-

Fire safety is a paramount concern in modern society, commanding unceasing attention across diverse domains. In the light of rapid population expansion, globalization and urbanization, a diverse array of amenities are established for convenience. These include convenient transportation options i.e., electric vehicles, metros, subways; shopping malls, commercial avenues, industries, medical facilities, construction sites, residential buildings, restaurants and kitchens among others. It is a necessity to have proper architectural designs supporting firefighting prerequisites to avoid fire accidents which can occur at any location or setting, leading to excessive damage[1−5]. Efforts are even diverted to implement artificial intelligence towards addressing fire safety issues and improving response times[6]. The ability to effectively combat, prevent, and minimize the impact of fires holds profound implications for safeguarding human lives, protecting property, and ensuring the continuity of vital operations. Central to the pursuit of robust fire safety strategies is the development of advanced materials that can withstand the ravages of flames and heat, thus providing a critical line of defense against the destructive force of fires. Flame retardants, a diverse group of substances encompassing inorganic and organic chemicals, find extensive use in applications like furniture, building materials, and electronics, often incorporating halogens like bromine and chlorine to acquire fire-resistant properties. The persistence of halogens, while enhancing flame retardancy, has led to issues of bioaccumulation and contamination even after phase-out, exemplified by the ongoing concern over compounds like polybrominated diphenyl ethers (PBDEs), tetrabromobisphenol-A (TBBPA), and hexabromocyclododecane (HBCDD), impacting both legacy materials and the broader environment[7].

Innovative sources such as phytic acid (PA) extracted from various herbal origins[8], salts and bioactive metabolites in vegetable extracts viz., spinach leaves, pumpkin juice, banana pseudo stem sap[9−11], natural materials like fishbone powder and rice husk silica[12,13], as well as bio-based compounds including cardanol resin, phloroglucinol, and levulinic acid[14], have demonstrated remarkable flame-retardant effects on polymers. Lignin-based compounds have also garnered attention due to their polyphenolic structure promoting char formation and diminishing flame propagation[15,16], exemplified by functionalized lignin's success in reducing heat release and enhancing char formation in wood plastic composite materials[17]. These diverse natural sources and compounds collectively exemplify the evolving landscape of sustainable and effective flame-retardant strategies. Chitosan, alginate, and tannins are several other naturally occurring material which provide fire retardancy to the textile materials[18,19]. The imperative to replace harmful flame retardants with environmentally friendly alternatives that promote insulating char formation on burning surfaces has led to the emergence of promising renewable-resource-based solutions, crucial for enhancing fire behavior across polymer matrices, minimizing smoke release, and supporting the sustainable integration of bio-based polymers in various technical applications[18].

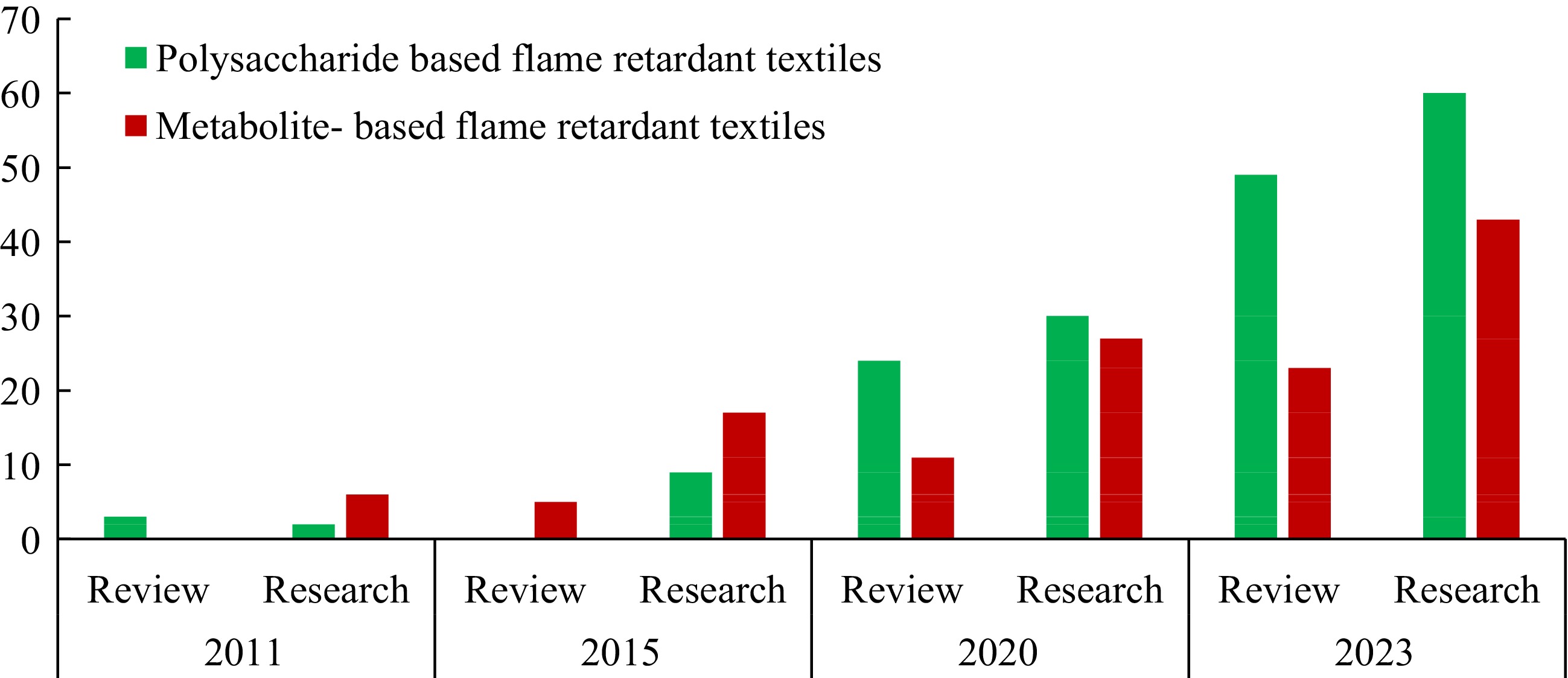

In recent decades, inedible lignocellulosic materials or polysaccharide-based materials (cellulose, chitosan, starch, alginate and pectin), and bioactive secondary materials have been utilized for developing ecofriendly fire-retardant materials thereby enabling the conversion of biomass into valuable bio-based products. This review aims to delineate recent advancements in utilizing plant originated materials as flame retardant additives for textiles and exploring the latest developments in bio-based flame-retardant additives. Fig 1 provides insights on the total number of publications (both review and research papers) that are published and listed in the Scopus database.

-

Traditional flame retardants for textile fabrics have been a cornerstone of fire safety measures across numerous industries, from clothing and upholstery to industrial applications. These chemical compounds are specifically designed to impede or delay the ignition, combustion, or spread of flames in textile materials, thereby reducing the inherent fire hazard and enhancing overall safety[20].

