-

One of the traditional techniques for increasing value and reducing agricultural produce spoilage is drying. Where more expensive alternative storage methods are used, this is especially crucial[1]. Through the addition of one or more energy sources, moisture from a product is removed throughout the drying process[2,3]. The physicochemical characteristics of the fruit are changed by drying, which can improve the flavor and texture of specific foods like raisins and dates[2]. It lowers the product's water activity (aw), and when the aw value drops to less than 0.6, it inhibits the growth and spread of spoiling bacteria[4]. Drying also reduces product weight, which reduces packing, storage, and shipping costs and ensures off-seasonal production[5,6]. The demand for dried fruit is rising globally as people become more health conscious[7].

Worldwide pomegranate production is steadily rising, although large post-harvest losses are also common, according to reports[8]. When fruit is unsuitable for standard processing methods due to fruit cracking or sunburn, drying is a great way to reduce post-harvest losses because it extends shelf life and can be utilized to reduce food waste[9]. Numerous products, such as pharmaceuticals, snacks, cereals, quick drinks, and other confectionary items, employ dried pomegranate arils[10]. Dried pomegranate arils, also known as anardana, are utilized both medicinally and culinarily in several regions of the world, including India[11]. Dried arils can therefore be quite useful as value-added items that generate revenue. According to research conducted in the Indian Ramban area, anardana trade accounts for at least 41% of all annual household income[11].

There are many different drying techniques. The most popular are freeze-drying, hot air drying, vacuum drying, and solar drying. Each technique has pros and cons in terms of the final product's quality and how efficiently it uses energy. Pre-drying procedures are frequently used in conjunction with drying. Pretreatment enhances the drying rate, product quality, and energy efficiency of the drying process. Enzymes that cause enzymatic browning, which lowers the product quality, are rendered inactive by pretreatments[12−14]. Sensory qualities like color, texture, taste, scent, microbiological activity, and general acceptability are among the criteria that determine the quality of dried pomegranate arils[15]. These elements are crucial because they can have a big impact on customer preferences and, if not taken into full account, can lead to financial losses[16,17].

Several studies[12,18,19] have looked at the impact of drying and pretreatment techniques on the general quality of the completed product. However, the combined impact of pretreatment and drying on quality was not sufficiently investigated. Reviews on pomegranate fruit often discuss the fruit's chemistry, nutritive value, and pharmacology. Therefore, by evaluating, highlighting, and reflecting on recent studies on pomegranate aril drying, this review seeks to close these gaps. This review paper compared and contrasted several pretreatment and drying setups with an emphasis on product quality.

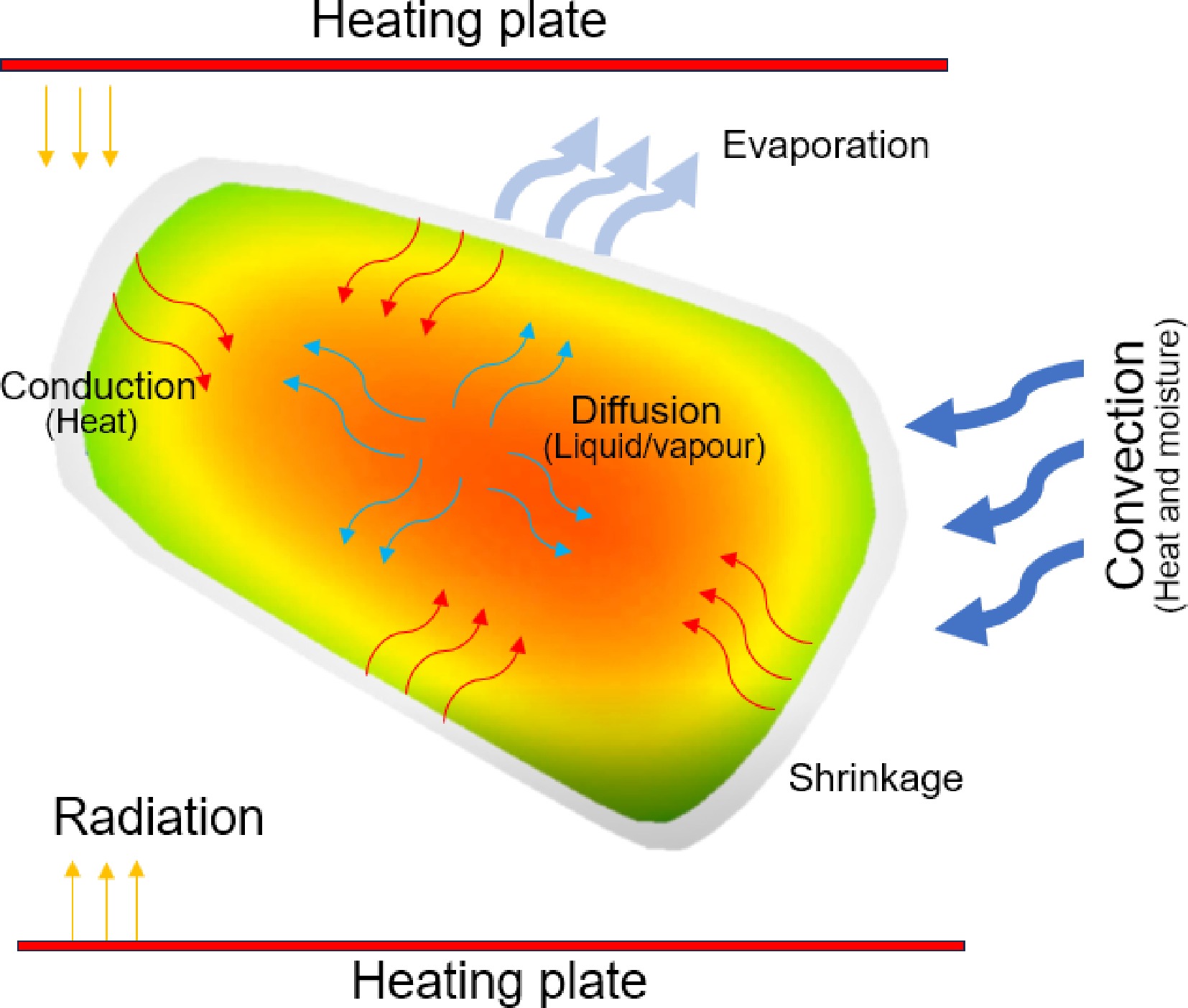

The heat and mass transport phenomena of the fruit drying process

-

Heat, mass, and momentum exchanges all occur simultaneously during the drying of fruit materials in a sophisticated cellular architecture of biological tissue[20,21]. The characteristics of the material that affect the drying process are intricately dependent on size, shape, porosity, moisture content, and time[22]. For instance, the initial moisture level and the bioactive chemicals in pomegranate arils can vary depending on the cultivar and fruit ripeness. The understanding, engineering, and management of the drying process are further complicated by the intrinsic diversity of biological materials[23,24]. The mass, heat, and momentum transfer events that happen during a typical drying process are shown in Fig. 1[25]. Conduction and convection are the most common heat transfer methods, but radiation is typically only employed for high-end items due to its expensive cost[1,26]. Diffusion, capillary action, and bulk flow are only a few of the processes that might transfer mass. These mass transfer mechanisms must adapt to the ongoing physical changes in the material that take place as it dries out[22,27].

The drying and nutritional qualities of fresh pomegranate arils

-

Although it is native to Iran, the pomegranate (Punica granatum L.) is widely distributed worldwide[28]. It belongs to the family Lythraceae and is a deciduous shrub. It is a versatile plant that can be found growing in both semi-arid and subtropical climates. Pomegranates, however, need hot summer temperatures to ripen[29]. Pomegranate fruit has a non-uniform round shape and a range of hues depending on the cultivar and fruit development stage, including yellow, green, pink, deep red, deep purple, and black[30,31]. An outsized calyx crowns the fruit. The leading producers worldwide are Peru, Australia, South Africa, and Chile in the southern hemisphere, and India, China, and Iran in the northern hemisphere[32].

