-

At present, the size of China's hazardous chemicals logistics market exceeds 2.45 trillion yuan, with road transport accounting for about 70% of the overall hazardous chemicals logistics market[1]. The main modes of hazardous chemical transportation include road transportation[2], waterway transportation, and railway transportation[3]. Among them, road transportation has the advantage of flexibility and occupies the main position in hazardous chemical transportation. Once a hazardous chemical road transportation accident occurs, it often causes serious casualties and property damage, such as a rear-end collision on Hukun Expressway in Shaoyang, Hunan Province (China) in 2014 and a rollover explosion in Wenling, China in 2020. In the process of road transport of hazardous chemicals, the status of the driver, the status of the vehicle, and the surrounding environment change dynamically in real-time, and the possibility of leakage, fire, and explosion also change in real-time, a real-time assessment of the likelihood of various accident patterns occurring during the road transport of hazardous chemicals is therefore essential.

The process of hazardous chemical road transport accidents is a joint coupling of traffic accidents and hazardous chemical accidents. Chen et al. analyzed 562 hazardous chemical road transportation accidents and found that the causes of hazardous chemical transportation accidents accounted for the largest proportion of traffic accidents such as collision and rear-end[4]; Wei & Shao found that the sum of leakage, fire, and explosion in the initial accident pattern was only 21.8% from 2016 to 2020, but in the final accident pattern, leakage, fire, and explosion accounted for 86%, 10.3%, and 3% respectively[5]. Acker & Yuan studied 12 variables representing time, location, and situational conditions based on space and time, and the accident chain was shown as accidental impact → hazardous chemical carrier breakage → hazardous chemical leakage → fire, multi-hazards transmission and spread in time and space, such as explosion[6]. The phenomenon of multi-hazard chaining is prevalent in major accidents involving the road transport of hazardous chemicals, and there is a relative lack of research on the possibility of chaining patterns of accidents.

The hazardous chemical tanker can be regarded as a mobile chemical device, so the study of multi-hazard chain accidents in fixed chemical devices is of significance. Hemmatian et al. conducted a statistical analysis of the characteristics of chain effects in 330 foreign chemical accidents, the order of accident form transformation, and found that secondary and tertiary domino accidents accounted for 84%[7]; Sarvestani et al. used fault tree to analyze the consequences, domino effect, and causes of 23 liquefied gas storage tank accidents, and found that the domino effect occurred in 70% of accidents and 43% of accidents led to the BLEVE phenomenon[8]; Cui et al. collected statistics of atmospheric storage tank domino accidents from 1970 to 2020, and constructed accident chains for each accident to explore the accident evolution expansion law[9].

In the occurrence and development of road transport accidents of hazardous chemicals, there is a coupling between traffic accidents and hazardous chemicals accidents, as well as a coupling between hazardous chemical accidents such as leakage, fire, and explosion, and a coupling between the damage effect of accidents and the surrounding personnel, environment, and property. At present, there is a certain research basis for traffic accident mechanisms and accident mechanisms of fixed chemical equipment similar to road transport tank cars. However, there are few studies on accident mechanisms and coupling between disaster species in the whole process of occurrence and development of road transport accidents of hazardous chemicals, which makes it difficult to support the research on multi-disaster coupling accident risk of road transport of hazardous chemicals.

In the process of real-time likelihood assessment of hazardous chemical road transport accidents, scholars have chosen influencing factors differently. Noguchi et al. introduced spatial characteristic factors for risk assessment, which were characterized by road structure, traffic volume, and population information[10]; Godoy et al. assessed considering stochastic uncertainty of atmospheric parameters[11]; Qiao et al. considered the effects of path-dependent and path-independent variables[12]; Ebrahimi et al. considered the most likely and most dangerous meteorological variables, as well as the socio-demographic characteristics of the affected population[13].

With the development of in-vehicle IoT and intelligent data management for urban public safety, various data collection and analysis capabilities are becoming increasingly powerful. Traffic data monitored in real-time by microwave vehicle detection systems were utilized in a study by Shi & Abdel-Aty[14]. Li et al. collected massive traffic flow data based on different sensors[15]. Travel speed was collected by Yuan & Abdel-Aty using Bluetooth detectors[16]. Lane-specific traffic volume and signal timing data were collected by an adaptive signal controller; Yang et al. used a dual induction coil detector to count the number of vehicles, average speed, and occupancy time on the one hand, and extracted accident data containing information such as date, time, collision type, weather conditions, and traffic conditions on the other hand[17]; Li et al. used the SMOTE algorithm as an oversampling technique applied to solve the imbalanced data problem and build a spatio-temporal network model to predict the accident likelihood[18].

The causes of road transport accidents of hazardous chemicals mainly come from five aspects: human, machine, material, environment, and management. However, limited by data collection technology and information technology, most of the data used in the risk assessment process of road transportation of hazardous chemicals is static data, and comprehensive and systematic statistical analysis and utilization of static and dynamic data from the five aspects have not yet been realized. With the rapid development of modern information technologies such as the Internet of Things and big data, the dynamic collection of the five aspects of data has already been based on hardware and software. Therefore, the application of real-time collection of dynamic multi-source data to achieve real-time risk assessment needs to be developed and researched.

Accident probability assessment methodsZarei et al. developed a dynamic analytical model based on dynamic Bayesian networks for analyzing domino effects in hazardous chemical railroad transportation[19]; Yuan & Abdel-Aty developed Bayesian conditional logic models for collisions within intersections and collision studies at intersection entrances, respectively[16]; Li et al. developed a probabilistic probability combining expert judgment and fuzzy set theory estimation models to determine the prior and conditional probabilities of BN nodes[20]; Zhai et al. used a random forest approach to identify important variables affecting fog-related collisions as inputs to a model and developed Bayesian logistic regression models for three time periods before a collision[21]. Yu & Abdel-Aty introduced classification and regression tree models and support vector machine (SVM) models for collision evaluation in real time[22]; Leung et al. proposed an approach based on an extended Dempster-Shafer evidence theory[23].

At present, research on risk assessment and prediction of road transport accidents involving hazardous chemicals is relatively extensive, but real-time assessment models and methods for the probability of occurrence of different accident patterns still need to be improved. In this paper, we develop a model for real-time accident probability assessment of different accident patterns in the road transport of hazardous chemicals, based on Bow-tie and Bayesian models with multiple data sources as the driving force, which can provide guidance for accident prevention and emergency response in road transport of hazardous chemicals.