One category of traditional flame retardants includes halogenated compounds, which were among the earliest forms of flame retardants utilized in textiles. Halogenated flame retardants incorporate elements such as chlorine, bromine, or fluorine into their chemical structure. Presently, many of these chemicals are recognized as global pollutants. They can damage the health of both animals and humans. This damage includes interfering with our hormones and thyroid, hurting our immune system, creating problems with reproduction, raising the chances of cancer, and negatively impacting the growth and brain development of babies[21]. During the period from 2004 to 2013, the widely employed brominated flame retardants known as polybrominated diphenyl ethers ceased production and usage. As a result, there was an increasing demand for alternative flame-retardant substances to fill the gap[22]. These elements have the capability to disrupt the combustion process by interfering with the fire's chemical reactions. However, concerns regarding the environmental persistence and potential health risks associated with these chemicals have led to a reevaluation of their use and a shift towards more sustainable alternatives such as natural polysaccharides and secondary metabolites.

Phosphorus-based flame retardants represent another widely employed category. These flame retardants are favored for their effectiveness and relatively lower toxicity[23]. In the condensed phase, phosphorous influence on materials manifests through a range of noteworthy effects[24]. Firstly, phosphorus exhibits the capacity to enhance the combustion of materials, resulting in their transformation into charred or blackened substances. Secondly, it instigates a process referred to as 'intumescence,' whereby materials subjected to phosphorus-containing conditions experience swelling and expansion. Notably, this phenomenon has garnered attention for its potential in fire-retardant applications. Additionally, phosphorus can induce the formation of a glass-like structure within the material when subjected to elevated temperatures, introducing novel properties and behavior. Conversely, in the gas phase, where phosphorus exists in a gaseous state, it assumes a distinct role. Here, phosphorus serves as a flame inhibitor, actively retarding the spread of fires[24]. Inorganic flame retardants offer a different approach to fire prevention in textiles. This category includes compounds like aluminum hydroxide and magnesium hydroxide. These materials operate by releasing water vapor when subjected to heat, which serves a dual purpose. Firstly, it cools down the fabric, reducing the chances of ignition. Secondly, the released water vapor dilutes the concentration of flammable gases, further inhibiting the fire's propagation[25].

In conclusion, traditional flame retardants have played an essential role in safeguarding lives and property by reducing the flammability of textile fabrics. However, in response to environmental and health concerns, there is a shift in the industry towards more sustainable and eco-conscious flame-retardant alternatives, striving to strike a balance between fire safety and ecological responsibility.

-

The flame retardancy mechanism is a complex and multifaceted process that operates to reduce the flammability of textile fabrics. This mechanism is crucial for the development of effective fire-resistant textiles, especially in environments where fire safety is paramount.

Release of flame-inhibiting gases and radicals

-

One fundamental aspect of flame retardancy involves the release of flame-inhibiting gases or radicals when the flame retardant-treated fabric is exposed to heat or flames. These gases and radicals act as diluents, which means they dilute the concentration of flammable gases present near the fabric's surface. By doing so, they effectively decrease the fuel available for the fire to sustain itself. This reduction in flammable gases significantly hampers the propagation of flames[26].

Formation of protective char layer

-

Another critical facet of flame retardancy is the creation of a protective carbonaceous layer (char layer). Certain flame retardants, especially those containing phosphorus, have the remarkable ability to promote the formation of this char layer when subjected to heat. The char layer functions as a robust physical barrier, shielding the underlying fabric from the heat source. It plays a dual role by limiting the fabric's exposure to oxygen, a critical component for combustion. By restricting oxygen access, the char layer retards the combustion process, making it significantly more difficult for the fire to spread[27].

Cooling effect of flame retardants

-

Certain flame retardants exhibit a cooling effect when exposed to fire. This cooling action involves the absorption of a substantial amount of heat energy (endothermic reactions) from the flames. By rapidly reducing the temperature of the fabric, this mechanism inhibits further ignition or combustion. By absorbing heat, they effectively reduce the overall energy available for sustaining the fire. This reduction in heat energy can be instrumental in preventing the fire from spreading further[28].

Production of free radicals

-

Certain flame retardants have the capacity to produce free radicals when exposed to fire. These free radicals disrupt the chemical reactions that are typically necessary for combustion to occur. They interfere with the chain reactions that propagate the burning process, effectively interrupting the fire's progression at a molecular level[27].

Synergistic mechanisms

-

It's important to highlight that these mechanisms often operate in synergy rather than in isolation. Flame retardant materials are typically designed to leverage multiple mechanisms simultaneously. This comprehensive approach to fire protection ensures a robust defense against flames and enhances the overall effectiveness of fire-resistant textiles.

Understanding these intricate mechanisms is pivotal for tailoring flame-retardant treatments to meet the diverse and specific requirements of various textile applications. Whether it's protective clothing, upholstery, or industrial textiles, an in-depth comprehension of these mechanisms enables the development of textiles that prioritize safety and fire resistance in a wide range of settings.

