-

Fruit wine is a low-alcohol beverage made from fermented fruits, rich in sugar, organic acids, vinegar, and various vitamins. Wine has a high content of vitamin C and rich superoxide dismutase (SOD), which enhances immune function. It has a higher nutritional value than distilled spirits made from grain wine. It has medical and health benefits such as regulating human metabolism, promoting blood circulation, controlling cholesterol levels, and anti-aging[1]. Aging is an important step in producing high-quality fruit wine[2]. Fruit wine that has been aged for a long time has a better taste and a more stable body than newly produced fruit wine. Long-term natural aging, under slow oxidation and esterification reactions, can increase aromatic substances such as esters and aldehydes, making the wine mellow and soft, eliminating bitterness and other impurities in the wine body, and improving the quality of the fruit wine[3].

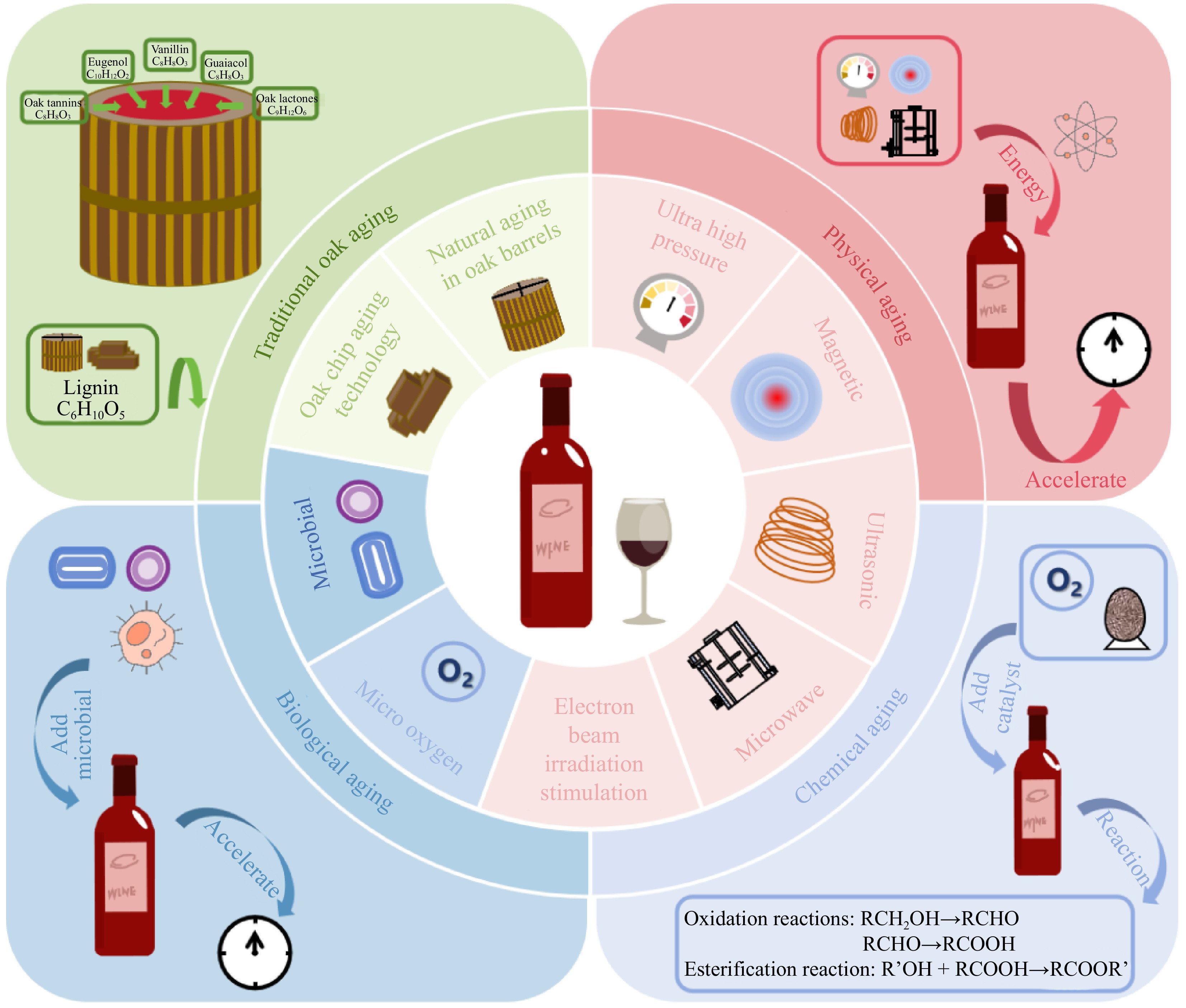

During the fermentation process of fruit wine, sugar is converted into alcohol and carbon dioxide while also producing a large amount of aromatic and taste substances, which are key factors in forming the unique flavour of fruit wine. The aging of fruit wine refers to allowing the wine to settle for a period after fermentation to mature and become more delicious gradually. Firstly, aging can improve the taste of fruit wine. During the aging process, the acidity and bitterness of fruit wine gradually decrease while the sweetness and softness gradually increase[4]. This is because, during the aging process, the substances in the fruit wine gradually decompose and transform, making the wine softer, smoother, and easier to drink. Secondly, aging can enhance the aroma of fruit wine. During the aging process of fruit wine, the aromatic substances in the fruit wine will slowly be released, making the aroma of the fruit wine more intense. At the same time, the taste of fruit wine will gradually become more complex and rich, making the flavor of fruit wine more deeply ingrained in people's minds[5]. Finally, aging can improve the quality and stability of fruit wine[6]. During aging, bacteria and microorganisms in the fruit wine are gradually killed, making the wine more stable[7]. At the same time, specific chemical reactions such as esterification and redox reactions in fruit wine will gradually occur, making the quality of fruit wine more stable and long-lasting[8]. At present, artificial aging methods mainly include traditional oak aging, physical aging, chemical and biological aging, and the specific aging technology and aging mechanism are shown in (Fig. 1).

This review focuses on summarizing the artificial aging technology of fruit wine, which makes a certain contribution to accelerating the aging effect of fruit wine, and lays a certain foundation for scientists and researchers to further explore more aging technology.

