-

In recent years, with the diversity of architectural styles and the pursuit of beautiful architectural appearance, the design of vertical fire separation components of building windows does not meet standards, which makes the fire protection requirements more stringent[1, 2]. In previous research, the window size, windowsill wall height and cornice width are often taken as variables[3−5]. There are few studies on fire disasters of buildings without cornices and new laboratory buildings at colleges and universities often have small windows and no cornice structure. Also, in the event of a fire, flames will spread upward to the upper floor along the periphery of the building, resulting in the phenomenon of 'leap-frog behavior', which makes the vertical fire separation components in many buildings invalid, and often the fire spreads to adjacent buildings. Therefore, the study of the fire vertical spread mechanism play a key role in controlling the occurrence and development of fire. This article takes a five-storey building as the numerical simulation object, the influence of the opening and closing conditions of building windows on the flame characteristics, the temperature, pressure and flow rate of fire in the vertical spread of the fire was studied using three different opening sequences of glass windows. The research on the movement law of high-temperature smoke in the high-rise area is of great significance to the design and evaluation of building fire safety.

-

Pyrosim, which is a Graphical User Interface software based on the FDS principle, was used to numerically simulate the fire spreading mechanism in a high-rise building. The basic governing equations of dynamics used in the FDS calculation are as follows[6−9]:

$ \frac{{\partial \rho }}{{\partial t}} + \nabla \cdot \rho \vec u = 0 $ (1) $ \rho \left( {\frac{{\partial \vec u}}{{\partial t}} + \left( {\vec u \cdot \nabla } \right)\vec u} \right) = \rho g + f + \nabla \cdot \tau + \nabla p $ (2) $ \frac{{\partial \left( {\rho h} \right)}}{{\partial t}} + \nabla \cdot \rho h\vec u = \frac{{Dp}}{{Dt}} - \nabla \cdot {q_r} + \nabla \cdot k\nabla T + \sum\limits_l {\nabla \cdot {h_l}\rho } {K_l}\nabla {Y_l} $ (3) $ \frac{\partial }{{\partial t}}\left( {\rho {Y_l}} \right) + \nabla \cdot \rho {Y_l}\vec u = \nabla \cdot P{K_l}\nabla {Y_l} + \dot m'''_l$ (4) Where ρ is density; t is time;

$ \vec u $ $\dot m'''_l$ $\tau $ The movement of fire smoke is usually a low Mach number flow. In order to simplify the calculation and improve the calculation efficiency of numerical simulation, the pressure is divided into three parts: reference pressure; static pressure term; pressure disturbance term caused by flow, and the reference pressure is used to replace the pressure term in the equation of state[10, 11]. Pyrosim's turbulent flow model is a sub grid scale large eddy model Les in the Smagorinsky form. The spatial discretization method adopts the second-order central difference scheme, and the time discretization method adopts the second-order Runge Kutta Scheme[12−14].

