform illness, gelatin procured from fish processing waste acts as an alternative and a replacement for mammalian gelatin[18]. Gelatin obtained from fish is used less in the food industry as it has a fishy odour, and a weaker gelling capacity[19].

Insect gelatin

-

Edible insects are rich in fat, protein, and other minerals. They are typically killed using hot water, dried, and defatted with organic solvents (diethyl ether, n-hexane, ethanol, and isopropanol) or by centrifuging in demineralized water. Gelatin extraction involves distilled water, mild acid, or hot water techniques. In the distilled water method, insects are treated with NaOH (0.1−0.5 mol/L) for 60 min at 2−4 °C, then extracted at 50 °C for 180 min, and freeze-dried[20]. Mild acid extraction uses 50 mM acetic acid for 3 h, followed by 16−18 h of extraction at 45 °C, and freeze-drying. The boiling hot water method includes sequential extractions at 50−70 °C and boiling at pH 3.5−4, followed by filtering and freeze-drying[21]. Insect gelatin has lower levels of hydroxyproline, glycine, and proline, affecting structure and gelling capacity[22].

Desert locust is a significant source of protein, which is about 70%[23]. According to previous studies, acid precipitation and the alkaline method are used for the extraction of protein from these insects. For the extraction of gelatin from grasshopper, the acid precipitation and alkaline methods of sonication assisted extraction (SON) are used. Because of its strong foaming characteristics and high solubility, the gelatin obtained from grasshopper has the potential to be used to create sustainable packaging and edible films[24]. In Sudan, the melon bug (Aspongopus viduatus) and the sorghum bug (Agonoscelis pubescens) are used for the extraction of oil, which is used for medicinal purposes, and for cooking in some areas[25]. The quality of the protein extracted was medium. The extraction of gelatin was carried out using hot water, distilled water, and the mild acid extraction method[26]. Figure 1 shows the various sources of gelatin, along with the structure of gelatin.

-

Gelatin is made up of 25.2% oxygen, 17.5% nitrogen, 6.8% hydrogen, and 50.5% carbon. It has a protein composition of 88%, a moisture content of 10%, and salts of 1%–2%. The protein content is 98%−99% based on dry weight[27]. Gelatin is a mixture of fractions of amino acid which are connected by peptide bonds to form low molecular weight polypeptides. Hydroxyproline and proline (20%−24%), and glycine (27%−35%) are the primary amino acids present in gelatin. Of the 20 natural amino acids they are composed of residues of 18 amino acids, with the exception of cysteine and cystine[28]. Gelatin on hydrolysis, gives peptide or amino acid components. Collagen, which is a fibrous and insoluble protein, is denatured chemically to produce gelatin. The rigid bar-like molecules that make up collagen are structured in the form of fibers and are linked by bonds of covalent attraction. The hydrophobic and hydrogen bonds strengthen the triple helix that is created because of the three polypeptide chains in these molecules. The development of a triple-helix structure is essential for the conversion of gelatin to gel. It has been suggested that hydrogen bonds, hydrophobic effects, and electrostatic interactions sustain the triple-helix structure, which serves as a junction zone in gelatin networks[29]. When the proportion of the triple helices is high, the films exhibit high tensile strength, Young's modulus, and reduced swelling[30]. The glycine-proline-hydro-proline repeats give the triple helix its distinct structure. The constituents of gelatin consist of α-chains, which are single polymers, β-chains, which are two covalently connected α-chains, and γ-chains, which are three covalently bonded α-chains[31].

-

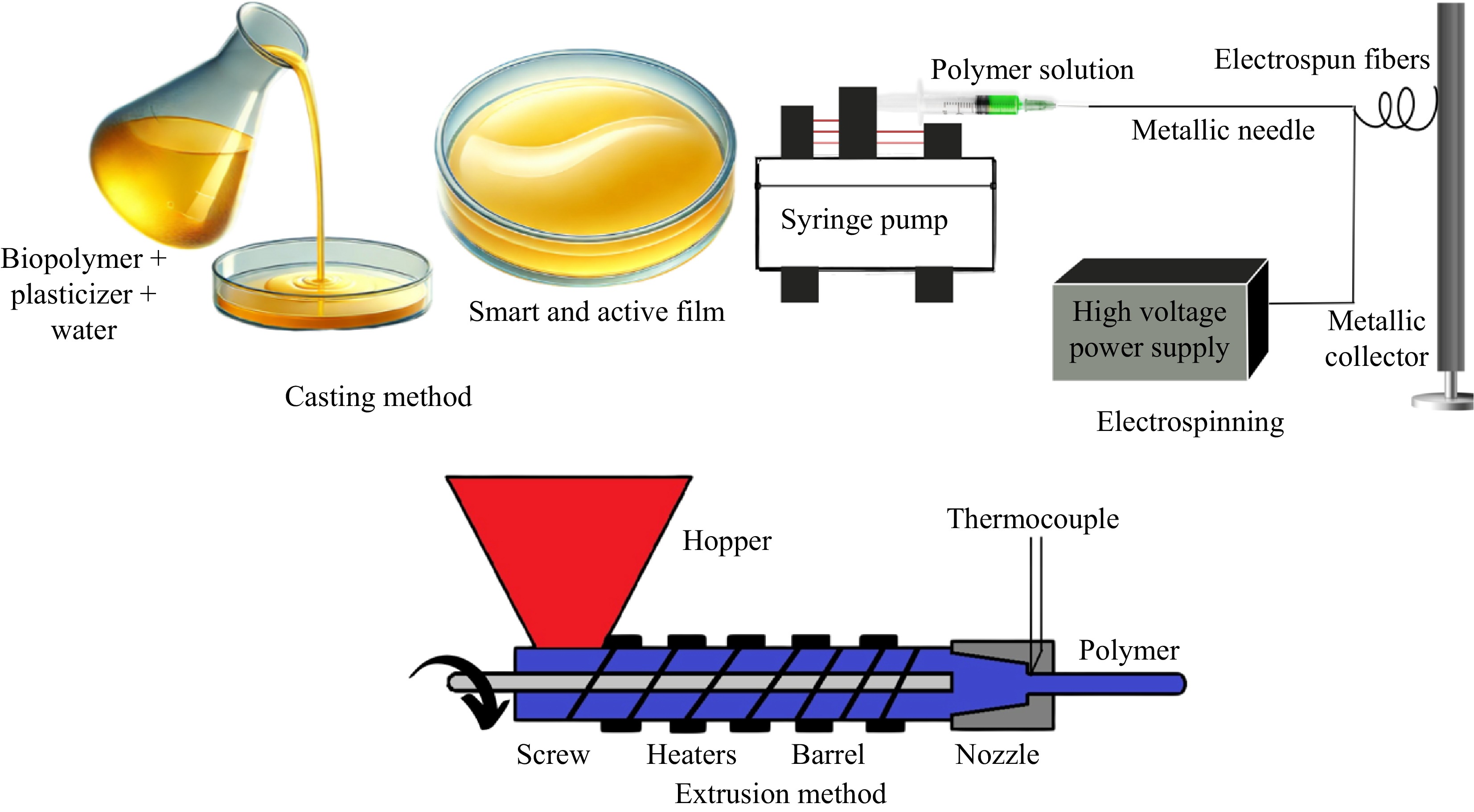

There are many methods for making gelatin film, and some of the more commonly used ones are discussed here, and graphically represented in Fig. 2.