-

Oak and oak products, including barrels, flakes, flour, and blocks, were originally used for wine aging. The use of oak for aging is inexpensive and easy to operate but also enhances and improves the organoleptic qualities of alcoholic beverages such as wine[9]. This is because the aromatic components of oak that are characteristic of oak, such as oak lactones, vanillin and eugenol, are dissolved in the wine to improve the aroma of the wine, and the extraction of tannins gives the wine a more layered appearance[10].

Natural aging in oak barrels

-

In traditional fruit wine-making, aging is a crucial step. During the aging process, the wine gradually becomes softer, smoother, and easier to drink, with more decadent aromas and complex flavors[11]. In the traditional wine-making process, natural aging in oak barrels is usually achieved by placing the wine in oak barrels or glass bottles and placing it in a cool, ventilated, and dry place, allowing the wine to gradually undergo natural aging over time. Aging in oak barrels can significantly affect the aroma components of wine. The volatile compounds naturally present in oak barrels can be transferred to wine through prolonged contact with it[12]. This process usually takes several months to several years, depending on the brewer's personal preferences and the type of wine[13]. From the perspective of its sensory impact, the main volatile compounds released by oak are wood thermal degradation derivatives (phenolic and ketone, volatile phenols, furan, and pyran compounds), which enrich the aroma of wine with toasted bread, coconut, wood, vanilla, and spicy notes[14]. During natural aging, the substances in the wine gradually decompose and transform, making the wine more flavorful and stable[15]. In addition to the traditional oak barrel aging method, modern natural aging techniques are constantly developing. Some distilleries are constantly innovating based on natural aging, such as using stainless steel barrels combined with temperature control systems to achieve more precise and controllable aging processes. In addition, some winemakers also attempt to age using different wooden barrels to achieve a more unique taste and aroma[16]. However, the drawbacks of traditional aging techniques, which require months to years and significantly extend the wine production cycle, have been criticized by many producers due to their impact on production costs. The lengthy process of traditional aging, which can span months to years, prolongs the wine production cycle significantly. This substantially impacts the production costs borne by various wine producers. In summary, traditional aging techniques for wine can endow it with higher quality, but the time cost is also relatively high.