-

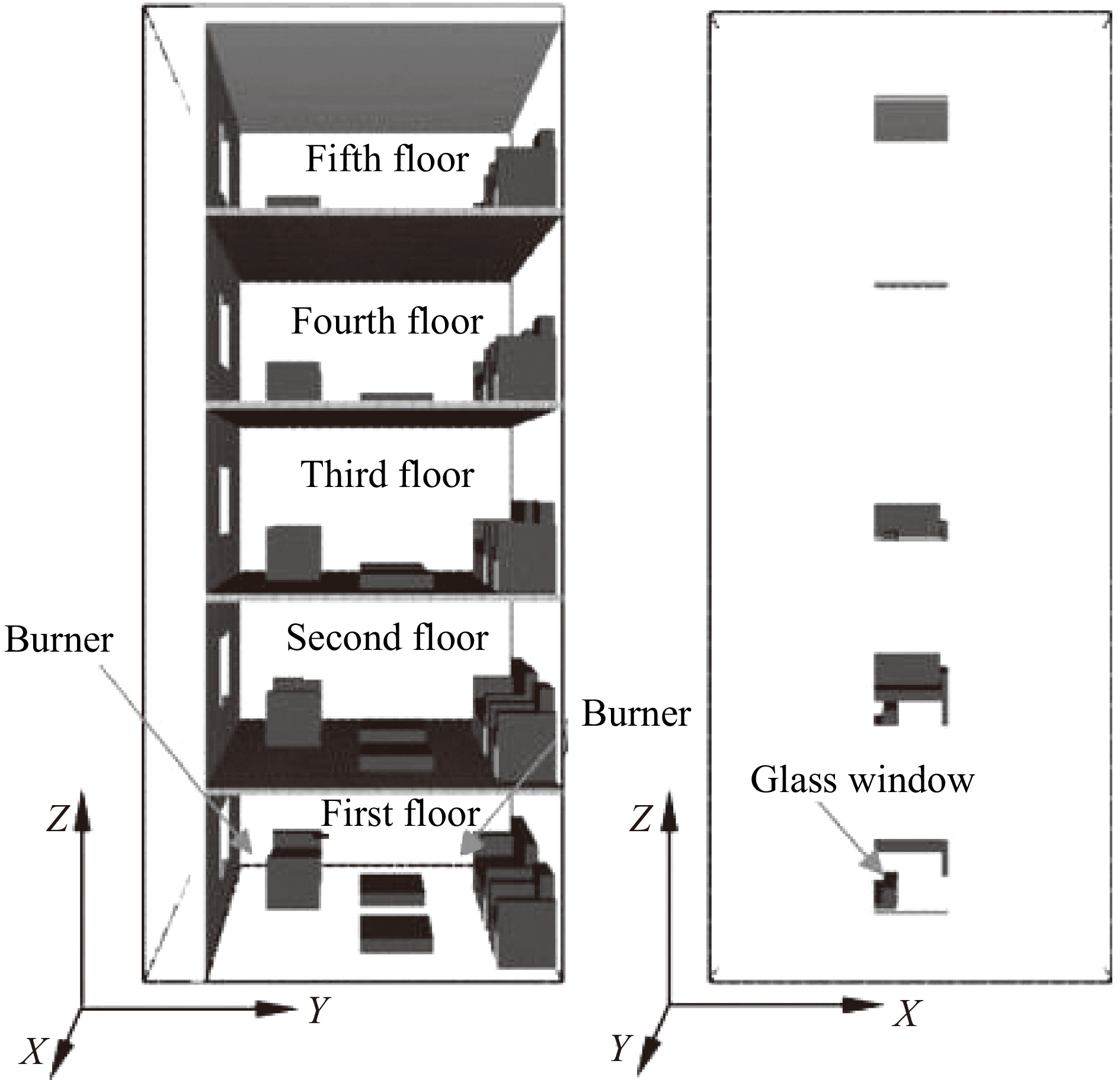

The numerical simulation object is a five-storey building[15], with a specific size of 5.2 m × 4.6 m × 12.6 m. The rooms on each floor have a 1 m × 1 m glass window in the center of the outer wall. The location of the fire is on the sofa on the first floor (the ignition point can be replaced by a wood material other than a sofa). The main combustible materials are foam and wood. The geometric model of the five-storey building is shown in Fig. 1. Based on the study conducted by Deng[16], the grid size can be set as 0.2 m × 0.2 m × 0.2 m considering the characteristic diameter of the fire source, the accuracy and calculation time of the computer results. In order to simulate the diffusion of flame combustion to the window, two burners are set: one is located at the sofa in the corner of the room with a size of 1 m × 1 m; the other is located under the window with a size of 1 m × 1 m. The burner under the window is turned on 30 s after the burner at the sofa has been turned on. The simulation mainly considers the flame spread in the vertical space after the burner under the windowsill burns, so the position of the ignition point can be ignored in the simulation. The whole simulation time is 300 s.

Figure 1.

Elevation view and side view of the five-storey building model. (a) Front view of five-storey building model, (b) side view of the five-storey building model.

The power of the fire source is set according to Heskestad et al. 's classification of the growth type of fire, which obeys the following equation[3]:

$ Q = \alpha {t^2} $ (5) Where Q is the fire source power; α is the growth rate of wood fire. Because wood fire burns in a stable fashion, the fire growth rate used the ultra fast growth rate of wood fire (α = 0.187800 kw/s2)[4], and the fire source power is set to be 5.0 × 104 kW.