-

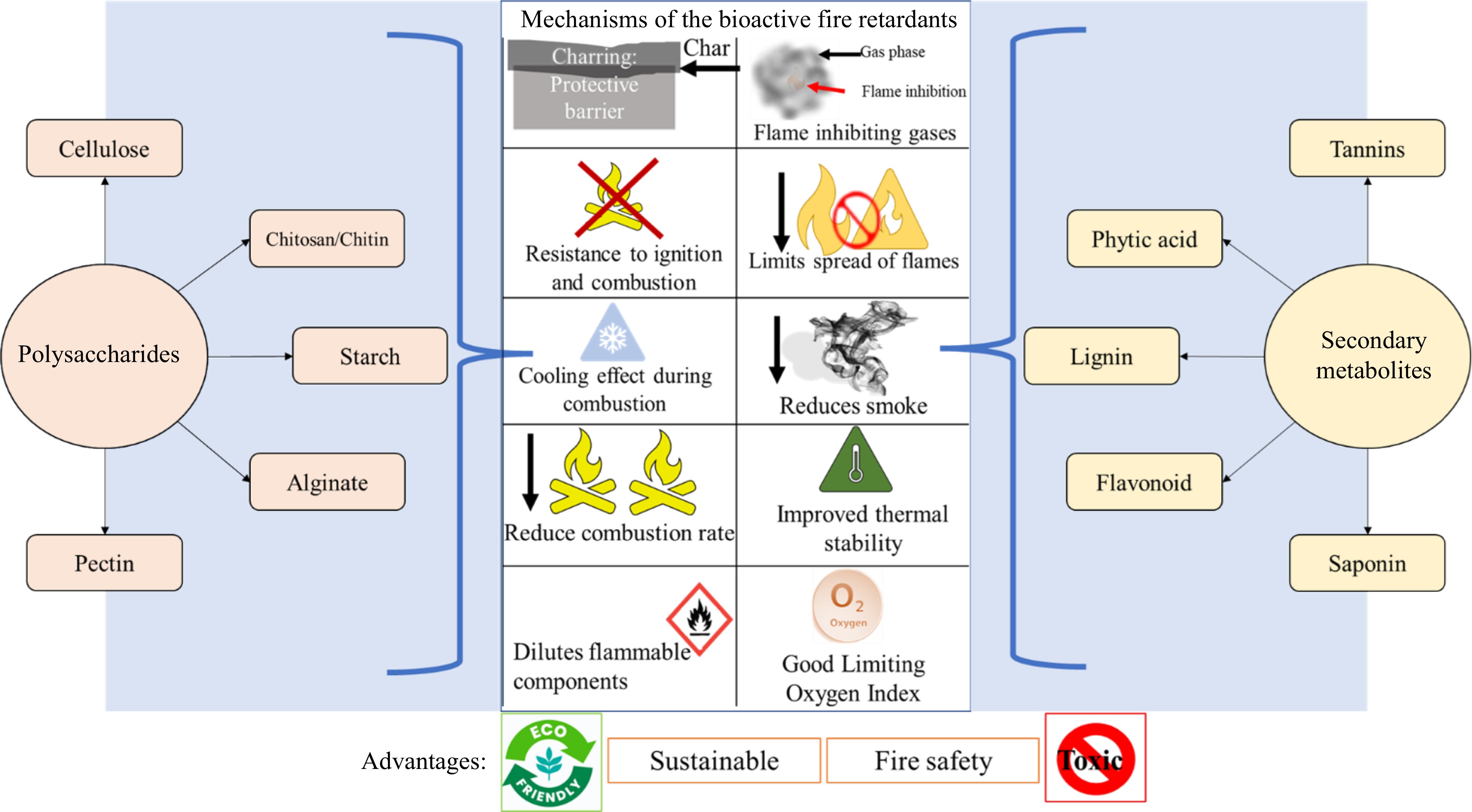

Polysaccharide-based fire retardants represent a promising avenue in the realm of fire safety and materials science. Derived from renewable sources, these compounds leverage the inherent properties of polysaccharides to impart fire resistance to various materials. Through their ability to char under heat exposure, form protective layers, and release non-flammable gases, polysaccharide-based fire retardants offer a sustainable, environment-friendly and effective approach towards enhancing the fire performance of diverse substrates, spanning from textiles to polymers. Table 1 summarizes the polysaccharide-based and Fig 2 focuses on the mechanism of the fire-retardants.

Table 1. Polysaccharide-based fire retardants.

Polysaccharide Source Mechanism Main finding of study Reference Cellulose Blanver (São Paulo, Brazil) Fire retardant made from graphite and cellulose by drying aqueous dispersions of graphite and cellulose on canvas and wood Surface temperature measurements and thermal images showed fast heat transfer from flamed spots and suppressing flare formation [52] Chitosan and microcrystalline cellulose Hangzhou, China Biobased flame retardant by surface-functionalizing microcrystalline cellulose with chitosan and sodium phytate via LBL assembly in water 15 wt% P-MCC@CS@PA-Na helped epoxy resin to pass UL-94 V-1 rating with LOI of 26.2%

Peak heat release rate, peak smoke production release, fire growth rate, and total heat release are greatly reduced, showing good fire retardance[53] Cellulose Viscose fibers obtained from Kelheim Fibres (Kelheim, Germany) Incorporation of silica (20%wt) into cellulose matrix during fiber formation, stabilization with aluminate treatment Incorporating silica reduced flammability, aluminate treatment prevented leaching.

Significant reduction in after glowing (−82%) and material destruction (−90%) observed.[54] Phosphorylated microcrystalline

celluloseAladdin Reagent Co. Ltd. (Shanghai, China) The cellulose spinning dope (2 kg) loaded with 20 wt% phosphorylated cellulose. The obtained lyocell fibers with 20% phosphorylated cellulose loading were called fire retardant fibers. The lyocell fibers loaded with 20 wt% P-Cell exhibited favorable thermal stability and fire retardancy.

The dehydration of the cellulose unit leading to the formation of phosphorus-containing oxides and a char layer, serving as a protective matrix layer[55] Chitosan Chitosan purchased from Sinopharm Chemical Reagent Company (China) Organic-inorganic composite aerogels (chitosan and aluminum chloride) prepared by freeze drying method CA1.5P aerogel showed high compressive strength of 8.55 MPa and specific modulus of 66.3 m

Inorganic components from AIP (7.7–20.1 wt%) showed increased LOI value (35%–41.1%)[56] Chitosan Chitosan derived from chitin flakes (LR grade), SD fine chemicals limited, Mumbai, India Chitosan underwent chemical modification using melamine and sodium pyrophosphate as sources of nitrogen and phosphorus, along with glyoxal as a crosslinking agent. Untreated cotton exhibits a low LOI than chitosan treated cotton fabric

Cotton fabric treated with modified chitosan, had enhanced thermal resistance with higher thermostability[36] Chitosan Chitosan derived from corn starch and sugarcane Chitosan was integrated into PLA to create flame-retardant and high-performance composite materials. Adding 3.75 wt% of chitosan furfural compound (CFU) along with 11.25 wt% of APP to PLA resulted in achieving the UL-94 V-0 rating, a nearly 28% increase in the LOI, and reductions of approximately 35% in total heat release and 90% in smoke release [57] Starch Synthesized from starch, phosphorus acid, and urea for cotton fabrics (Chengdu Kolon Chemicals Co, China) Biomass starch-based phosphorus-containing flame retardant, ammonium starch phosphate synthesized for cotton fabrics Phosphorus-based flame retardant (ammonium starch phosphate) showed flame retardancy for cotton fabrics (LOI: 45.2%, even after 50 laundry cycles), attributed to successful grafting onto cotton fibers with P-O-C covalent bonds [44] Starch Potato starch (Superior, Emslandstärke, Emlichheim, Germany) Thermal degradation of ammonium starch phosphate carbamates with varying degrees of substitution Increased charring and polyphosphate formation in condensed phase as DS of SPC rose showed reduced temperature mass losses and lower activation temperatures in comparison to native starch [45] Alginate Qingdao, China Fe3+- modified alginate coatings on PET fabrics by simple dip-coating technique ZnAlg/Ag3PO4 showed highest flame-retardant performance with LOI of 79.8% and HRC of 79.8 J/(g·K). Coated PET fabrics achieved a LOI of 29% and exhibited a significant 70.3% reduction in peak heat release rate [48] Pectin Purchased from Yantai Andre Pectin Co., Ltd, USA Biomass-derived polymer aerogels composed of pectin and aniline via polymerization–coagulation followed by supercritical drying process Biomass-derived polymer aerogels showed 3D hierarchical networks with high surface areas (103−205 m2 g−1), good compressive strengths (4.7−9.2 MPa), exhibited low thermal conductivity (0.033−0.038 W m−1 K−1) [50] Pectin Purchased from Aladdin Company, Shanghai Self-cross-linked aerogel, from pectin and MF using a freeze-drying method with water as solvent M10Pe5 aerogel showed compressive modulus of 23.2 MPa and specific modulus of 188 MPa cm3/g, showing both thermal stability and excellent water resistance [51] AIP: Acidic hydrolysis of aluminum isopropoxide; SPC: starch phosphate carbamates; PET: polyester; LOI: limiting oxygen index. Cellulose-based flame retardants