Pomegranate is a one-of-a-kind fruit with distinct edible seeds (arils) that must be extracted by hand (Fig. 2)[33]. An aril is made up of a seed and fleshy, moist tissue surrounding the seed. Color, sweetness, juice content, and hardness of arils vary depending on cultivar and fruit maturity[30,31]. While the arils can be eaten fresh, they can also be made into jams, jellies, coloring agents, juices, vitamins, and anardana (dried arils). They can also be mixed into yoghurts, biscuits, and cereals[34]. Fresh pomegranate arils can be kept at 7 °C for up to 14 d without losing much quality. Dried pomegranate aril has an extremely low perishability, with a potential shelf life of more than 14 weeks in ambient air[35].

Figure 2.

A typical breakdown of the material balance throughout the drying process for pomegranate aril.

As demonstrated in Table 1, pomegranate is high in ellagitannins, gallic acids, ferulic acids, anthocyanins, flavonoids, fiber, and minerals like vitamin C, calcium, and phosphorus. Pomegranates' phenolic components and high vitamin C content (Table 1) have attracted the interest of both researchers and consumers due to their health advantages[36−38]. As a result of its strong antioxidant activity and nutritional benefits, pomegranate is considered a superfruit. Pomegranate can also be employed in cosmetics and pharmacology due to its phytochemical and antioxidant qualities[39]. Pomegranate fruit extract (PFE) has bioactive elements that have been found to inhibit or prevent various types and levels of cancer[40]. Punicalagic acid, ellagic acid, urolithin, and luteolin are the most important pomegranate components known to have anticarcinogenic characteristics[40,41]. Pomegranate fruit has also been linked to the prevention of diseases such as Alzheimer's, hypertension, and diabetes[42,43]. Pomegranate supplements may also help during or after exercise because they have the potential to speed up hard exercise recovery[44].

Table 1. The nutritional composition of 100 g of pomegranate arils.

Nutrient Value Unit Water 77.9 g Energy 346 kJ Protein 1.67 g Total lipid fat 1.17 g Ash 0.53 g Total dietary fiber 4 g Total sugar 13.7 g Calcium 10 mg Phosphorus 36 mg Magnesium 12 mg Iron 0.3 mg Potassium 236 mg Sodium 3 mg Zinc 0.35 mg Vitamin C 10.2 mg Vitamin K 16.4 µg Vitamin E 0.6 mg Vitamin B-6 0.075 mg Total choline 7.6 mg Folate 38 µg Adapted from United States Department of Agriculture (Agricultural Research Service), FoodData Central[52]. -

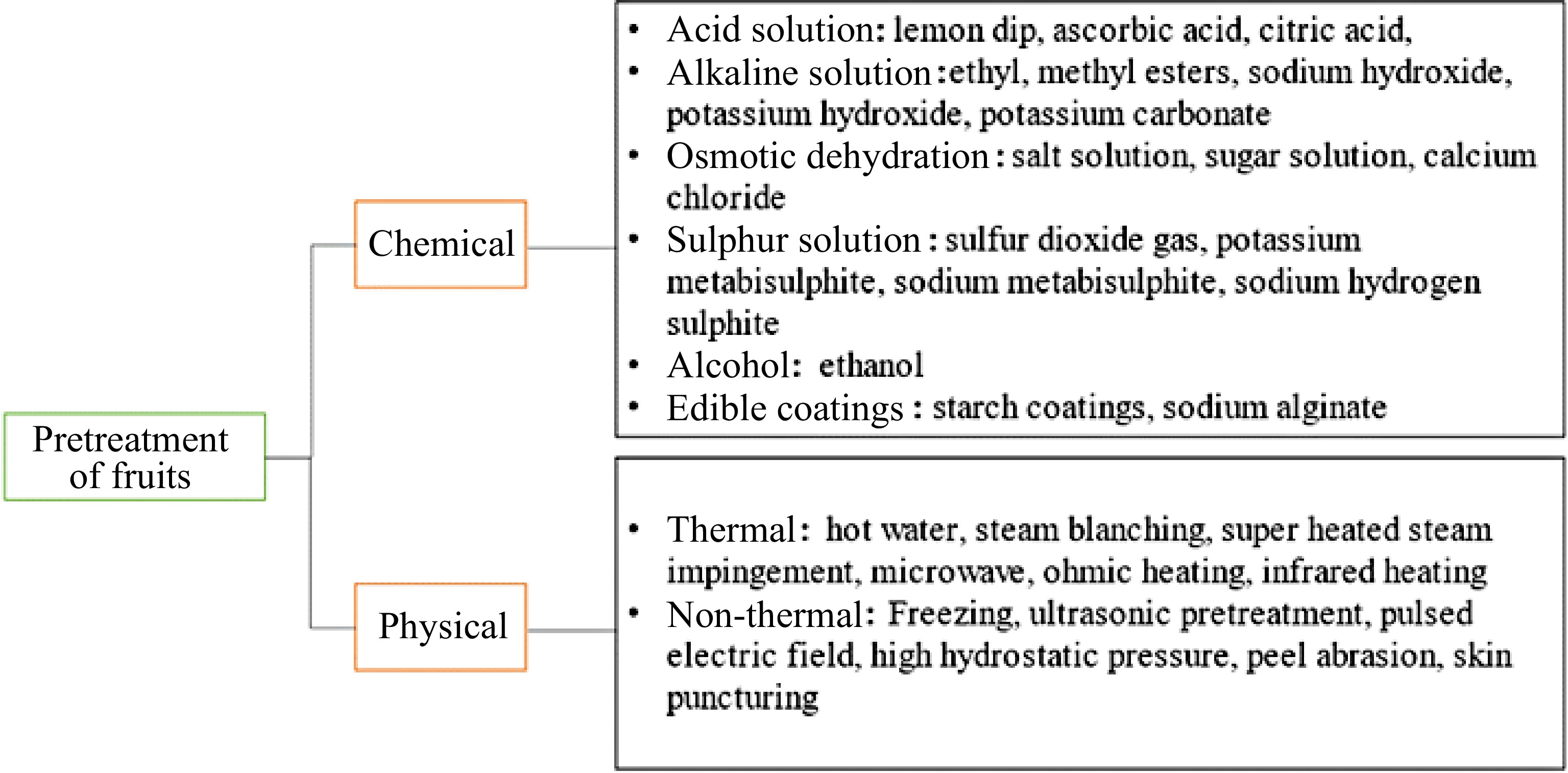

Pretreatment procedures are utilized to improve the drying process's effect on product quality characteristics such as color, flavor, appearance, and some physicochemical aspects[45,46]. Figure 3 depicts the most often used pretreatment procedures[46]. A product is immersed in a chemical solution prior to drying in chemical pretreatment. Physical pretreatments, on the other hand, necessitate a physical alteration of the product. When drying with heat, Maillard reactions might occur, resulting in an unpleasant color change[47]. As a result, pretreatment techniques are critical in many drying applications, including the drying of pomegranate arils[45,48,49]. There is evidence that pretreatment reduces the product's exposure to heat by reducing drying time[50,51].

Figure 3.

A classification of the numerous pretreatment techniques utilized in the drying process for pomegranate aril.

Soaking in acidic solutions

-

Soaking in acidic solutions involves immersing the product to be dried in a hot acidic solution for many minutes before drying. Pretreatment with an acidic solution keeps the product's color and speeds up the drying process. The acidic solution suppresses polyphenol oxidase enzyme activity, slowing the rate of enzymatic browning (Fig. 3). Furthermore, numerous investigations[53−55] have documented the retention of nutrients such as vitamin C in acidic solution pretreatment samples. Some acid-sensitive components, on the other hand, can be destroyed or leached away. As a result, while employing this strategy, this effect must be considered. In a pomegranate aril drying research, arils prepared with 3% citric acid had the highest sensory acceptance[56]. Vardin & Yilmaz[57] conducted research on the combined effect of acid blanching and subsequent drying temperature. The authors blanched the arils in 0.1% citric solution for 2 min at 80 ± 2 °C followed by drying at 55, 65, or 75 °C and discovered that drying at 55 °C had the maximum antioxidant capacity[46]. Understanding the connection between soaking in acid (balancing in acid) and the subsequent drying temperature is required to carry out the operation correctly.