Oak chip aging technology

-

With the increasing demand for wine quality, there is a growing demand for aged wines[17]. Nevertheless, a pronounced disparity exists between the global availability of oak and the quantity of oak barrels manufactured worldwide. This disequilibrium has precipitated a substantial escalation in the price of oak barrels, rendering them exorbitantly costly. To solve the long-term problems, high cost, and poor effect of the aging process of oak barrels, the oak chip aging technology has been applied. The oak chip aging technology achieves a similar aging effect as oak barrels by using oak chips with different degrees of roasting. Meanwhile, adopting oak chip aging technology instead of traditional oak barrel aging will significantly reduce the use of oak and protect ecological balance. The principle of oak chip aging wine is mainly to simulate the extraction function of oak barrel aging, so that the wine has an oak flavour[18], thereby achieving a better aging effect. The study by Tao et al. showed that using oak products during wine aging can increase the extraction rate of volatile compounds from oak and accelerate the aging process[19]. In contrast to oak barrels, which have a contact area of merely 40%, oak chips, boasting a substantially larger contact area, enable the wine to permeate and infuse more effectively. Consequently, oak chips can, to a certain degree, curtail the aging duration and enhance the aging outcome. Using oak chips during the primary fermentation process increases the concentration of straight-chain fatty acids, ethyl, hexyl, isoamyl acetate, and higher alcohols in fruit wine[20]. Oberholster et al. demonstrated that adding oak chips and incorporating micro-oxygenation technology during the aging of wine can accelerate the maturation of the wine. It can simulate the sensory characteristics of the wine after a short-term aging of six months in oak barrels, thus not only shortening the aging duration but also achieving the same effect[21]. Research by Gómez García-Carpintero et al. has shown that using oak chips in fruit wine after the primary fermentation process can increase the concentrations of benzene compounds, oak lactones, and furan compounds[22]. However, there are also some drawbacks to the oak chip aging technique, as the content of vanillin, volatile phenols, and oak lactones varies in oak leaves from different regions. Therefore, when using the oak chip aging technique, it is necessary to choose the appropriate one based on the type of wine[23]. When the aging time and contact area are not properly controlled, excessive extraction of tannins may occur, causing the wine to taste overly bitter and rough. Additionally, an excessive amount of oak lactone may be extracted, which can also affect the wine's aroma. At the same time, although oak chip aging technology can shorten the natural aging time to a certain extent, it still cannot significantly shorten the production cycle of wine. Shortening the aging time of wine is still a problem that many scholars continue to explore.