-

Cellulose, a prominent polysaccharide found in plant cell walls and due to their sustainable nature, cellulose fibers are advocated for diverse textile applications, although their mechanical and flammability attributes differ significantly based on chemical composition, which in turn is influenced by their source (such as grass, bast, wood, cane, seed, leaf, and fruit), and being organic, they present a substantial fire hazard[29]. Cellulose can be modified to create fire-retardant materials through its ability to char, serve as charring catalysts, dilute flammable components, reduce smoke, slow down the combustion and provide cooling by neutralizing free radicals during combustion[30]. Cellulose-based derivatives often generate char during combustion, forming a protective barrier that limits the spread of flames. For instance, cotton cellulose and peat cellulose (P-Cell) are two types of knitted textiles sharing similar construction of fabrics. However, P-Cell displays a longer total burning time (~281 s) and extended after-glow compared to Cot-Cell (~199 s)[29]. This divergence is potentially influenced by the lignin present in P-Cell's brown fibers, as lignin's slow combustion and aromatic char production may contribute to the observed differences[31,32]. A recent study employed an ionic liquid, 1,3-dimethyl imidazolium methyl phosphite, to create phosphorylated cellulose, demonstrating its compatibility and dispersity in cellulose spinning. This structural affinity between phosphorylated cellulose and cellulose units led to enhanced lyocell fiber's mechanical strength in, resulting in flame retardant lyocell fibers with excellent flame retardancy (< 1% phosphorus content), reducing rate of peak heat release (pkHRR) (50.9%) and increasing breaking strength by 6.44% compared to pure lyocell fibers[33]. In another study, a bio-based coating containing PA and DL-arginine was applied to cellulose fabric via layer-by-layer (LBL) self-assembly, resulting in a fabric with enhanced properties. With 20 assembly cycles, the coated cellulose fabric demonstrated a limiting oxygen index (LOI) value of 27.0% ± 0.2%, along with 18.6% lower pkHRR and 33% lower total heat-release (pkTHR) compared to pure fabric. Moreover, the fabric exhibited significant antibacterial effects against Staphylococcus aureus, an inhibition zone diameter of 2.1 mm, and excellent resistance for washing (6%–8%: P loss rate, after 30 washes), making it a promising choice for vehicle interiors and soft decorations due to its combined flame retardancy and antibacterial properties[34]. In a study, researchers successfully developed multifunctional organic coatings for viscose textiles, emphasizing their flame retardancy properties. These coatings, derived from sustainable materials like cellulose nanocrystals from discarded cotton clothes, mandarin shell-based graphene sheets, and polyaniline nanofibers, were meticulously characterized. The treated fabrics exhibited remarkable fire safety improvements, achieving a zero-burning rate compared to 193 mm/min for untreated textiles. This enhanced flame retardancy resulted from a synergistic effect among coating components, forming a protective char barrier[35].

It is prudent that cellulose's inherent properties for flame retardancy by exploring modifications that generate char during combustion, forming a protective barrier against flames. Phosphorylated cellulose and bio-based coatings with bioactive c polysaccharides and amino acids can provide dual properties such as flame retardancy and antibacterial properties.

Chitosan and chitin-based flame retardants

-

Chitosan and chitin, derived from crustacean shells, are polysaccharides with inherent flame-retardant capabilities. They release non-flammable gases upon heating, diluting flammable gases and reducing the overall combustion rate. These compounds have been incorporated into various materials, including textiles and polymers, to enhance their fire resistance. In a study, simple method was devised to synthesize nitrogen-phosphorus-rich multifunctional agents for flame-retardant, UV-protective, and antibacterial cotton fabrics by chemically modifying chitosan with melamine, sodium pyrophosphate, and glyoxal. The treated fabrics exhibited enhanced fire retardancy (LOI > 30), excellent UV protection (UPF > 100), significant bacterial inhibition, and acceptable mechanical properties[36]. A recent study showed that fish waste-derived chitosan (CS) to create environmentally friendly flame retardants, such as CS-ammonium polyphosphate-4,40-methylenebis(N,N-diglycidylaniline) (CS-APP-NDY), this study significantly enhanced flame-retardant performance. The addition of CS-APP-NDY to silicon polyurethane (Si-PU) led to notable improvements, including an increase in char yield from 0.5 wt% to 25.8 wt%, an elevated LOI from 18.2% to 26.3%, and an enhanced UL-94 rating from 'Fail' to V-1, underscoring its potential in advancing flame retardancy[37]. Further studies synthesized single-molecule intumescent flame retardant, created by microencapsulating chitosan-based ammonium polyphosphate with melamine-formaldehyde resin, demonstrated improved thermal stability at high temperatures. This positively charged polymer exhibited excellent coordination due to its multiple reactive hydroxyl and amino groups, while the incombustible gas generated by decomposing of melamine-formaldehyde resin reduced surface heat absorption, resulting in enhanced flame retardancy, including improved LOI (25.7%), vertical combustion rating (V-1), and anti-dripping effect in polypropylene composites. The smoother decomposition process, lower surface temperature during combustion, and higher crystallinity of the carbon layer further confirmed the positive flame-retardant effect on polypropylene[38]. A self-extinguishing coating comprising biobased chitin derivatives, namely deacetylated chitin (chitosan) and phosphorylated chitin was successfully applied to cotton fabrics through LBL assembly. The deposition of phosphorylated chitin content on cotton fabric surfaces was contingent on the bilayers' number and phosphorylated chitin concentration. Notably, in vertical flame tests, cotton fabric coated with 20 bilayers at a high phosphorylated chitin concentration (2 wt%) could extinguish the flame, while micro combustion calorimetry revealed reduced pkHRR and pkTHR values in all coated cotton fabrics compared to the pure fabric. Additionally, thermogravimetric analysis indicated enhanced thermal oxidation stability within the higher range of temperature (400–700 °C), thus presenting an innovative biobased approach to augmenting cotton fabric's flame retardancy[39]. Further, modified-chitosan based flame-retardant with organic salts like nickel, iron and boron were able to exhibit improved fire retardation. This was due to the crosslinking ability of the salts allowing the flame-retardant coat to decompose before the fiber, forming a shielding coat of char, preventing heat transfer, and oxygen between the flame and the fabric[40]. In an independent study, researchers developed textile fabric coatings, primarily concentrated on improving flame resistance. These versatile coatings were crafted using a precise, single-step procedure, combining UiO-66 metal-organic frameworks with environmentally friendly green polypyrrole nanoparticles and chitosan chains. These resultant coatings were carefully applied to cotton fabrics, and an exhaustive assessment of their characteristics followed. Substantial accomplishments were discerned across diverse aspects. The coatings showcased outstanding flame-resistant qualities, resulting in a remarkable 54% reduction in the combustion rate when compared to untreated samples[41]. In another research endeavor, scientists achieved a significant enhancement in the coatings applied to textiles. Their primary focus was to improve these coatings' ability to prevent fires. They accomplished this by developing new coatings using minuscule particles created through an energy-efficient method, ensuring precise sizing. Subsequently, they applied these particles to create layers on cotton and polyester fabrics. The findings were quite remarkable. During rigorous testing, the coated fabrics displayed exceptional fire resistance. These textiles did not catch fire at all, and they exhibited a 34% improvement in fire resistance compared to untreated cotton fabrics commonly used[42]. In a different research investigation, scientists created a coating using a combination of rice husk silica nanoparticles and chitosan. They observed that this nanocomposite coating displayed enhanced resistance to high temperatures[43]. It is thereby evident that biobased materials, derivatives of chitin and chitosan, are applied as self-extinguishing coatings through LBL assembly, resulting in enhanced flame retardancy, reduced pkHRR, transmission of heat, improved thermal stability, and potential extinguishing capabilities.