Dipping in alkaline solutions

-

This entails immersing products in an alkaline solution. Alkaline solutions act by dissolving the wax covering on the fruit's surface, removing resistance to moisture transfer and increasing drying rate[58]. As a result, this pretreatment accelerates the drying process. However, the usage of alkaline solutions raises food safety concerns because the residue might be harmful to one's health[46,59]. In addition, although acidic solutions retain vitamin C, alkaline solutions leach it out and destroy it[46]. Samples dipped in ethyl oleate for roughly one minute revealed a considerably reduced drying rate: a 26.9, 28.5, and 27.2% decrease in drying time at drying air temperatures of 55, 65, and 75 °C, respectively, than the control[60].

Osmotic dehydration

-

The fruit is dipped into a hypertonic solution, such as salt or sugar solutions, in this approach (Fig. 3). Because of the osmotic pressure differential, the hypertonic solution causes water to diffuse out of the fruit tissue[61]. When compared to other drying processes, osmotically pretreated dried products have great rehydration capability and little losses in quality parameters such as color, appearance, and nutrients[62]. Madhushree et al.[63] discovered that osmotic pretreatment (in 50oBrix sugar syrup concentrations) dried arils had high color retention. This could be owing to the samples' reduced exposure to oxygen when immersed in the sucrose solution. A separate investigation on the osmotic pretreatment of pomegranate arils with a 65°Brix sucrose solution revealed a decrease in drying rate in hot air drying at 70 °C compared to untreated control samples[64]. The scientists attributed the longer drying time (lower drying rate) to the creation of a dense sucrose layer beneath the fruit's surface, which created an additional barrier to moisture transfer. To that aim, the osmotic solution concentration must be assessed because it can result in prolonged drying times.

Fumigation with sulfur dioxide or dipping in sulfur solutions

-

Gaseous or liquid sulphur solutions have been used as a food preservation method and as a pretreatment in food drying procedures. Typically, sulphur solutions are utilized for their browning properties, both enzymatic and non-enzymatic[65]. In addition, sulfur pretreatment is associated with high vitamin C and A retention after drying, as well as inhibition of spoilage-related microbial proliferation[66].

More et al.[23] compared physical pretreatments to chemical pretreatments with 1% potassium metabisulphide on arils. It was discovered that arils prepared with potassium metabisulphide had superior nutritional quality as well as improved color, flavor, taste, and overall acceptability (Table 2)[23]. As a result, processing of pomegranate arils with sulfur solutions can result in high-quality dried goods. Despite their anti-browning, antibacterial, antifungal, and nutrient retention qualities, sulphites might be harmful to one's health if the recommended dosage or daily intake is exceeded[67,68]. Furthermore, while the sulfur solutions maintain vitamins A and C, they deplete vitamin B1[65].

Table 2. Key findings in pomegranate aril pretreatment and drying studies.

Pretreatment method Pretreatment Drying technique Key findings Reference Blanching Water blanching at 90 and 100 °C Hot air oven drying Blanched samples had a shorter drying time. [24] Water blanching at 80 °C Hot air oven dryer Blanched samples had higher phytonutrient retention than unblanched samples. [69] Blanching using 0.1% citric solution

at 80 ± 2 °CCabinet tray dryer Drying process was shorter for blanched samples and there was a higher rate of bioactive compounds. [57] Sulphuring 1% potassium metabisulphide Solar drying

Cabinet tray dryer

Freeze dryerFruit of cv. Ganesh 1% potassium metabisulphide was of the highest quality and the highest acceptance. [23] Blanching and Sulphuring Hot water blanching 85 °C and 0.2% potassium metabisulphate Mechanical dryer

Solar dryerKeeping quality of mechanically dried arils was higher than the solar-dried arils. [70] Steam blanching, potassium metabisulphide and 0.3% Sulphur fumigation Cabinet tray dryer The highest dried aril quality was obtained from the combination of steam blanching and 0.3% Sulphur fumigation. [71] Steam blanching, sulphuring at 0.3% Vacuum dryer

Hot oven dryer

Sun drying

Poly-tent house drying

Room dryingSun drying had the highest moisture content reduction and the highest overall acceptance. [72] Hot water blanching 85 °C,

potassium metabisulphite varying

from 0.25% to 1%Hot air oven dryer The best treatment was blanching in hot water at 85 °C for 1 min and then dipping the arils in 0.25% potassium metabisulphite. [70] Steam blanching, sulphuring Sun drying

Cabinet dryerBlanching reduced drying time. Cabinet drying of blanched samples without sulphuring was considered optimum for anthocyanins. [73] Acidic solution 2%, 3% and 4% citric acid Cabinet tray dryer 3% acidic treatment was found to be the most acceptable. [56] Microwave 100 and 200 W. Hot air oven dryer 200 W pretreatment resulted in minimum energy utilization and drying time. [74] 100 and 200 W Hot air oven dryer 200 W had the highest drying rate. [75] Osmotic treatment Sugar syrup, freezing at minus 18 °C Open sun drying,

Solar tunnel dryer,

Cabinet tray dryerOsmotic treatment and cabinet tray dryer produced dried arils with better physicochemical and sensory qualities. [63] • 100% pomegranate juice

• 50% pomegranate and 50% chokeberry juice

• 50% pomegranate and 50% apple

• 50% apple and 50% chokeberry

• 75% apple and 25% chokeberryFreeze drying

Convective pre-drying vacuum microwave finish drying

Vacuum-drying and freeze dryingPomegranate and chokeberry concentrated juice improved the quality of the dried arils. [12] Sucrose solution Hot air oven drying Pretreatment increased the drying time of the samples. [64] Blanching with alcohol

-

The dipping or soaking of a product in an alcoholic solution, usually ethanol, is known as alcoholic pretreatment. Ethanol dissolves the cell wall components, which increases moisture loss and thus the drying rate[76]. Several fruits, including melon (Cucumis melo L.) and apples (Malus domestica), have been pretreated in alcoholic solutions before drying[77,78]. However, no investigations on the pretreatment of pomegranate arils with alcohol were reported. This could be owing to the aril's waxy layer, which could impede permeability and hence the efficacy of the alcohol pretreatment[79].

Dipping in or spraying edible coatings

-

In this method, the fruit is dipped, submerged, or sprayed with a liquid solution that forms a thin coating layer on the product's surface and then dried (Fig. 3). According to studies, the use of edible coatings can help to retain the color, texture, and nutrient retention of dried items[80]. It is critical to note that the drying pace and dried product quality are affected by the coating thickness, drying method, and coating solution. Most of the research on edible coverings for pomegranate arils has focused on cold preservation and packing.

Ultrasound pretreatment

-

Acoustic cavitation is utilized to rupture cell walls using ultrasound pretreatment[81]. According to one investigation on the effect of sonification on osmotic dehydration and subsequent air drying of pomegranate arils, ultrasonography caused a 2-fold and 2.7-fold increase in water loss[82]. The authors hypothesized that ultrasonic promoted cell wall disintegration and enhanced permeability. While using ultrasonic improved color quality, it also reduced anthocyanin content when compared to osmotically dehydrated samples[82].

Steam or hot water blanching

-

Blanching is a pretreatment technique that involves rapidly heating and then cooling a product that will be dried[45]. Blanching can be used to inactivate enzymes that potentially degrade product quality, such as polyphenol oxidase, peroxidase, and polygalacturonase[4]. Unwanted sensory traits in color, flavor, texture, and nutritional aspects are examples[4,83]. Blanching also improves cell membrane permeability, resulting in a faster drying rate[45]. Furthermore, blanching kills bacteria that might cause product spoiling[45,83]. As indicated in Fig. 3, there are several blanching processes, including hot water blanching and modern technologies such as microwave blanching and infrared blanching.