-

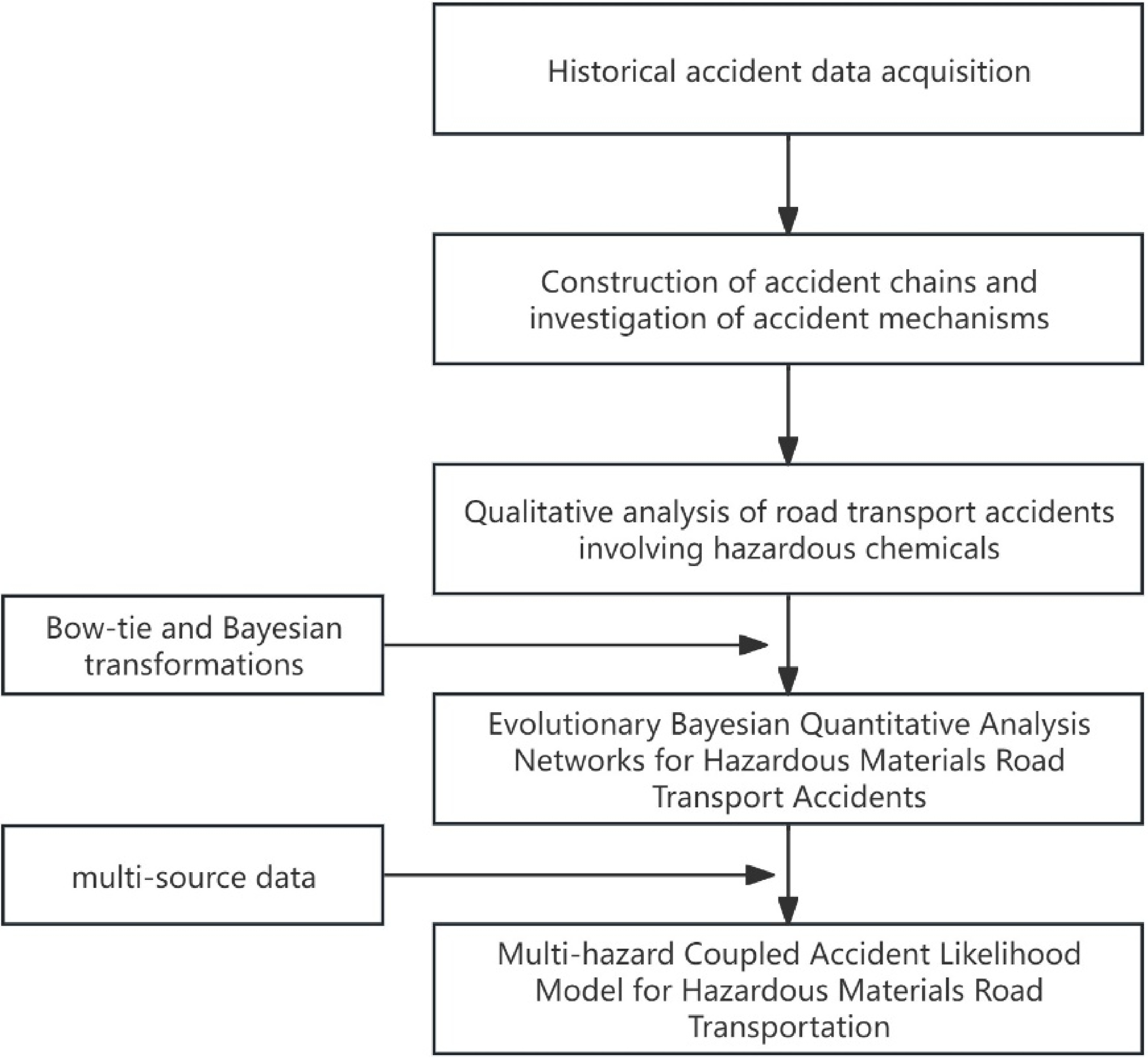

In this study, 1,115 historical accidents are counted, the accident chains are constructed, and the accident mechanism is explored. Then, the Bow-tie theory is used to construct a qualitative reasoning model and the Bayesian model network structure is constructed to evaluate the real-time possibility of the accident mode of road transportation of hazardous chemicals and the prior probability and conditional probability of the Bayesian network nodes are determined by multi-source data. Finally, an example is used to verify the feasibility of the model. The technical roadmap of this study is shown in Fig. 1.

Historical accident data acquisition

-

The historical accident data are mainly from the websites of transportation management departments, official websites of Chinese associations, and news reports, etc. In this paper, 1,115 accidents of road transportation of hazardous chemicals that occurred in China between 2013 and 2021 were collected. To achieve accurate descriptions of each accident, a data framework consisting of basic information, environmental information, basic information on hazardous chemical safety, accident causes and consequences, and casualty loss information is designed in the process of historical accident data statistics, considering all aspects of accident development. The basic information includes: province, city, year, month, day, alarm time, end time, disposal time, and other data fields; environmental information includes: weather, road type, road alignment, road section type, and other data fields; basic information of hazardous chemical safety includes: transport medium, status, transport volume, hazard category, substance classification, and other data fields; accident cause and consequence includes detailed accident cause, accident cause, and accident The accident cause and consequence data fields include detailed accident cause, accident cause, accident chain, initial accident form, front-end accident consequence, accident consequence, etc.; casualty and loss information includes: number of injuries, number of deaths, number of affected vehicles, and environmental pollution data fields.