Starch-based flame retardants

-

Starch, a carbohydrate polymer, can be treated to improve its fire-retardant properties. Modified starch forms intumescent char layers upon exposure to heat, creating a barrier that shields the material from flames. Starch-based flame retardants have found applications in textiles, coatings, and even building materials. New phosphorus-based flame retardant, ammonium starch phosphate (ASTP), synthesized from biomass starch, exhibited high and durable flame retardancy for cotton fabrics (LOI: 45.2%, even after 50 laundry cycles), attributed to successful grafting onto cotton fibers with P-O-C covalent bonds. ASTP treatment significantly improved vertical flammability and thermal properties, offering a promising, formaldehyde-free solution for enhanced and lasting flame retardancy in textiles[44]. The thermal degradation of ammonium starch phosphate carbamates (SPC) with varying degrees of substitution (DS) was extensively analyzed, revealing increased charring and polyphosphate formation in the condensed phase as DS of SPC rose. This led to reduced temperature mass losses, decreased decomposition product amounts, and lower activation temperatures compared to native starch. The presence of ammonia, contributing as an inert gas to flame extinguishment, further signifies SPC's potential as environmentally friendly and sustainable flame-retardants based on renewable resources[45]. In another attempt, a biomass intumescent flame retardant (IFR) system was created by blending the reaction product (PA@HS) of PA and hydrolyzed silk (HS) with potato starch (PS), incorporated into polyacrylonitrile (PAN) to produce flame retardant PAN (FR-PAN). PAN-10%PA@HS/5%PS sample exhibited improved tensile strength (18.8%) and elongation (86.3%), while significantly reducing pkHRR by 54.8% and peak smoke production rate (PSPR) by 79.3%, demonstrating excellent flame retardant and smoke suppression performance. Moreover, derived FR-PAN Char (FRPC) enhanced fire safety in modified cellulose and polyvinyl alcohol (PVA) by reducing thermal decomposition rate and PHRR, offering both eco-friendly flame retardancy and waste material recycling[46]. It was observed that starch when combined with other compounds results in enhanced flame retardancy, as seen in the fabrication of fully biomass IFR systems and the subsequent incorporation into PAN to achieve improved flame retardant and smoke suppression performance, alongside the fruitful recycling of waste flame retardant PAN materials.

Alginate-based flame retardants

-

Alginate, extracted from seaweed, is a polysaccharide that can be modified for fire retardancy. Alginate-based flame retardants have shown the ability to reduce the heat release rate and improve char formation, making them suitable candidates for enhancing the fire performance of various materials. In a recent work, sodium alginate fibers loaded with urushiol via an environmentally friendly wet spinning method, resulting in flame retardant, acid-resistant, and targeted antibacterial properties. The uniform distribution enables the alginate fibers to acquire flame retardant properties, enhancing their resistance to ignition and combustion. The fabricated fibers exhibited acid resistance, retained their shape, displayed superior flame retardancy, and achieved remarkable antibacterial efficiency of 99.99% against Staphylococcus aureus[47]. In another study by Lv et al.[48], divalent metal ions (Ca2+, Cu2+, Zn2+) combined with alginate/silver phosphate (MAlg/Ag3PO4) materials exhibited exceptional flame-retardant properties. Notably, ZnAlg/Ag3PO4 displayed the highest flame-retardant performance, with a LOI of 79.8% and a heat release capacity (HRC) of 79.8 J/(g·K), indicating strong thermal stability and fire safety performance. The synergistic effect of Ag3PO4 and divalent metal ions was proposed as the mechanism behind the enhanced flame retardancy, as determined through TG-FTIR and Py-GC/MS analysis. Researchers also enhanced the flame retardancy of polyester (PET) fabrics by applying Fe3+-modified alginate coatings using a simple dip-coating technique. The resulting coated PET fabrics achieved a LOI of 29%, self-extinguished without drips during vertical flame tests, and exhibited a significant 70.3% reduction in pkHRR. Moreover, the tensile strength of coated PET textiles hiked significantly, showcasing a green and effective line of action to improve flame retardancy and anti-dripping properties in PET fabrics[49]. Therefore, modification of alginate coatings with various elements to improve the flame retardancy of different fabrics. The study demonstrates effective flame-retardant outcomes, such as reduced pkHRR and improved self-extinguishing behavior, highlighting alginate's potential as a versatile and eco-friendly solution for enhancing fabric flame retardancy.

Pectin-based flame retardants

-

Pectin, commonly found in fruits, is another polysaccharide with fire-retardant potential. When exposed to heat, pectin can undergo a gelation process, forming a protective layer that hampers flame spread. This characteristic has led to the exploration of pectin-based flame retardants in coatings and textiles. Biomass-derived polymer aerogels composed of pectin and aniline demonstrated a unique cross-linking structure, leading to 3D hierarchical networks with high surface areas (103−205 m2 g−1), good compressive strengths (4.7−9.2 MPa), and water resistance. These aerogels exhibited low thermal conductivity (0.033−0.038 W m−1 K−1) and excellent flame retardancy, with LOI values and vertical burning tests indicating inherent low flammability. These findings highlight the potential of these aerogels in thermal insulation applications[50]. A self-cross-linked aerogel, created from pectin and melamine-formaldehyde resin (MF) using a freeze-drying method with water as a solvent, exhibits network microstructures and enhanced compressive modulus with increasing pectin content. The M10Pe5 aerogel reaches a compressive modulus of 23.2 MPa and a specific modulus of 188 MPa cm3/g, showcasing both thermal stability and excellent water resistance. Its remarkable properties position it as a promising candidate for diverse applications[51]. Utilizing pectin and cross-linking agents like melamine-formaldehyde resin, the study showcases the fabrication of self-cross-linked aerogels with enhanced compressive modulus, thermal stability, water resistance, and low flammability. These pectin-based aerogels offer promising prospects for various applications due to their impressive properties.

Secondary metabolites-improving fire-retardant property of polymeric materials

-

Secondary metabolites-based fire retardants leverage naturally occurring compounds from plants to enhance the fire resistance of materials. These bioactive substances, such as tannins, lignin, and terpenoids, offer promising avenues for sustainable fire safety solutions (Table 2; Fig 2).

Table 2. Secondary metabolites from plants as fire retardant material.