Casting

-

This process is among the most common methods to make edible films. Producing edible films by solvent casting usually consists of four key stages: casting, drying, heat treatment, and dissolving of biopolymers in solvents. At the start of the process, the biopolymer and solvent are blended, and to facilitate the breakdown of biopolymer in the solvent, heat treatment is performed[32]. To break the chemical bonds between them, heat treatment is carried out. Following homogenization, the mixture is poured in an appropriate mould to produce an edible film of gelatin with the necessary shape. For the film to completely dry out, the solvent is evaporated inside the oven, in which the temperature stays below 50 °C to prevent drying out and structural damage. Following drying, the film is then delaminated and put to use[33]. Gelatin-cellulose nanocrystal bio-nanocomposite films were produced by the continuous casting method which displays improved properties[34]. Five percent gelatin was used to prepare film using the drop casting method in which the poured solution was dried at 80 °C[35]. Likewise, zein/gelatin film, incorporated with oregano essential oil, has been prepared by the continuous casting method, and the shelf life studied for strawberries[36].

Extrusion

-

Extrusion is another approach for creating polymeric film, and is one of the most commercially available methods of processing. The extruded material structure, and the physiocochemical characteristics are modified and enhanced in this process. Three different zones make up the extrusion process: feeding, kneading, and heating zones[37]. In the feeding zone, a mixture of the film components are moved, and air is used for compression. This process is known as a dry process and works best when there is little to no water or solvent present. The flexibility of the film is increased using plasticizers[38]. In the extrusion process, gelatin is blended with distilled water and glycerol to obtain a moisture of 35%. A single screw extruder is used along with a rectangular die. The feeding zone has a temperature of 65 °C, the intermediate zone has a temperature of 100 °C, and the die has a temperature of 75 °C, all controlled using a thermocouple. The screw speed was 47.2 rpm, while the feed screw was maintained at a steady 18 rpm[39].

The quick processing time and minimal energy consumption makes the extrusion method better than the casting method. It also has enhanced optical and mechanical attributes such as transparency and film extensibility[39]. Extruded film was obtained by combining fish gelatin, xanthan gum, and malic acid, which had good physical properties and better tolerance to water[40]. Starch/gelatin films incorporated with resveratrol were developed by thermal extrusion and used to reduce the oxidative rancidity of soybean oil[41]. Potato starch/gelatin and eggshell powder were used to produce films by thermal extrusion followed by compression molding[42].

Electrospinning

-

A polymeric solution gets spun or is sprayed to generate fibers or particles in an electrodynamic process using a strong electric field. This process is known as electrospinning. The fibers that are formed because of this process have an elevated surface-to-volume and pore density ratio on submicrometric dimensions, improving their encapsulation effectiveness. Due to these qualities, the nanofibers are increasingly used in food packaging because of their antimicrobial properties, their ability to adhere to large microbial cells, and to destroy cell structure[43]. Also, as it is a nonthermal process, it can be used to preserve heat sensitive bioactive compounds. It reduces the solvent residues in food systems due to rapid evaporation, and allows for controlled fiber design. The main drawback of electrospinning is its limited scalability. Due to the high rigidity of natural biopolymers, it is difficult to process[44]. A standard electrospinning system consists of four parts: a glass or plastic syringe, a collection plate/rotating drum, a moderate or heavy polymer solution that has to be electrospun, and the flow rate regulator[45]. The following parameters are taken into consideration during the electrospinning process: flow rate (low flow rate produces finer fibers), optimized voltage based on the polymer solution, distance between the collector and syringe, and solution properties such as surface tension, concentration, viscosity, and conductivity[46]. Active films were created by electrospinning technology using gelatin, polylactic acid, and eugenol[47]. Nanofiber films having antibacterial properties were prepared by electrospinning using 3-phenyl lactic acid, gelatin, and chitosan[48]. Multilayer films were produced by sequential electrospinning with nanofibers of curcumin-loaded gelatin as inner and outer layers of ethyl cellulose nanofibers[49].

-

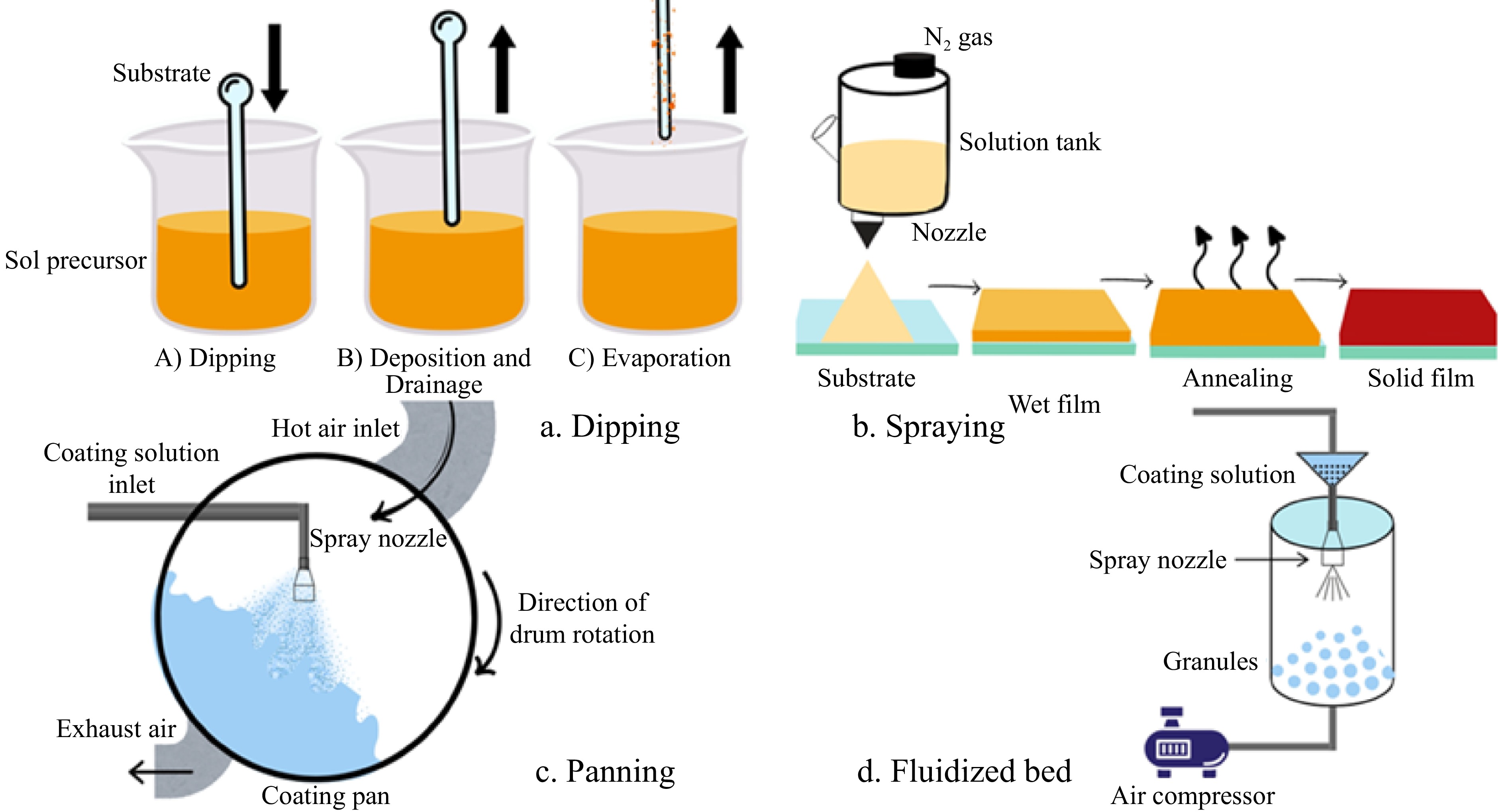

There are many methods for the production of gelatin-based coatings, some of the more commonly used ones are discussed here, and graphically represented in Fig. 3.