Construction of accident chains and investigation of accident mechanisms

Construction of accident chains

-

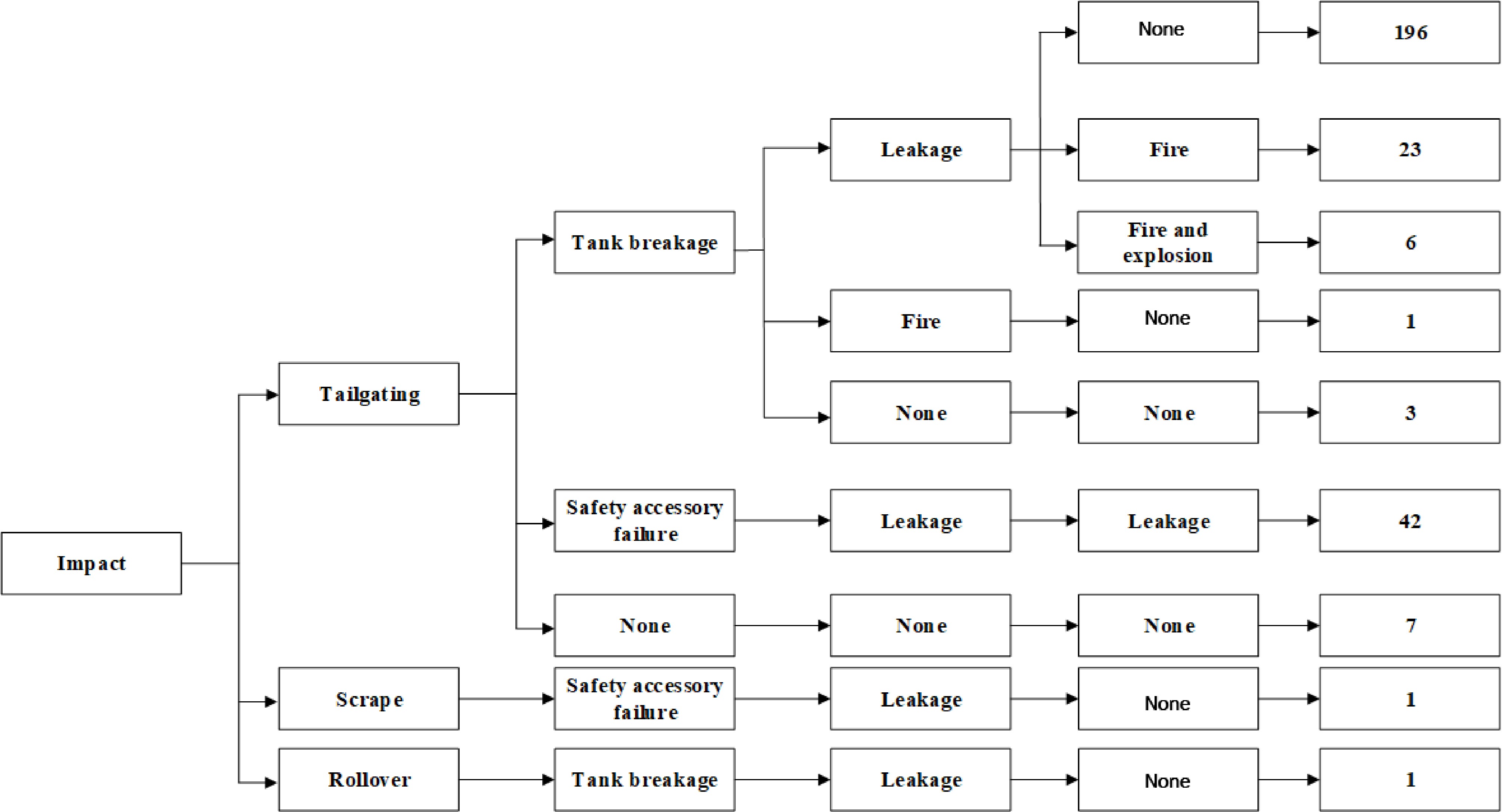

This study constructs the accident chains based on the data of 1,115 historical accidents in China from 2013 to 2021. The accident chains construction model is as follows: accident cause → accident initial form → failure form → front-end hazardous chemical accident disaster → subsequent hazardous chemical accident disaster. There are 120 accident chains, among which the most frequent accident chain is 'impact → rear-ended → tank breakage → leakage', 195 times. Table 1 shows the types of each node of the accident chain, and Fig. 2 shows some of the accident chain construction results.

Table 1. Accident chain nodes and categories.

Accident chain nodes Category Accident cause Improper operation, improper avoidance, speeding, poor driving condition, collision, abnormal vehicle, tire failure, safety accessory failure, aging and breakage, bad weather, bad roads, and hazardous chemical spontaneous combustion Accident initial form Tailgating, rollover, scraping, impact with fixtures, falling, safety accessory failure, tank damage, vehicle failure, vehicle spontaneous combustion, tire blowout, and tire fire Failure form Tank breakage, safety accessory failure Front-end hazardous chemical accident Leaks, fires, explosions Subsequent hazardous chemical accident Leaks, fires, explosions Investigation of accident mechanisms

-

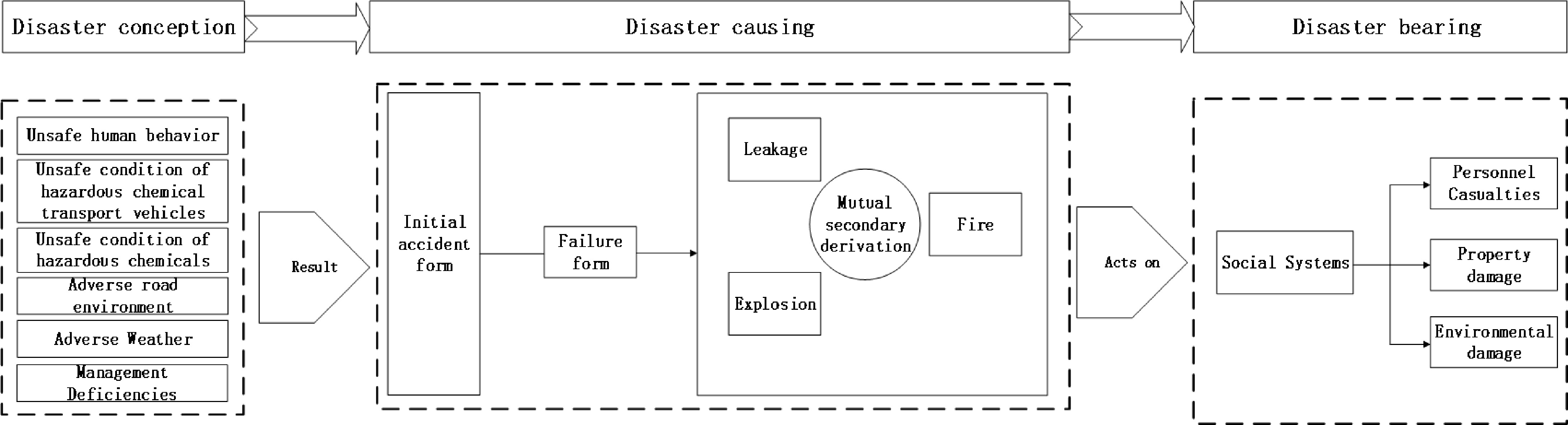

Based on the analysis of historical accident data, the direct cause of hazardous chemical road transport accidents is the unsafe behavior of drivers and escorts, and the unsafe state of hazardous chemical road transport vehicles and hazardous chemicals, both of which have a decisive role in the occurrence of hazardous chemical road transport accidents. The external road environment, the weather environment, and enterprise management are indirect factors that lead to accidents, through the direct cause of the accident to influence the accident, so these factors also have a significant impact on the occurrence of accidents. Therefore, when exploring the mechanism of hazardous chemical road transportation accidents, we should consider the direct and indirect causes of accidents comprehensively.

The occurrence and development of hazardous chemical road transportation accidents can be divided into three stages, namely, disaster conception, disaster causing, and disaster bearing, as shown in Fig. 3. Pregnancy disaster is the pregnancy stage of the accident, that is, the development stage of the direct cause and indirect cause of the accident, from the five aspects of human, machine, material, environment, and management, after experiencing the pregnancy disaster stage, the accident will further develop. The disaster stage refers to the whole process from the occurrence of the accident to the end of the accident. There are two accident modes for road transport accidents of hazardous chemicals. The first accident mode includes both the coupling of traffic accidents and hazardous chemical accidents, and the mutual coupling between three types of hazardous chemical accidents, such as leakage, fire, and explosion, which first occurs in a traffic accident and causes damage to the tank or storage tank safety accessories due to the traffic accident, thus triggering one of the three types of hazardous chemical accidents (leakage, fire, or explosion), after which the three types of accidents secondary derivation among the disaster types. The second accident mode is the direct occurrence of a hazardous chemical accident without a traffic accident. Disaster bearing is the mutual spatial and temporal coupling phase between the accident and the social system, in which the accidental release of hazardous substances and energy acts on the people, environment, and other equipment and facilities in the social system, bringing casualties, property damage, and environmental damage.