-

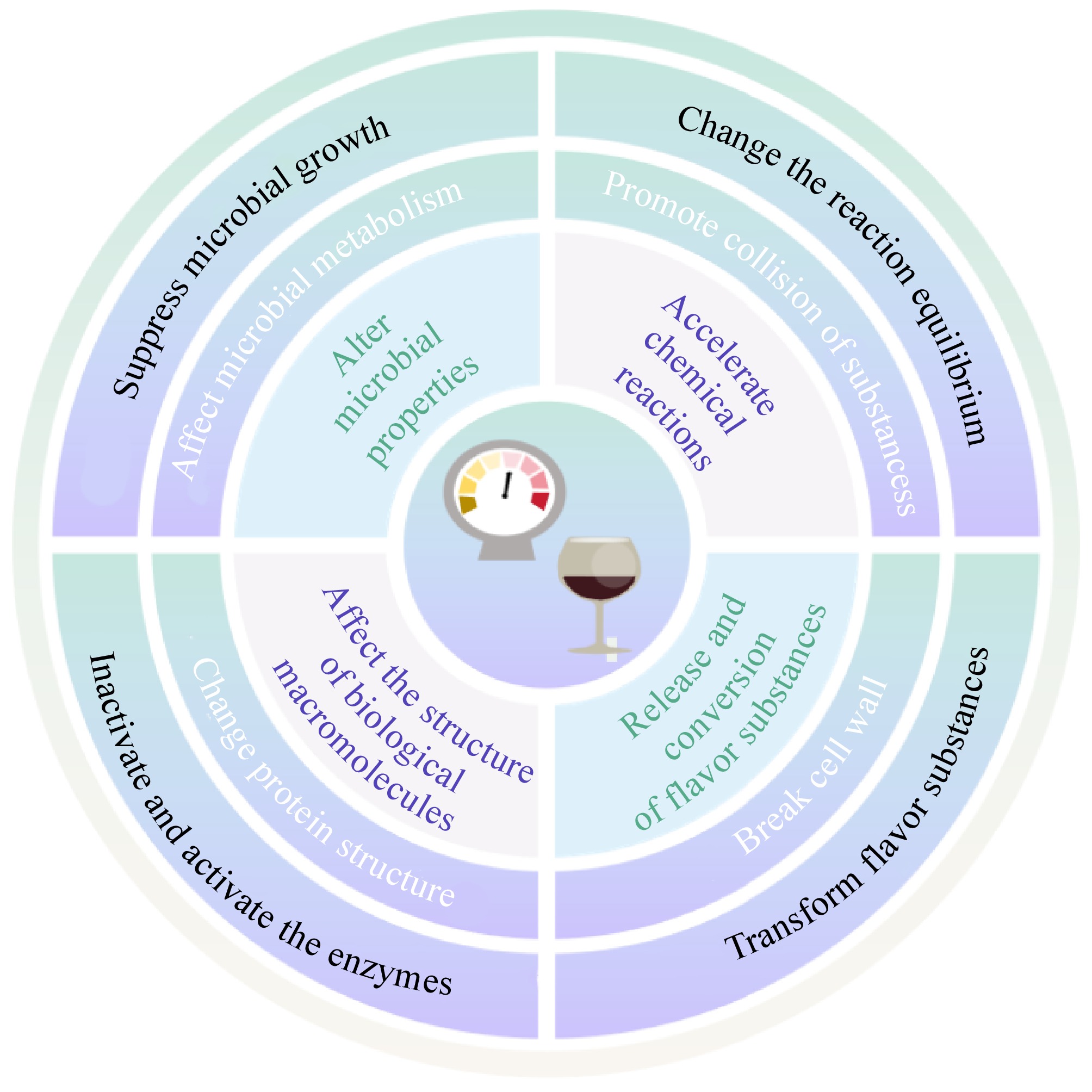

The physical aging method mainly includes ultra-high-pressure treatment, ultrasonic treatment, ultraviolet radiation, infrared radiation and other aging methods. Its basic aging principle is to provide external energy to the ingredients in the liquor, accelerate the rate of esterification and other chemical reactions, and achieve the purpose of accelerating aging[24].

Ultra-high-pressure aging technology

-

Ultra-high-pressure processing technology was first applied to the shelf life of dairy products and later gradually applied to food products such as fruit juice, jam, and wine[25]. Ultra-high-pressure technology is the process of using water as a pressure medium, placing ginger samples in ultra-high-pressure equipment, and maintaining pressure for a certain period at a pressure of over 100 MPa. During the processing, non-covalent bonds in the wine are broken, causing enzymes, proteins, and other substances to become inactive and deformed. This accelerates the collision of substances in the wine and chemical reactions, thereby improving the quality and flavor of the wine[26]. Processing wine with ultra-high-pressure can cause physical and chemical changes, including those observed in ultraviolet and visible spectra, thereby improving the overall quality of the wine. This method accelerates the aging of wine.

Ultra-high-pressure is a new type of wine aging technology that can not only reduce the microbial activity in wine and achieve a sterilization effect by applying ultra-high-pressure under non-thermal conditions but also stimulate the aroma in wine, thereby promoting the aging process of wine. Ultra-high-pressure aging technology can not only accelerate the aging speed of wine but also improve the quality of wine[27]. Wen et al. found that after processing banana fruit wine under 300 MPa pressure for 6 min, the aroma components decreased, and the relative content of alcohols increased, the relative content of esters decreased, but the content of ethyl acetate increased significantly[28]; Leng subjected Cabernet Sauvignon wine to ultra-high-pressure treatment at 100−500 MPa, and the results showed that compared with the untreated wine sample, the red color of the wine after ultra-high-pressure treatment increased, the pH did not change much, and there was a slight increase compared to the original wine[29]. The total acid and reduced sugar content decreased. After ultra-high-pressure treatment, the total phenolic content in wine increases, making the taste fuller and thicker. The taste and flavor of wine vary to varying degrees. The taste and flavor of the wine are optimal when subjected to a pressure of 300 MPa for 30 min. Xia et al. studied the aging effect of ultra-high-pressure treatment on jujube wine[30]. Under a pressure of 300 MPa, the pH value and sugar content of jujube wine increased, the color became more vivid, the aroma became more intense, and the antioxidant activity was significantly improved, showing a good aging effect (Fig. 2).

Ultra-high-pressure aging technology refers to treating wine by exposing it to a high-pressure environment, with a processing pressure generally above 100 MPa. Under ultra-high-pressure conditions, the activity of microorganisms and yeast in wine can be disrupted[31], effectively inhibiting the activity and reproduction of microorganisms and avoiding wine spoilage. Meanwhile, ultra-high-pressure can also alter the structure and properties of various substances in wine, improving its taste and aroma characteristics, and thereby enhancing the quality of wine[32]. Ultra-high-pressure is processed under non-thermal conditions, which can significantly preserve the nutritional components in wine. Ultra-high-pressure aging technology generally only takes a few minutes to achieve the effects that traditional aging methods take several years to achieve[33]. The ultra-high-pressure aging technology can also be completed in a smaller space, so more wine can be produced in a smaller space. A study by Sheng et al. showed that wine polyphenols treated with ultra-high-pressure at 300 Mpa have an enhancing effect[34]. However, some drawbacks to using ultra-high-pressure to induce aging exist. Firstly, ultra-high-pressure aging technology requires special equipment and materials, resulting in high costs. Secondly, excessive pressure and temperature may also hurt the aroma and flavor of wine, and even damage the structure of wine, thereby reducing the quality of fruit wine. For example, studies have shown that treating wine at 650 MPa for 2 h can significantly reduce the content of substances such as color, total phenols, anthocyanins, total acids, flavonols, tannins, etc.[19].