Dipping method

-

The most frequently used technique for coating food is dipping. A food sample is immersed in the dispersion which forms a coating[50]. Three steps constitute the process of dipping. It includes immersion and dwelling, deposition, and finally evaporation. As a first stage, at an even rate, the substrate is immersed in the coating solution, or emulsion. To provide a sufficient solution for soaking the substrate, and for complete interaction between the coating matrix and the substrate, submerging is done at a steady pace[51]. On the outermost layer of the food items, the initial emulsion is produced in thin layers using the deposition method. By deposition, any extra liquid on the surface is eliminated[52]. Using a heating and drying process, the solvent or any extra liquid is removed during the evaporation process. Following the additional coating, the product is dried using a drier, or at room temperature[53]. Fresh fruits and vegetables are placed for 5 to 30 s in the solution of the edible coating. Aside from the viscosity and density of the coating solution, the dipping time and drying technique used also affect the formed coatings' thickness, homogeneity, and texture. Longer dwelling time results in a thicker protective layer around the substrate[54]. Rice starch and gelatin was used to create an edible coating for fresh cut zucchini using the dipping method[55]. Minimally processed watermelon was dip-coated with gelatin from yellowfin tuna fish skin, black tea extract, and sodium lactate solution[56]. Dip coating of red chilli, was carried out using gelatin from tilapia fish skin, pectin, and garlic essential oil[57].

Spraying method

-

In the spraying method, droplets are created, which increases the size of the liquid's surface and disperses it across the surface of the food. In industry, three different types of spraying techniques are currently in use:

a. Air spray atomization: In this process a low-speed fluid moves around a high-velocity stream of air. The flow of liquid is accelerated, disrupted, and atomized by fluid air friction. It is an economical method of coating food items. It is used for low to medium viscous fluids and has the finest atomization so a high-quality finish is obtained when coated. It has the lowest transfer efficiency leading to over spraying[51];

b. Air-assisted airless atomization: The fluid is first partly atomized with air-assisted airless spray guns utilising a fluid-filled nozzle tip, resembling a typical airless tip. From the air nozzle, tiny quantities of pressurized air are used to complete the atomization. This results in a pattern of spray that is highly atomized, and it mimics a compressed air system. In this manner, higher volumes of production and a superior finish are obtained. Materials of medium viscosity are used and have a soft spray finish. This method has an initial high capital cost, and the application tip can become easily clogged, making it unsuitable for highly viscous coatings[58].

c. Pressure atomization/airless atomization: This method uses pressure to apply a coating on food. Through tiny nozzles, high-pressure energy is supplied that gives food a highly viscous and good surface tension coating. Throughout the procedure, the pressure remains below 3.5 bars. This method can handle a wide range of viscosities, and has significantly less material wastage due to the high transfer efficiency of 96%[53].

Button mushrooms were spray coated with bitter almond gum and fish gelatin conjugate to extend their shelf life[59]. Gelatin and chitosan were sprayed on vacuum packaged beef to extend the shelf life up to 21 d[60]. Poultry waste gelatin and lotus stem starch were used to develop edible coating sprays to extend the shelf life of cherry tomatoes[61].

Fluidized-bed processing method

-

In fluidized-bed processing, a thin coating of material is applied in layers on a dry particle with a very low density. Onto a fluidized powder surface, the solution of coating and suspension are sprayed, utilising many nozzles to form a structure resembling a shell. Fluidization is the process that occurs when liquid flows across the particle bed at a velocity that enables the particles to be moved without being in contact with the liquid. The three types of fluidized bed method are rotary-fluidized, top spray, and bottom spray, amongst which the conventional top spray works better than the others in the food industry[53]. In the food industry, it is used to manufacture a variety of food and additive encapsulations such as peanut, puffed wheat, and almonds[62].

Panning method

-

Food to be coated are placed in a pan, which is a large bowl that can be rotated. For an even distribution of coating solution on the the food item's surface, pouring or dusting of the layering solution is done in a pan, and the product is flipped. Drying of the coating is done using forced air, or by keeping it at room temperature. This process yields a glossy transparent edible covering with high elasticity[30].

-

Mechanical properties of gelatin film can vary depending on the fabrication process and fillers used. It has been stated previously, that the mechanical characteristics of pure gelatin film are enhanced as the triple-helix content increases. With the rise in triple-helix content, the films' stiffness improves from 3.6 to 12.0 MPa (Young's modulus). When the film is treated with a crosslinking agent, (1% glutaraldehyde) it becomes stronger, reaching up to 27 MPa. The tensile strength (TS), and elongation at break (EB) of plasticized gelatin film was measured, and the EB values of films with glycerol content of 10 and 20 g/100 g displayed values ranging from 4.7% to 21.4%. There was no change in the TS of films with glycerol content more than 60 g/100 g[63].

The impact of pH and cellulose nanocrystal (CNC) content on Young's modulus (stiffness), TS, and EB of gelatin-cellulose films was studied. At higher pH (such as 8), films with 0.5 wt% showed an increase in Young's modulus (152%), and TS (56%), but a decrease in EB. Electrostatic interactions between gelatin and CNCs are responsible for these changes. Therefore, the mechanical characteristics of gelatin (G) films are affected by both pH and CNC (C) concentration[64]. The TS and EB of gelatin-chitosan film were investigated and the results showed that the G100 exhibited lower TS (40.26 MPa) though higher EB (4.76%), C100 indicated higher TS than G100 (59.4 MPa), and EB of (1.26%). The composite films (G75/C25, G50/C50, G25/C75) results varied as per the composition ratio: TS: G75/C25: 50.2 MPa, G50/C50: 54.3 MPa, G25/C75: 59.1 MPa and EB: G75/C25: 3.4%, G50/C50: 2.8%, G25/C75: 2.1%. The results demonstrated that an increase in chitosan content enhanced the tensile strength, resulting in the formation of thinner films[65].

In a recent study, the incorporation of 4% bacterial cellulose improved the tensile strength of the gelatin-based films cross-linked with transglutaminase > 18 MPa, with a low elongation at break value over 11%. Indicating that the incorporation of bacterial cellulose enhanced the rigidity and structural stability of the film[66]. Addition of protein-rich additives such as eggshell membrane and gluten can influence the mechanical properties of the gelatin-based films. It was stated that the tensile strength of the gelatin film improved to a value of over 32 MPa, and the elongation of break of 3%[67]. Gelatin film with multiple-layers (furcellaran, chitosan, and gelatin) improved the mechanical functionality. When active ingredients, such as silver nanoparticles, montmorillonite, and curcumin-capsaicin mixture were added, the Young's modulus of the film doubled, supporting the fact that the addition of multiple film layers can improve the mechanical functionality of films[68]. Incorporation of Premna microphylla leaf extract and glycerol influenced the TS and EAB of the gelatin-based composite film. As the glycerol content increased, the EAB increased whereas the TS decreased[69]. Incorporation of curdlan, a polysaccharide derived from microbial processes, when integrated with gelatin film decreased the elasticity and TS of the film; however it increases the EAB. This observation suggests that the addition of polymers from microbial sources can improves the extensibility of the gelatin-based films[70]. Another work found that blending gelatin film with hydroxypropyl methylcellulose improved the EAB over 160% but displayed low TS (< 5 MPa), whereas incorporating carboxymethyl cellulose increased the TS (> 13 MPa), and an EAB between the range 120%−127%[71].