Bow-tie model construction

-

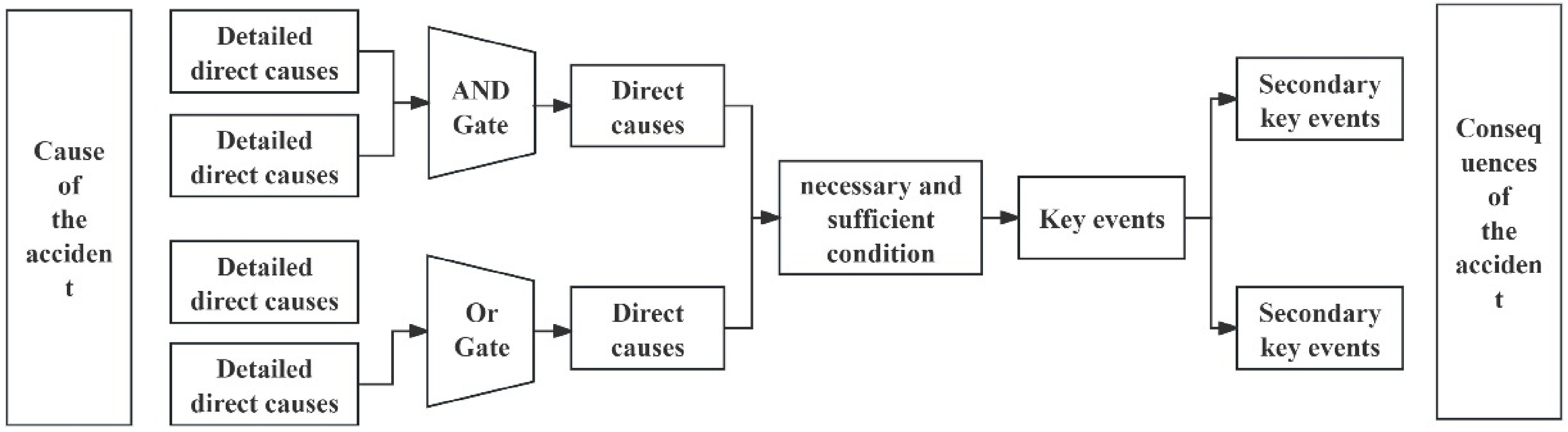

Bow-tie analysis is an effective way to show the consequences of risks and to develop risk management plans before and after the occurrence of risks, and can show the overall process from the cause to the occurrence to the expansion of accidents. Bow-tie diagrams consist of three parts: key events, fault trees, and event trees, so the construction of Bow-tie diagrams is divided into three parts. Firstly, the key events of the Bow-tie diagram are determined; secondly, the fault tree is constructed with the key events as the top events to investigate the development process and causes of the accident; finally, the event tree is constructed with the key events as the top events to determine the paths and patterns of the evolution of different types of accidents considering internal and external factors.

Bayesian model construction

-

A Bayesian network is a directed acyclic graph that can be used to represent causal and dependency relationships between events. In this paper, the Bayesian network structure is constructed based on the Bow-tie model, and the prior probability is determined based on real-time monitoring data and transportation enterprise management data, and the conditional probability is determined based on historical accident data.

-

The risk assessment process of hazardous chemical road transport, under the premise of determining the accident mechanism, needs to clarify the specific process of accident development, so the historical accident data that can clarify the whole process of accident development needs to be collected and analysed. At the same time, this paper aims at real-time risk assessment, real-time data need to be obtained, based on the actual available data, real-time monitoring data and transport enterprise operation and management data are considered. In summary, the multi-source data constructed in this paper consists of historical accident data, real-time monitoring data, and transport enterprise management data.

Historical accident data

-

1,115 road transport accidents involving hazardous chemicals occurred in China between 2013 and 2021. Data are collected from five aspects: basic accident information, environmental information, information on hazardous chemicals transported, causes and consequences of accidents, and casualty losses.

Real-time monitoring data acquisition

-

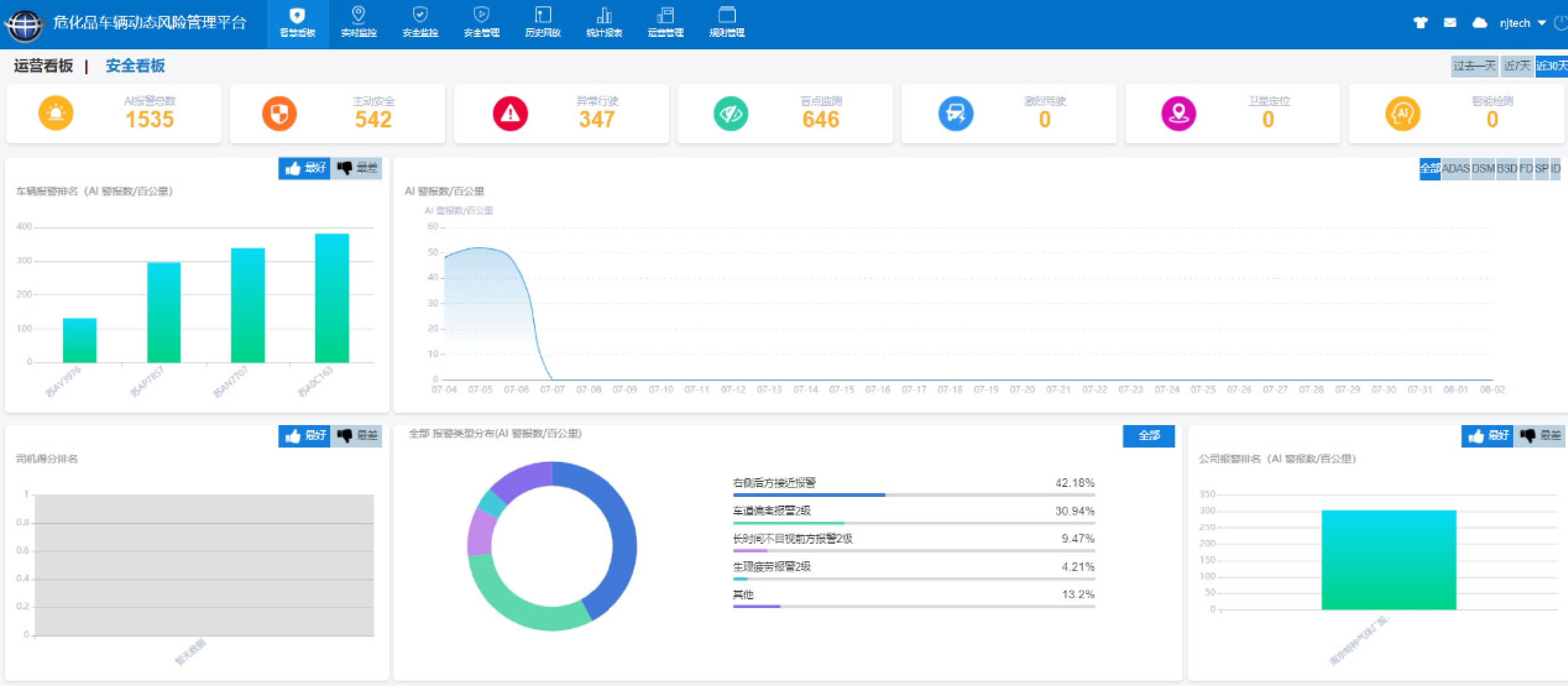

Real-time monitoring data are mainly obtained by the vehicle-mounted active security system. The vehicle-mounted active security system consists of a hardware system, as shown in Fig. 4, and a software system, as shown in Fig. 5. The hardware system collects parameters and enables alarms by installing a series of hardware sensors on hazardous chemical road transport vehicles, as shown in Table 2; the software system enables the collection and storage of data.

Figure 4.

Hardware system for dynamic risk management data collection of dangerous chemical vehicles.

Table 2. Hardware system and its functions.