Compound name Plant source Chemical structure Fire retardant properties Applications Reference Tannin Dioscorea cirrhosa tuber

Treated silk exhibited higher LOI values (>28%) and shorter char length (12 cm) than the untreated fabric with a LOI of 24.7% and a char length of 30 cm, and very low pHRR (18.1 W/g) and THR (1.3 kJ/g) indicating their remarkably reduced flammability Production of flame-retardant silk fabric [58] Tannin Cotton fabric treated with tannic acid, tartar emetic and Ca2+ showed excellent durable flame retardancy with pHRR ranging from 113.8-138.7 kW/m2. Additionally, even after 50 cycles of tap washing, treated fabric show much lower heat release and pass the horizontal flammability test Production of eco-friendly and durable flame-retardant coating for cotton fabrics [59] Phytic acid −

Treated cotton fabric showed LOI value of 34.6%, accompanied by damage length < 150 mm and burning time < 5 s. CCT revealed that PHRR reduced by 61%, THR by 74% Average residue improved to 21% at 650°C and exhibits significant delay in thermal decomposition time Production of flame-retardant cotton fabric [60] Phytic acid − Treated silk fabric exhibits lower smoke and heat generation, self-extinguishing behavior, and a char length of 13.5 cm even after 20 washing cycles Production of durable flame-retardant silk fabric [61] Phytic acid − Silk fabric with phytic acid, TiO2 and 1,2,3,4–butanetetracarboxylic acid show excellent flame retardancy with increased LOI and decreased char length and pHRR (56.3%) even after 25 times of washing Production of improved flame-resistant silk fabric [70] Phytic acid − Treated silk fabric showcased self-extinguishing properties in vertical burns with an add-on exceeding 10.7% maintained after 15 washes, coupled with remarkable reduction in heat and smoke release during combustion, showcasing high thermal stability Production of intumescent flame-retardant silk textiles [62] Lignin −

Inclusion of 8 wt% LF in PLA results in a UL-94 V-0 rating, and LOI value of 25.8%, signifying enhanced fire resistance and thermal stability. Moreover, the PLA/LF composite

exhibits increased elastic modulus while retaining the strength and ductility characteristics of pure PLAProduction of PLA biocomposites which can be used in packaging, fabrics, electronic, and automotive applications [63] Lignin − 30% [w/v] SLS treatment via hot padding reduced after-glow to 9 s and resulted in a 4 cm char length in treated cotton fabric. Additionally, TGA analysis indicated SLS enhanced char formation, preserved fabric structure and also improved UV protection without compromising fabric strength Used for home textile materials, curtains, sofa cover, tent, pandals and other products [16] Lignin An efficient flame-retardant effect in PLA fabric is achieved with 5 wt% of lignin and 5 wt% of ammonium polyphosphate and significantly reduces the heat release rate Additionally, ammonium polyphosphate slightly enhances the thermal stability of composites, with increased residue at 500 °C Used in packaging, textile [71] Flavonoids (baicalin, quercetin, rutin)

Silk fabric treated with flavonoid and metal salt (ferrous sulfate and titanium sulfate) exhibits increase in LOI (26.5-27%) and decrease in char length (< 12 cm) as the concentration increases. Further, fabric shows increased thermal stability of silk fiber at high temperature (600ºC) Production of colored and flame-retardant silk textiles with antibacterial and antioxidant functions [65] Flavonoids (daidzain, naringenin and luteolin) Cycloaddition of benzopyrone ring improved the crosslink density of natural flavonoid-based epoxy resin contributing to the synergistic improvement of mechanical properties and thermal stability of epoxy resin with glass transition temperature of 184.4 °C Development of high-performance bio-based epoxy resin with flame-retardant properties [72] Tea saponin

TS significantly impacts char layer structure, enhancing flame retardancy and pyrolysis performance in CTS-IFRCs, minimizes heat loss, contributing to dual effects as both a gas-phase blowing agent and a condensed-phase carbon agent Used as coating to enhance flame retardancy [66] Tea saponin TS exhibits significant impact on the combustion behavior and thermal stability of TS-IFRCs. It degrades into water vapor and carbon at high temperatures, forming a protective char layer that enhances flame retardancy and reduces smoke production Used as flame-retardant coatings [67] LOI = Limiting oxygen index; pHRR = peak heat release rate; THR = total heat release; CCT = cone calorimeter test; LF = lignin-derived fire retardant; PLA = Polylactide; SLS = sodium lignin sulfonate; TGA = Thermo-gravimetric analysis; TS = Tea saponin; CTS-IFRCs = composite tea saponin intumescent flame-retardant coatings; TS-IFRCs = Tea saponin intumescent flame-retardant coatings. Tannins

-

Tannins are polyphenolic compounds found in various plants. They can form stable char layers when exposed to heat, acting as a barrier that hinders the spread of flames. Tannins have been investigated for their potential to enhance fire resistance in materials like textiles, wood, and polymers. Condensed tannin extracted from Dioscorea cirrhosa tuber acts as an eco-friendly flame retardant for silk textiles, exhibiting a LOI above 27% and a char length below 12 cm even after 20 washing cycles. This approach enhances both thermal shielding and flame resistance, while also providing antibacterial and antioxidant properties. Usage of condensed tannin as an alternative flame retardant showcases its multifunctional potential for silk textile finishing[58]. An eco-friendly, durable flame-retardant coating for cotton fabrics is achieved by combining biomass tannin acid (TA), tartar emetic (TE), and Ca2+. The coating's longevity, maintained by tap water's natural Ca2+ replenishment, enables extended tap washing. Ca2+ facilitates the formation of graphitized carbon residues from TA and cotton fibers, resulting in high flame retardancy. Even after 50 tap washing cycles, the treated cotton fabric demonstrates lasting flame retardancy, as evidenced by reduced heat release and successful horizontal flammability testing. The mechanism involves a dense graphitized carbon layer and abundant CO2 release, effectively hindering heat transfer and diluting combustible gas, respectively, showcasing an innovative approach for efficient, environmentally favourable, and durable flame-retardant coatings for cotton textiles[59]. Tannins have emerged as pivotal agents in advancing fire retardant textile materials. Their inherent properties enable them to be integrated into coatings that enhance the flame resistance of fabrics. Through processes like adsorption and dynamic coordination, tannins contribute to the formation of durable and eco-friendly flame-retardant layers on textiles. This innovative approach not only improves the thermal shielding of fabrics but also imparts additional benefits such as antibacterial and antioxidant properties. Consequently, tannins offer a promising avenue for the development of multifunctional and sustainable fire-retardant solutions in the textile industry.

Phytic acid

-

Phytic acid, commonly found in seeds and grains, contains phosphorus and has been studied for its fire-retardant properties. It can release phosphorous compounds during thermal decomposition, which contribute to char formation and inhibit combustion. In a study, LBL technology was employed to create a bio-based flame-retardant coating (U@PA-Na) using positively charged urea (U) and negatively charged sodium phytate (PA-Na). This system, characterized by safety and high efficiency, was applied to cotton fabric and evaluated for flame retardancy before and after washing. The treated fabric exhibited a high LOI of 34.6%, passing UL-94 B1 grade with minimal damage length and burning time. Cone calorimeter tests reveal reduced heat release rates and delayed decomposition for the treated fabric, attributed to a dense carbon layer that forms a barrier against combustion. The U@PA-Na system significantly enhances cotton fabric's flame retardancy and safety, highlighting its potential for fire risk reduction[60]. In another study, a novel approach was presented for creating durable flame-retardant (FR) silk fabric using biomass-derived PA. A robust, in situ sticky coating was developed on the silk surface through sequential adsorption of PA, 1,4-Phthalaldehyde, and 3-aminopropyltriethoxysilane (KH550). This coating leverages synergistic effects of phosphate groups and silica networks, exhibiting high functional efficiency, thermal stability, and reduced fire hazards. Modified silk fabrics demonstrate lower smoke and heat generation, self-extinguishing behavior, and a char length of 13.5 cm even after 20 cycles of washing. The covalently grafted sticky coating enhances washing resistance, presenting a promising method for producing durable flame-retardant silk textiles using bioderived PA[61]. The utilization of plant-based PA as an effective and enduring flame retardant (FR) in textiles holds significant importance for ecologically sound functional textile products. This study investigates a reactive phytate-based FR, specifically pentaerythritol phytate ethylenediaminetetraacetic ester (PPEDTE), as an intumescent FR agent for silk fabric. PPEDTE, resulting from esterification, forms a deposition and covalently cross-linked layer on silk fabric, enabling self-extinguishing behavior and remarkable reduction in heat and smoke release during burning. The coated silk fabric demonstrates high thermal stability, substantial combustion residues, and good washing durability. This approach showcased the potential of PPEDTE as an efficient and reactive intumescent FR technique for silk textiles[62]. Phytic acid emerges as a crucial contributor to the advancement of fire-retardant textile materials. Its utilization in coatings, such as PPEDTE, showcases its significance. By forming robust and enduring layers on fabrics through processes like esterification, phytic acid enhances flame resistance, thermal stability, and combustion residue formation. The resulting textiles display reduced heat and smoke release during burning, as well as improved washing durability. This underscores the pivotal role of phytic acid in innovating fire-retardant solutions for textiles, presenting a potential avenue for sustainable fire safety enhancement in the industry.