Adetoro et al.[18] discovered that blanching pomegranate arils in hot water accelerated drying rates compared to unblanched samples. In a separate investigation, the authors found that blanching arils at 90 °C for 30 s and drying at 60 °C had higher total anthocyanin content and radical scavenging activity than blanching at 100 °C for 60 s and drying at 60 °C. In another work, Karaaslan et al.,[69] blanched arils in water at 80 °C for 2 min to investigate the effects of temperature and pretreatment on the arils. The authors discovered that while 75 °C had the fastest drying time, 55 °C had the maximum anthocyanin concentration, phenolic content, and antioxidant capacity. In other studies, pretreatment procedures are combined to produce high-quality dried fruit products.

Combined pretreatment techniques

-

Singh et al.[73] conducted a study to evaluate the drying of pomegranate seeds under various drying conditions. They discovered that blanched samples dried faster and had higher acidity than sulphured samples. Furthermore, the anthocyanin concentration of blanched samples was higher than that of blanched and sulphured samples using the mechanical dryer. The authors hypothesized that the reduced anthocyanin concentration seen after sun drying was caused by the long drying hours in the sun. They also suggested that pomegranate arils be dried using blanching rather than sulphuring to achieve the maximum nutritional quality. Sharma et al.[70] investigated ideal methods for drying pomegranate arils by blanching them in hot water at 85 °C for one minute and then immersing them in a solution of potassium metabisulphite with concentrations ranging from 0.25% to 1% for two minutes (Table 2). The highest potassium metabisulphite content resulted in the lowest acidity.

Thakur et al.[71] used steam blanching for 30 s and 0.3% sulphur fumigation for one hour to standardize pretreatments for dried arils from wild pomegranate. The authors discovered that cabinet drying outperforms solar drying and open sun drying. The solar dryer ranked second in terms of sensory characteristics like texture, taste, and general acceptability. Sun-dried pomegranate arils, on the other hand, exhibited the highest reduction in moisture content and overall acceptance when compared to vacuum drying, hot air oven drying, polytent drying, and room temperature drying, according to Bakshi et al.[72].

The effect of pulsed electric field treatment on the behavior of microwave-assisted hot air drying of pomegranate arils was examined by Amiali et al.[84]. When compared to drying at 70 °C, they found that pulsed electric field treatment was only advantageous when the subsequent drying process was done at the lowest temperature (50 °C). The lower the temperature, the higher the overall phenolic concentration. Arils treated with a pulsed electric field had a 21.02% higher total phenolic content than untreated arils.

Various pretreatment procedures on pomegranate arils have been utilized with the goal of conserving physicochemical, physical, and chemical properties or enhancing drying rates. However, pretreatment standardization is currently restricted and underexplored. Table 2 lists some of the methods for preparing dried pomegranate arils.

-

Despite the fact that pomegranate is a fruit with numerous health and nutritional benefits, it is now a modest crop with limited marketability. The difficulty in collecting the interior edible seeds (arils) is the greatest impediment to realizing the full potential of this unusual fruit[29,31]. Only manual extraction of pomegranate arils for laboratory scale testing is described in the literature.

Pomegranates are first cleaned and sorted for uniformity in color, size, shape, and weight before aril extraction[18,85]. All pomegranates should be washed. To avoid introducing bacteria into the arils when the fruit is sliced open, excess water from the fruit surface is dried before cutting[86]. Following that, the fruit is cut along the ridges and the segments are gently pulled apart to form a flower-like structure. The deconstructed pomegranate is then flipped over a bowl of water and gently tapped with a wooden spoon on the skin side. As a result, the arils will begin to come out without being broken. Once all arils have dropped out, the white membranes are skimmed off the surface of the water as it floats, the water is drained, the arils are separated, and the surplus water is gently patted off with a towel. This method involves cutting the pomegranate with a knife, which results in a loss of more than 30% of the arils owing to mechanical damage[86]. As a result, a better approach was required, such as the machinery developed by Schmilovitch et al.[87], which allows opening the fruit without cutting, extracting the arils with minimal damage, separating the arils from extraneous materials, and delivering clean arils to a packaging machine. This technology could be used to produce dried pomegranate on a greater scale.

The drying time is determined by the pretreatment process, kind, and technique of dehydration used. The dehydration methods that will be investigated in this study are low-temperature drying and high-temperature drying.

Low-temperature drying methods

-

Low-temperature drying methods employ temperatures ranging from subzero to 50 °C[49,88]. These drying processes are time-consuming and are usually utilized for temperature-sensitive goods like herbs. Furthermore, low-temperature drying procedures reduce the risk of scorching the fruit, protecting heat-sensitive components such as vitamin C[89]. Freeze drying, vacuum drying, and sun drying are all low-temperature drying procedures[90]. Pomegranate arils dried using low-temperature procedures such as freeze drying and vacuum drying have a more acceptable look and nutrient composition than most high-temperature drying methods[12,91].

Freeze-drying

-

Freeze-drying (FD) is a low-temperature technology frequently used for drying food samples for high-quality or heat-sensitive products[92]. It is also recognized as one of the most expensive, time-consuming, and energy-intensive procedures in the food industry[93]. It entails removing moisture from food ingredients under low temperature and high vacuum via ice sublimation[48]. Because the product is frequently frozen, it is also known as sublimation drying.

Adetoro et al.[94] freeze-dried fresh pomegranate arils at a freezer temperature of −80 °C for 96 h to examine the effect of drying procedures on pomegranate arils. The researchers discovered that color, total phenolic compounds (TPC), total anthocyanin content (TAC), and radical-scavenging activity stability differed significantly from the hot air-drying procedure (Table 3). More et al.[23] investigated the effect of drying procedures on the quality of dried pomegranate arils from three varieties. The authors discovered that FD produced the greatest results in terms of color, flavor, taste, and nutritional factors across all cultivars. However, FD stood out due to its prolonged drying duration, 24−48 h, when compared to solar drying (17 h) and hot air drying (10 h). A study on the influence of freeze-drying on the color attributes of 'Assiuty' pomegranate arils revealed that FD had the best color attributes (L* value of 46.50 ± 4.4 and a* value of 13.97 ± 1.23)[95]. Gölükcü[91] discovered that the FD had the maximum phenolic matter content (5580 mg/kg), followed by vacuum, convective, and sun-dried pomegranate arils (Table 3). Caln-Sánchez et al.[96] investigated the chemical composition, antioxidant capability, and sensory quality of pomegranate arils and rind after exposure to FD. The investigators found that FD pomegranate arils retained the most sensory characteristics and punicalagin content. Similarly, Cano-Lamadrid et al.[12] discovered the best sensory profile and sweetness in FD pomegranate arils at 65 Pa for 24 h at −60 °C. The drying kinetics, total bioactive content, in-vitro bio accessibility of bioactive compounds, and color and microstructural features of pomegranate arils were also studied[97]. When compared to alternative drying methods, the FD was shown to be the best approach in terms of final product quality and has been highly recommended by multiple reviewers[48]. FD arils have been demonstrated to have a higher bioactive chemical content, less shrinking, and excellent color quality. The FD for pomegranate arils has a disadvantage in terms of bioactive chemical recovery when compared to other methods, as well as extensive drying times[97]. Furthermore, FD is costly due to high energy consumption and initial investment expenses[98].

Table 3. A summary of the many techniques for drying pomegranate arils.

Cultivar Drying method Drying

time (h)Drying condition Initial moisture

content (%)Final moisture

content (%)Key findings Reference Wonderful Freeze dryer 96 −80 °C

5,999.1 Pa74.7 (w.b.) − FD showed a higher color shift (19.6% ± 2,77%) at week 4 compared to hot air drying at week 0. [94] Ganesh, Bhagwa and Arakta Freeze dryer 24−48 −45 °C 79.9 (w.b.)

80.5 (w.b.)

78.9 (w.b.)9.65−9.9 (w.b.)

9.8−10.2 (w.b.)