Main hardware Acquisition parameters Realisation of alarms Vehicle-mounted terminal GPS information, real-time speed, weather, wind speed and direction, driving hours, and vehicle tilt angle, etc. Speeding alarm, fatigue driving alarm, cumulative driving hours for the day alarm, rapid acceleration alarm, rapid deceleration alarm, rollover warning Advanced driving aids Forward distance and lane boundary information Forward collision alarm, vehicle distance too close alarm, pedestrian collision alarm, lane departure alarm Driver condition detection equipment Driver facial features and driver behavioral and movement information Prolonged failure to look ahead alarm, physiological fatigue alarm, telephone alarm, smoking alarm Blind spot monitoring equipment Information on the right-hand rear of the vehicle Right rear approach alarm Temperature pressure sensors Tyre temperature, tyre pressure, tank temperature and tank pressure High tyre pressure alarm, low tyre pressure alarm, high tyre temperature alarm, high tank temperature alarm, high tank pressure alarm Transport enterprise management data capture

-

Transport enterprise management data is the data generated by the enterprise in the daily production and operation activities, mainly macro-static data (enterprise qualification, enterprise scale, transport practitioners information, vehicle inspection, and maintenance information, etc.), but also contains part of the dynamic data (transport time, transport scale, transport turnover, nature of hazardous chemical products, etc.) from the enterprise vehicle active security systems and software systems. The enterprise operation and management data used in this paper are part of the data related to the safety of hazardous chemical road transport, i.e., vehicle inspection and maintenance information, nature of hazardous chemicals, scale of transport, etc. of hazardous chemical transport enterprises.

Construction of qualitative Bow-tie model

-

Bow-tie analysis is an effective way to show the consequences of risks and to develop risk management plans before and after the occurrence of risks, showing the overall process of ‘cause of accident → occurrence → expansion’. In the Bow-tie diagram, the left side is the incident tree, which describes the process of occurrence of critical events, critical event-related failures, and effective preventive and control measures, which enables the search for the causes of critical events; the middle is the critical events under study; and the right side is the event tree, which is a description of the subsequent evolutionary development after the occurrence of critical events. The Bow-tie structure is shown in Fig. 6.

A Bow-tie diagram consists of three parts: critical event, fault tree, and event tree, and the construction of a Bow-tie diagram is divided into four steps. The first step is to determine the critical events; the second step is to construct the fault tree with the critical events as the top-level events to explore the causes and development process of the accidents; the third step is to construct the event tree with the critical events as the top-level events to determine the paths and patterns of the evolution and development of different types of accidents by combining internal and external factors. In the last step, a Bow-tie diagram is constructed.

Identifying key events

-

Based on the statistical analysis of historical accidents, it was found that 980 of the 1,115 historical accidents involved hazardous chemical accidents, accounting for 87.9%; hazardous chemical accidents included single-hazard accidents and multi-hazard coupled accidents, with 871 and 109 accidents, respectively; among these accidents, 99.4% and 98.2% were in the form of leakage as the initial accident. Therefore, the critical event is identified as leakage.

Construction of fault tree

-

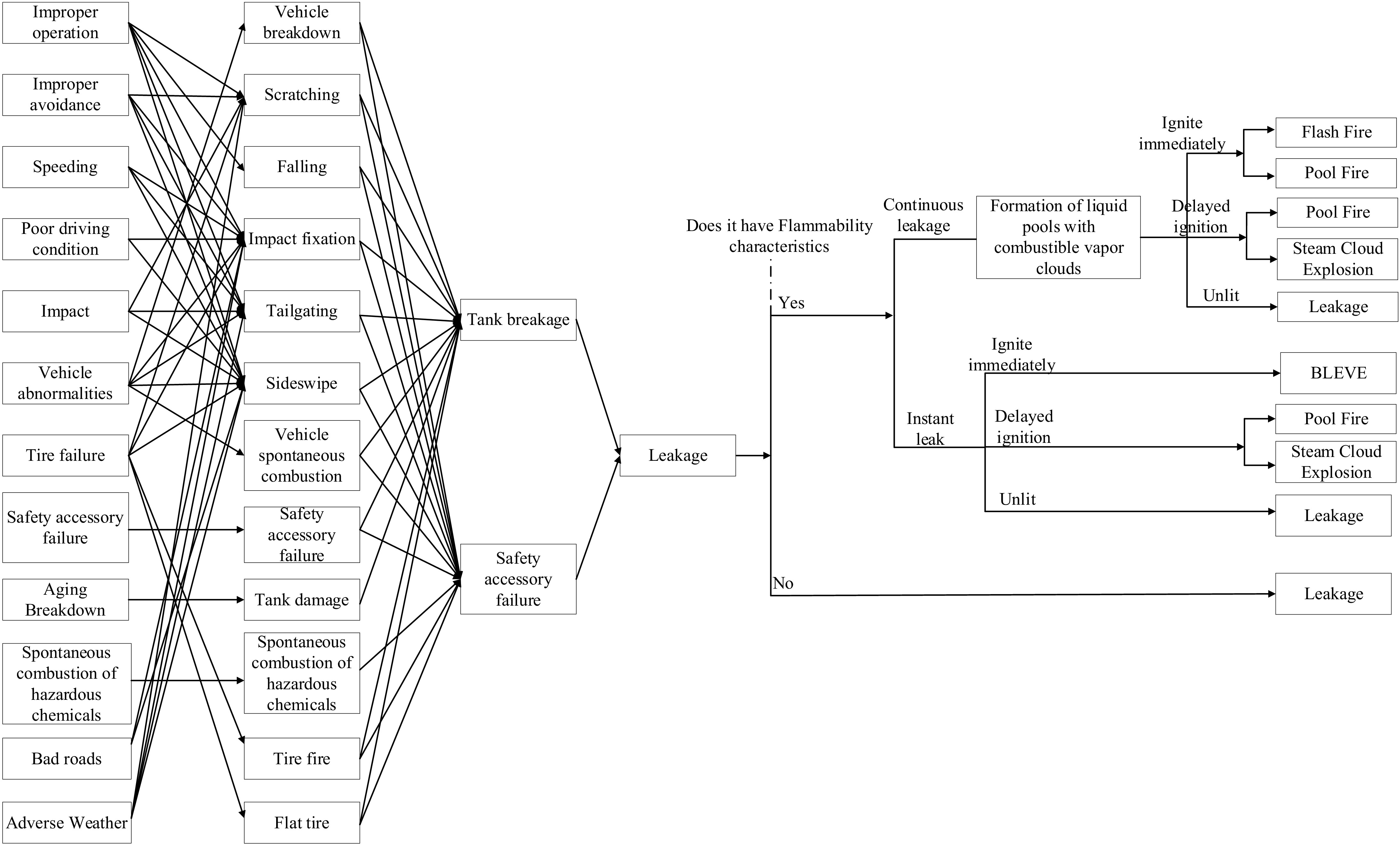

The fault tree and the accident chain are both the investigation of the development process and the cause of the accident, so the fault tree can be compared with the accident chain in the process of establishing the fault tree. The fault tree is composed of the top event, the top event occurrence sufficient conditions, the direct cause, and the detailed direct cause. In the Bow-tie method, the top event of the fault tree is the critical event 'leak'; the top event of the accident chain is a sufficient condition for the occurrence of the leak to fail. Failure has two forms of manifestation, which are tank breakage and safety accessories failure; similarly, the direct cause is the initial form of the accident, and the detailed direct cause corresponds to the accident chain node 'accident cause'.