The five windows have many combinations of opening and closing conditions, it is difficult to study all possible combinations. Therefore, this paper sets up three different opening sequences of the glass windows:

Sequence 1: Only the windows on the first floor are open (combustion chamber), and the windows on other floors are always closed no matter how high the temperature reaches.

Sequence 2: The glass window is burned out according to the temperature. It is generally recognized that when the thermal stress on the glass is higher than a certain value, the glass is broken[17]. In the simulation, the thermal stress that the glass can hold was converted into the maximum temperature. According to actual experiments in literature, the glass window was set from a closed state to an open state when the glass center temperature is higher than 500 °C[18−20].

Sequence 3: All the glass windows in the building are kept open during the whole simulation process. We believe the above three sequences can produce typical gas flues, and it is helpful for studying the flow of smoke, and finding ways to reduce the temperature and delay the spread of flames.

-

To explain the upward spread mechanism of fire and smoke in a high-rise building, the distribution characteristics of pressure, temperature and gas velocity in the fire field are simulated. To avoid the influence of window status of the second floor (or the floor above) on the fire spread characteristics, the first window opening sequence (only the window on the first floor is open) was taken as an example.

Vertical fire spreading characteristics along walls

Upward spread of flame and high-temperature flue gas perpendicular to the wall

-

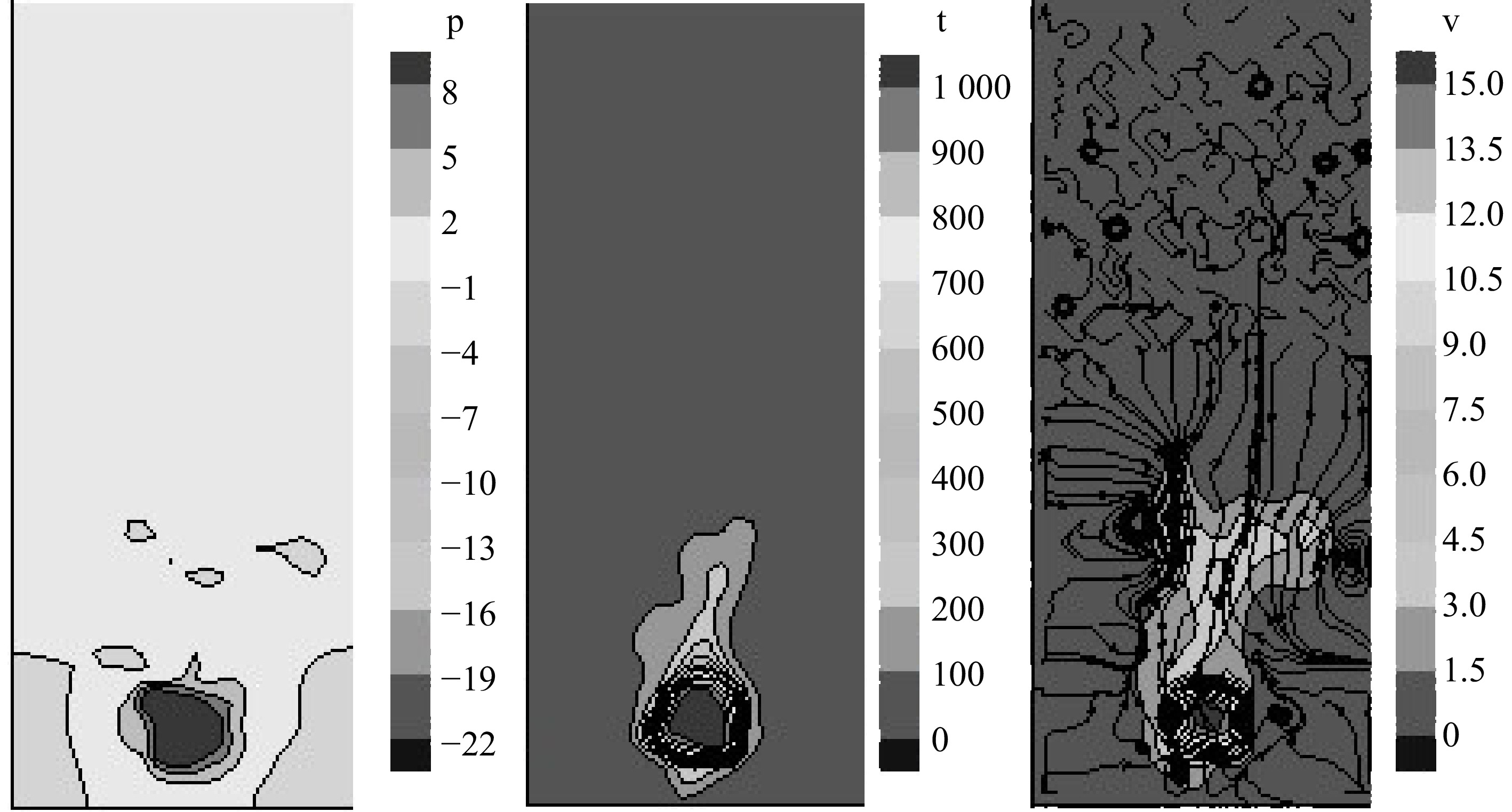

At this time, only the window on the first floor is opened, and the windows on other floors cannot be burned out no matter how high the temperature is (Sequence 1). The cloud images of fire site pressure (Pa), temperature (°C) and flow velocity (m/s) are intercepted at the outer wall (y = −0.2 m) perpendicular to the wall direction. At 5.6 s after the fire, the ground floor partially gets burned, and the gas temperature in the house becomes higher. The pressure begins to increase and the air flow rate increases,as shown in Fig. 2. Meanwhile, the fire pressure is greater than the pressure of the air inlet. The high-temperature flue gas passes through the window in the center of the wall, and naturally diffuses upward from the outside, it then diffuses after leaving the window. Thermal convection occurs due to the temperature difference between the