Barrier properties

-

The water vapor transmission rate (WVTR) of plasticized gelatin film was measured in the presence and absence of plasticizer. WVTR values of plasticized films demonstrated a huge difference from unplasticized films when the glycerol content reached 40 g/100 g of protein. WVTR values rose from 3.21 × 10−10 to 3.87 × 10−10 g/s/m/Pa as the glycerol content increased to 40 g/100 g of protein. But there was no significant difference in WVTR when the glycerol content was above 60 g/100 g. The water vapor permeability (WVP) and barrier properties of gelatin-CNC film were investigated, and it was observed that the incorporation of CNC decreased the WVP by 68% at pH 3 and at 39% at pH 6[64]. The physical properties of gelatin-starch composite films were studied upon the addition of fatty acids. The oxygen permeability (OP) of the films was analyzed to assess the efficiency of its barrier properties. The films were subjected to a condition in which pure nitrogen on one side, and pure oxygen on the other. The OP was calculated by dividing the oxygen transmission rate by the difference in oxygen partial pressure, and then multiplying by the average film thickness. The results proved that pure gelatin film (OS-100G) had higher OP as compared to pure starch film (100S-0G). The incorporation of gelatin led to an increase in the OP of the starch-gelatin composite film. Furthermore, the addition of esters further elevated the OP, contributing to the higher solubility of oxygen in the hydrophobic regions formed by lipid droplets[72]. Another study stated that the addition of bovine gelatin enhanced the barrier characteristics of the chitosan film. Oxygen permeability (PO2) of food packaging materials is crucial to prevent undesirable reactions such as browning, lipid oxidation, colour change, etc. Biopolymer films have good gas barrier properties, but have poor efficiency at high humidity. The incorporation of bovine gelatin enhanced the film's resistance to oxygen transmission rate. PO2 reduced from 943.21 to 296.67 × 10−12 g/m/s/Pa when gelatin content increased from 50% to 100%. The enhanced PO2 of the film can be attributed to strong intermolecular interactions such as hydrogen bonding between gelatin and chitosan molecules[73].

Gelatin films, due to their high porosity, exhibited high air permeability around 200 mm/s. Modification with xanthum gum reduced this to < 45 mm/s and further to 15 mm/s with the addition of molasses-derived carbon dots. The WVTR of snakehead gelatin film from > 28 to < 0.18 g/mm2/h upon the addition of κ-carrageenan and sorbitol. While glycerol served as a plasticizer, sorbitol had a greater influence on WVTR of the film due to its higher molecular weight[74]. Addition of probiotic and prebiotic additives into gelatin films can influence its WVTR, as these additives can alter the molecular interactions of the film matrix. It was demonstrated that incorporation of probiotic strains such as Lactobacillus paracasei, Bifidobacterium bifidum, and Lactobacillus plantarum to gelatin-based film, reduced the WVTR[75]. Addition of dextrin as a prebiotic into duck feet gelatin film reduced the WVP to < 3 g/m/Pa/s, because of the reduced intermolecular spacing and stronger hydrogen bonding[76]. Blending gelatin film from different sources significantly affects their barrier properties. A study demonstrated that combining cold-water fish and poultry gelatin increased WVP from 1 to 4 g/m/Pa/s and OP from > 48 to > 96 cm3·μm/(m2·d), due to higher concentrations of proline and hydroxyproline in poultry gelatin, which expands free space in the film matrix. In comparison, pure fish gelatin displayed WVP and OP of 1 × 10−11 g/m/Pa/s and > 48 cm3·μm/(m2·d), while pure poultry gelatin exhibited values near 5.0 × 10−11 g/m/Pa/s and ~97 cm3·μm/(m2·d)[77].

Physical treatments such as cold plasma can alter the barrier properties of gelatin film. In a study, cold plasma treatment reduced the OP of fish gelatin films by < 26% because of partial cross-linking formed due to the processing treatment in the film matrix with no effect on the WVP of the film[78]. In contrast, a study highlighted the change in WVP after cold plasma treatment on gelatin-based film and found that the WVP reduced from 2 to < 0.80 g·m/m2·s·Pa[79]. The practise of adding plant-derived polysaccharides and extracts into packaging films are gaining attention due to their ability to induce many functionalities in the film. A study was conducted to understand the effect of adding tomato seed mucilage to the gelatin film matrix. Adding tomato seed mucilage increased both WVP and OP with rising concentrations[80]. Another related study focused on gelatin film incorporated with cellulose and purple sweet potato anthocyanins. The gelatin-based composite film exhibited a reduced WVP of around 6 × 10−11 g/m/Pa/s. This reduced WVP is due to the increased compactness of the film after the addition of the functional plant additives[81].

Antioxidant properties

-

The antioxidant potential of gelatin-chitosan composite film was assessed using methods such as DPPH(2,2-diphenyl-1-picrylhydrazyl) based antioxidant assay, ferric ion reduction capacity assay, and β-carotene-linoleate bleaching test[65]. Pure gelatin films (G100) had the best antioxidant activity (7.24 mmol vitamin C/g) in a DPPH free radical-scavenging experiment. With pure chitosan films (C100) exhibiting the lowest activity (1.24 mmol), activity declined as chitosan concentration rose. Gelatin films have the maximum power (10.21 mmol vitamin C/g) for ferric reducing ability, whereas chitosan films had the lowest (1.36 mmol). All films showed some capacity to prevent bleaching in the β-carotene bleaching experiment. The most effective films were those composed of gelatin (G100) (0.32 mmol), whereas the least effective were made of chitosan (C100) (0.13 mmol)[41]. It was analysed using the ABTS Radical Scavenging method. The ABTS [2,2'-azino-bis (3-ethylbenzothiazoline-6-sulfonic acid)] radical scavenging activity of SG film without any extract was 37.58% ± 2.36%. When 20% RES was incorporated into the starch/gelatin film, the scavenging activity improved to 81.12% ± 0.60% due to the strong polyphenolic scavenging properties of RES, which is essential for product preservation[41].

The incorporation of sea buckthorn oil into the gelatin-based film improved its antioxidant property. It was observed that the incorporation of sea buckthorn oil increased the antioxidant property of the film by four times. This improvement was due to the nature of the amino acid profile present in the gelatin and along with natural antioxidants present in the oil[82]. A study was conducted on gelatin film to understand the change in the antioxidant property of the film after the incorporation of chitosan. The findings suggested that the gelatin-chitosan blend exhibited higher antioxidant activity (over 22 µg Trolox/cm2) compared to pure chitosan (more than 7 µg/cm2). After the incorporation of rice bran extract to the gelatin-chitosan blend, the antioxidant activity increased nearly to 30 µg Trolox/cm2. So, it can be concluded that the antioxidant properties of the gelatin film can be improved upon the addition of chitosan, and higher when more extracts are added[83]. The addition of miscanthus liquid hydrolysate improved the antioxidant activity of the fish gelatin film compared to that of pure gelatin. The DPPH radical scavenging activity of pure gelatin was < 25%, while that of the gelatin film with the plant extract was > 80%[84]. Similar findings were observed in the antioxidant activity when clove extract was incorporated into fish skin gelatin film. The free radical scavenging activity of the films increased from 72% to nearly 87%. This is due to the presence of phenolic compounds in clove such as eugenol[85].