Magnetic aging technology

-

Magnetic aging is a technique that can improve the quality of wine by applying a magnetic field to promote chemical reactions and molecular motion in the wine, thereby shortening the aging process of the wine[35]. Magnetic aging technology has the advantages of speed, efficiency, and low cost and can preserve the original aroma and flavor of wine[36], so magnetic aging technology has attracted much attention. The research on magnetization aging technology began in the 1980s, initially mainly applied to aging red wine, and gradually expanded to other types of wine. The apparatus for magnetizing wine is typically positioned in front of the oscillator. By means of a permanent magnet or an electromagnet, a potent electromagnetic field is generated, which disrupts the molecular configurations of the chemical contaminants in the wine. This disruption effectively expedites the maturation process of the wine[37]. The theoretical basis of magnetization-induced aging is the influence of magnetization on molecules. Magnetic fields can affect the molecular structure and motion in fruit wine, thereby affecting the aging process of wine[38]. In recent years, magnetization-induced aging technology has been widely applied and has achieved certain results. The aging of wine is faster, and compared to traditional wine aging methods, it can complete the aging of wine in a shorter time, improving the quality of wine. Research has shown that magnetic fields can generate additional magnetic moments on water molecules, which are beneficial for the mutual polarization of water molecules and enhance hydrogen bonding, facilitating the binding reaction between ethanol and water[39]. After a particular magnetic field treatment, the wine can be shortened for the aging time. At the same time, it saves a lot of wine storage containers and space, reduces the factory's production cost and cycle time, reaches the best drinking period as soon as possible, and shortens the time to market[40]. No additional chemicals are required during the magnetization aging process. This not only ensures the purity of the wine-making process but also aligns seamlessly with the sustainability imperatives of modern wine production, thereby safeguarding the long-term environmental and quality-related aspects of the wine industry. Magnetic aging technology can also promote microbial metabolism and enzyme activity in wine, and improve the taste and flavor of wine while reducing the acidity and bitterness of wine[41]. However, this effect on promoting microbial and enzyme activity also has certain drawbacks. The increase in microbial and enzyme activity also has an impact on the stability of wine. Therefore, when using magnetic aging technology to process wine, more attention should be paid to the sterilization and enzyme inactivation of wine to avoid spoilage. Magnetic aging requires specialized magnetization equipment, which incurs high equipment costs. At present, magnetization-induced aging technology is still in its early stages of development, so more research and practice are needed to improve its maturity. There is relatively little research on the effect of magnetic aging on improving the quality of wine, so it may not be applicable to all types of wine. In summary, magnetic aging technology, as an emerging wine-aging technology, has some significant advantages but also some limitations and challenges.