high-temperature flue gas/flame coming out of the window and the cold air in the external environment. On the one hand, the flame propagates upward; on the other hand, a vortex is generated due to the viscous effect and diffuses to both sides of the window. At this time, there is a strong pulsation in the flow outside the wall, which is caused by the strong diffusion and transportation of turbulence.

Figure 2.

Cloud map of the outer wall at y = −0.2 m perpendicular to the direction of the wall at t = 5.6 s. (a) Pressure cloud map, (b) temperature cloud map, (c) velocity cloud map.

About 40 s after the beginning of the fire, the flame in the house spreads to the window. After the flame comes out of the window, it diffuses to the left and right due to the action of turbulence, and the flow outside the wall changes from strong short-term pulsation to stable upward flow, as shown in Fig. 3. The distribution of temperature and velocity is basically symmetrical to the central axis. At this time, a dead water zone appears at the window on the first floor, which does not convect heat transfer with the outside, only molecular diffusion exists. This area has a low temperature, a low flow rate. It is a stable safety zone. It can be seen that the flame temperature and combustion component transport (CO2 transport) are mainly caused by turbulent diffusion. When the flame spreads to a certain height above, it will not continue to develop upward. This is because the temperature difference in the upper space is small and the thermal convection is weak. Flame and high-temperature flue gas will no longer diffuse upward continuously if they do not encounter combustibles.

Figure 3.

y = −0.2 m of the outer wall perpendicular to the direction of the wall at t = 45.2 s. (a) Temperature cloud map, (b) velocity cloud map, (c) one-dimensional temperature cloud image at Z = 1.15 m.

The spread of flame and high-temperature flue gas parallel to the wall

-

As can be seen in Fig. 4a, at y = −0.2 m, most of the pressure area outside the wall is negative (lower than the atmospheric reference pressure), which is the area formed by the thermal escape of flame and high-temperature flue gas from the outer wall. At the same time, the flame and high-temperature flue gas are subject to the atmospheric pressure of the surrounding cold air, so the flame and high-temperature flue gas burn close to the wall.

Figure 4.

The pressure at y = −0.2 m on the outside wall and the temperature at x = 2.6 m on the parallel wall when t = 58.5 s. (a) Pressure cloud map, (b) parallel to the wall temperature cloud map.