Addition of Melaleuca alternifolia essential oil to the gelatin film enhanced the antioxidant activity > 55% of the gelatin film in terms of the ABTS assay[86]. The incorporation of Prosopis cineraria extract into the Tigertooth croaker fish scale gelatin film increased the antioxidant activity between a range of 50%−60%. The reducing power of the film also increased as the extract content increased[87]. A study was conducted to improve the antioxidant property of the gelatin film by the incorporation of phycocyanin nanoliposomes, zero-valent iron nanoparticles, and gold/iridium photoluminescent pigment. The results concluded that gelatin film with phycocyanin nanoliposomes had the highest DPPH radical inhibition (> 20%) whereas zero-valent iron nanoparticles displayed < 20% and the gold/iridium photoluminescent pigment made no significant changes[88]. The addition of Bauhinia sirindhorniae leaves extract in the gelatin-based film increased the antioxidant activity to more than 54%. Before the addition of the extract, the antioxidant activity of the film was < 50%[89].

Antimicrobial properties

-

Researchers evaluated the antimicrobial activity of nanocomposite films composed of fish protein isolate, and fish skin gelatin incorporated with zinc oxide (FPI/FSG-ZnO) by the disk diffusion method against Listeria monocytogenes and Pseudomonas aeruginosa as test organisms[90]. Zinc oxide nanoparticles (ZnONPs) incorporated in the films exhibited potential activity against Gram-positive bacteria compared to Gram-negative bacteria, due to their interaction with bacterial surface proteins and cell membrane components. The antimicrobial potential of gelatin films with regenerated cellulose nanocrystals (r-CNCs) was investigated using S. aureus and E. coli. To assess the effectiveness of the antimicrobial properties, the films were wrapped around a food sample (Mozzarella cheese), and stored at room temperature. r-CNCs suspension exhibited a strong bactericidal effect, at lower concentration (5.5 mg/mL) to inhibit S. aureus compared to E. coli (22 mg/mL). E. coli and S. aureus were effectively inhibited by gelatin/r-CNCs films, whereas no such effect was observed in CNCs-gelatin film[64]. The antimicrobial effect of gelatin-chitosan film was assessed using agar diffusion method using S. aureus, B. cereus, P. aeruginosa, K. pneumoniae, E. coli, M. luteus, S. typhi, and S. enterica as test organisms. The antibacterial activity in the film increased as the chitosan content increased. It was due to its overall positive charge, which disrupts microbial cell membranes[65].

A study was carried out on fish scale gelatin film to understand the antibacterial activity of the film after the incorporation of chitosan, nano-photocatalyst, and a nanocomposite of platinum loaded with carbon nitride. The incorporation of the functional additives exhibited excellent inhibition against the activities of E. coli and S. aureus. The gelatin-based bio nano-composite film displayed 97% inhibition against E. coli, and 96% inhibition against S. aureus[91]. The effectiveness of the antimicrobial activity of the gelatin film can be increased by the addition of essential oil. Aligned with this, a previous study demonstrated the effect of incorporating citral-montmorillonite and eugenol-montmorillonite in the gelatin film. Gelatin film incorporated with eugenol displayed the most effective activity against bacterial microorganisms and brought the microbial population below the detectable limit. The film reduced the activity of Listeria monocytogenes lower than 6 log CFU/mL and Escherichia coli by 6.4 log CFU/mL[92]. Another study observed that incorporating cinnamon essential oil on to the gelatin-based film enhanced the antifungal activity of the film, and displayed an inhibition of > 70% against Rhizopus oryzae, R. microsporus, and Syncephalastrum racemosum[93]. Integrating gelatin film with TiO2/Ag nanocomposites have enhanced antimicrobial activity as compared to individual antimicrobial activities of both TiO2 and Ag nanocomposites. Inhibition zone diameters between 20 and 30 mm were observed against A. fumigatus, B. spectabilis, C. xanthochromaticum, and S. albidofavus[94]. Embedding Bay-laurel essential-oil in centrifugally spun gelatin fibers depleted the growth of E. coli and S. aureus by 2% and 7%, respectively. The antimicrobial activity of the fibers was dose-depent on the essential oil content[95]. Table 1 shows various gelatin films and coatings along with their functional ingredient and key changes observed after their application.

Table 1. Gelatin films and coatings with functional ingredients for food packaging.

Polymer Gelatin source Additives Functional ingredient Main result Food product Method of application Ref. Gelatin Skin of dogfish (Squalus acanthias) Glycerol (15%) Lepidium sativum extract (20 μg/mL) Film reduced syneresis by 40%, maintained colour and minimized texture changes after 6 d of storage Cheese Wrapping [96] Gelatin Protein polymer gelatin Sorbitol (3 g) AgNP (30 and 40 mg) Film with 40 mg of AgNP exhibited excellent antimicrobial property against S. typhimurium, S. aureus, E. coli, and B. cereus with an inhibition zone of ≥ 12 mm − Solvent casting [8] Gelatin Puffer fish skin Sorbitol (2 g) Moringa oleifera L Leaf (0, 0.3, 0.5, 0.7, and 1.0) Increasing Moringa oleifera Lam. leaf extract concentration from 0.3% to 1%, improved the microbial inhibition zone from 9.63 to 20.00 mm Gouda cheese Solvent casting [97] Gelatin Bovine skin Glycerol (0.1 g), Tween 80 (2 wt %) Cinnamaldehyde (5.8%), ZnO nanoparticles (10 mg) Decreased water permeability by 86.86% and oxygen permeability by 12.07%. Increased EB by 11.27%. Efficient antimicrobial property of an inhibition zone of 25.0 ± 1.52 mm − Solvent casting [77, 98] Gelatin Cold-water fish gelatin, bovine gelatin (type B) Fish gelatin, bovine gelatin, glycerol (25 w/w%) − The water vapor permeability of the film increased 4-fold from 1.21 to 4.95 × 10−11 g/m/Pa/s and the oxygen permeability doubled from 48 to 97 cm3·µm/(m2·d) − Solvent casting [77] Gelatin, CMC − CMC (0.2 g), Glycerol (30%, w/w), hydrochloric acid (12 N), calcium chloride, magnesium nitrate − Coated fruits maintained their original appearance for 4 d with a lower decay index of 34.4% while the uncoated stayed only for 2 d Blueberry, walnut Immersing [99] Gelatin Fish Glycerin (10%, w/w), Tween 80 Ginger essential oil (0.5% v/v) Reduced weight loss of product from 20.19% (uncoated) to 15.95% and 13.12% at a storage temperature of 25 °C Pork Immersion-wrapping [100] Gelatin Pork skin − Propolis extract (0%, 1%, 2%, 3% w/v) Coatings with 2% and 3% (w/v) propolis extract reduced unfavourable colour changes, oxidation and growth of microorganisms at a storage temperature of 2 °C Pork loin Dipping [101] Gelatin Fish Acetic acid (30% v/v) Cinnamaldehyde (1%, 3%, 5%), limonene (1%, 3%, 5%), eugenol (1%, 3%, 5%) Mat with 5% eugenol exhibited highest radical scavenging activity of (89.33%). Mat reduced the growth of aerobic bacteria by 81% and yeast and molds 61% after a storage period of 10 d Wheat bread The mat was positioned inside the petri plate without any direct contact with the product [102] Gelatin − Glycerol (2 g) Carvacrol (0.6% w/v) Total oxidation index (TOI), p-anisidine value (AV) and peroxide value (PV) were decreased by 18%, 16%, and 30%, as compared to the control samples Breaded hake medallions Solution casting [103] Gelatin, chitosan Fish skin Chitosan (2% w/v), acetic acid (1% v/v), glycerol (0.3 g/g of gelatin) − Decreased browning reaction and increased vitamin C retention over 12 d of storage at 5 °C Fresh cut apples Dipping [104] Gelatin − Tween 80, sorbitol M. pulegium essential oil (0.5%, 1%) Gelatin coating with 1% MEO preserved over 60% of strawberries from deterioration during 13 d of storage period Strawberry Dipping [105] Gelatin Pork Glycerol (4%, 6%) Vegetable broth (25% and 50%) Increased the water activity of the product in a safe range of 0.215–0.389 Carrots (freeze dried bar) Immersing [106] Gelatin − Glycerol (0.1 mL/g), D-sorbitol (0.15 g/g) Propolis extract (2%, 8%, 16%) The shelf life of the fish was extended to 9–12 d, while the uncoated one lasted only 6 d Rainbow trout (Oncorhynchus mykiss) fillets Solution casting [107] Gelatin Trigger fish Glycerol (15% v/v) Moringa oleifera extract (5, 10, 20 µg/mL) Reduced water permeability by 35% and exhibited low changes in colour, pH and textural change Ricotta cheese Wrapping [96] Gelatin, HPMC − Xanthan gum (0.09 g), linseed oil (0.5 g) Cinnamon extract (0.3 g), clove extract (0.3 g) Film with clove extract showed antioxidant activity of 40.73% and cinnamon extract of 36.74% Muffin cake Solvent casting [108] -