Constructing an event tree

-

Event tree analysis is a common inductive reasoning analysis method. The event tree is established in two steps, one is to determine the initial event, and the other is to determine the event tree branches. In this paper, the event tree analysis is a part of Bow-tie analysis and is combined with the fault tree analysis of the Bow-tie analysis process, so the initial event is 'leakage'. The derivation of subsequent disasters after a hazardous chemical leak is first associated with the nature of the hazardous chemical itself, which has different physical and chemical properties, and the possibility and types of accidents occurring under the same external conditions are different. Flammable explosive substances in the occurrence of leaks can occur after the fire explosion, non-flammable and non-explosive substances even if the leak is very difficult to fire and explosion. Combustible explosive material leakage occurs in the form of two continuous leakage and instantaneous leakage. Continuous leakage will form a liquid pool or vapor cloud, in the immediate ignition conditions flash fire or pool fire; in the delayed ignition conditions will occur under the pool fire or vapor cloud explosion; if not ignited is simply a leak. Instantaneous leaks tend to form BLEVE if ignited immediately; pool fire or vapor cloud explosion if ignition is delayed; and just leaks if not ignited.

Construction of a Bow-tie diagram

-

Based on the above contents of this summary, the constructed Bow-tie diagram for qualitative reasoning of multi-hazard coupled accidents of hazardous chemical road transportation is shown in Fig. 7.

Figure 7.

Qualitative reasoning Bow-tie for multi-hazard coupled accidents in hazardous chemical road transport.

Construction of a quantitative Bayesian model

-

The Bayesian network model can be divided into the following four steps:

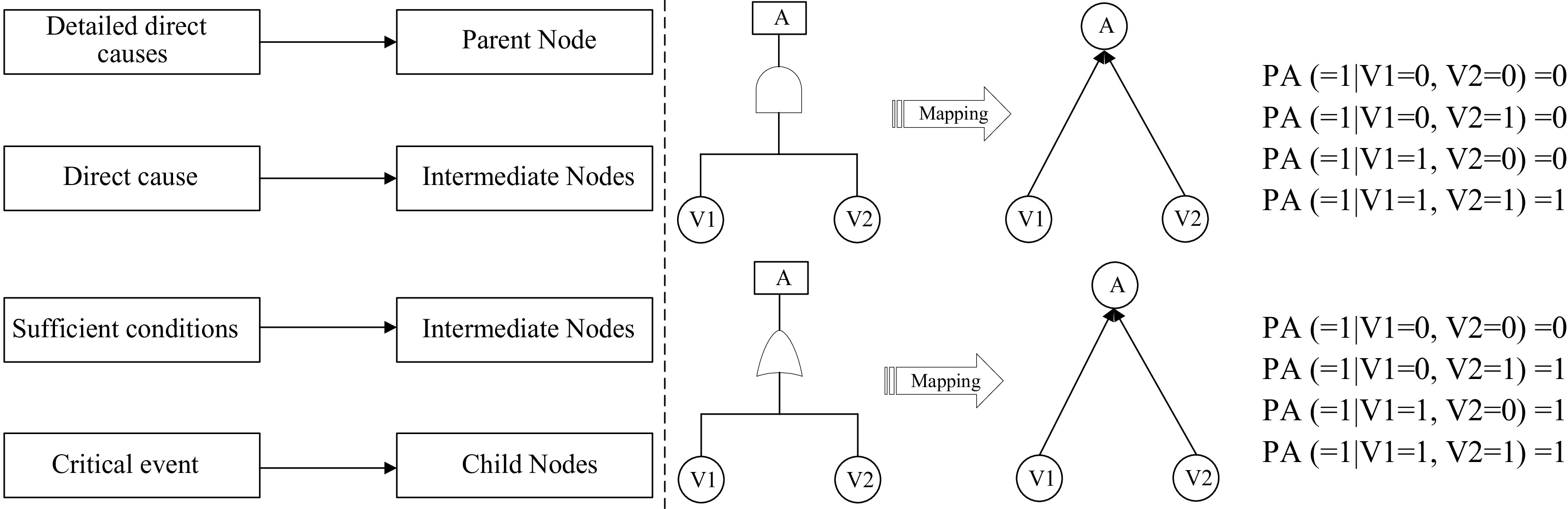

(1) Bow-tie transformation into Bayesian networks

Convert the Bow-tie model into a Bayesian network: First, determine the Bayesian network nodes, then convert the left fault tree of the bow-tie graph into a Bayesian network, and finally convert the right event tree of the bow-tie graph into a Bayesian network. The conversion rules are shown in Fig. 8.

(2) Determine the conditional probability value of the Bayesian network model

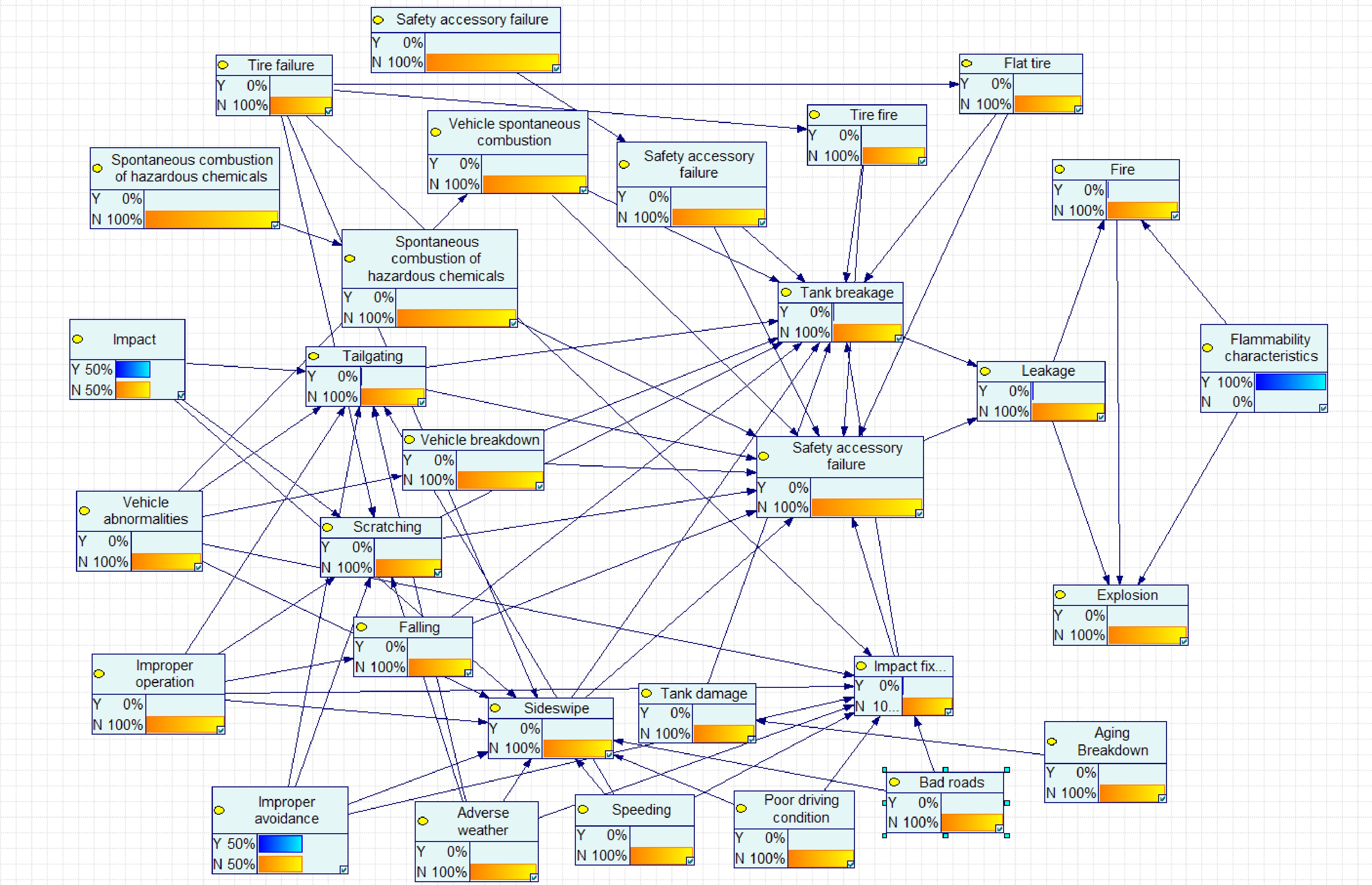

Using 1,115 historical accident data as the training set, the conditional probabilities of the Bayesian network nodes were determined using the EM algorithm with the help of the GeNIe analysis software parameter learning function. 'Y' means the node occurs and 'N' means the node does not occur. Some of the node conditional probability tables are shown in Tables 3 and 4.