9.8−9.9 (w.b.)Arakta pre-treated with 1% potassium metabisulphide had the highest ascorbic acid concentration (6.81 ± 0.07 mg 100 g−1). [23] Assiuty Freeze dryer 36 −70 °C − − TA (18.80, 2.80 mg 100 g−1), TP (608.09a, 41.26 mg 100 g−1), DPPH (68.91, 0.72%), and ABTS (2,956.59c, 120 mol trolox

100 g−1) were all higher in frozen pomegranate arils than in freeze-dried arils.[95] Mollar de Elche 24 −60 °C, 65 Pa, 81.5 (w.b.) − FD showed higher anthocyanin content (646 mg kg−1) compared to osmotic drying and conventional drying. [12] Hicaznar 36 −20 °C, 100 Pa for

12 h

−70 °C, 0.26 Pa76.96 (w.b.) 10 (w.b.) Arils dried using FD had the highest magnesium content (96.17 ± 6.95 mg kg−1), manganese content (0.96 ± 0.05 mg kg−1) and zinc content (3.93 ± 0.07 mg kg−1) compared to sun drying, hot air drying and vacuum drying. [91] Keben Freeze dryer 57 −55 °C 77.6 ± 1 (d.b.) 20 ± 1 (d.b.) FD had lower bioactive recovery during in-vitro gastrointestinal digestion (TPC of 2.92%, ABTS of 6.12% and CUPRAC of 38.85%) compared to vacuum drying, hot air drying and ultrasound-assisted vacuum drying. [97] Keben Vacuum dryer 10.8 55 °C 77.6 ± 1 (d.b.) 20 ± 1 (d.b.) Vacuum drying had the highest bio accessibility recovery of bioactive compounds at 10.32% compared to HAD, FD and ultrasound-assisted vacuum drying. [97] Hicaznar Vacuum dryer 3.7

4.6

7.875 °C

65 °C

55 °C

85,000 Pa78.1 ± 0.2 (w.b.) 16 (w.b.) Drying temperatures of 75°C resulted in higher degradation of anthocyanins, phenolic compounds and antioxidant capacity (20.0%, 51.0%, 29.7% ± 0.28% respectively). [99] Hicaznar Vacuum dryer 24 55 °C

3 500 Pa76.96 (w.b.) 10 (w.b.) FD had the highest quality attributes such as TAC-1288.73 mg/kg) compared to VD and HAD however, due to physical changes that were undesirable physical changes, VD and HAD are recommended for pomegranate aril drying. [91] Wild pomegranates (cultivar- unspecified) Vacuum dryer 13 42 ± 2 °C − − VD had a higher sensorial overall acceptance (17.1) compared to sun drying (16.2) and room temperature (12.6). [72] Bassein Sun drying 17 − 15.73

(unspecified)Drying rate of pomegranate arils is affected by tray load and the recommended tray load is 1.25 kg m−2 [73] Wild pomegranates (cv. Unspecified) Solar poly-tunnel 140 14.9−28.4 °C

48.5%−74% -RH

0.639−0.944 -wind speed− − Arils dried in the solar poly-tunnel had higher ascorbic acid, anthocyanins, and phenol content, 12.7 mg 100 g−2, 28.12 mg 100 g−2, and 108.60 mg 100 g−2 respectively than open sun drying. [100] Sefri Indirect solar dryer 75

10

6

440 °C

50 °C

60 °C

75 °C78 ± 0.1(w.b.) − The optimal water activity for drying and storing arils is 0.3684 ± 0.03. [101] Wild pomegranates

(cv. Unspecified)Solar tunnel − 30−45 °C − − Arils from the Karsog location had the highest TSS, sugars, anthocyanin, total phenols and antioxidant activity [102] − Microwave 2.3

1.3

0.7270 W

450 W

630 W70.25 ± 0.5(w.b.) 10(d.b.) Color changes increased from 6.77−13.11 with an increase in microwave power from 270−630 W and were lower compared to arils dried using HAD. [85] Hicaz Microwave 1.2

0.6

0.4210 W

350 W

490 W23.93 ± 1.4 (unspecified) 22.2

(unspecified)Based on quality parameters, a microwave drying power of 350 W was recommended for drying pomegranate arils. Sweet acid

(cv. Unspecified)Infrared 4.3

2.2

1.650 °C

60 °C

70 °C78 ± 0.2 (w.b.) 9 ± 0.2 (d.b.)

22.2

(unspecified)Drying time for infrared drying was less than for HAD. [103] Hicaz HAD 24 50, 60, 70 °C at

1.0 m/s air velocity− − To obtain better dried aril quality, 60 °C was recommended for drying pomegranate arils. [104] Wild pomegranates

(cv. Unspecified)HAD 16.5 42 ± 2 °C − − Sun drying resulted in a maximum loss of moisture compared to VD, HAD, poly-tent house drying and room drying. [72] Wild pomegranates

(cv. Unspecified)HAD 10 62 ± 2 °C − − HAD achieved the highest total soluble solids (39.6°Brix) and drying rate compared to solar drying and open sun drying. [105] Keben HAD 5 55 °C; with 1.3 m s−1 constant air velocity 77.6 ± 1 (d.b.) 20 ± 1 (d.b.) In comparison to hot air oven drying, ultrasound-assisted vacuum drying and freeze-drying have higher quality characteristics. [97] Bassein seedless HAD 5−6 60 ± 5 °C. Airflow in

the dryer was 1.2−1.8 m s−1.− 8.98 ± 0.091 For the finest preparation of anardana, blanched samples (with sulphur) should be dried in a cabinet. [73] Mollar de Elche Vacuum-

microwave− 240, 360, 480 W and pressure ranging

from 4,000−6,000 Pa80.4 (w.b.) − Arils dried using vacuum microwave drying at 240 W had the highest sensorial scores for odour and aroma at 3.1 and 5.6 respectively. [106] Vacuum drying

-

Vacuum drying (VD) is the process of subjecting items to low pressure in a vacuum. Because of the low pressure, water has a lower boiling point, allowing samples to be dried at low temperatures. As a result, VD is appropriate for heat and/or oxygen-sensitive items. During VD, heat transmission can occur by conduction, radiation, or microwave energy. VD is distinguished by faster drying times when compared to FD, and the products are not initially frozen as necessary for FD[107]. This low-temperature operation, combined with the elimination of oxygen during vacuum drying, allows nutrients and bioactive components such as phenolic compounds and vitamins to be retained[108,109].

Ozay-Arancioglu et al.[97] investigated the influence of drying methods on dried pomegranate arils by comparing four distinct drying techniques: FD, VD, ultra-assisted vacuum drying, and hot air drying. They discovered that VD had better antioxidant capacity values than the samples tested for ABTS following FD. According to Gölükcü[91], VD is second only to FD as the finest choice for producing dried pomegranate (Hicazar) arils. Another study found that arils dried at 55 °C had higher phytonutrient levels than those dried at 65 and 75 °C under vacuum conditions[69]. When compared to other drying procedures, vacuum drying produces products with higher levels of phytochemical components. However, drying times range from 7.8 to 24 h at 55 °C, contributing to high costs, and products can only be dried in batches[91,99,110].

Sun drying

-

Sun drying is one of the oldest and most used methods of drying. Sun drying is a low-cost, renewable energy-based drying process. In a nutshell, products are laid out on a flat area where they can be fully exposed to the sun for as long as possible. Because the drying process is dependent on solar radiation, the temperature is low and the drying process can be lengthy, taking approximately 15 d for pomegranate arils[60]. Furthermore, exposure to light and oxygen can lead to decreased preservation of substances like vitamin C. Furthermore, solar drying is an uncontrolled process with substantial risks of pest contamination, dust exposure, and product remoistening at night. To increase safety, solar dryers and solar tunnels are proposed to reduce pest and dust contamination[111]. Solar dryers use a contained environment comprised of a transparent or opaque cover, resulting in either direct or indirect drying[112]. The indirect drier system captures solar heat and transfers it to the product drying chamber via a second solar collector. A solar tunnel dryer is typically large in size and has a clear cover (Fig. 4). To regulate drying conditions such as temperature and relative humidity within the tunnel, solar tunnels often require a forced convection facility. A solar tunnel dryer may also include a solar air heater[111]. Solar dryers have the potential to boost drying temperatures, resulting in a quicker drying time[113].

Figure 4.

This image depicts a sample of wild pomegranate arils being dried in a solar tunnel drier. Reprinted from Thakur et al.[102].