Lignin

-

Lignin, a complex polymer found in plant cell walls, has shown fire-retardant potential due to its ability to generate char and hinder flame propagation. Lignin-based compounds have been explored for enhancing the fire performance of various materials. A novel lignin-derived fire retardant (LF) was created by grafting polyphosphoramide into lignin waste through polymerization. With the addition of 8 wt% of LF, enhanced thermal stability was achieved, and a UL-94 V-0 fire rating was obtained for polylactide (PLA). The resulting PLA/LF composite also experienced an increase in elastic modulus while maintaining strength and ductility. This approach offers a promising strategy for using industrial lignin waste to develop biobased fire-retardant additives, with potential applications in diverse sectors such as packaging, fabrics, electronics, and automotive industries[63]. Sodium lignin sulfonate (SLS) was examined as a fire-retardant finish for cotton fabric. Cotton treated with 30% [w/v] SLS achieved an LOI of 28.5 and a char length of 4 cm (self-extinguishing). Thermo-gravimetry exhibited 35% mass retention at 500 °C for treated fabric, compared to 8% for untreated fabric. GC–MS analysis revealed limited flammable gas release from SLS-treated fabric, and char morphology and elemental analysis were characterized. The treatment also provided natural yellow color, UV protection, and maintained fabric strength, in addition to the flame-retardant effect[16]. The study investigated novel intumescent formulations with lignin and phosphinates to enhance Polyamide 11's flame retardancy while maintaining its bio-based nature. Melt blending lignin and metal phosphinates with the polymer showed potential for flame retardant multifilament melt spinning. The combination induced charring behavior and decreased pkHRR through the formation of a protective char layer, effectively slowing down combustion[64]. The involvement of lignin in advancing fire retardant textile materials is evident. Lignin's utilization in intumescent formulations, proves pivotal as its by melding with other additives, contributes to effective intumescent systems, enhancing flame retardancy while maintaining bio-based qualities. This innovative approach not only promotes charring behavior but also slows combustion by forming a protective char layer. Lignin's significance in developing fire-retardant textiles is underscored, offering promising strategies for sustainable fire safety improvement in the textile industry.

Flavonoids

-

Flavonoids are another class of polyphenolic compounds with fire-retardant potential. They can contribute to char formation and exhibit antioxidant properties, which can protect materials from oxidative degradation during combustion. Flavonoids (quercetin, baicalin, rutin) were applied to silk with mordanting by metal salts, revealing novel flame retardancy for silk. The combined treatment facilitated good char formation, enhancing flame retardancy and smoke suppression. After 20 wash cycles, the treated silk retained flame retardancy, antibacterial traits, and moderate antioxidant activity, presenting a simple approach for producing functional flame-retardant silk textiles[65]. Novel bio-based epoxy resins were created using flavonoids (daidzein, naringenin, luteolin) and maleic anhydride as the curing agent. Comparisons with di-glycidyl ether of bisphenol A revealed enhanced mechanical properties in the bio-based resins, while flame retardancy showed less improvement. The cycloaddition reaction of the benzopyrone ring facilitated higher crosslink density, which in turn bolstered mechanical properties and thermal stability. Daidzein epoxy resin demonstrated superior impact strength and initial thermal degradation temperature compared to di-glycidyl ether of bisphenol A. The cured daidzein epoxy resin also attained a glass transition temperature of 184.4 °C, showcasing the potential of these bio-based epoxy resins[4]. The contribution of flavonoids to the advancement of fire-retardant textile materials is evident. Their integration into novel bio-based epoxy resins showcases their significance. While resulting in enhanced mechanical properties, flavonoids' impact on flame retardancy might be less pronounced. The observed correlation between cycloaddition reactions and higher crosslink density elucidates their positive influence on mechanical strength and thermal stability. This underlines the potential of flavonoids in creating improved fire-retardant materials, emphasizing their role in fostering innovation within the textile industry.

Saponins

-

Saponins are glycosides found in various plants and have been explored for their fire-retardant effects. They can generate foam when heated, creating a barrier that restricts oxygen supply to the flames. Tea saponin intumescent flame-retardant coatings (TS-IFRCs), based on natural tea saponin (TS), demonstrated significant flame retardancy. Qian et al.[66] investigated TS's impact on composite coatings (CTS-IFRCs) through TG-DSC, FT-IR, SEM-EDS, and pyrolysis kinetics analysis. TS, in synergy with other components, notably influenced char layer microstructure, flame retardancy, and pyrolysis performance. TS served as a blowing agent in the gas-phase flame retardant mechanism and a carbon agent in the condensed-phase mechanism, manifesting its dual role thus highlighting TS's potential for effective, eco-friendly, bio-based flame-retardant materials, offering a novel utilization approach[66]. Additionally, Qian et al.[67] also highlighted that tea saponins were environmentally friendly flame-retardant materials exhibiting low smoke production. Natural tea saponin (TS) extracted from camellia nutshell was incorporated into intumescent flame-retardant formulations as both a blowing agent and carbon source. Formulations were optimized to attain the best TS proportion, resulting in intumescent flame-retardant coatings (TS-IFRCs). TS significantly influenced combustion behavior and thermal stability, evident from cone calorimetry and thermal analysis. At high temperatures, TS degrades into water vapor and carbon, forming a robust char layer in combination with other components. This char layer hindered erosion, enhancing flame retardancy[67]. The involvement of saponins in advancing fire retardant textile materials is evident. The incorporation of natural tea saponin (TS) in intumescent flame-retardant formulations underscores their significance. TS's role as a blowing agent and carbon source in optimized formulations contributes to improved combustion behavior and thermal stability. The formation of a robust char layer in conjunction with other components enhances flame retardancy and inhibits erosion. This study highlights the potential of saponins in shaping effective and environmentally friendly fire-retardant textiles, marking their pivotal role in the field's development. In addition to exploring natural polysaccharides and secondary metabolites, there are ongoing efforts to create flame-retardant textiles through different approaches[68,69].