Ultrasonic aging technology

-

Ultrasonic aging technology is a modern wine aging method that accelerates chemical reactions in wine through the action of ultrasound, thereby significantly reducing the aging time of wine[42]. Compared with traditional natural aging methods, ultrasonic aging technology has the advantages of fast aging speed, good effect, reduced production costs, space, human resources, and green environmental protection. In addition, ultrasonic aging can improve the taste and aroma of wine and reduce the content of adverse odors such as hydrogen sulfide and carbon disulfide in wine[43]. The application prospects of ultrasonic aging technology are broad, and it has been widely used in industrial production. Ultrasonic aging technology can transfer the energy of ultrasound into wine, resulting in mechanical vibration and cavitation phenomena[44]. This can instantly expose wine to high temperature and pressure, increase the activation energy of some components in wine, and promote a series of positive changes, thereby improving its quality. Ultrasonic aging causes changes in the content of ingredients and physical and chemical indexes in wine (Table 1). Research has shown that when ultrasound time is 20 min, ultrasound power is 180 W, and ultrasound is used four times; it can effectively accelerate the degradation and transformation of free anthocyanins in wine and promote the generation of anthocyanin derivatives in the wine body, and increase the chromaticity value of wine, promoting the transformation of wine from a purple red color to a brick red color[45]. Ultrasonic waves can increase the dissolved oxygen and solubility in wine, promote oxidation reactions and microbial metabolism in wine, thereby accelerating the aging process of wine. The study by Leng et al. showed that after ultrasonic treatment, the pH and chromaticity of wine slightly increased. At the same time, the total acid, volatile acid, and reducing sugar all decreased[46]. In addition, ultrasound can destroy large molecular compounds in wine, making them more easily degraded and metabolized by microorganisms[47]. Shen et al. found that the antioxidant activity of red wine decreased due to the decrease of total phenolic content and total flavonoid content after ultrasonic treatment[48]. Sun detected that the contents of volatile acids and total acids decreased significantly, and the volatile esters and total esters increased after ultrasonic treatment of prickly pear dry red wine for 25 min and 50 kHz[49]. The changes in these color parameters in wine aged by ultrasound at different storage times are similar to those in non-ultrasound aged wine, indicating that ultrasound-aged wine does not undergo the 'regeneration' phenomenon[50]. Ultrasonic aging technology can also help wine reach its optimal state faster, and the wine treated with ultrasonic aging technology maintains its optimal state for a more extended period of time than naturally aged wine, which is of great significance for extending the shelf life of wine[44]. The application of ultrasonic aging technology in wine is still in continuous development, and the influence of ultrasonic process parameters on the aging effect of wine still needs further research. According to research by Shi [51], the total ester content of blackened jujube wine treated with ultrasound and ultra-high pressure has increased, while the total acid content has shown a decreasing trend. Compared to other methods, ultrasound has the highest effect on increasing the total ester content of blackened jujube wine. In contrast, ultra-high pressure has a better effect on reducing acidity in blackened jujube wine. Shu et al. conducted a detailed review of the ultrasonic aging technology of wine products. They concluded that in terms of the frequency of ultrasonic aging of wine, the effect of selecting low frequency is better than high frequency, and the frequency selected in most studies is between 20−60 kHz[52]; In terms of ultrasound treatment, the effect of multiple interval ultrasound is better than that of one ultrasound; In terms of ultrasonic treatment time, it can be roughly selected within 1 h, and too long a time will cause the flavor of the wine to decline. In summary, ultrasonic aging technology has a certain aging effect on alcoholic beverages. Moreover, under appropriate ultrasonic treatment, the quality of fruit wine will undergo certain changes or even improve to some extent. There are few grape varieties used for ultrasonic aging technology, and the impact and mechanism of ultrasonic aging technology applied to other dry red wines have not yet been explored.

Table 1. Effects of different treatment conditions on ultrasonic treatment of different types of fruit wine.

Fruit wine varieties Treatments Effects Ref. Wine Ultrasound time: 20 min Anthocyanins↓ [40] Ultrasonic power: 180 W Anthocyanin derivatives↑ Number of ultrasounds: 4 Chromaticity value↑ Cabernet Sauvignon Ultrasound time: 5−35 min pH, Chromaticity value↑ [41] Ultrasonic power: 250 W Total acid↓ Ultrasound frequency: 40 kHz Volatile acids↓ Reducing sugars↓ Red wine Ultrasonic power: 180 W Total phenols↓ [43] Ultrasound frequency: 100 kHz Total flavonoids↓ Ultrasound time: 20 min Antioxidant activity↓ Ultrasonic temperature: 20 °C Rosa Roxburghii Tratt dry red wine Ultrasound frequency: 50 kHz Volatile acids↓ [44] Ultrasound time: 25 min Total acids↓ Volatile esters↑ Total esters↑ Blackened jujube wine Ultrasonic power: 360 W Total acids↓ [46] Ultrasound time: 19 min Total esters↑ Ultrasonic temperature: 52 °C Microwave aging technology

-

Microwave-assisted aging refers to the process of using the impact force of microwaves to recombine molecules in fruit wine, achieving the desired aging effect. Qiu[53] found that after microwave treatment at 200 W for 4 min, the total phenolic content of kiwi brandy increased the most, reaching 329.2 mg/L, while methanol decreased by 101 mg/L. This condition had the highest sensory evaluation. Ultrasonic aging can increase the anthocyanin content and decrease the tannin content in wine. The sensory quality of the wine after ultrasonic treatment can be improved in a short time[54]. Yu et al. treated mangosteen fruit wine under microwave medium power for 6 min, which improved the volatile aroma and increased the total ester content to 2.79 g/L[55].

Electron beam irradiation stimulation technology

-

The mechanism of radiation aging also lies in the fact that radiation can efficiently and quickly provide energy to the irradiated materials, so some researchers have tried to apply radiation technology to wine aging. At present, the most studied is gamma irradiation technology[2]. Chang used gamma irradiation technology to treat wine and found that the correct dose of gamma irradiation could improve certain indicators of the wine[56]. For example, the content of polyols derived from the greasy sensation in wine decreases, and the content of ethyl acetate, an aromatic substance that provides fruity aromas, increases[57]. Electron beam irradiation is to pass the energy of ionizing radiation through the fruit wine to promote the redox reaction of the fruit wine and increase the ester aroma. Zeng irradiated citrus wine with different degrees of irradiation, and when irradiated at 1,000 Gy, the citrus wine had a rich aroma and smooth taste[58]. Ma treated the pear brandy base wine with an irradiation dose of 6 kGy, and the aroma results of the fruit wine were better, with a sensory score of 87.53 points[59].