Table 3. Conditional probability table of node 'leakage'.

Tank breakage Y N Safety accessory failure Y N Y N Y 0.99974 0.97494 0.98947 0 N 0.00026 0.02506 0.01053 1 Table 4. Conditional probability table for node 'fire'.

Flammability characteristics Y N Leakage Y N Y N Y 0.12104 0 0 0 N 0.87896 1 1 1 (3) Determine the prior probability value of the Bayesian network model

The prior probability value of each parent node of the Bayesian model is not fixed, and its value is associated with real-time data such as vehicle daily management data and alarm real-time monitoring data. The correspondence between each parent node and the data and the rules of taking values are shown in Table 5.

Table 5. The correspondence between each parent node and data and the rules of taking values.

Parent node Multi-source data A priori probability Data information Priori probability taking value Improper operation Right rear approach alarm, long time not looking ahead alarm, smoking alarm, answering phone alarm, lane departure alarm Number of alarms = 1 0.5 Number of alarms > 1 1 Number of alarms = 0 0 Improper avoidance Rapid acceleration alarm, rapid deceleration alarm, rollover warning Number of alarms = 1 0.5 Number of alarms > 1 1 Number of alarms = 0 0 Speeding Over speed alarm Number of alarms = 1 0.5 Number of alarms > 1 1 Number of alarms = 0 0 Poor driving condition Fatigue driving alarm, cumulative driving hours over the day alarm, physiological fatigue alarm Number of alarms = 1 0.5 Number of alarms > 1 1 Number of alarms = 0 0 Impact Forward collision alarm, too close to vehicle alarm, pedestrian collision alarm Number of alarms = 1 0.5 Number of alarms > 1 1 Number of alarms = 0 0 Tire failure Tire pressure too low alarm, tire pressure too high alarm, tire temperature too high alarm Number of alarms = 1 0.5 Number of alarms > 1 1 Number of alarms = 0 0 Spontaneous combustion

of hazardous chemicalsHigh tank temperature alarm, high tank pressure alarm Number of alarms = 1 0.5 Number of alarms > 1 1 Number of alarms = 0 0 Adverse Weather Real-time weather data Cloudy, sunny, cloudy 0 Rain, fog 0.5 Snow, hail, dust storms 1 Bad roads Real-time road data Road characteristic factor ≤ 1 0 1 < Road characteristic factor ≤ 5 0.5 Road characteristic factor ≥ 5 1 Vehicle abnormalities Regular vehicle inspection and maintenance data Regular inspection, repair and replacement 0 Unscheduled inspection, repair and replacement 1 Safety accessory failure Safety accessories regular inspection and maintenance data Regular inspection, repair and replacement 0 Unscheduled inspection, repair and replacement 1 Aging Breakdown Vehicle and accessory usage time data Regular inspection, repair and replacement 0 Unscheduled inspection, repair and replacement 1 Flammability characteristics Data on the nature of hazardous chemicals With flammability characteristics 0 Non-flammable and non-explosive properties 1 (4) Quantitative inference Bayesian network model

In summary, the constructed quantitative inference Bayesian network model for multi-hazard coupled accidents of hazardous chemical road transportation is shown in Fig. 9.

-

The transport operation took place on 9 January 2023, from 10:30:07 a.m. to 11:45:15 a.m. Data was collected every 30 s, with a total of 31 data points collected. The transport route was approximately 17.4 km long and was located on a section of the city's ring road, as shown in Fig. 10. The hazardous chemical being transported was liquefied natural gas, with a load weight of 10 tons.

Example accident possibility assessment

-

To realize the real-time assessment of the possibility of accidents of hazardous chemical road transportation, real-time alarm data, real-time environmental data, and transportation management data are collected every 30 s. The data are input into the multi-hazard coupled real-time risk assessment model established for the road transportation of hazardous chemicals, and three types of accident probabilities are output: 'leakage', 'leakage → fire', and 'leakage → fire → explosion'. Accident development mode probability, the collected data, and probability values are shown in Table 6.

Table 6. Real-time data, accident probability, and risk for each collection point.

Collection points Real-time alarm data Real-time environmental data Transportation management data Accident mode occurrence probability Weather Road characteristic factor Vehicle Status Safety accessory status Aging breakdown Flammability characteristics Leakage Leakage → fire Leakage → fire → explosion 1 / Clear sky 0.64 Good Good Good Yes 0 0 0 2 / Clear sky 0.64 Good Good Good Yes 0 0 0 3 / Clear sky 1.408 Good Good Good Yes 2.09E-04 2.79E-05 8.46E-07 4 Rapid acceleration alarm *1 Clear sky 0.64 Good Good Good Yes 1.64E-04 2.19E-05 6.63E-07 5 / Clear sky 0.64 Good Good Good Yes 0 0 0 6 Over speed alarm *1 Clear sky 0.64 Good Good Good Yes 2.08E-04 2.78E-05 8.41E-07 7 / Clear sky 0.64 Good Good Good Yes 0 0 0 8 / Clear sky 0.832 Good Good Good Yes 0 0 0 9 / Clear sky 0.832 Good Good Good Yes 0 0 0 10 Physiological fatigue alarm *1 Clear sky 0.832 Good Good Good Yes 2.05E-04 2.74E-05 8.31E-07 11 / Clear sky 0.832 Good Good Good Yes 0 0 0 12 Close distance alarm *1 Clear sky 0.832 Good Good Good Yes 2.19E-04 2.93E-05 8.88E-07 13 / Clear sky 0.832 Good Good Good Yes 0 0 0 14 Lane departure alarm *1 Clear sky 0.832 Good Good Good Yes 2.61E-04 3.48E-05 8.88E-07 15 / Clear sky 0.832 Good Good Good Yes 0 0 0 16 / Clear sky 0.832 Good Good Good Yes 0 0 0 17 Emergency deceleration alarm *1, close vehicle distance warning *1 Clear sky 0.832 Good Good Good Yes 8.14E-04 1.09E-04 3.30E-06 18 / Clear sky 0.64 Good Good Good Yes 0 0 0 19 / Clear sky 0.64 Good Good Good Yes 0 0 0 20 Lane departure alarm *1 Clear sky 0.64 Good Good Good Yes 2.61E-04 3.48E-05 1.06E-06 21 Answer phone alarm *2 Clear sky 0.64 Good Good Good Yes 5.21E-04 6.97E-05 2.11E-06 22 Answer phone alarm *2 Clear sky 0.64 Good Good Good Yes 5.21E-04 6.97E-05 2.11E-06 23 / Clear sky 0.64 Good Good Good Yes 0 0 0 24 / Clear sky 0.64 Good Good Good Yes 0 0 0 25 Lane departure alarm *1 Clear sky 0.64 Good Good Good Yes 2.61E-04 3.48E-05 8.88E-07 26 Emergency deceleration alarm *1, forward collision alarm *1 Clear sky 0.64 Good Good Good Yes 8.14E-04 1.09E-04 3.30E-06 27 / Clear sky 0.64 Good Good Good Yes 0 0 0 28 Forward collision alarm *1 Clear sky 0.64 Good Good Good Yes 2.19E-04 2.93E-05 8.88E-07 29 / Clear sky 0.64 Good Good Good Yes 0 0 0 30 Right rear approach alarm *1 Clear sky 0.64 Good Good Good Yes 2.61E-04 3.48E-05 1.06E-06 31 / Clear sky 0.64 Good Good Good Yes 0 0 0 Results and discussion