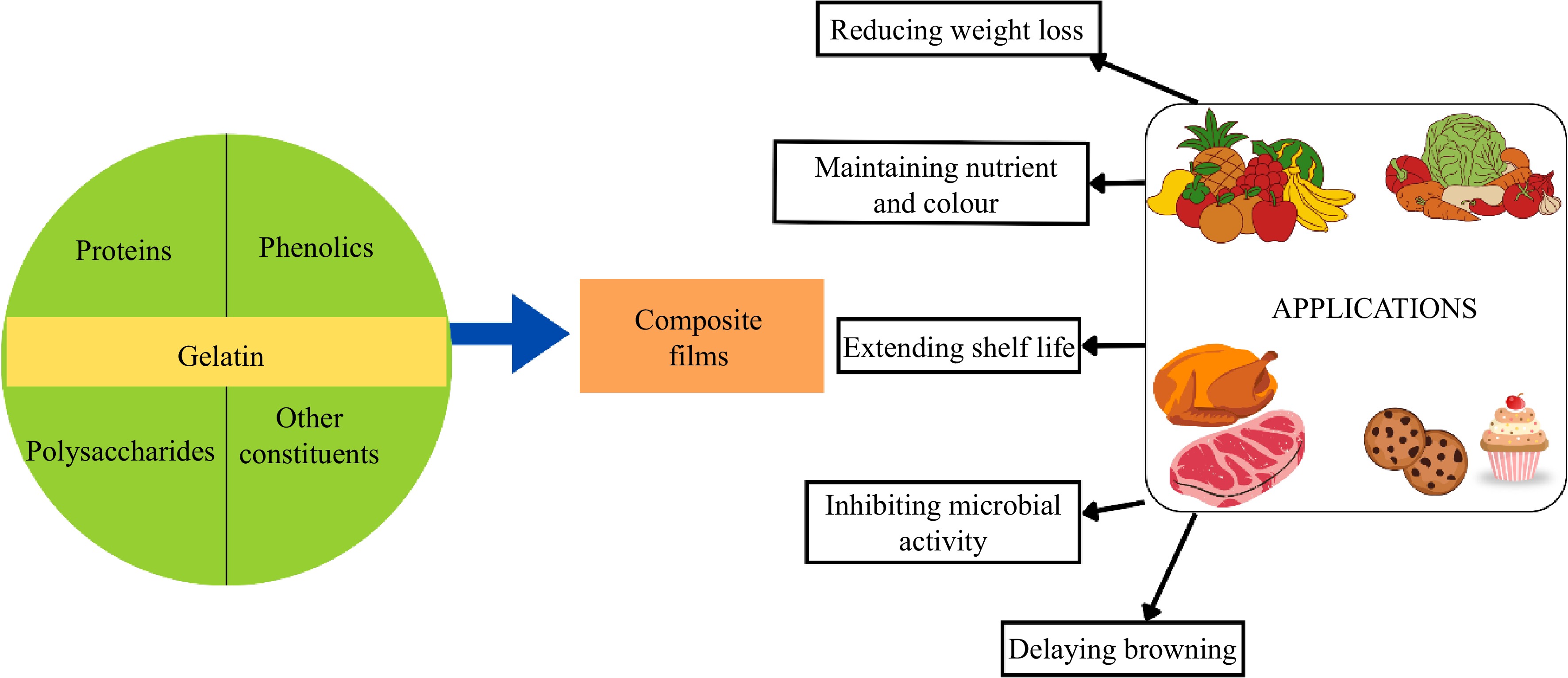

Gelatin-based packaging has been increasing as a promising solution for food preservation due to its biodegradability and functional properties. This packaging material can be used to improve food quality, and increase shelf life by implementing various bioactive compounds. The pliability of gelatin allows it to be used in various forms, such as films, coatings, and antifreeze peptides, each contributing unique preservation benefits. However, gelatin films are sensitive to moisture and easily dissolve, and also swell, or split when exposed to water, which is a disadvantage in food packaging. To overcome this, different natural and synthetic materials can be included to enhance their mechanical and thermal stability, flexibility, elasticity, and O2 and light barrier properties. Gelatin-based packaging also extends the product's shelf life due to its anti-oxidant and anti-microbial properties. Figure 4 illustrates the various applications of gelatin-based functional packaging films in preserving various food systems.

Fresh fruits

-

During post-harvest practices like harvesting, storage, and transportation, the quality and appearance of fresh fruits is affected because of continuous ethylene production, which causes over ripening, water loss, and decay. An earlier study reported that gelatin, chitosan, and calcium carbonate combined into an advanced nano edible film for post-harvest fruits (longan and banana) preservation. The results show that the weight loss rate of fruits wrapped in this nano edible composite film was radically decreased more than the other samples. This film also showed better water resistance and antibacterial properties, and it could productively extend the shelf life of longan for more than 3 d, and bananas for more than 5 d[109]. Gelatin, casein, sorbitol, and cassava starch were physically combined to create a thin film with very limited WVP and poor solubility. Because the coated guava fruit's chlorophyll degradation rate was slowed down, the fruit's quality declined less, and it had a greater amount of vitamin C and TSS. Additionally, the guava fruit coated with this film had a 2-d longer storage life. After 3 d of storage, the uncoated fruit had lost its green hue, but the coated fruit remained green for 9 d. It is evident that gelatine-based mixtures successfully postpone the ripening and deterioration of guava fruit[110].

Biofilms made from gelatin CNCs were developed to improve the storage life of strawberries, and to aid in storage between harvest and consumption. Strawberries were coated with a filmogenic solution (G-CNC) for 1 min before drying at 15 °C for 24 h. Strawberries were then refrigerated and regularly evaluated for water content, weight loss, ascorbic acid content, and titratable acidity. GEL/CNC-coated strawberries had a significantly longer shelf life due to reduced microbial deterioration. Furthermore, coating reduced weight reduction after 8 d of storage by 65% to 31%. This research also found that gelatin-coated samples had a slower ascorbic acid concentration decline than unprotected fruits. Banana fruits were also coated with a shellac-gelatin composite film to enhance their shelf life. This investigation involved coating bananas with a dipping technique and storing them at 25 °C for 30 d. Researchers found that a composite coating made of 60% shellac and 40% gelatin offered a robust barrier to ripening and kept post-harvest fruits fresh for more than 30 d[111].