From the direction parallel to the wall, 'leap-frog behavior' often occurs in the high-rise area where the flame and high-temperature flue gas spread along the wall, that is, a new fire source will appear at a certain distance from the original fire source on the first floor at the bottom. This is because when the fire is large, the temperature is high and the oxygen concentration is less than 2%, the fire source produces a large amount of volatile gas for fuel-rich combustion. The high-rise smoke flow of fuel-rich combustion is often high-temperature premixed combustible gas, which can easily become a new fire source after intersecting with the side fresh airflow. Therefore, the main reason for the upward development of flame and high-temperature flue gas is the thermal convection caused by temperature differences. At the same time, because the density of flame and high-temperature flue gas is lower than that of cold air, the flame and high-temperature flue gas also spread upward under the influence of buoyancy. The turbulence outside the wall causes the flame and high-temperature flue gas to develop to the left and right parallel to the wall. The pressure difference has little effect on the upward development of flame and high-temperature flue gas. The main reason for the phenomenon of flame and high-temperature flue gas sticking to the outer wall is the pressure difference between the surrounding cold air and the heated air.

Influence of window state on flame and high temperature smoke spread

-

When other parameters are the same, the opening sequences of the glass window is changed as listed in Table 1. By analyzing the distribution changes of pressure, temperature, and gas velocity in the fire scene with three different glass window opening sequences, the similarities and differences of the vertical spread of building fire and high-temperature smoke in different glass window opening sequences were explored.

Table 1. Flame characteristics of the three window opening sequences.

Rupture mode Average area

(m2)Average width

(m)Average length

(m)Case 1 10.430 2.563 5.403 Case 2 10.970 3.688 5.062 Case 3 10.350 2.719 5.091 Due to the same fire source power, the average area in the first and third cases is roughly the same, and the average area in the second case is slightly larger. Just over 5 s after the fire occurrence (5.6 s), the temperature, pressure, and velocity distributions of the first and second opening sequence are the same. This is because the temperature in Case 2 is not enough to break the glass of other floors. Compared to the changes of temperature, pressure, and flow velocity in Case 1, the parameters in Case 2 will soon be transmitted to the upper layer, and vortices will appear on both sides of the second-floor window since all windows in the third opening sequence are open.