-

In an era marked by heightened environmental consciousness, the quest for fire safety solutions extends beyond efficacy to encompass ecological ramifications. This section delves into the intricate interplay between bioactive polysaccharides and secondary metabolites-based textiles, conventional fire-retardant materials, and the overarching pursuit of sustainability.

Evaluation of the environmental impact of polysaccharides and secondary metabolites based fire retardant textiles

-

A comprehensive assessment of the environmental impact of polysaccharides and secondary metabolites-based fire-retardant textiles probes into intricate nuances. Factors such as resource consumption during extraction, energy expenditure in synthesis, and potential biodegradability intertwine to shape the textiles' ecological footprint. Life cycle analyses illuminate the holistic impact of these textiles, considering their birth, lifespan, and eventual decomposition. The evaluation extends beyond immediate environmental effects, shedding light on the long-term consequences that ripple through ecosystems. To the best of the authors' knowledge and based on a literature survey, there are no available reports regarding the evaluation of the environmental impact of fire-retardant textiles based on polysaccharides and secondary metabolites.

Comparison with traditional fire-retardant materials

-

Conventional fire-retardant materials, characterized by chemical compositions that can raise ecological concerns, serve as a pertinent reference point for comparison. Scrutinizing aspects like production processes, toxicity profiles, and persistence in the environment unravels a nuanced juxtaposition. By contrasting the ecological implications of polysaccharides and secondary metabolites -based fire-retardant textiles with traditional counterparts, a holistic understanding of the sustainable advantages emerges[11,30,73].

Assessment of the sustainability of polysaccharides and secondary metabolites-based approaches for development of fire-retardant textiles

-

Central to the discourse on polysaccharides and secondary metabolites-based fire-retardant textiles is the overarching question of sustainability. An evaluation rooted in sustainability principles embraces considerations of renewability, minimal ecological disruption, and harmonious coexistence with natural systems. The inherent properties of polysaccharides and secondary metabolites, coupled with their potential for circularity and reduced environmental harm, position these textiles as compelling candidates for sustainable fire safety solutions. Nevertheless, a well-informed evaluation requires skillful navigation of the complex interplay between production, utilization, and disposal, in order to uncover the full scope of their ecological impact. Such future research endeavors could pave the way for a more sustainable utilization of textiles based on polysaccharides and secondary metabolites.

There exists a significant connection between fire safety, ecological responsibility, and sustainable innovation, and this connection is well-founded. Through the analysis of environmental impact, comparison with conventional materials, and assessment of the overall sustainability of fire-retardant textiles utilizing polysaccharides and secondary metabolites, we create a comprehensive picture of the potential these textiles have in promoting a more balanced relationship between human requirements and the well-being of the planet.

-

The development of fire-retardant textile materials using bioactive polysaccharides and secondary metabolites from plant-based resources represents a significant step towards sustainable fire safety solutions. This review article has provided an overview of the advancements, challenges, and opportunities in this interdisciplinary field, highlighting the potential of bioactive plant compounds in enhancing the fire resistance of textiles. Through careful selection and extraction of bioactive polysaccharides and secondary metabolites, researchers have demonstrated the ability to incorporate these natural fire retardants into textile materials. The flame retardancy mechanisms associated with these compounds have been explored, shedding light on their effectiveness in reducing the flammability of textiles. Moreover, various techniques and methods have been developed for the incorporation of bioactive polysaccharides and secondary metabolites, enabling their integration into textile manufacturing processes. Performance evaluation studies have demonstrated the improved fire retardancy properties of textiles treated with bioactive plant compounds. These textiles have shown promising results in standardized testing methods, exhibiting reduced flame spread rates and enhanced time to ignition. The comparison with conventional fire-retardant textiles further supports the efficacy and potential of bioactive polysaccharides and secondary metabolites-based approaches.

Looking towards the future, several avenues for research and development exist in this field. First, continued exploration of different bioactive polysaccharides and secondary metabolites from diverse plant sources can expand the pool of options for fire retardant textiles. This includes investigating lesser-known plant species and their fire-resistant properties. Additionally, optimizing the incorporation techniques and understanding the long-term durability and wash resistance of bioactive polysaccharides and secondary metabolites treated textiles are important considerations. The potential applications of bioactive polysaccharides and secondary metabolites based fire-retardant textiles are extensive. Industries such as construction, transportation, and personal protective equipment could greatly benefit from the integration of sustainable fire safety solutions. Further research and collaboration with industry stakeholders are necessary to facilitate the practical implementation of these textiles. While bioactive polysaccharides and secondary metabolites-based fire-retardant textiles offer exciting opportunities, addressing the environmental impact and sustainability aspects remains crucial. Future studies should focus on assessing the life cycle analysis and ecological footprint of these textiles, ensuring that they align with sustainable principles and contribute to reducing overall environmental harm.

It is evident throughout the review article that the utilization of bioactive polysaccharides and secondary metabolites from plant-based resources presents a promising avenue for developing sustainable fire-retardant textile materials. By harnessing the power of nature, these textiles offer enhanced fire safety while reducing the reliance on conventional chemical-based fire retardants. Continued research, innovation, and collaboration are essential for unlocking the full potential of bioactive polysaccharides and secondary metabolite based approaches and establishing them as viable alternatives in the field of fire safety.

-

The authors confirm contribution to the paper as follows: study conception and design, draft manuscript preparation: Kumar M, Barbhai MD. Both of authors reviewed the results and approved the final version of the manuscript.

-

Data sharing not applicable to this article as no datasets were generated or analyzed during the current study.

-

The authors declare that they have no conflict of interest.

- Copyright: © 2023 by the author(s). Published by Maximum Academic Press on behalf of Nanjing Tech University. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Kumar M, Barbhai MD. 2023. Sustainable fire safety solutions: bioactive natural polysaccharides and secondary metabolites as innovative fire retardants for textiles. Emergency Management Science and Technology 3:17 doi: 10.48130/EMST-2023-0017

Sustainable fire safety solutions: bioactive natural polysaccharides and secondary metabolites as innovative fire retardants for textiles

- Received: 05 September 2023

- Accepted: 17 October 2023

- Published online: 30 November 2023

Abstract: Fire safety is a critical concern in various industries, including residential, transportation, and industrial sectors. The development of sustainable solutions for fire safety has gained significant attention in recent years. This review article explores the utilization of polysaccharide and secondary metabolites as fire retardants in textile materials, presenting a promising avenue for sustainable fire safety solutions. By harnessing the inherent fire-resistant properties of these bioactive polysaccharide and secondary metabolites, researchers aim to develop textiles with enhanced flame retardancy without compromising on sustainability. This review offers a comprehensive overview of recent advancements in this field, encompasing the selection of polysaccharides and secondary metabolites, their integration into textile materials, and the assessment of fire-retardant properties. The use of sustainable materials and compounds in the textile sector is exemplified through a comparison with traditional flame retardants. The mechanisms by which flame retardants operate, as well as case studies that focus on polysaccharides and bioactive secondary metabolites along with environmental impact and sustainability, are also emphasized in this review. The synthesis of knowledge presented in this review article contributes to the growing body of research on sustainable fire safety and provides insights for future developments in the field of fire-retardant textile materials using bioactive plant compounds.