Vegetables

-

Vegetables can also be preserved using gelatin-based film and coatings. Components like vitamins, minerals, and other nutrients which are present in vegetables play a crucial role in healthy dietary patterns. Vegetables have high moisture content, which may lead to rapid spoilage and decay. High moisture content favours microorganisms and vegetables. Fruits regulate respiration rate to affect the concentration of oxygen and CO2, to achieve relatively stable metabolic activities. Vegetables are susceptible to spoilage by mold, yeast, and bacteria, so it is necessary to package and coat freshly picked vegetables for protection[7]. Using the electrostatic spinning method, chitosan nanoparticles containing clove oil and gelatin composite membrane were created to preserve cucumbers. The amount of E. coli on yellow blossoms was assessed at various temperatures. The findings demonstrated that, at low temperatures, gelatine nanofiber membranes were more effective than pure gelatin films at inactivating antibacterials than at high temperatures. Following 4 d of storage, the experimental group's foods outperformed the control group in terms of both appearance and sensory evaluations. When compared to the control groups, both colour and flavour improved. In another study a researcher created a gelatin-based film with tannic acid, methylcellulose, and chitosan (CS) to preserve grapes and cherry tomatoes. Gelatin (22.1%–15.5%), CS (21.3%–19.6 %), methylcellulose (26.2%–20.5%), and tannic acid (15%) were used to wrap the cherry tomatoes. Following extended storage, they examined the physical, chemical, andmicrobiological characteristics, and discovered that the complex covering effectively maintained cherry tomatoes and grapes by lowering weight loss and browning index readings. The antibacterial qualities of gelatin-coated tomatoes against S. aureus and E. coli demonstrated that they were also immune to microbial deterioration[112].

Meat and meat products

-

Meat, a significant product in the human diet, is rich in essential fatty acids that the human body requires, also contains proteins and nutrients which play a role in overall health. During production, processing, and storage, meat products are susceptible to spoilage. Metabolic changes caused by microorganisms lead to freshness, texture, and colour changes. Various preservative methods like smoking, refrigeration, and freezing protects meat and meat products. Gelatin-based edible films and coatings are also used in the preservation of meat products to delay microbial spoilage and maintain the texture of meat. To preserve chicken breast, a gelatin film containing essential oil and nano chitosan has been produced. When compared to the control and samples wrapped in pure polylactic acid, the results demonstrated that the preserved chicken breast flesh had desired sensory qualities like colour, taste, and odour during the entire storage period, and that the antibacterial activity was greatly increased[113].

Sensory attributes of meat are also affected by coatings made up of gelatin. Gelatin was seen to support or improve sensory qualities of appearance, odour, texture, and general acceptability. As suggested in a previous study, gelatin coatings protect the visual quality and odor of vacuum-packed beef. It was identified that antioxidant-rich gelatin films would attenuate off-odours and conserve the freshness of beef. All these attributes make it necessary to take sensory evaluation into account when assessing edible coatings applied to meat[60]. The surfaces of collagen and gelatin have also been used to protect the colours, aromas, and freshness of shelf-life foods by blocking microbial and oxidative spoilage. For example, beef steaks enveloped in collagen showed significantly lower purge losses and lipid oxidation due to lower OP, compared to that of plastic wrap. In dry sausage applications, the coatings formed from pig gelatin with the additional use of kappa-carrageenan and locust bean gum for minimum weight loss and moisture retention helps with quality retention and economy[114]. Pectin-fish gelatin films incorporated with 3,4-dihydroxyphenylglycol or hydroxytyrosol completely inhibited lipid oxidation after 7 d, outpacing unfortified films with gelatin[115].

Fishery products

-

Fish is among the most perishable foods because of microbial spoiling, enzymatic processes, and chemical reactions, and contains polyunsaturated fatty acids, proteins, and free amino acids leading to discoloration, taste change, and rancidity. Proper handling, pre-treatment, and preservation can enhance the quality of fish products. To maintain shelf life and quality parameters, edible film and coatings can be developed. In a previous study, a gelatin, chitosan, gallic acid, and clove oil mixture coating (GE-CH-GA-CO) was created to test the freshness-preserving characteristics of fresh salmon fillets stored in a refrigerator at 4 °C for 15 d[116]. This study discovered that the combination coating may successfully stop the salmon fillet from becoming less brilliant. This could be because the film itself has an antioxidant impact on the fish's surface, protecting and isolating it[117,118]. Additionally, all the coated fillet samples pH values and the gelatin coating's gas permeability and WVP dropped, and the addition of GE–CH–CO greatly increased the antibacterial and antioxidant properties, increasing the storage life by at least 5 d. Salmon is arguably the most researched fish in terms of oxidative and organoleptic degradation because it is one of the most delicate dietary items. Gelatin has been used in several studies to protect salmon from cooking procedures by combining it with other biopolymers or active ingredients like lignin, barley bran protein, and grapefruit seed extract. Furthermore, because cold-smoked salmon is typically eaten raw, it can contain harmful bacteria, primarily E. coli and L. monocytogenes, which can lead to major health issues for customers. To circumvent this issue, smoked salmon was packaged using chicken feathers, a by-product of the poultry industry, as a film base material after the protein from the feathers was extracted and combined with gelatin and clove oil as an antioxidant and antibacterial active agent[116]. Table 2 shows how various gelatin-based films perform in the preservation of various food items.

Table 2. Characteristic features of various film compositions in extending the shelf life of food.

Film composition Food items Characteristics features Sensory characteristics Ref. Gelatin, chitosan, and CaCO3 Longan and banana Exhibited better water resistance and antibacterial properties, it could effectively extend storage life of longan for more than 3 d, and bananas for more than 5 d. Not reported. [119] [120] Gelatin, casein, sorbitol, and cassava starch Guava fruit Successfully extended the ripening and deterioration of guava fruit. Green color retained for up to 9 d, with delayed chlorophyll breakdown. [121] Shellac-gelatin Banana fruit Offered a robust barrier to ripening and kept post-harvest banana fruits fresh for more than 30 d. External appearance and stiffness are likely to have been kept. [111] Chitosan nanoparticles, gelatin composite membrane, clove oil Cucumbers Both colour and flavour of cucumber improved, more effective than pure gelatin films at inactivating antibacterials than at high temperatures. Enhanced color and flavor during preservation. [112] Gelatin-based film with tannic acid, methylcellulose, and chitosan (CS) Grapes and cherry tomatoes The antibacterial qualities of gelatin-coated tomatoes against S. aureus and E. coli demonstrated that they were also immune to microbial deterioration. Improved surface quality; decreased browning index. [122] Gelatin film containing essential oil (Zataria multiflora), and nano chitosan Meat products– chicken breast Antibacterial activity was greatly increased and colour, taste, odour of the meat breast was preserved. Preserved favorable sensory characteristics (color, odor, taste). [113] Gelatin, chitosan, gallic acid, and clove oil Fish products-salmon fillets Increased the antibacterial and antioxidant properties, increasing the shelf life of fish fillet by at least 5 d. Prevented color loss and off-odor development. [116] Gelatin-chitosan, and guava leaf extract Bovine meat Increased the shelf life of the meat by 15 d due to the enhanced antimicrobial and barrier properties such as water permeability and oxygen permeability. Not reported. [123] Chitosan, fish gelatin, and mango peel carbon dots Minced pork UV barrier, antioxidant, and antimicrobial properties helps the extension of shelf life of pork to 15 d. Not reported. [124] Gelatin and zein Strawberries UV barrier properties, excellent antioxidant properties, significant antimicrobial activity provide effectiveness in increasing shelf life of 7 d at room temperature. Not reported. [99] Gelatin and CuO nanoparticles Tomatoes Increased antimicrobial property and increased biodegradability of the film by 9 d along with the increase in shelf life by 18 d. Not reported. [125] Gelatin/chitosan coating with ginger essential oil/β-cyclodextrin Blueberries Increased antioxidant activity suppressed the growth of Botrytis cinerea, Penicillium italicum, and Alternaria, and increased the shelf life by 16 d at at 25 °C and 40 d at 4 °C storage. Not reported. [126] Gelatin/zein, and cinnamaldehyde Strawberries Increased the antibacterial properties and the shelf life of strawberries by 6 d. Not reported. [127] Gelatin/rapeseed meal Rapeseed Increased the antioxidant properties and decreased the oxidation process of rapeseed. Not applicable. [128] Gelatin-sodium alginate Cheese Improved the mechanical and barrier properties along with the enhanced antimicrobial properties against Escherichia coli, Listeria monocytogene, and Penicillium expansum and the shelf life of cheese improved by 15 d. Not reported. [129] Gelatin-lignin composite Salmon (cooked) Protection against oxidation during heat processing. Improved flavor and less rotten odor. [130] -