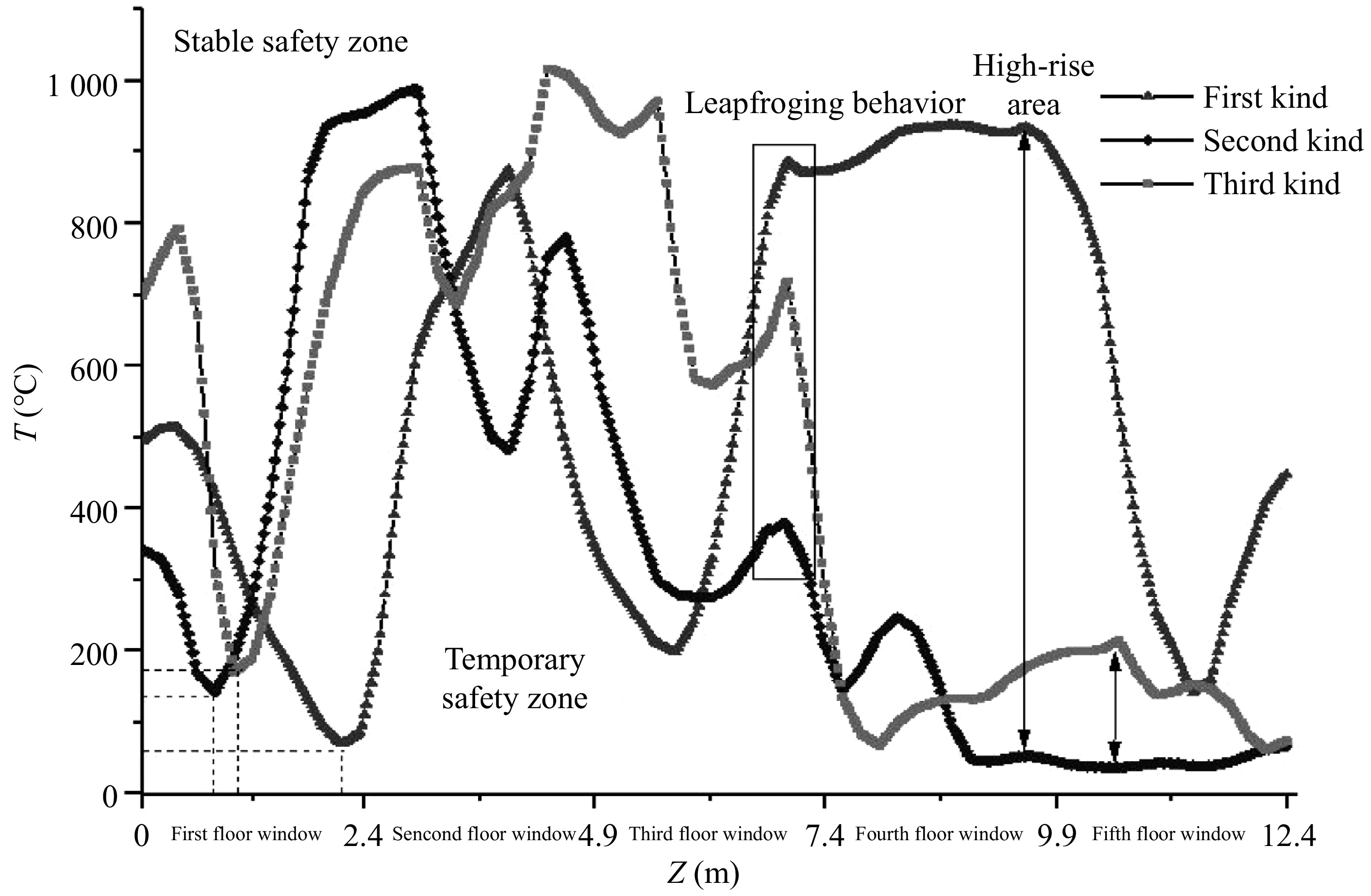

Fig. 5 shows the temperature change curves of three glass window opening sequences at y = −0.2 m and x = 2.6 m on the outside wall, 40 s after the beginning of the fire. It can be seen that the opening sequence of the three glass windows forms a stable low-temperature and low-speed safety zone on the first floor because of the turbulence outside the wall. The temperature in this zone is less than 200 °C and the speed is less than 3 m/s. The second and third glass window opening sequences form unstable temporary safety zones on other floors. The low temperature of the first glass window opening sequence on the third floor is caused by 'leap-frog behavior'. In the high-rise area, the temperature of the third glass window opening sequence is about 722 °C lower than that of the first sequence, while the second sequence is about 160 °C lower than that of the first sequence on the higher floor, as the windows on the first and second floors of the building were open 46.4 s after the fire occurred. The pressure distribution of the second glass window opening sequence is roughly the same as that of the first. In Case 2, there is a low-temperature and low-speed area at the window on the second floor, but this is a temporary safe area, and its appearance is unstable (the stable safety zone caused by the turbulence outside the wall is called the stable safety zone. A safe zone that is not stable due to high temperature smoke entering the room becomes a temporary safety zone).

Figure 5.

Temperature change curves of three glass window opening sequences at y = −0.2 m and x = 2.6 m on the outside wall.

By observing the flow velocity pattern outside the wall, it is known that the temporary safety zone in Case 2 on the second floor is different from the stable safety zone on the first floor, which is not caused by turbulence outside the wall. As can be seen from Fig. 6, the indoor velocity diagram at y = −0.2 m shows that the temporary safety zone is caused by the turbulence generated by the ceiling jet and anti-buoyancy jet when high-temperature flue gas enters the room. The reasons for the temporary safety zone occurring in Case 3 are the same as those occurring in Case 2. On each floor, there is always turbulence generated by the ceiling jet and anti-buoyancy jet of high-temperature flue gas inside the door.

Figure 6.

Flow velocity maps at y = 0.2 m and y = −0.2 m of the inner and outer walls in the opening sequence of the second and third case at t = 47.4 m. (a) Velocity cloud map at y = 0.2 m for Case 2, (b) velocity cloud map at y = −0.2 m for Case 2, (c) velocity cloud map at y = 0.2 m for Case 3, (d) velocity cloud map at y = −0.2 m for Case 3.