In a comparison of hot air drying (60 °C), solar tunnel drying, and sun drying by Madushree et al.[63], hot air-dried arils were shown to have the highest quality. However, of all the drying techniques, solar drying had the greatest L* values (lightness), a desired quality. This was due to the comparatively low temperature of sun drying. Additionally, Bakshi et al.[72] discovered that when compared to vacuum drying, oven drying (42 ± 2 °C), and room drying (23 ± 2 °C), sun dried arils had the highest sensory overall acceptance and the lowest moisture content. In their comparative analysis of drying techniques, Singh et al.[73] discovered that hot air-dried pomegranate arils had the greatest anthocyanin and acidity contents. But in hot-air oven-dried samples, undesirable non-enzymatic browning was most pronounced. Sharma & Thakur[100] demonstrated that the quality of arils dried in solar polytunnels was superior to that of arils dried in the open sun (Fig. 4). The ascorbic acid, anthocyanins, and phenols were found to be significantly greater in the sun polytunnel dried arils, according to the authors. They also received superior sensory ratings for color, texture, taste, and acceptability.

High-temperature drying methods

-

Temperatures above 50 °C are used in high-temperature drying processes[88]. These drying processes are energy intensive, have large operating expenses, and so are costly. These technologies rely on fossil fuels, which pollute the environment where they are generated and utilized, and their continued usage is seriously harming our environment[114]. The drying mechanism is designed such that there is a controlled direct or indirect heat transmission to the product, leading in moisture elimination. These drying procedures may not be suited for some foods because they may induce nutritional breakdown[115]. Furthermore, high temperatures might cause product shrinkage and distortion. Hot-air drying ovens, steam drying, heat pump drying, and spray drying are all examples of high-temperature drying processes.

Hot air oven drying

-

Using forced convection, hot air oven drying (HAD) eliminates moisture from materials. Objects dry out through evaporation when hot air is forced through and around the substance. As a result, the dried product's flavor, color, nutrients, and ability to rehydrate may alter unintentionally[97,104,106]. The HAD techniques were shown to have a comparatively high total color change by Ozay-Arancioglu et al.[97]. As shown in Fig. 5, hot air-dried arils were darker than freeze-dried and vacuum-dried arils.

Figure 5.

Illustration of dried pomegranate arils that have been dried using different methods. (a) Freeze drying, (b) vacuum drying, and (c) hot air drying. Adapted from Ozay-Arancioglu et al.[97].

Başlar et al.[99] prepared dried aril samples using the hot air-drying process and subjected them to various quality assessments. Fresh aril samples were dried at three different temperatures (55, 65, and 75 °C). According to the authors' findings, high temperatures and short drying times are optimal for retaining valuable food biocomponents. However, whereas bioactive chemical losses increased over time, they degraded faster at higher temperatures. The antioxidant activity, on the other hand, decreased with drying time and was unaffected by drying temperatures. Horuz & Maskan[104] investigated the effect of hot air drying on pomegranate aril cv. Hicaz at three different drying temperatures and compared quality metrics such color, shrinkage, rehydration capacity, and drying time (Table 3). The authors suggested 60 °C for pomegranate aril HAD. The authors also discovered that shrinkage was greater in HAD than in microwave drying. In a second study, researchers discovered that the optimal drying temperature for retaining bioactive chemicals when drying pomegranate arils (cv. Hicaznar) in a hot air dryer was 65 °C[116]. When compared to the sun drying method for anardana made from wild pomegranate, Bhat et al.[105] discovered HAD dried arils with maximum acidity of 13.72%, phenols of 110.7 mg per 100 g, total sugars (24.2%), and reducing sugars (21.2%).

However, Bakshi et al.[72] carried out a study with lower temperatures in which they studied the influence of different drying processes on the moisture content of dried pomegranate aril (cv. Wild). Lower temperatures were employed to gain insight into the quality of the dried product when compared to the low temperature drying methods used in the study, such as sun drying, poly tent house drying, room drying, and VD. When compared to alternative drying methods, the authors discovered that HAD (42 ± 2 °C ) for 16.5 h and drying in room at normal air (23 ± 2 °C ) for 10−12 d produced in the greatest loss of moisture from fresh arils of wild pomegranate (75.12%).

Singh et al.[73] evaluated the influence of different drying conditions on the quality of dried pomegranate arils (Bassien Seedless) samples (Table 3). The scientists discovered that sun-drying preserved more MC while drying was faster with a HAD dryer and generally recommended it as a better strategy for preparing dried pomegranate arils.

HAD drying of pomegranate arils is a standard drying procedure that can be utilized in commercial settings. Although HAD does not generate high-quality goods like FD, it does provide better TSS, TA, and antioxidant capacity stability. Furthermore, although having a higher rate of bioactive component degradation, higher temperatures may result in higher retention compared to approaches such as solar drying due to the short drying times.

Electric and dielectric drying

-

Electrical current is passed through the pomegranate aril during electric drying techniques including ohmic heating. The intrinsic resistance of the aril induces internal heating as the electrical current flows through it[117,118]. Ohmic heating is typically employed for liquid, viscous, and particle-containing foods[119]. Regardless of the meal's densities, food products prepared using this approach are heated quickly and uniformly[120].

Dielectric techniques, on the other hand, use electromagnetic waves to directly produce heat inside the product, such as microwave, radio frequency drying, and infrared radiation[121]. Dielectric heating results from the conversion of electromagnetic energy to kinetic energy by dipolar molecules oscillating in accordance with the rapidly oscillating electric field[122,123]. Compared to traditional methods like hot air drying, dielectric technologies dry materials more quickly[124]. Additionally, the items are of a higher caliber than those produced by traditional drying techniques.

Microwave drying

-

Microwave drying (MD) is one of the emerging drying technologies. Unlike other techniques, MD utilizes volumetric heating to rapidly dehydrate the sample material[104]. Some studies[85,104] have indicated that arils desiccated at 150 W microwave power and 58 bar (abs) pressure produced the highest quality arils. In another study, microwave power of 80 W and vacuum pressure of 60 mm Hg provided the highest drying efficiency and qualitative attributes, including color and texture[125]. Horuz & Maskan[104] observed that microwave-dried pomegranate samples had lower levels of shrinkage and bulk density than hot air-dried samples. The authors also noted that microwave drying caused a greater loss of color in terms of total color difference (E) compared to air drying. It was observed that microwave-dried samples had a brownish hue.

Drying with MD reduces drying time, but essential quality parameters, such as color, are sacrificed. Since the product is directly heated, the lack of heating uniformity during MD, which is difficult to control and could contribute to product burning has been cited as a disadvantage[126].

Infrared drying

-

Infrared drying is an effective technique of drying in which the product is heated directly without the use of air as the drying medium. In a comparative study of drying methods (hot air drying and infrared drying) to dry pomegranate arils, the authors discovered that infrared drying effectively dried pomegranate arils and that the polyphenol content in arils dried using infrared drying was higher at 50 and 60 °C than in arils dried using hot air drying at similar temperatures[103]. Therefore, pomegranate arils can be infrared-dried at 50 °C for optimal nutrient retention[103]. In contrast, a distinct study dried pomegranate arils under near-infrared vacuum conditions and found that drying at 60 °C and 20 kPa air pressure resulted in optimal colour retention and shrinkage[127].

Although infrared drying is a rapid drying method, it is challenging to control due to parameters such as infrared intensity and radiation distance, and its energy consumption is unpredictable[26].

-

Drying kinetics is the study of how factors that influence the removal of moisture from products during a drying process interact[110]. The drying kinetics of a substance is dependent on its thermal and mass transport properties. Understanding drying kinetics relates to process variables, and therefore aids in identifying suitable drying methods and controlling drying processes[57,96,116]. For optimal operating conditions, drying kinetics can be used to estimate drying time, energy requirements, and drying efficiency[2]. Due to the complexity of the drying phenomenon, however, mathematical models describing the drying kinetic of biological tissues are devised based on the time history of the moisture ratio from a controlled drying experiment[128]. There are numerous mathematical models, but Table 4 provides a summary of the most used models.

Table 4. A summary of the mathematical equations that are most commonly used to model the drying kinetics of pomegranate arils is shown here.