-

The chemical aging method mainly accelerates the chemical change rate in liquor by adding chemical substances, which is mainly divided into the oxidation and the catalytic methods. The oxidation method is to add potent oxidizing substances to the wine, such as high-purity oxygen, ozone, or strong oxidants, such as hydrogen peroxide and potassium permanganate, to accelerate the oxidation rate of alcohol compounds and achieve the effect of accelerating aging[24]. In addition to micro-oxygen aging, there are also potassium permanganate oxidation, acid catalysis, metal ion catalysis, and other chemical aging methods, the basic principle of which is to increase the oxidation reaction and esterification reaction rate in the wine body through oxidation or adding catalysts[60].

Micro-oxygen aging technology

-

Micro-oxygen treatment is a technology that improves the color, aroma, and structure of wine by introducing a small amount of controlled oxygen into the wine and requires specific equipment to achieve the supply of trace oxygen[61]. This technology was proposed by Patrick in 1990[62]. Micro-oxygen aging is a technique that utilizes trace amounts of oxygen to promote the aging of wine. Its principle is to add an appropriate amount of oxygen during aging. This method can simulate the aging state of wine in oak barrels, thereby shortening the aging time of wine and improving its quality and taste. Micro-oxygen aging technology is widely used in wine aging due to its simplicity, ease of operation, and low cost. At present, there is a wide variety of micro-oxygen control devices both at home and abroad. Among them, the ceramic aeration device injects oxygen into the wine regularly in a semi-continuous manner in the form of bubble plumes. The semi-permeable membrane tube device enables oxygen to continuously penetrate the membrane and enter the wine by means of pressurization. There is also a micro-oxygen addition device designed with simple and practical basic components, including oxygen cylinders, oxygen pressure reducing valves, gas flow control valves, gas flow meters, diffusers, solenoid valves, transformers, microcomputer time-controlled switches, and connecting hoses, etc. This device can supply trace amounts of oxygen regularly and quantitatively, thus achieving the purpose of micro-oxygen aging[2]. The key in the micro-oxygen aging technology is to control the amount of oxygen added. Excessive oxygen can cause excessive oxidation of wine, leading to a decrease in quality. The principle of micro-oxygen treatment is to select wines that are rich in tannins and can bind anthocyanins. The ratio of tannins to anthocyanins (optimal ratio of 4:1) is most suitable for micro-oxygen treatment, as lower anthocyanins may lead to the risk of tannic drying[63]. Research has shown that controlling the amount of oxygen added between 2−5 mL/(L·month) can promote the aging process of wine without affecting its quality. In addition, after two months of micro-aerobic aging treatment at a rate of 2 mL/(L·month), the total phenolic and total anthocyanin content in the wine significantly increased[64]. After 12 months of using 5 mL/(L·month), micro-oxygen accelerated aging treatment on wine, the harmful odors such as methyl mercaptan and hydrogen sulfide in the wine were significantly reduced[65]. Under appropriate micro-oxygenation treatment, the content of free anthocyanins in wine will significantly decrease, and the color of the wine will become increasingly similar to aged wine[66]. Zhang proved that after introducing of pure oxygen, the total acid content and total ester content in the wine were significantly higher than those in the control group[67]. Micro-oxygen treatment is an aging technique that combines trace oxygen and oak chips in stainless steel storage tanks, which may reduce the total acid during the aging process[68]. This may be due to the precipitation of tartaric acid[69]. In addition, the aging time and temperature are also important factors affecting the effect of micro-oxygen aging, which should be adjusted according to different grape varieties and production conditions. Applying micro-oxygen aging technology can improve the quality and taste of fruit wine and save production costs. However, the micro-oxygen aging technology requires strict control over the amount of oxygen added. If there is an excess of oxygen, it can lead to a considerable accumulation of dissolved oxygen in the wine, which can reduce the fruit flavor of the wine, increase the volatile acid content, and cause a deterioration in the color of the wine, as well as other harmful effects[70]. Although micro-oxygen aging technology can significantly improve the quality of wine, it still does not shorten the aging time of wine.

-

Bio-aging is characterized by using bio-ripening agents such as yeast or yeast extract to catalyze the oxidation and esterification reactions in liquor, and the catalytic reaction has significant specificity[71]. Since the main functional substances in the bio-aging method are enzymes, its extremely high catalytic efficiency and substrate specificity determine the characteristics of high-aging efficiency and low impurity content of the bio-aging method. However, the biological aging method can more accurately evaluate liquor's quality and define liquor's characteristics[72].