The second and third glass window opening sequences also have 'leap-frog behavior' in the high-rise area. Because of the occurrence of broken windows, the maximum temperature and velocity outside the wall are not in the center of the wall, but besides the wall, different from those in Case 1. Besides, separated vortices appear in the high-rise area (Fig. 6b). Turbulence accelerates heat exchange, reduces temperature, and slows down velocity. The height of the third floor of the building is between 5.1 meters and 7.6 meters, and the maximum flame length is about 5.4 meters, therefore, the opening and closing state of the fourth and fifth layers of glass is not expected to affect the distribution of pressure, temperature and flow velocity. The high-temperature flue gas will enter the upper room. After 40 s, the distribution of temperature, pressure, and velocity at the outer wall in Case 3 is roughly the same as that in Case 2. At this time, the left-right diffusion of flame and high-temperature flue gas caused by turbulence is weakened.

-

With the simulation software of Pyrosim based on the principles of fire dynamics, the vertical spread mechanism of flame and high-temperature flue gas is studied in three different glass window opening sequences: 1. Only the windows on the first floor are open; 2. The windows are randomly open by the high temperature of the glass; 3. All glass windows from the first to the fifth floors are open. The main conclusions are as follows:

1) Three different opening sequences of glass windows form a stable safety zone characterized by a low temperature, low speed, and low pressure at the window on the first floor 40 s after the fire. The temperature in this zone is about 150 °C and the speed is less than 3 m/s. Case 2 and Case 3 will form an unstable low-temperature and low-speed safety zone on the second and third floors.

2) The opening and closing state of the window will enhance the left and right spread of fire. The second glass window opening sequence has the maximum average flame area of 10.970 m2 and the maximum average flame width of 3.688 m.

3) Different glass window opening sequences has a great influence on the temperature and velocity in the high-rise area. In the high-rise area, the temperature in Case 3 is about 722 °C lower than that in Case 1, while the temperature in Case 2 is about 160 °C lower than that in Case 1 on the higher floor. If the turbulent flow near the fire area can be enhanced, the temperature in the high-rise area can be greatly reduced, which is of great significance to the motion law of high-temperature flue gas in the high-rise area and the design of fire safety performance.

The authors are grateful to the financial support from the National Science Foundation of China (Nos. 51904311, 52130409, 52121003), China University of Mining and Technology (Beijing) Undergraduate Innovation training program (202112011), and Beijing university students' innovative entrepreneurial training inter-school cooperation program (202198027).

-

The authors declare that they have no conflict of interest.

- Copyright: © 2022 by the author(s). Published by Maximum Academic Press on behalf of Nanjing Tech University. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Wang K, Zhao W, Yuan Y, Jianyao Y, Song Y, et al. 2022. Influence of open and closed windows on the vertical spread characteristics of fire. Emergency Management Science and Technology 2:1 doi: 10.48130/EMST-2022-0001

Influence of open and closed windows on the vertical spread characteristics of fire

- Received: 20 October 2021

- Accepted: 07 March 2022

- Published online: 24 March 2022

Abstract: In order to systematically explain the spreading mechanism of vertical fire, Pyrosim software with fire dynamic modules is used to simulate the fire spreading characteristics in a five-storey residential apartment building. The vertical spread characteristics of fire, high-temperature smoke, and leap-frog behavior are analyzed by evaluating the distribution of pressure, temperature, and gas flow velocity in the studied numerical fire field. In addition, considering the possible cases of high-rise building fire in reality, the fire spreading characteristics of three different opening sequences of glass windows are given: (i) only the windows on the first floor are open; (ii) the windows are randomly opened by the high temperature of the glass; (iii) all glass windows from the first to the fifth floors are open. The simulation results show that an appropriate increase of turbulent flow in the low-level area can greatly reduce the fire temperature in the high-level area, which can provide a certain reference for the safety and design of building fire protection in the future.

-

Key words:

- Numerical simulation /

- Vertical fire spread /

- Window state /

- High-rise building