Gelatin has been an innovative biopolymer for tackling the usage of nonbiodegradable plastics, such as PET (polyethylene terephthalate), PE (polyethylene), PVA (polyvinyl alcohol), and PVC (polyvinyl chloride) as packaging materials which cause several health and environmental concerns. Being a natural biopolymer, gelatin has the potential to overcome the concerns regarding environmental pollution due to its biodegradable nature, but poses several limitations. One of the major limitations with gelatin films is they are not suitable for high moisture foods, as they show poor barrier properties against moisture, which leads to microbial contamination, and lower shelf life of the products. Additionally, gelatin films often lack the mechanical strength needed for practical applications, and their high WVP further limits their usage in the commercial sector.

The next limitation is associated with the source materials employed for gelatin film production, primarily derived from mammals, particularly pig and bovine skins, which are not a suitable source for a particular religious group, such as Jewish and Muslim consumers, as they do not consume products which involves the usage of pigs. Microbial contamination is particularly evident in raw materials sourced from slaughterhouses and butchers, and are also seen in the production or processing sector with aerobic endospore bacteria. There has been no concrete research on the health hazards and allergic toxins of gelatin when using the products with these films.

Future research should prioritize methodological strategies that improve both the performance and safety of gelatin-based films. A key direction is the optimization of cross-linking agents, such as genipin, transglutaminase, and carbodiimide, to increase intermolecular bonding and reduce solubility. Variables such as active agent concentration, reaction kinetics, and solvent compatibility should be systematically studied. Embedding nanoparticles such as AgNPs, ZnO TiO2, clay minerals, or cellulose nanocrystals may improve antimicrobial activity and barrier properties, with attention to dispersion methods and food safety standards. Hybrid systems incorporating chitosan, starch, pectin, or whey protein offer synergistic improvements in flexibility and moisture resistance. Fabrication methods like electrospinning, extrusion molding, and solution casting should be optimized for porosity, scalability, and environmental impact. To ensure safety and inclusivity, future studies must assess toxicity, allergenicity, and techno-economic feasibility while exploring halal/kosher-certified and fish-derived gelatin alternatives.

Despite these limitations, gelatin-based films have great potential for modifications on an industrial scale. Further research is required to broadening the utilization scope of gelatin-derived edible layers and protective barriers. With proper modifications, such packaging could emerge as a dominant trend across food packaging industries by providing eco-friendly biodegradable solutions compared to conventional plastics. Future research should have focus areas that ensure consumer safety when using the products, address the ethical concerns, and make these kinds of products available to all sections of society in terms of cost, application, and accessibility. By overcoming these limitations, gelatin-based films and coatings revolutionize the field of packaging by paving the way for a greener and more sustainable future.

-

Gelatin coatings and films have shown great potential as a replacement for synthetic packaging material. They are capable of forming biodegradable films and can serve a variety of purposes. Pigs, cattle, and fish, are all sources from which gelatin can be derived for the development of sustainable packaging. These gelatin matrices have improved the product quality, increased the shelf life, and also acted as a matrix for active ingredients like antimicrobials and antioxidants. A thorough assessment of the physical attributes, which include mechanical strength, moisture sensitivity, and barrier properties provide insights into their function and industrial application. Although there are some drawbacks with respect to moisture, strength, barrier, and thermal stability, the use of additives has expanded the range of applications for gelatin films and coatings. Gelatin-based materials have a lot of potential to meet the expanding need for environmentally friendly and useful packaging systems for foods and other industries with the advancement of research.

-

Not applicable.

No funding was received.

-

The authors confirm their contributions to the paper as follows: experimental design: Roy S; initial manuscript writing: Reji RE, Mathew CB, VJ, Sabu CS; data investigation and interpretation: Reji RE, Mathew CB, VJ, Sabu CS; figure production: Reji RE; manuscript editing: Roy S. All the authors revised and approved the final version of the manuscript.

-

Data sharing is not applicable to this article as no new data were created or analyzed in this study.

-

The authors declare that they have no conflict of interest.

- Copyright: © 2025 by the author(s). Published by Maximum Academic Press on behalf of China Agricultural University, Zhejiang University and Shenyang Agricultural University. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Reji RE, Mathew CB, VJ, Sabu CS, Roy S. 2025. A review on gelatin films and coatings for active food packaging: functional properties and applications. Food Innovation and Advances 4(3): 423−436 doi: 10.48130/fia-0025-0046

A review on gelatin films and coatings for active food packaging: functional properties and applications

- Received: 17 May 2025

- Revised: 23 August 2025

- Accepted: 26 August 2025

- Published online: 26 September 2025

Abstract: Gelatin, a biodegradable biopolymer sourced primarily from the collagen of mammals, fish, and poultry, exhibits promising potential in sustainable food packaging due to its antioxidant, antimicrobial, and film-forming properties. However, its practical application in food preservation is challenged by poor moisture resistance, limited mechanical strength, and source-related ethical concerns. These shortcomings can lead to microbial spoilage, reduced shelf life, and restricted consumer acceptance. Recent strategies to overcome these limitations include the use of cross-linking agents (genipin, citric acid, transglutaminase, etc.) to improve structural stability, incorporation of nanomaterials (silver nanoparticles, zinc oxide, TiO2, etc.) to enhance barrier and antimicrobial functions, and blending with other biopolymers (chitosan, agar, pectin, cellulose, etc.) for better flexibility and water resistance. Advances in processing techniques such as electrospinning and extrusion molding further optimize film morphology and performance. This review offers new insights by synthesizing these approaches and identifying future research directions focused on scalability, safety assessments, and inclusive sourcing. Gelatin films, when strategically modified, can serve as a viable replacement for conventional plastics in food packaging, offering a pathway toward safer and more sustainable preservation systems.

-

Key words:

- Gelatin /

- Biopolymer /

- Edible films and coatings /

- Cross-linking /

- Nanomaterials /

- Food preservation /

- Sustainable packaging