The most common models that best describe the hot air drying of pomegranate arils include the Logarithmic, Midili and Page models[24,99]. Baslar et al.[99] found the Logarithmic model as the best in describing hot air drying of arils at 55, 65 and 75 °C. In another study, it was found the Sigmoid model describing the kinetics of hot air drying of pomegranate arils at similar drying temperatures[116].

In their study on the infrared drying of pomegranate arils, Briki et al.[103] discovered that the Midili model was the most accurate representation of the drying kinetics. In a similar manner, it was discovered that the Midili model provided the best fit to the experimental data for drying using a combination of infrared and hot air[136]. Another investigation indicated that the Aghbashlo model provided the greatest fit for the data obtained from near-infrared vacuum drying at a temperature of 60 °C[127].

Based on measurement data from three pomegranate cultivars (cvs. 'Acco', 'Herkaswitz', and 'Wonderful') at 60 °C, Adetoro et al. demonstrated cultivar as another influencing factor in selecting an optimal model. While the drying data of the blanched samples of all the cultivars in this investigation were best fit by the Logarithmic model, the unblanched samples of 'Acco' and 'Herkaswitz' and 'Wonderful' were best fitted by the Page and Midili models, respectively[24].

The bioactive chemicals retained and drying periods may be affected by the pretreatment process, although frequently the drying kinetics of both untreated and pretreated samples may be described by the same model. The Page and Modified Page were determined to be the best models to fit the drying data of both blanched and unblanched pomegranate arils under vacuum air drying by Karaslaan et al.[69]. In a different investigation, the Page and Modified Page were shown to be the model that best suited the drying data of pomegranate arils that had been bathed in citric acid and dried by hot air[57]. Although the drying rate of pre-treated samples is higher than that of untreated samples, the scientists noted that the same models were found to best reflect the drying kinetics. The Page, Logarithmic, and Midili drying models are the most popular and effective drying models for pomegranate arils employing HAD, MD, and VD. The mathematical models that were utilized to explain the drying kinetics of pomegranate arils are summarized in Table 5.

Table 5. A synopsis of the results of mathematical modeling of the kinetics of drying pomegranate arils.

Cultivar Drying method Drying parameters Pretreatment Suitable drying model Reference cv. Hicaz HAD 55, 65, 75 °C 0.1% citric acid Page and Modified Page [57] cv. Hicaznar HAD 55, 65, 75 °C − Sigmoid [116] − HAD 55, 55, 60 °C − Page [137] − HAD 50, 60, 70 °C − Page [85] MD 270, 450, and 630 W − Page [85] cv. Hicaznar VD 55, 65, 75 °C Hot water blanching Page and Modified page [69] − HAD 45, 50, 55, 60, 65, and 70 °C Microwave Midili [75] cvs. Acco, Herskawitz and Wonderful HAD 60 °C Hot water blanching (at 90 and 100 °C, each for 30 s

and 60 s)Logarithmic, Page,

Midili for unblanched arils

Midili and Page for blanched[24] -

The drying procedure aids in reducing bacterial growth, which can result in reducing spoilage. However, while food is being dried, other changes may occur that degrade its quality. To determine the product's expiration life, chemical, physical, physicochemical, and microbiological changes are monitored[138,139]. These modifications are affected by stowage, environment, and packaging methods. The most significant factor affecting the integrity of stored food products is temperature[140]. Consequently, most shelf-life experiments are designed to evaluate the temperature-time history in relation to changes in product quality[138,141]. To accurately evaluate quality changes and safety, shelf-life evaluations should ideally simulate actual storage conditions[142]. In the case of desiccated goods, the actual storage period is lengthy, and the evaluation of shelf-life can become time-consuming and expensive. When the actual storage time is lengthy for practical reasons, an accelerated shelf-life test or analysis of the worst-case scenario is employed[142]. Ordinarily, the end of shelf life is determined by relevant food legislation, guidelines issued by enforcement authorities or agencies, guidelines issued by independent professional organizations, current industrial best practices, self-imposed end-point assessment, and market data[142].

Appropriate packaging material can help to reduce quality losses. The packaging and shelf-life tests on dried pomegranate arils are summarized in Table 6. Sharma et al.[70] examined the packaging of dried pomegranate arils with high-density polyethylene (HDPE), low-density polyethylene (LDPE), and polypropylene (PP) films. For 12 months, samples were held at 7 °C and ambient (14−39 °C). They found that HDPE retained the most color, total tannins, and acidity while gaining the least moisture. The authors proposed a safe storage time of 6 and 9 months for HDPE packed dried pomegranate arils under ambient and refrigerated conditions, respectively.

Table 6. A list of the several types of containers used to store dried pomegranate arils.

Drying method Drying temperature Packaging material Storage period (months) Shelf-life performance Reference MC drier

Solar cabinet drier

Open sun62−64 °C

50−55 °C

18−24 °CAluminum laminated polyethylene pouch, polyethylene pouches and thermoform trays. 6 Aluminum laminated polyethylene pouches were best for packaging. [105] Microwave-vacuum drying 38 °C High-density polypropylene (HDPP) and aluminum laminated polyethylene (ALP). 3−6 Pomegranate arils stored showed that ALP is more protective than HDPP. [35] Solar tunnel 30−45 °C Gunny bags, aluminum laminated polyethylene pouches (ALP) and vacuum-sealed aluminum laminated polyethylene pouches (ALPV). 12 Both refrigerated and ambient storage can securely preserve dried pomegranate samples for 12 months. Best performance was ALP with vacuum and cold storage. [144] Hot air dryer 60 °C Aluminum laminated polyethylene pouch (ALP), polyethylene pouch (PEP), and thermofoam tray (TT) covered in shrinkable polypropylene transparent sheet. 6 Moisture absorbers aid in the preservation of samples. [100] Bhat et al.[105] compared aluminum-laminated polyethylene (ALP, 99.8 g m−2) and polyethylene pouches (93.9 g m−2) each storing 100 g dried pomegranate arils and stored at ambient (15−25 °C). The authors discovered that aluminum laminated polyethylene pouches performed best after a 6-month storage period. Dak et al. [35] compared HDPP and ALP under accelerated shelf-life conditions (38 ± 1 °C and 90% ± 1% relative humidity) and evaluated the correlation between packaging material, storage period, and anthocyanin, phenolics, TSS, TA, and microbial count. The authors estimated that HDPP and ALP have shelf lives of 96 and 187 d, respectively. The above two research confirmed that ALP had the best performance features. This could be owing to the pouches' thickness and the opaque barrier of the aluminum lamination. The use of opaque packaging material may extend the shelf life of pomegranate arils by minimizing photodegradation of components such as carotenoids, flavonoids, and lipids, which can alter qualitative qualities such as aroma, texture, and color[143]. Based on safe consumption criteria, Mokapane et al.[19] proposed a shelf life of 5 months for citric acid pretreatment and dried arils wrapped in kraft paper pouches.