-

In the process of road transportation, the risk changes dynamically in real time, the risk can be prevented, and the behavior can be modified according to the risk value in each detection period. When there are high-risk values, by giving an alarm reminder to the behavior in the most recent time period, the driver can correct the behavior in time and effectively prevent the risk. If high-risk value appears for a long time and there is no downward trend, education training, and vehicle detection can be carried out later. For example, collection points 17 and 26 have the highest risk value, because collection point 17 has a sharp deceleration alarm and too close alarms at the same time, and collection point 26 has a sharp deceleration alarm and a forward collision alarm at the same time, so the risk can be avoided through timely alarms. In the Bayesian accident probability network, the prior probability of improper avoidance and collision of two parent nodes is 0.5, which greatly improves the possibility of accidents. High- and low-risk values can be detected within 30 s, effectively realizing real-time evaluation. Therefore, the model can realize the real-time risk assessment of multi-disaster coupling accidents in road transport of hazardous chemicals, and provide important data support for the safety decision of road transport of hazardous chemicals.

-

Road transport occupies an important position in the transport of hazardous chemicals. During the transport process, vehicles, drivers, and the external environment are in the process of real-time dynamic change, and once an accident occurs in the road transport of hazardous chemicals, the consequences of the accident are complex and diverse, seriously threatening people's lives. Therefore, it is of great theoretical value and practical significance to assess the real-time likelihood of accidents during the road transport of hazardous chemicals.

This paper explores the accident mechanism of hazardous chemicals road transport on the basis of historical accident analysis, statistically analyses 1,115 historical accident data, constructs 120 accident chains, researches the accident mechanism based on the accident chains, and constructs multi-source data, such as historical accident data, real-time monitoring data, and management data of transport enterprises;

Based on the Bow-tie theory, integrate the accident chains, take the leakage as the key event, construct the fault tree and event tree, and establish the Bow-tie diagram for qualitative reasoning of multi-hazardous source coupling accidents of hazardous chemicals road transport; according to the mapping relationship between the Bow-tie diagram and the Bayesian network, determine the nodes and the structure of the Bayesian network, and determine the conditional probability of the occurrence and non-occurrence of each sub-node through the historical accident data and determine the prior probability of the parent node in real-time according to the real-time monitoring data and the management data of the transport enterprise, and finally realise the real-time assessment of the possibility of the occurrence of Multi-hazard coupled accidents.

In the example validation, based on the data in Table 6, it can be seen that when there is only one alarm, the probability of an accident occurring is low. For example, at collection point 6: the probability of a leak is 0.000,207,626, the probability of a fire is 0.000,027,75, and the probability of an explosion is 0.000,008,4, which suggests that although there is a risk of a single alarm, the probability of directly triggering a major accident is low. Collection point 17: The probability of leakage is as high as 0.000,814,156, which is significantly higher than the probability of leakage at a single alarm collection point. This indicates that when multiple alarms occur simultaneously, the probability of an accident is significantly higher. The values in the ‘Road characteristics’ column in Table 6 fluctuate between 0.64 and 1.408. For example, collection point 3: the probability of leakage is 0.000,208,759, which is higher than other collection points with the same conditions. The road characteristics reflect complex road conditions such as curves and gradients, and the increase in their values indirectly leads to higher operating pressure on the driver, thus increasing the risk. Multi-hazard coupled risk in the road transport of dangerous goods is primarily driven by composite alarm events and complex road characteristics. Although the direct impact of a single alarm is limited, the combination of multiple factors can significantly increase the probability of an accident.

Eventually, the real-time assessment of the possibility of occurrence of multi-hazard coupled accidents is achieved every 30 s, reflecting the influence law of the risk under the multi-hazard coupling scenario, which is conducive to the control of the accident risk that may be caused by the driver, the management of the enterprise's vehicle transport, and the analysis of the risk of the urban area.

This work was supported by the National Natural Science Foundation of China (Grant No. 71971110); The Key Project of National Natural Science Foundation of China (Grant No. 51834007); Postgraduate Research & Practice Innovation Program of Jiangsu Province (Grant No. SJCX21_0517, 2021); and Jiangsu Province Emergency Management Technology Project (Grant No. YJGL-YF-2020-10, 2020).

-

The authors confirm contribution to the paper as follows: study conception and design: Wang S, Zhang M, Liu M; data collection, processing: Wang S, Zhao J; analysis and interpretation of results: Wang S, Liu M; draft manuscript preparation: Wang S; All authors reviewed the results and approved the final version of the manuscript.

-

The data that support the findings of this study are available in the official website of the China Chemical Safety Association, the China Hazardous Chemical Logistics Network, and authoritative news reporting websites. These data were derived from the following resources available in the public domain: www.chemicalsafety.org.cn; www.hcls.org.cn.

-

The datasets generated during and/or analyzed during the current study are available from the corresponding author upon reasonable request.

-

The authors declare that they have no conflict of interest.

- Copyright: © 2025 by the author(s). Published by Maximum Academic Press on behalf of Nanjing Tech University. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Wang S, Zhang M, Liu M, Zhao J. 2025. A possibility evaluation model for road transportation of hazardous chemicals based on Bow-tie theory and Bayesian model. Emergency Management Science and Technology 5: e011 doi: 10.48130/emst-0025-0009

A possibility evaluation model for road transportation of hazardous chemicals based on Bow-tie theory and Bayesian model

- Received: 27 December 2024

- Revised: 28 April 2025

- Accepted: 16 May 2025

- Published online: 24 June 2025

Abstract: The complexity and diversity of road transport environments and the unique nature of hazardous chemicals pose significant challenges in quantifying the risk of accidents in the transport of hazardous chemicals, and further research is still needed to assess the possibility of real-time accidents. In this study, 1,115 Chinese hazardous chemical road transport accidents are analysed, and 120 accident chains are constructed to reveal the development law of the accidents. Based on the Bow-tie theory, a qualitative inference Bow-tie diagram for multi-hazard coupled accidents in road transport of hazardous chemicals was constructed to show the evolution of the accidents. The mapping relationship between the Bow-tie diagram and the Bayesian network is established, and the Bayesian network structure is constructed to achieve the dynamic real-time accident possibility assessment combining quantitative and qualitative. In the example application, data collection every 30 s, and real-time accident probability calculations are realised, which verifies the feasibility and reasonableness of the model and method in this study and has important theoretical significance and application value for the prevention of road transport accidents of hazardous chemicals.