Microbial aging technology

-

Microbial aging is a traditional wine aging technique that involves adding specific microorganisms to wine to induce microbial metabolism over a certain time, thereby achieving the desired aging effect. The commonly used microorganisms are different types of wine yeast and lactic acid bacteria, which can metabolize sugars, acids, and other components in wine, producing substances such as carbon dioxide and ethanol, thereby changing the taste, aroma, and color of wine[73]. The process of microbial aging technology appears to be longer than other manual aging techniques; for example, the average aging time for Sherry wine aged by microorganisms is 4 years[74]. Microbial aging technology has many advantages, including good aging effect, low cost, and easy operation. Compared with traditional aging methods, microbial aging technology can increase the nutritional content of wine and improve its quality and taste. However, microbial aging technology also has some drawbacks, such as the aging effect being affected by the type, quantity, and activity of microorganisms, being easily disturbed by external environments, and being more demanding in fermentation environments. During the aging process, microorganisms can also produce some harmful substances[75], which may affect the quality and safety of wine. At present, there is still a lack of effective methods to shorten the microbial aging time and control microbial stability. We need to focus our future research on shortening the microbial aging time and controlling the stability of microbial aging technology. Overall, microbial aging technology is a traditional wine aging technique with both advantages and disadvantages in terms of aging effect and broad application prospects.

Conclusions and prospects

-

In short, artificial accelerated aging is a method that can help fruit wine reach its ideal state more quickly and effectively. However, each method has its specific usage conditions and risks, which need to be selected and controlled according to the type and quality of fruit wine. For industrial-scale production, in terms of space cost, time cost, and equipment cost, each aging technology has its own advantages and disadvantages. For example, although oak aging has a relatively low cost in some aspects, its time cost and space cost are quite high; physical aging, on the other hand, requires a relatively high investment in equipment cost, and so on. Therefore, it is essential for us to conduct research on the adoption of combined aging methods, aiming to minimize the costs of equipment, time, and space to achieve the best aging effect. Therefore, fruit wine producers and consumers need to fully understand the methods of artificial accelerated aging and its impact on the quality and safety of fruit wine in order to produce better and consume fruit wine. At the same time, scientists and researchers need to continue conducting in-depth research and exploring new artificial accelerated aging methods to continuously improve fruit wine's quality and production efficiency.

Finally, it should be emphasized that although artificial accelerated aging can improve the quality and production efficiency of fruit wine, not all fruit wines are suitable for this method. Some high-quality, high-end fruit wines require a natural aging process to achieve optimal quality and flavor. Therefore, when using artificial accelerated aging methods, it is necessary to comprehensively consider factors such as the type, quality, and target market of fruit wine.

This work was financially supported by the Basic Research Project of Liaoning Provincial Department of Education (JYTQN2023316), and supported by the earmarked fund for CARS (CARS-29-7)

-

Not applicable.

-

The authors confirm their contributions to the paper as follows: study conception and design: Liu S; data collection: Liu S; analysis and interpretation of results: Yu Z, Qin J, Gao H, Yan W, Xu L; draft manuscript preparation: Liu S. All authors reviewed the results and approved the final version of the manuscript.

-

The datasets generated during and/or analyzed during the current study are available from the corresponding author upon reasonable request.

-

The authors declare that they have no conflict of interest.

- Copyright: © 2025 by the author(s). Published by Maximum Academic Press on behalf of China Agricultural University, Zhejiang University and Shenyang Agricultural University. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Liu S, Liu S, Qin J, Yu Z, Xu L, et al. 2025. Research progress on artificial aging techniques for fruit wine. Food Innovation and Advances 4(3): 334−341 doi: 10.48130/fia-0025-0031

Research progress on artificial aging techniques for fruit wine

- Received: 23 December 2024

- Revised: 23 April 2025

- Accepted: 23 April 2025

- Published online: 24 July 2025

Abstract: Aging is a crucial process in fruit wine production, which refers to the storage and fermentation of fruit wine in a bottle or wooden barrel for a period of time to make its taste and flavor more mellow and complex. In traditional fruit wine production, aging usually takes several years. However, with the continuous development of technology, more and more artificial methods for accelerating aging have been developed, allowing fruit wine to achieve the desired aging effect faster. This article introduces some of the main artificial methods for accelerating aging, including traditional oak aging, ultra high-pressure aging, magnetic aging, ultrasonic aging, microwave aging, electron beam irradiation stimulation, micro-oxygen aging, and microbial aging. The advantages and disadvantages of these methods will be discussed, to promote the development of the fruit wine industry.

-

Key words:

- Fruit wine /

- Artificial aging /

- Ultra-high pressure aging /

- Ultrasonic aging technology