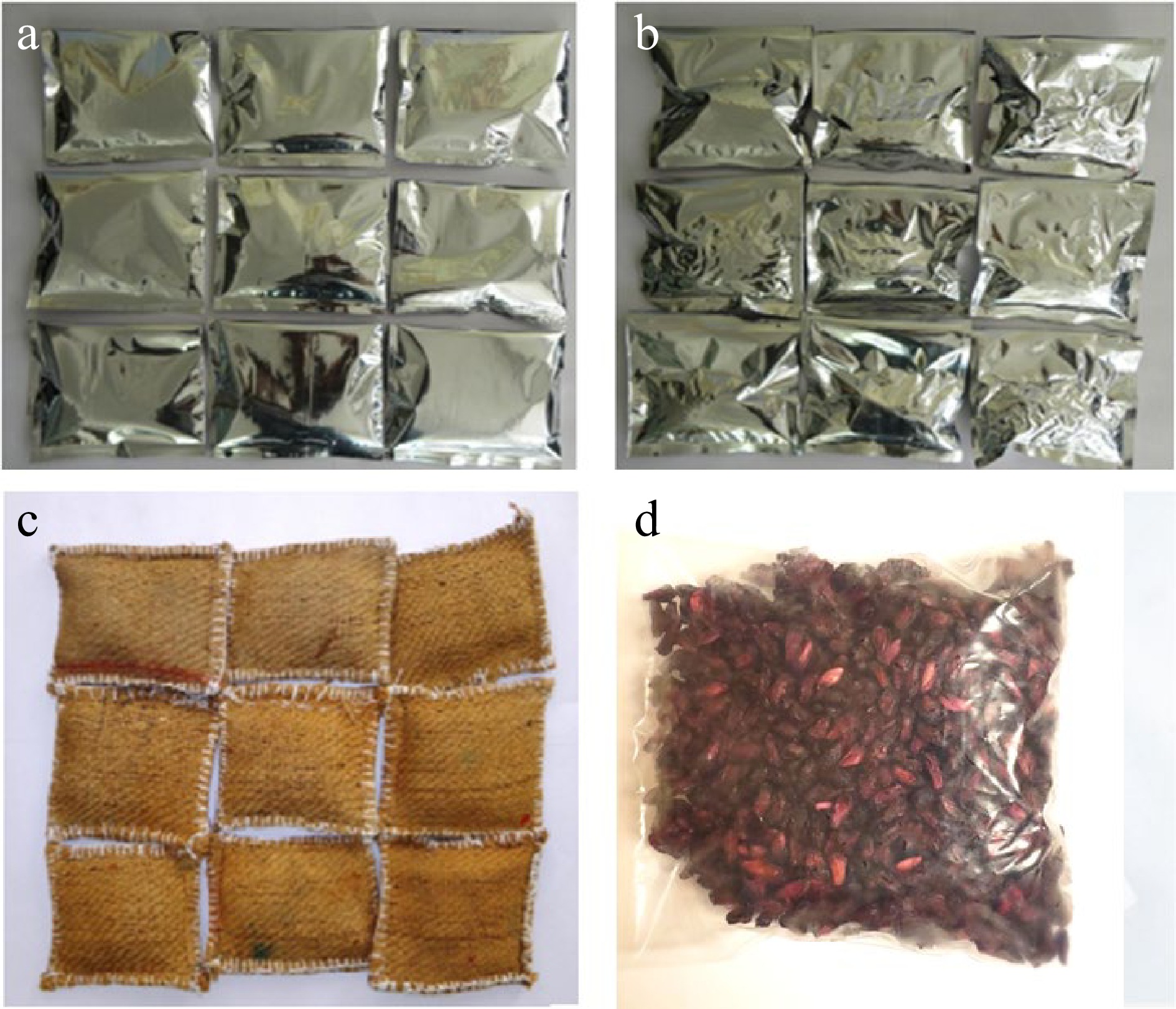

In a second investigation, Thakur et al.[144] examined the effectiveness of gunny bags, ALP, and ALP combined with vacuum for storing dried pomegranate arils for a period of one year. According to the authors' findings, ALP performed best when performed under vacuum. The various types of containers that are used to store dried pomegranate arils are broken down into categories and shown in Fig. 6.

Figure 6.

Different types of storage bags for dried pomegranate arils. (a) Aluminum-laminated polyethylene pouches, (b) vacuum-sealed aluminum-laminated polyethylene pouches, (c) gunny bags and (d) transparent polyethylene pouch. From Thakur et al.[144], modified.

Sharma & Thakur[100] investigated the effect of active packaging on the quality features of dried wild pomegranate arils over a 6-month storage period. Salt or sugar sachets were inserted in ALP pouches or Thermofoam trays that had been wrapped in shrinkable polypropylene transparent film or polyethylene pouches. The researchers reported that for arils dried in a mechanical drier, ALP pouches had the best quality retention of criteria such as ascorbic acid, anthocyanins, total phenols, color, and texture. Furthermore, the inclusion of salt or sugar in active packing aids in the production of high-quality dried arils. However, salt-based active packaging had somewhat higher TA, ascorbic acid content, total sugars, anthocyanin content, and total phenols than sugar-based active packaging.

-

The shelf life of dried pomegranate aril can range anywhere from three months to a year depending on the pretreatment, drying procedures and packaging that were used. There is, however, no definitive guideline about the influence that pretreatment and drying procedures have on the quality characteristics of the product when it is being stored. Many studies on the shelf life of dried pomegranate arils focus on examining the influence that different types of packaging material have on the storage life. These studies pay less attention to the physical and microbiological changes that accompany quality alterations. Additionally, a specialized shelf-life testing process and quality standard for dried pomegranate arils can be difficult to locate in the literature.

While high temperatures have a positive influence on the drying rate, it has a negative effect on the product's texture, color, and nutritional content. Because of this, lower temperatures are often ideal for retaining the pomegranate arils' nutritional value and maintaining their consistency. Freeze dryers offer the best result in this regard. Freeze-drying, on the other hand, is a time- and money-consuming process. When paired with other types of pretreatment, inexpensive procedures such as sun dryers can be adjusted to produce high retention on chemicals that are virtually identical to those obtained in freeze dryers. However, before implementation, it is necessary to examine the intended outcome of the pretreated arils. This is because pretreatments affect both the drying rate and the retention of nutrients. Therefore, in order to completely optimize the process, it is necessary to have an awareness of the interaction that occurs between the pretreatments and the subsequent drying procedure. It is proposed that recommendations be formulated to assist in the manufacture and marketing of dried pomegranate arils that are consistent, nutritious, and hygienically safe.

-

The authors confirm contribution to the paper as follows: study conception and design: Ambaw A, Opara UL; project administration and supervision: Ambaw A, Opara UL; draft manuscript preparation: Maphosa B; manuscript review and editing: Ambaw A. all authors reviewed the results and approved the final version of the manuscript.

-

Data sharing not applicable to this article as no datasets were generated or analyzed during the current study.

This work is based on the research supported wholly/in part by the National Research Foundation of South Africa (Grant No. 64813). The opinions, findings and conclusions or recommendations expressed are those of the author(s) alone, and the NRF accepts no liability whatsoever in this regard. Research reported in this publication was supported in part by the Foundation for Food and Agriculture Research under award number 434—grant ID: DFs-18- 0000000008.

-

The authors declare that they have no conflict of interest.

- Copyright: © 2023 by the author(s). Published by Maximum Academic Press, Fayetteville, GA. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Maphosa B, Ambaw A, Opara UL. 2023. Review of the effects of various pretreatment and drying techniques on the qualities of dried pomegranate (Punica granatum L.) arils. Technology in Horticulture 3:26 doi: 10.48130/TIH-2023-0026

Review of the effects of various pretreatment and drying techniques on the qualities of dried pomegranate (Punica granatum L.) arils

- Received: 07 August 2023

- Accepted: 27 October 2023

- Published online: 15 December 2023

Abstract: Drying inhibits the growth of microorganisms by reducing the amount of available moisture. This slows the process of food deterioration, extends its shelf life, and makes it easier to access food year round. It is possible to use a variety of drying techniques, from expensive freeze-drying to low-cost sun drying. For a high-quality dried aril, fruit is frequently pretreated before drying using techniques including hot water or steam blanching, sulphuring, vacuum, microwave, and ultrasound. Lower shrinkage and improved nutrient retention were linked to freeze-drying and ultra-assisted vacuum drying. These processes are however expensive and need to be optimized for less expensive drying techniques and the use of pretreatment techniques that lower cost and enhance the quality of the dried arils. Fresh pomegranate arils have a shelf life of five to seven days in cold storage, compared to more than 14 weeks for dried pomegranate arils stored in normal air. The major goals of the various pretreatments are to maintain the final product's physical, physicochemical, and chemical characteristics and/or to accelerate drying. However, knowledge of the fundamental causes is still incomplete and underexplored. In this review paper, the current state of research on pomegranate aril drying is critically reviewed. Various pretreatments and drying methods were assessed. Various drying procedures' energy efficiency and product attributes are summarized. The pretreatment effects on the quality of the finished product are highlighted. Researchers, engineers, policy officials, and agroprocessors will find this material useful.

-

Key words:

- Blanching /

- Hot-air-drying /

- Freeze-drying /

- Shelf-life /

- Value-addition /

- Anardana /

- Drying kinetics